Connecting line of forming machine

A connecting wire and forming machine technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve problems affecting the long-term operation of equipment, aging damage of the end of the connecting wire, bad influence of the connecting wire, etc., to achieve convenient and fast connection Effects of installation, waste reduction, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

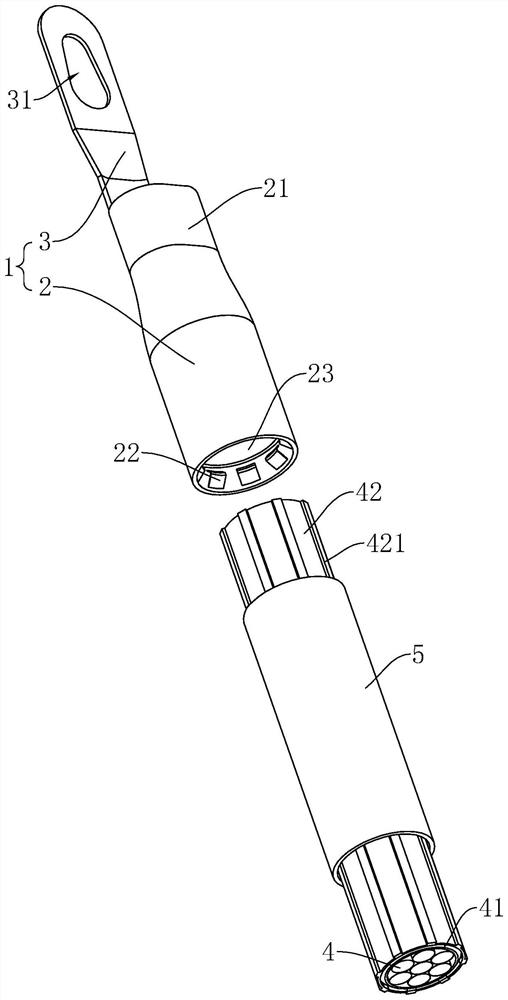

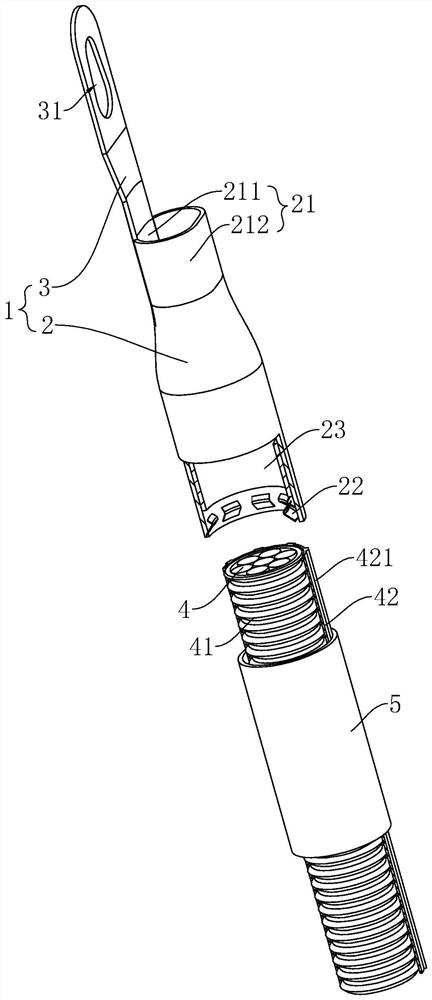

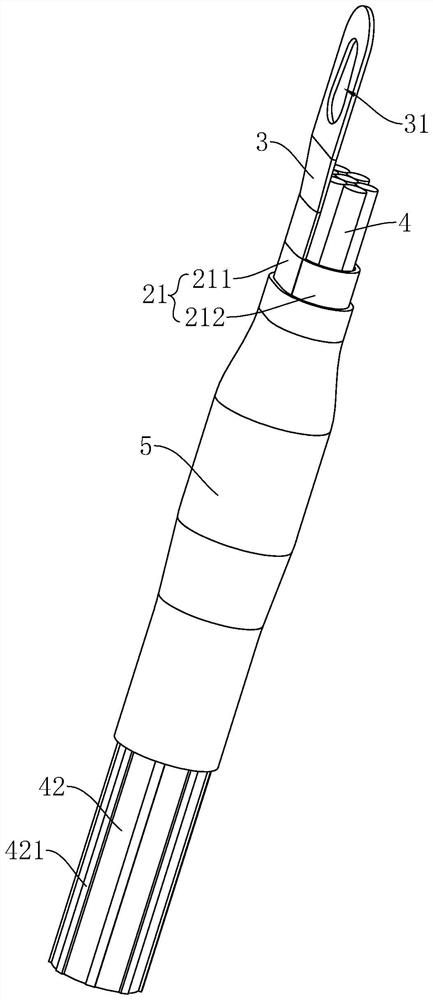

[0034] The following is attached Figure 1-Figure 4 The application is described in further detail.

[0035] The embodiment of the present application discloses a connecting line of a molding machine. refer to figure 1 with figure 2 , a connection line for a molding machine, including a plurality of inner cores 4, a plurality of inner cores 4 are provided with a protective cover 41, which facilitates the collection and restraint of the plurality of inner cores 4, and a connector is provided at the end of the protective cover 41 1. The connector 1 includes a sleeve 2 surrounding the end of the protective sleeve 41, and a connecting piece 3 connected to the end of the sleeve 2. The ends of the multiple inner cores 4 inserted into the sleeve 2 are all cut off from the outer skin. , so that the bare wires of the plurality of inner cores 4 are in contact with the inner wall of the sleeve 2 , which facilitates the electrical communication between the inner core 4 and the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com