Assembly type prefabricated truss balcony and installation method therefor

A prefabricated and truss technology, which is applied to balconies, building components, buildings, etc., can solve the problems that the steel bars of the main structure are easily disturbed, speed up the overall project construction speed, and the construction quality is difficult to guarantee, so as to achieve low lifting difficulty and improve construction quality , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

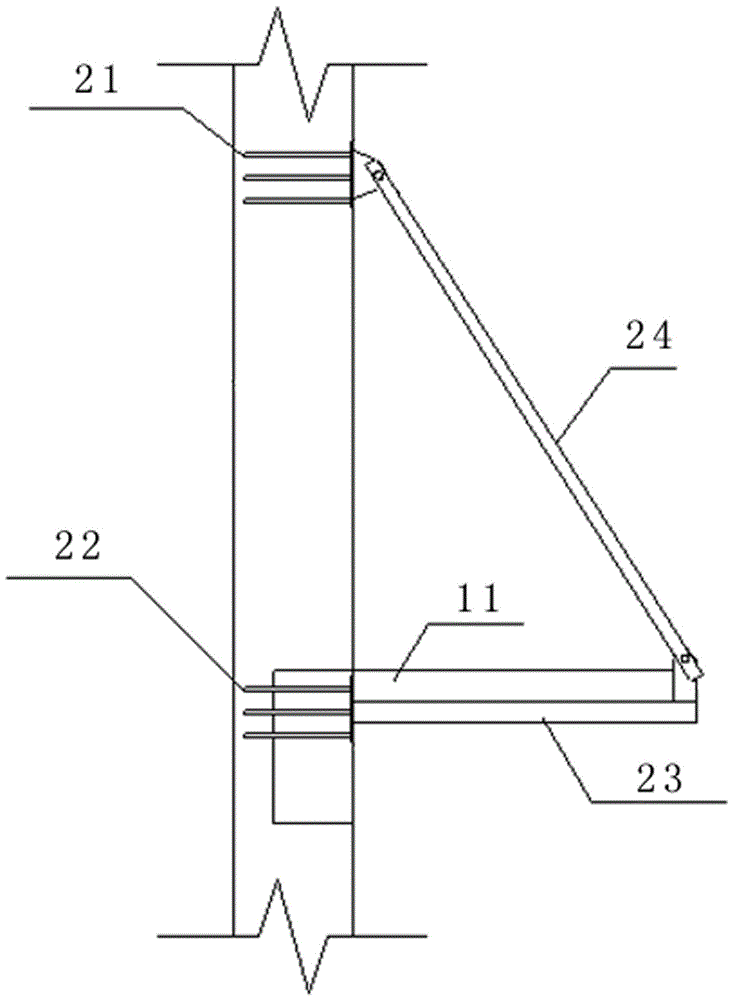

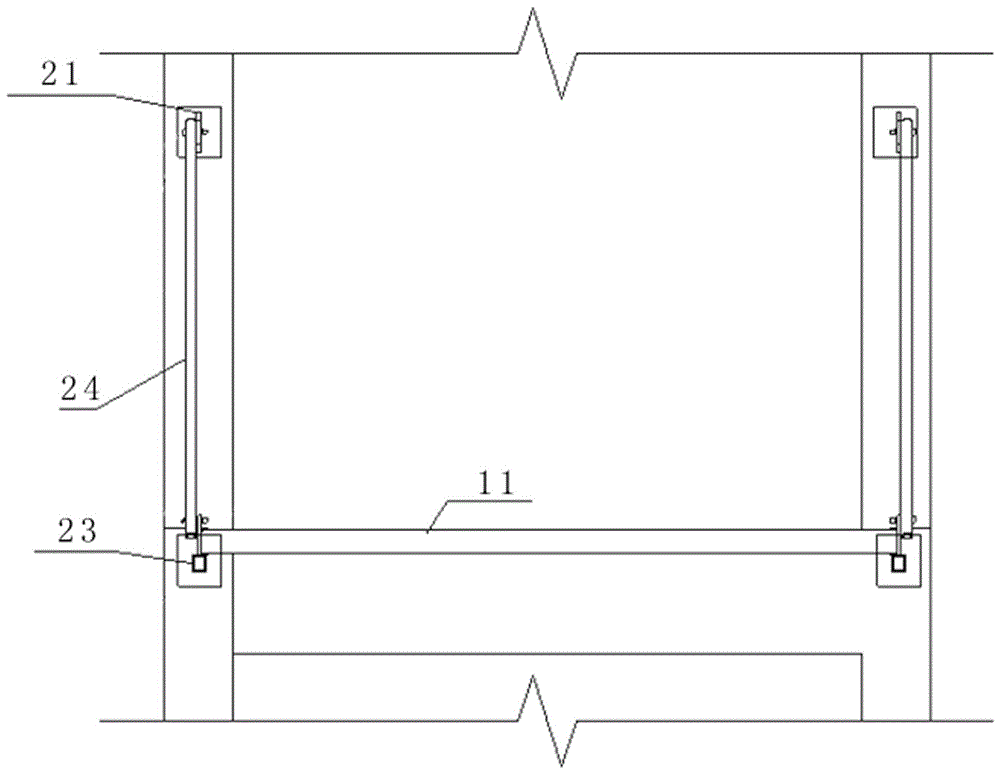

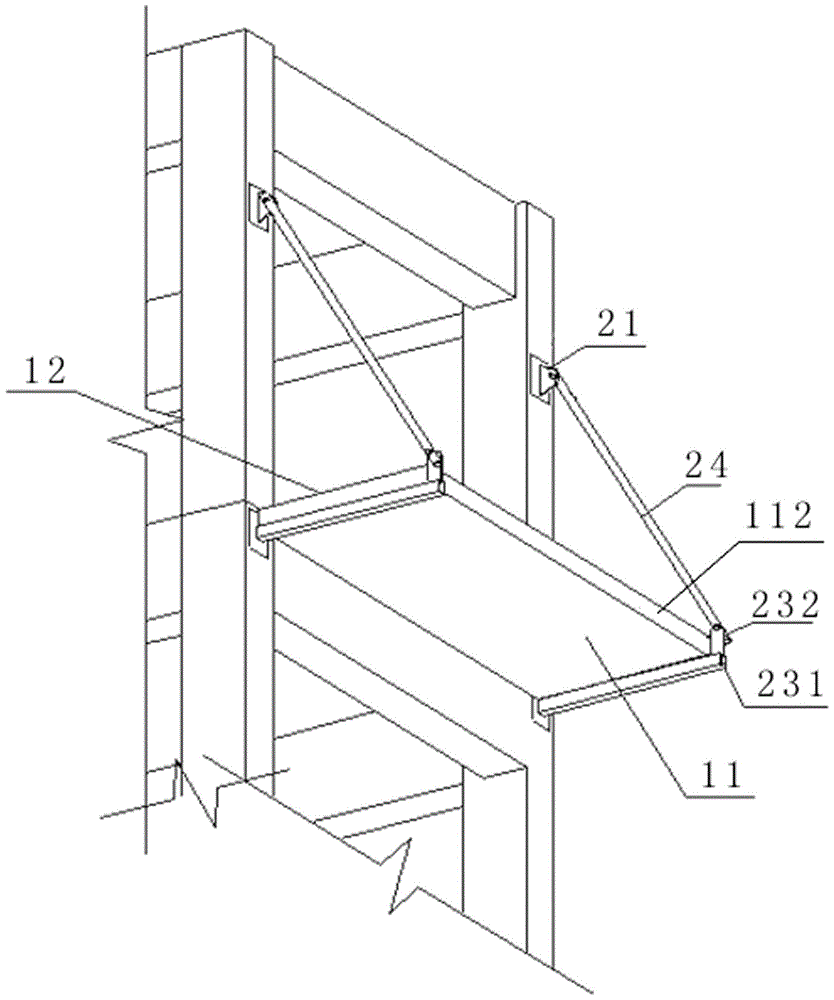

[0039] Such as Figure 1-8 As shown, the prefabricated prefabricated truss balcony of the present invention includes a balcony slab and two sets of connection assemblies for fixedly connecting the balcony slab to the main structure.

[0040] Wherein, the balcony slab includes a slab body 11 and two metal connectors 12, the slab body 11 is a prefabricated concrete slab, and its specification and size can be pre-manufactured according to specific requirements. The plate body 11 includes two side walls (not shown in the figure) and two end walls 112. At least one steel bar runs through the plate body 11, and the two ends of any steel bar protrude from the two sides of the plate body 11 respectively. The side wall is used for welding with the metal connecting piece 12 , so that the plate body 11 is fixedly connected with the metal connecting piece 12 . One end wall 112 of the board body 11 is adjacent to the main structure.

[0041]Any metal connector 12 includes a vertical sect...

Embodiment 2

[0049] The present application also discloses a method for installing a prefabricated prefabricated truss balcony. The structure of the prefabricated prefabricated truss balcony has been described in detail in Embodiment 1, and will not be repeated here. The installation method of the assembled prefabricated truss balcony includes the following steps:

[0050] Step 1: Prefabricate balcony panels, two first embedded parts 21, two second embedded parts 22, two first connecting parts 23 and two second connecting parts 24 according to design requirements;

[0051] Step 2: Pre-embed the first anchor bars 211 of the two first embedded parts 21 and the second anchor bars 221 of the two second embedded parts 22 in the main structure respectively, and keep the corresponding first embedded parts 21 and the center of gravity of the second embedded part are on the same vertical line, the corresponding two first embedded parts 21 are at the same level, and the corresponding two second embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com