Post-cast strip inflatable arc angle rectangular flexible pipe side mold support construction method

A construction method and technology of post-pouring belts, which are applied to building components, building insulation materials, buildings, etc., can solve problems such as powerlessness, and achieve the effects of improved construction quality, good application prospects, and smooth concrete sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, the base plate thickness is 100-300mm.

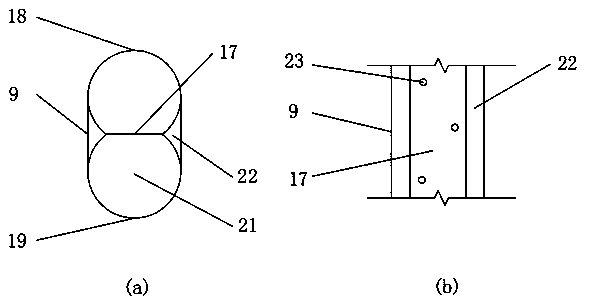

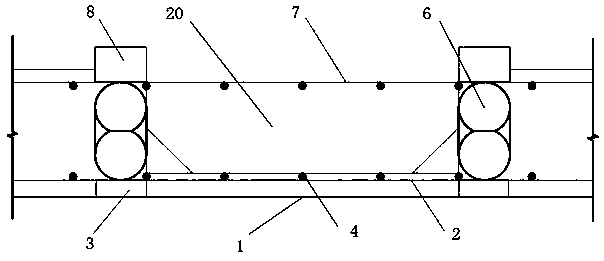

[0055] Lay the lower template 1 first, bind the bottom reinforcement 2 on the upper side of the lower template, and set a pair of wooden strips 3 for plugging on the lower side of the bottom reinforcement and the lower side of the area used to form the post-casting belt; Bind the steel bar bracket 4 on the upper side of the wooden strip, and install a curved rectangular hose 6 on both sides between the steel bars; bind the gluten 7, and set interception on the upper side of the gluten and above the hose Wooden square 8, so that it can be used to intercept concrete when pouring concrete later. The area between the two sidewalls of the two hoses forms a post-casting belt, and the steel bars in the post-casting belt are penetrated.

[0056] In this embodiment, the steel bar bracket is made of steel bars with a diameter of 14mm arranged at a distance of 500mm, so as to reinforce the air column (hose), reduce the latera...

Embodiment 2

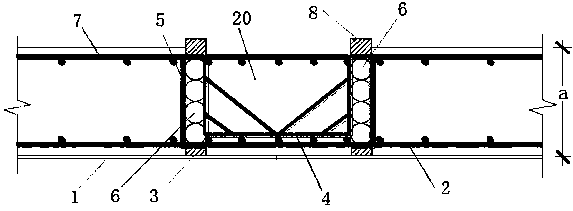

[0057] Embodiment 2, the base plate thickness is 300-600mm without water-stop steel plate.

[0058] Lay the lower formwork 1 first, and tie the bottom reinforcement 2 on the upper side of the lower formwork, and a pair of wooden strips 3 are arranged between the bottom reinforcement and the lower formwork and on the lower side of the area for forming the post-casting belt 20, so as to be used for plugging; Install the steel bar support 4 on the bottom bar and on the upper side of a pair of wooden strips, and set the limit steel bar 5 forming the air column installation cavity between the outside of the steel bar support and the steel bar support; put 2 hoses 6 from bottom to top The top is installed in the air column installation cavity; the gluten 7 is bound, and wooden squares 8 are respectively arranged on the upper side of the gluten and above the air column installation cavity, so as to be used for intercepting concrete during later concrete pouring. A post-casting strip ...

Embodiment 3

[0061] Embodiment 3, the thickness of the foundation bottom plate is 300-600 mm and there is a water-stop steel plate.

[0062] Lay the waterproof coiled material 13 in the preset cushion layer recess 12, bind the bottom rib 2 on the upper side of the cushion layer, and set a pair of Concrete bar 14; bind the first steel bar bracket 4 on the bottom bar and on the upper side of a pair of concrete bars, and bind the second steel bar bracket 16 on both sides of the first steel bar bracket respectively, located on the first steel bar bracket and the second steel bar bracket. A hose installation cavity is formed between the reinforcement brackets; water-stop steel plates 10 are arranged on both sides of the hose installation cavity to abut against the upper ends of the first reinforcement bracket and the second reinforcement bracket respectively, and the water-stop steel plates and a U-shaped steel bar The lower end of the hoop 15 is welded; two superimposed hoses 6 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com