Combined guided slipping type forepoling hydraulic support

A technology of advanced support and hydraulic support, which is applied to mine roof support, mining equipment, earth-moving drilling, etc., can solve the problems such as insufficient use of advanced support hydraulic support, insufficient performance, and inability to adapt to large sections, etc. Realize the effect of automatic control of the work cycle, avoid the movement deflection and the difficulty of moving the frame, and improve the control flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

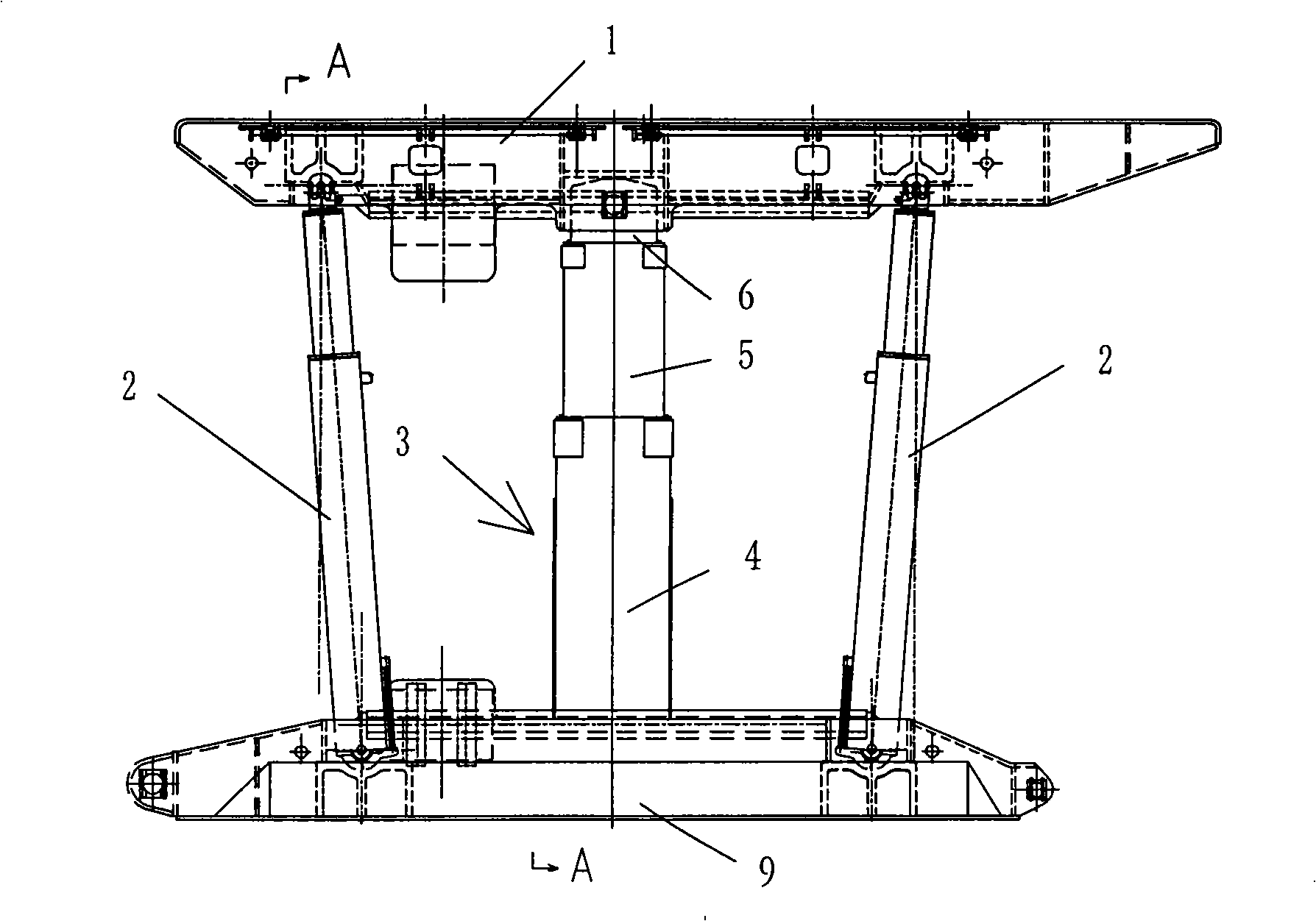

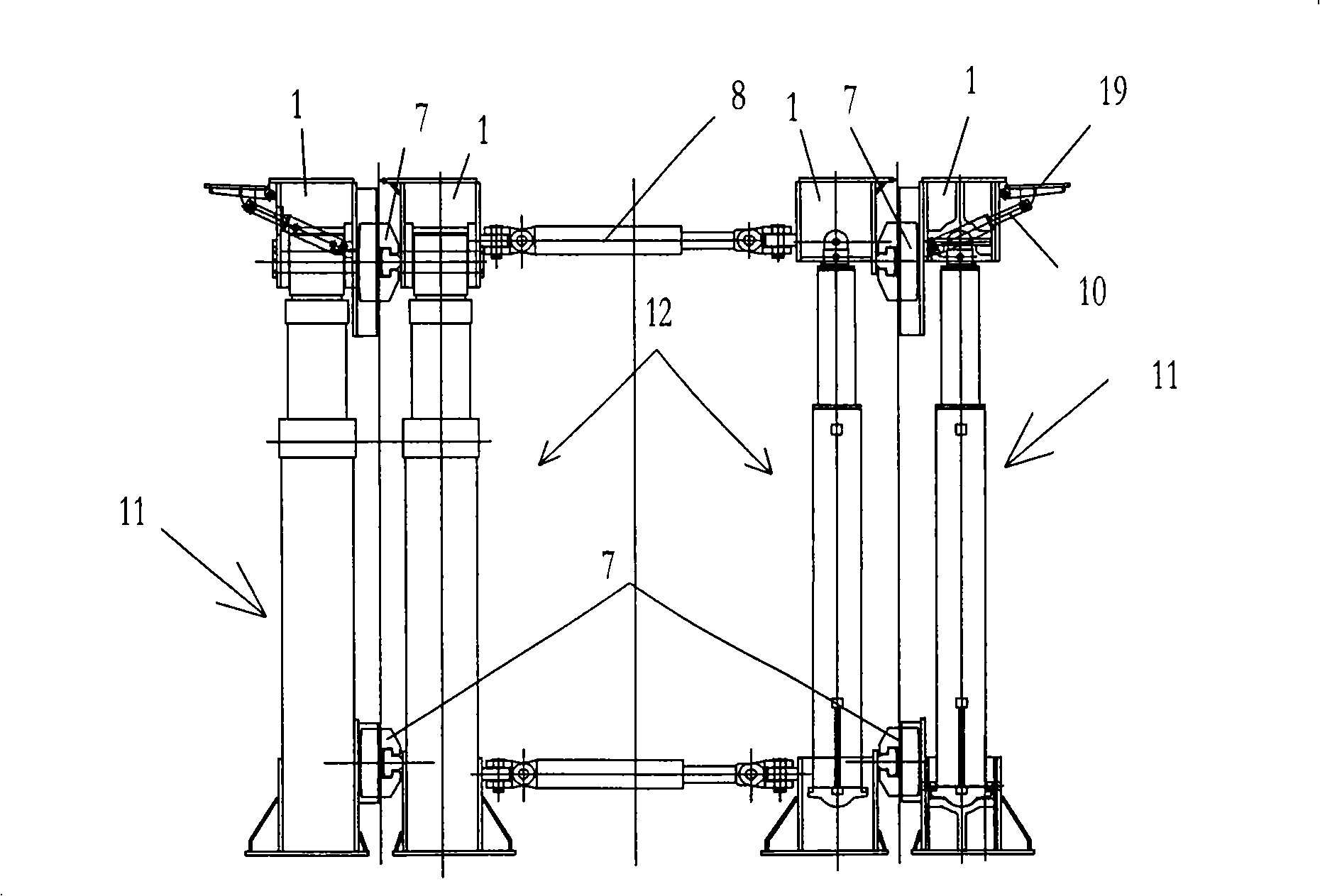

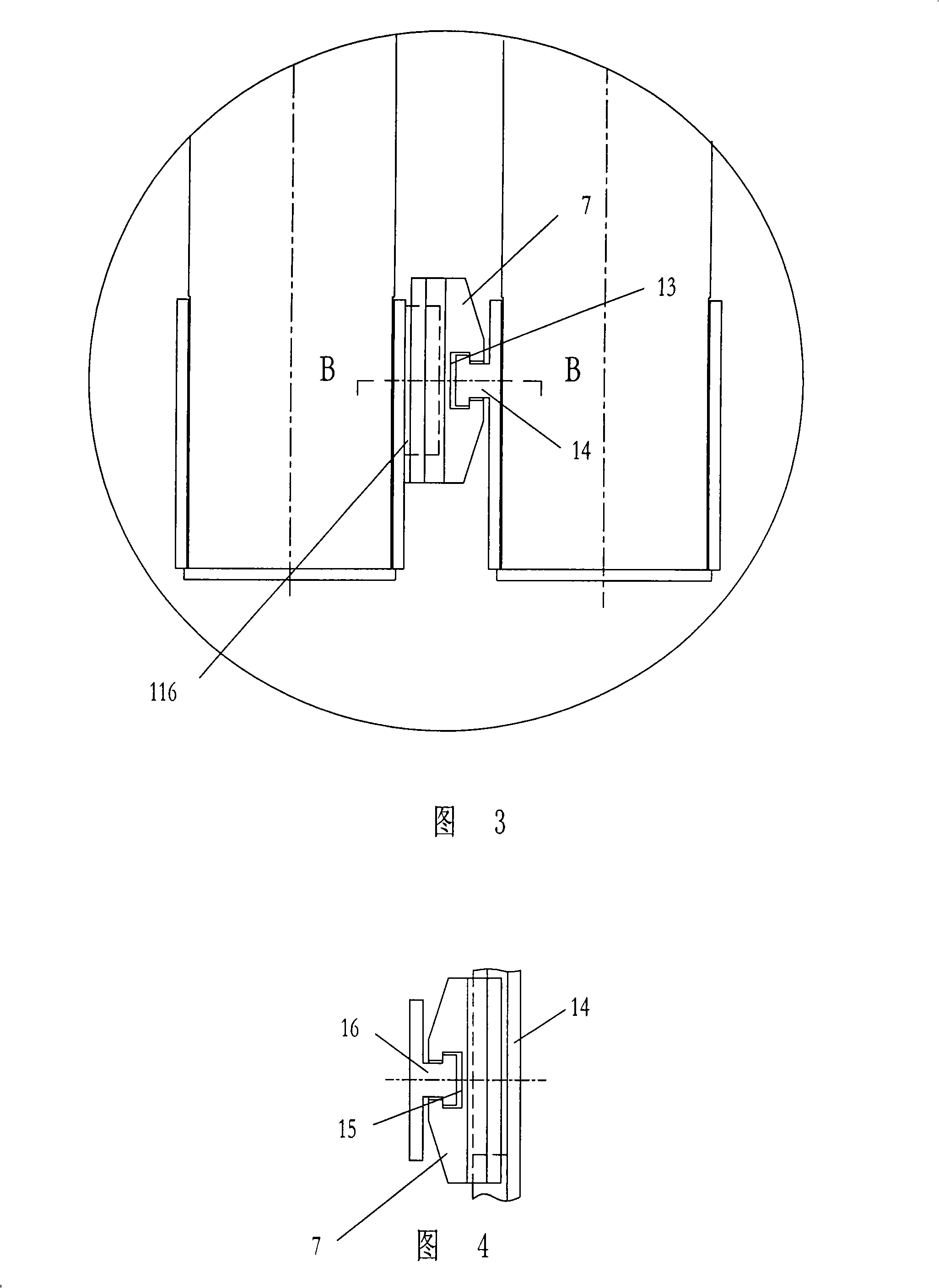

[0043] see Figure 1 to Figure 5 Shown: a combination guide sliding type advance support hydraulic support, which mainly includes: automatic control system 25, head frame pulling mechanism 24, inner support unit 12, outer support unit 11, side roof guard 19, tail guard Top plate 18, slide block 7, moving jack 17, roof protection jack 10, frame adjustment jack 8;

[0044]The inner and outer support units 12 and 11 respectively include a roof beam 1, a base 9, a telescopic rod-type guiding and stabilizing mechanism 3 and a column 2, and two columns 2 are connected on both sides between the roof beam 1 and the base 9, and on the top The middle part between the beam 1 and the base 9 is connected with a telescopic rod-type guiding and stabilizing mechanism 3, and a frame adjustment jack 8 is connected between the top beams 1 of the two inner support units 12, and the outer sides of the two inner support units 12 are respectively arranged There are outer support units 11, sliders 7...

Embodiment 2

[0069] See Figure 6 As shown: the combined guide sliding type advance support hydraulic support is composed of three-section brackets and the head frame pulling mechanism, two of which are connected to form an independent movement unit, and the other section of the bracket constitutes a movement unit alone, on the base of the two movement units Between by moving jack 17 articulated connections.

[0070]The specific connection structure is that the inner support unit 36 and the inner support unit 37 form the front inner movement unit, and the inner support unit 38 forms the rear inner movement unit; the outer support unit 32 and the outer support unit 33 form the front outer movement unit, and the outer support unit 34 forms Rear outer motion unit; Hinge with moving jack 17 between the two motion units.

[0071] Headstock pulling mechanism such as Figure 13 As shown, one end of the push rod 241 is hinged to the front end of the inner support unit head frame 36, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com