A hose corner connector

A corner connector and hose technology, which is applied to hose connection devices, adjustable connections, pipes/pipe joints/pipes and other directions, can solve the problems of inconvenient disassembly, inability to adjust, and complicated installation, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

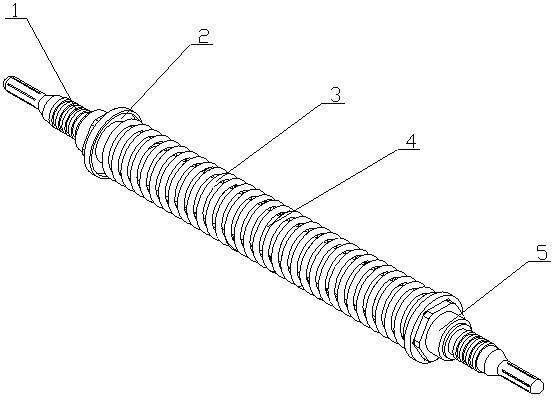

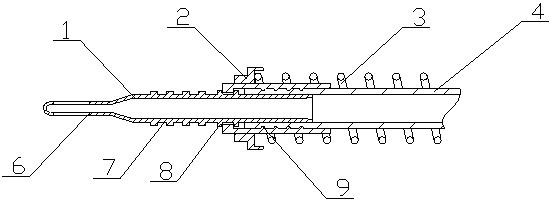

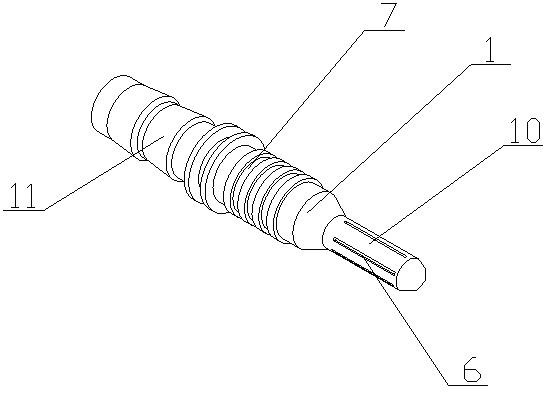

[0018] A hose corner connector of the present invention is realized in this way, consisting of a connecting nozzle 1, a screw sleeve 2, a spring 3, a middle connecting pipe 4, a fixing sleeve 5, a communication groove 6, a fastening protrusion 7, and a limit snap ring 8 , an inner fixing ring 9, an introduction nozzle 10 and a tower-shaped connector 11, two fixing sleeves 5 are respectively placed on the outer walls of the two ends of the middle connecting pipe 4, the middle connecting pipe 4 is a rubber tube, and the fixing sleeve 5. There is a through hole in the middle of one end, and one end of the two connecting nozzles 1 is placed in the two ends of the middle connecting pipe 4 respectively, and the other ends of the two connecting nozzles 1 pass through the through holes on the two fixing sleeves 5 respectively. Note that a limit snap ring 8 is placed on the outer wall of the connecting nozzle 1, and is clamped on one end of the fixed sleeve 5, and a plurality of conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com