Realization method of seamless rail for straddle-type monorail transportation

A straddle-type monorail and seamless line technology, applied to roads, tracks, bridge parts, etc., can solve the problems that affect the life of vehicles, passenger comfort, increase the wear of train rubber tires, and operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with accompanying drawing:

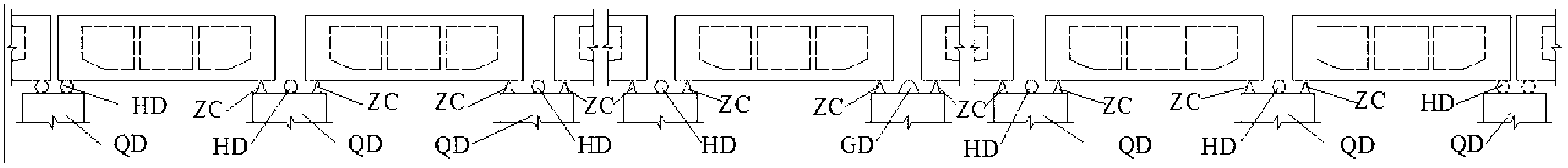

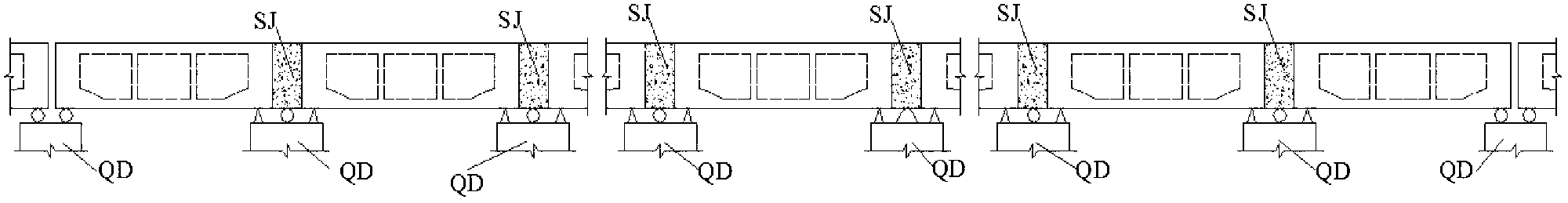

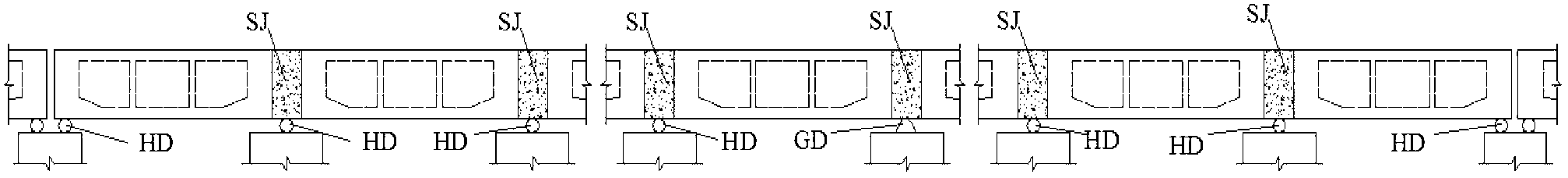

[0034] A method for realizing a seamless line of straddle-type monorail traffic, the seamless line of the straddle-type monorail traffic is composed of multiple continuous girder bridges, multiple continuous rigid frame bridges or simply supported girder bridges; or the The straddle-type monorail traffic seamless line is composed of the above three or any two mixed forms;

[0035] The connection between the running surface, guide surface and stable surface at the expansion joints of adjacent continuous girder bridges, continuous rigid frame bridges and simply supported girder bridges shall be connected by seamless expansion joints; or adjacent continuous girder bridges, continuous rigid frame The connection between the running surface, the guide surface and the stable surface at the expansion joints of the bridge and simply supported girder bridges is connected by joint plates; o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com