Patents

Literature

58results about How to "Simple demoulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

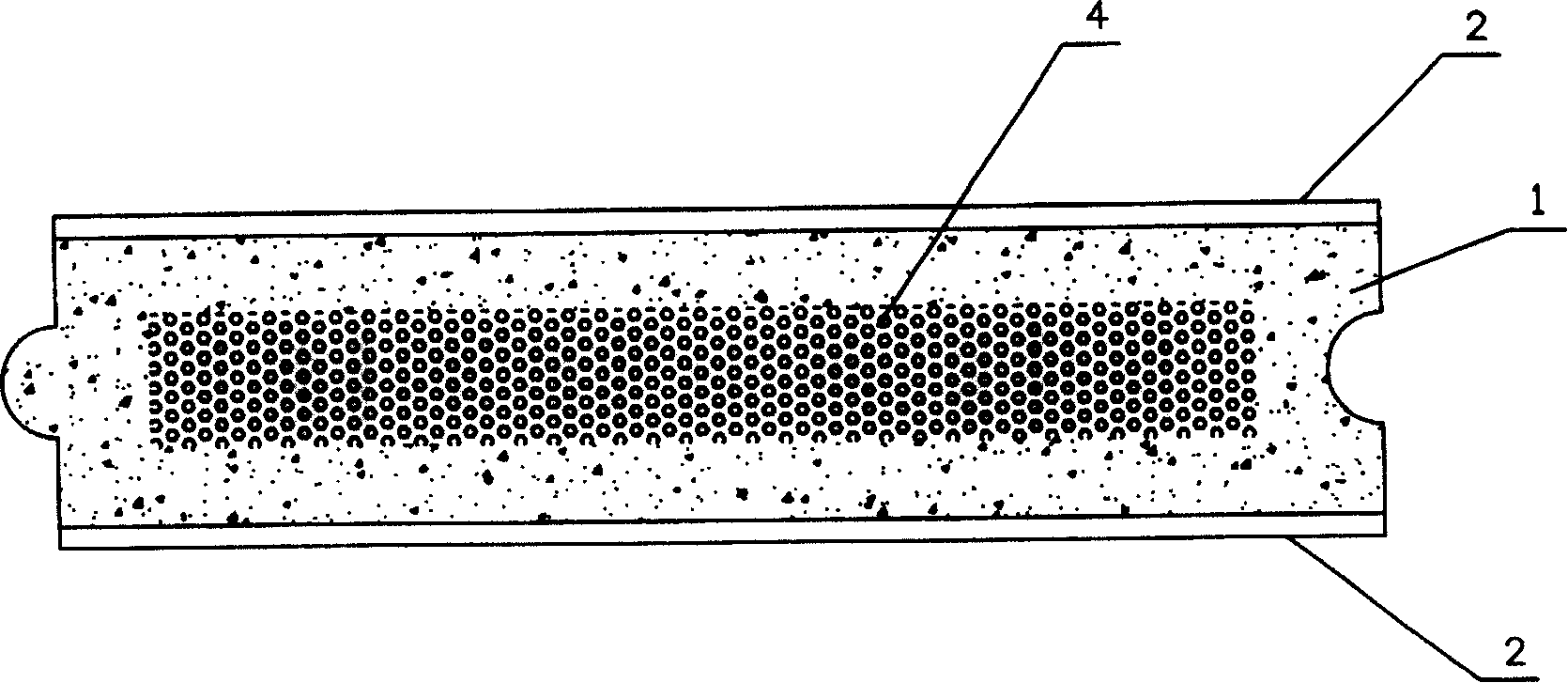

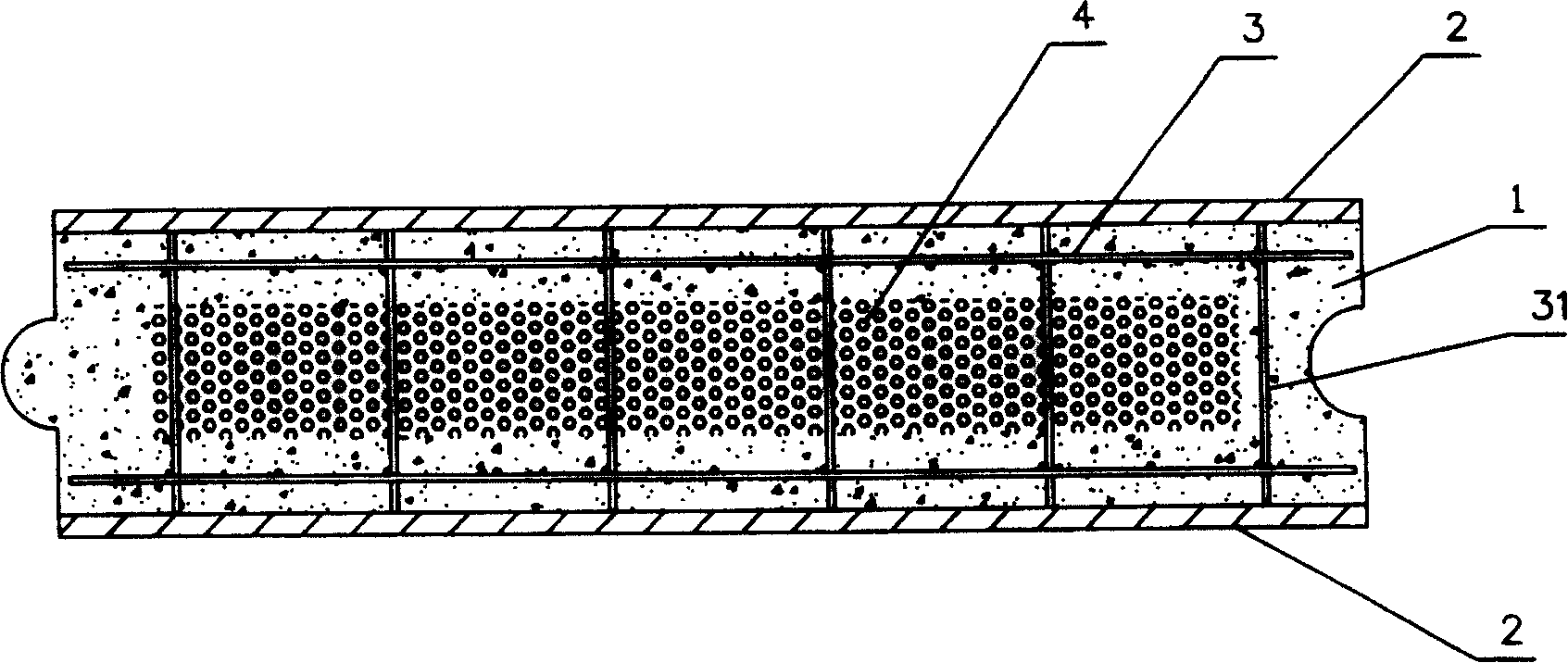

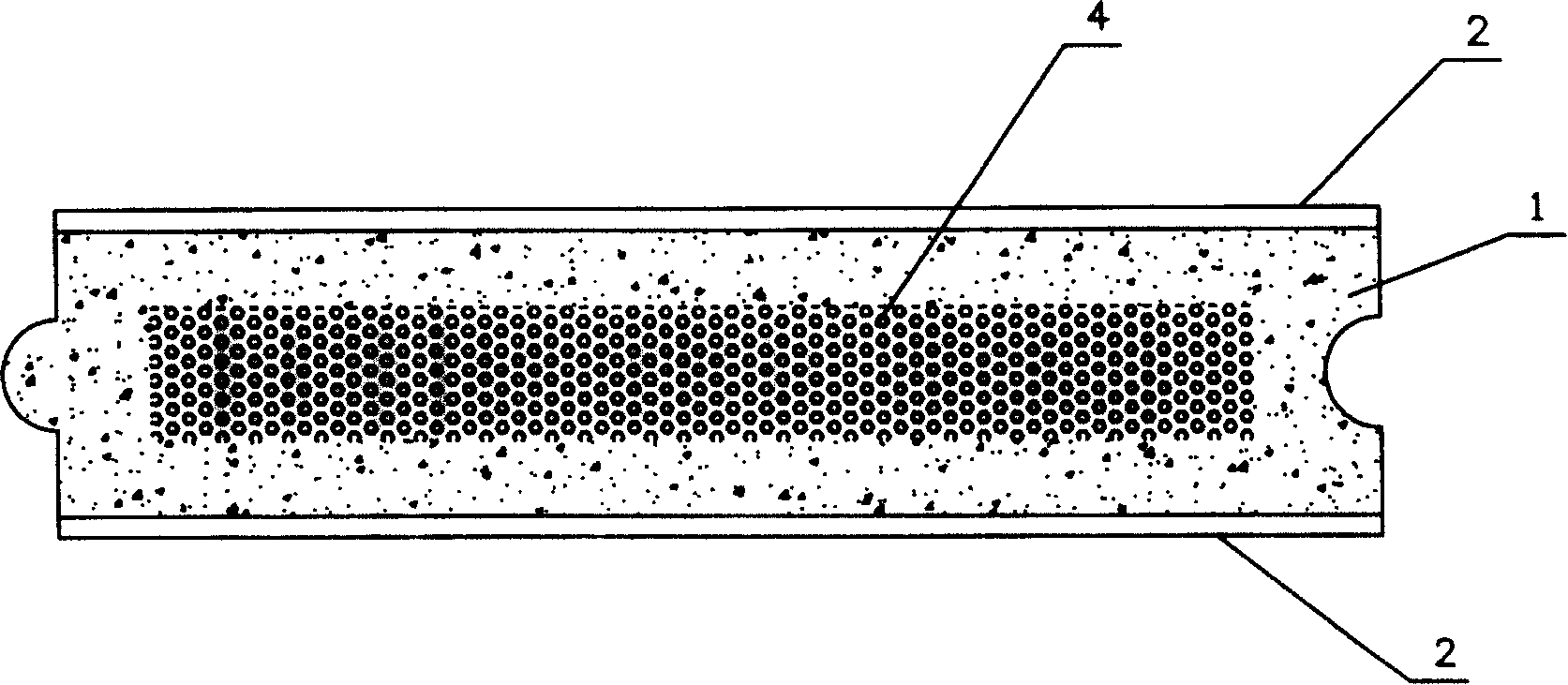

Light compound side fascia and its manufacturing method

ActiveCN1831270AReasonable structureSuperior performanceConstruction materialMouldsRebarHigh intensity

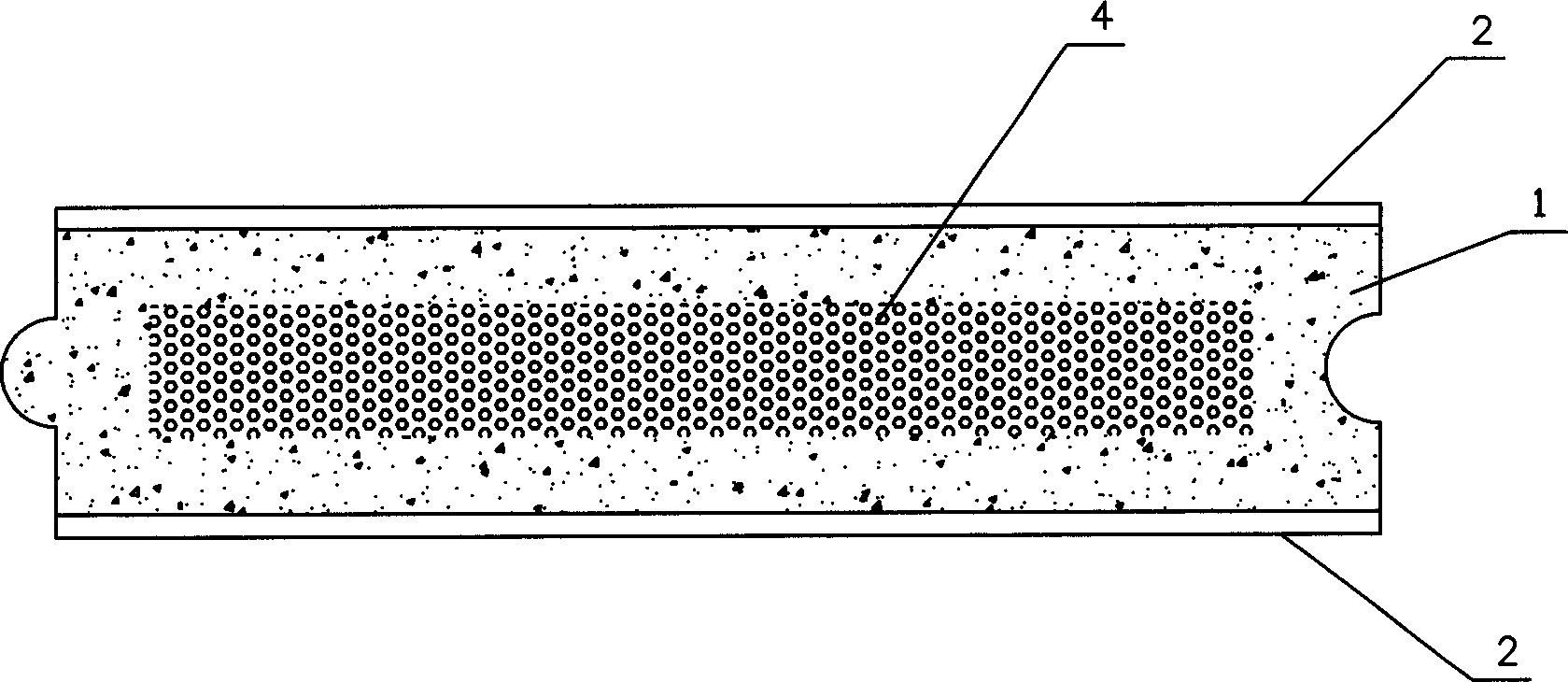

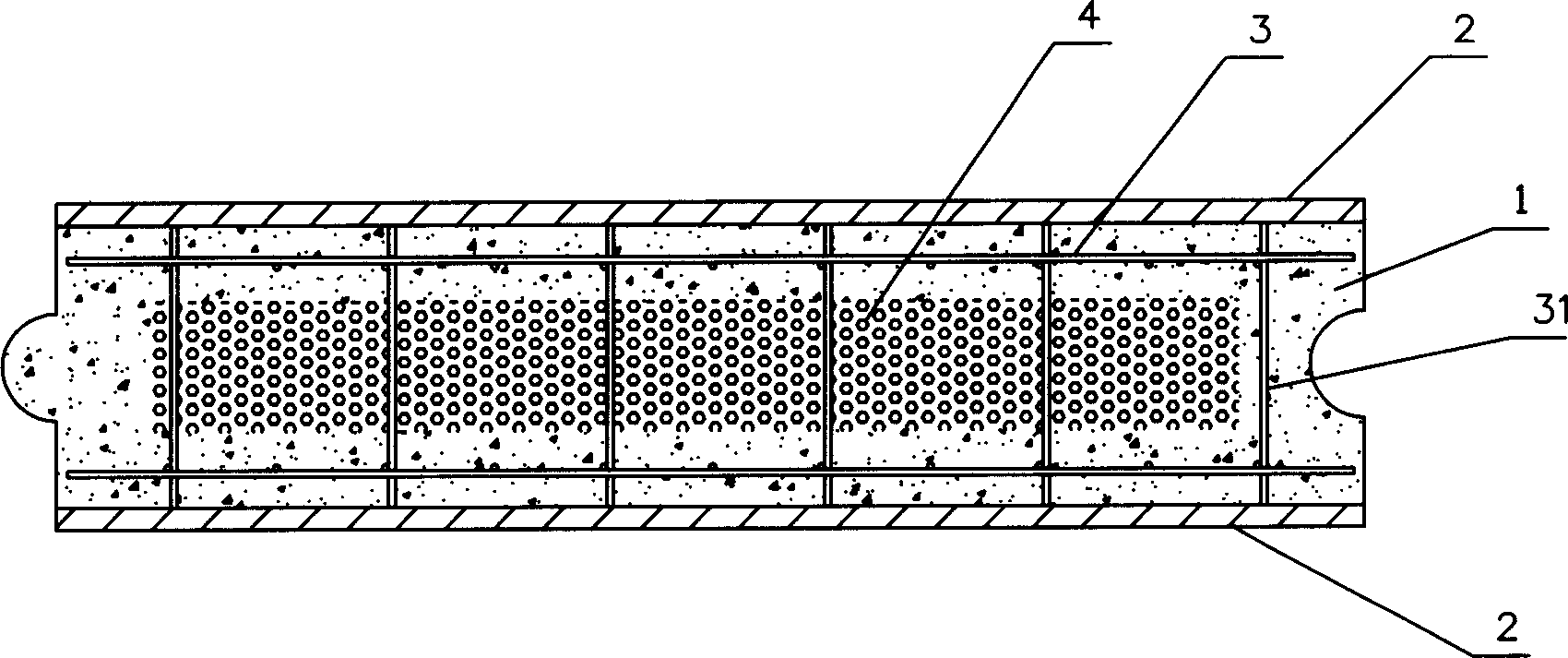

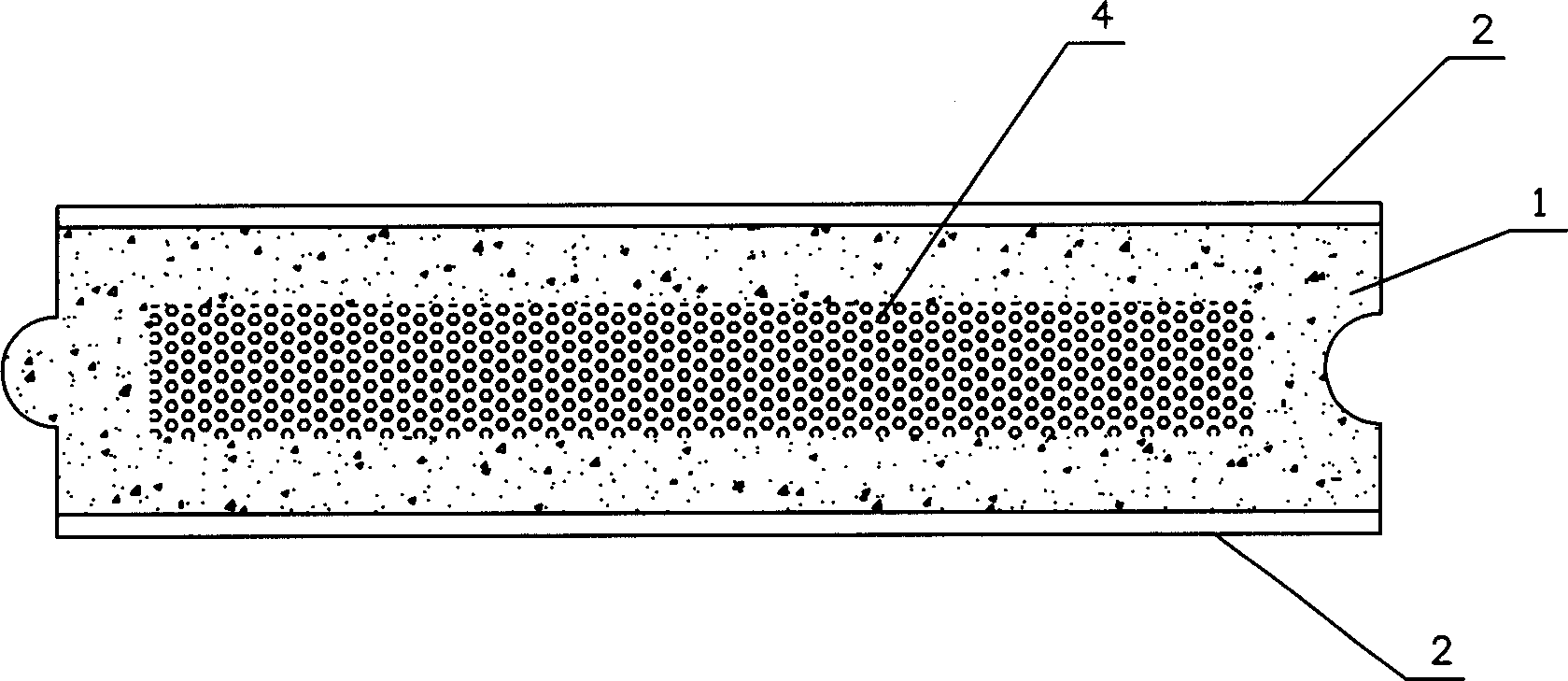

The invention relates to a lightweight compounded outer wallboard and the manufacturing method thereof. And it is compounded of fiber or wire fabric reinforced cement slab and bearing layer, where the bearing layer is made of reinforcing fabric reinforced light aggregate concrete, one or two sides of the bearing layer are combined with cement slabs and a cavity in the bearing layer is enveloped by light aggregate concrete and full of heat insulator. And its manufacturing method comprises a process as follows: A. placing cement slabs on one or two sides in a die space; B. placing reinforcing fabric provided with heat insulator in the middle by the cement slabs in the die space; C. pouring light aggregate concrete in the die space to bury the reinforcing fabric; and D. staying, curing and hardening and then demoulding to make it. And the method is simple, practical, high-efficiency and it has advantages of lightweight, high intensity, strong bearing capacity, good heat insulating property, seismic resistance, seepage prevention, etc.

Owner:广州益群板业有限公司

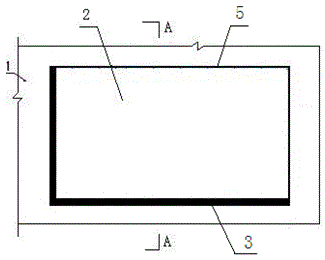

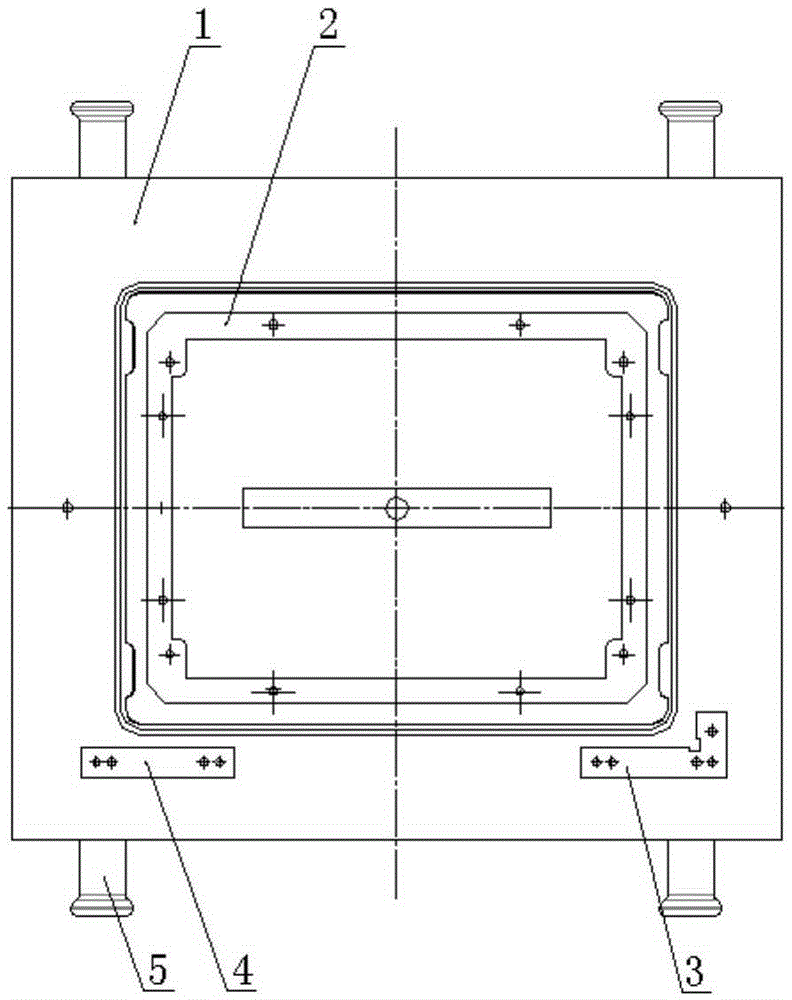

Template for construction

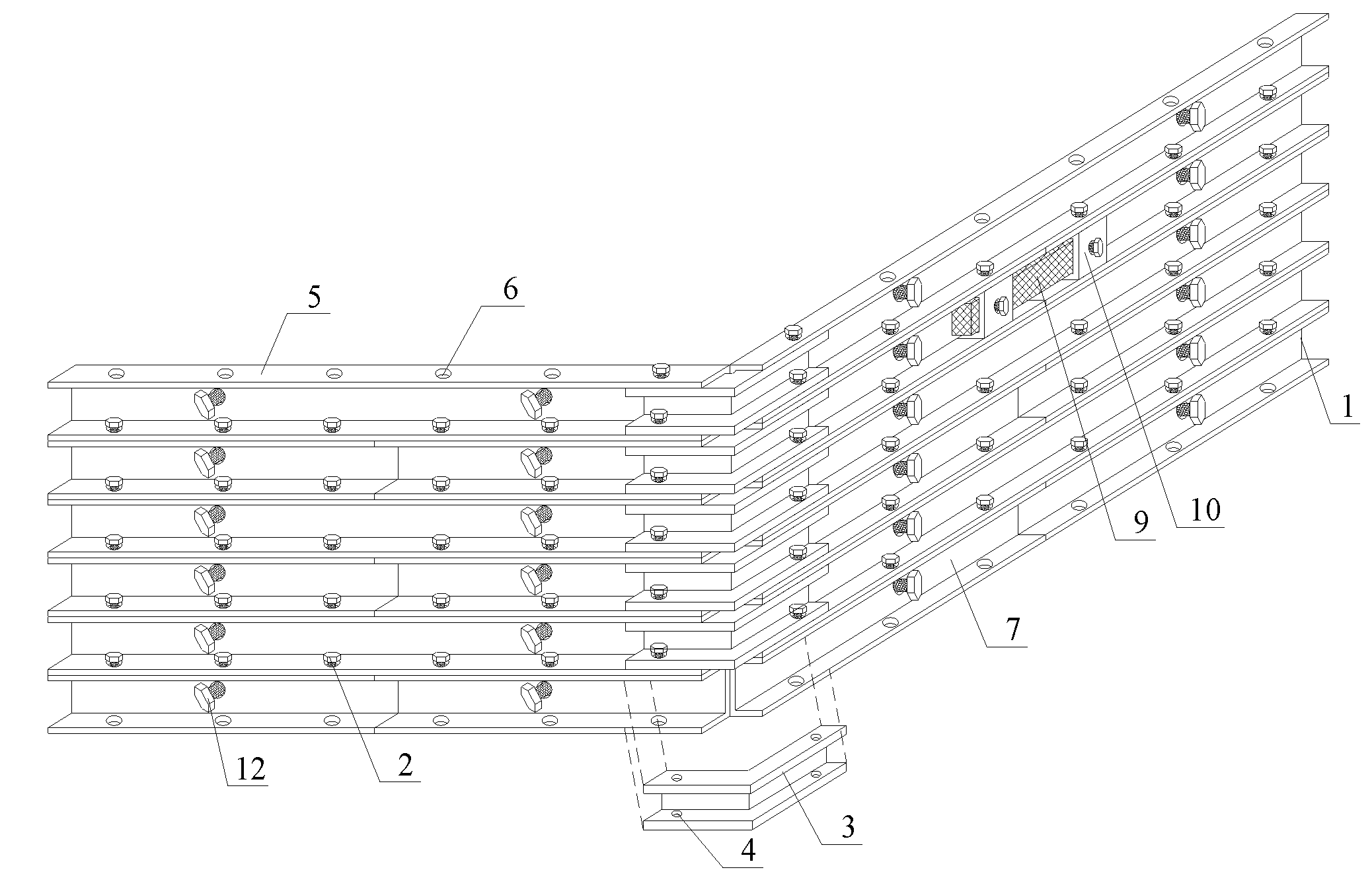

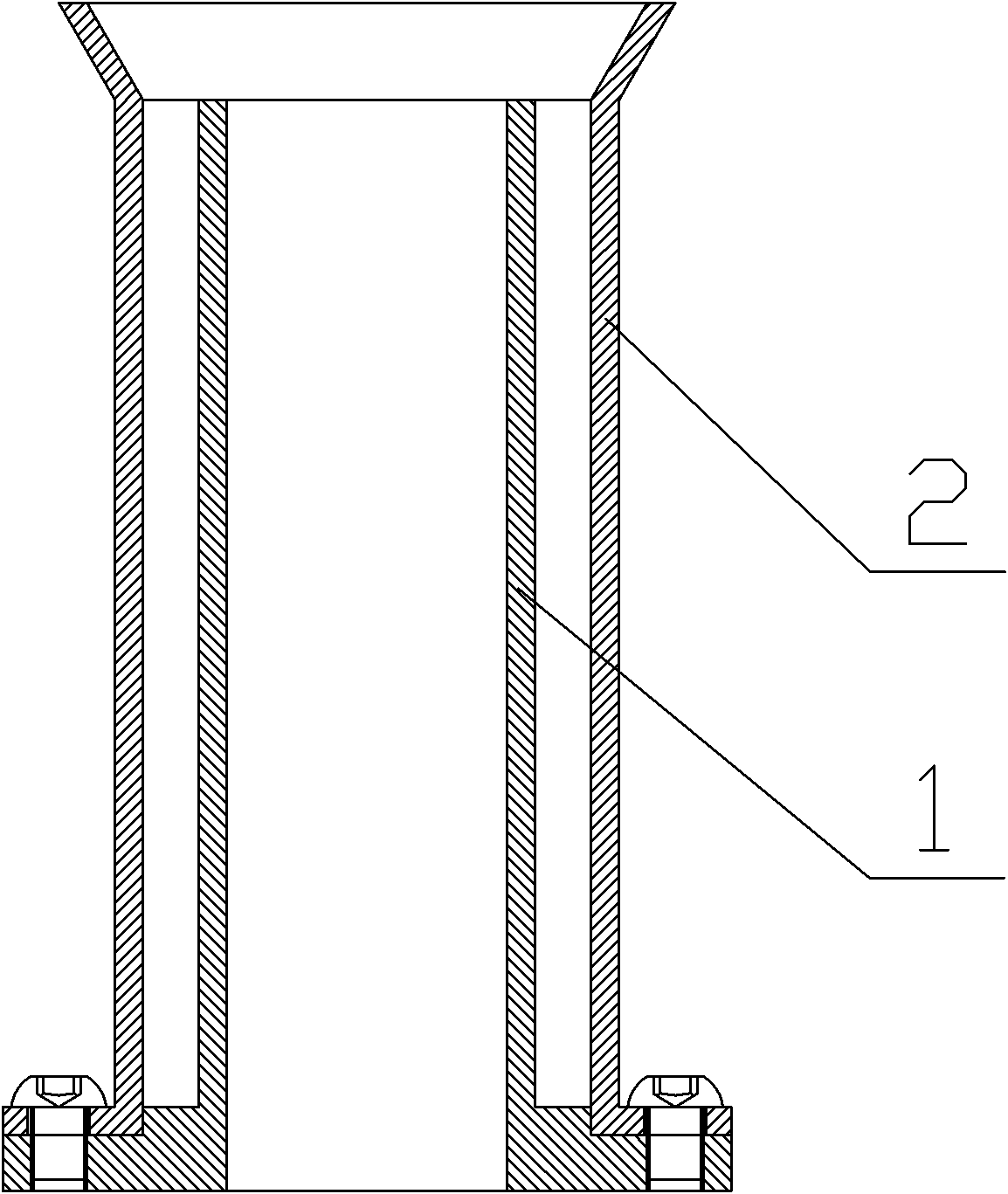

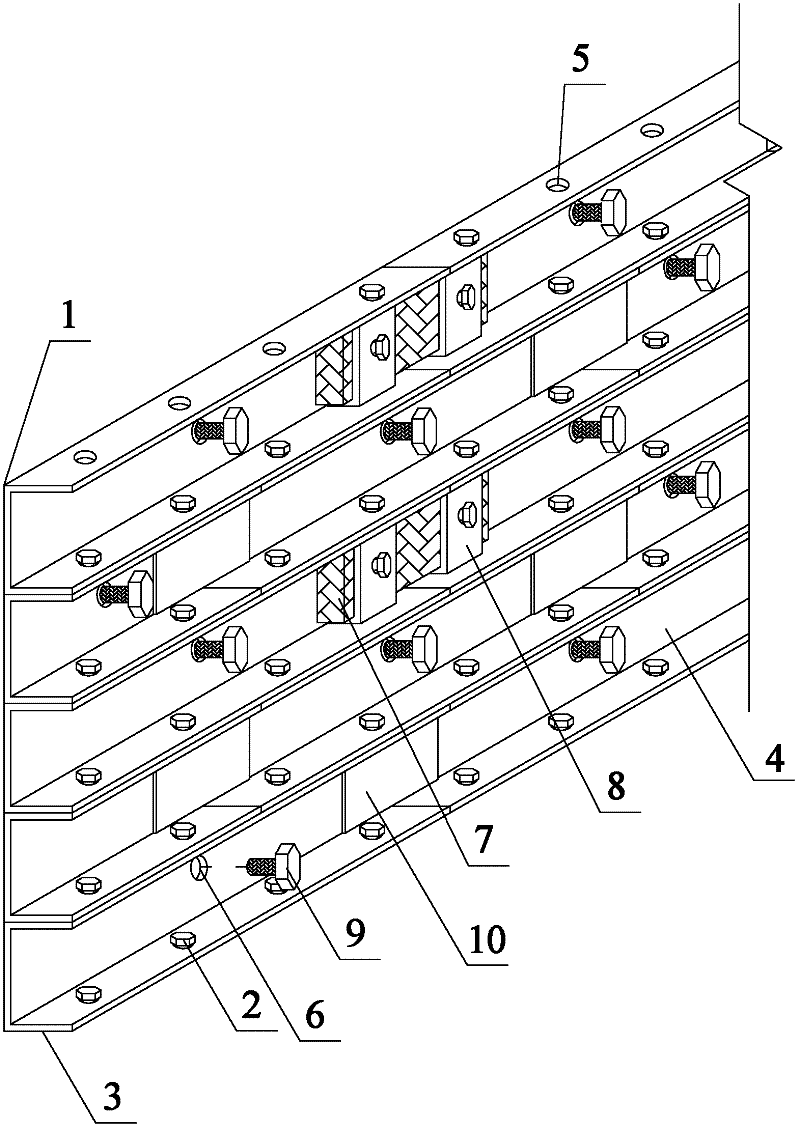

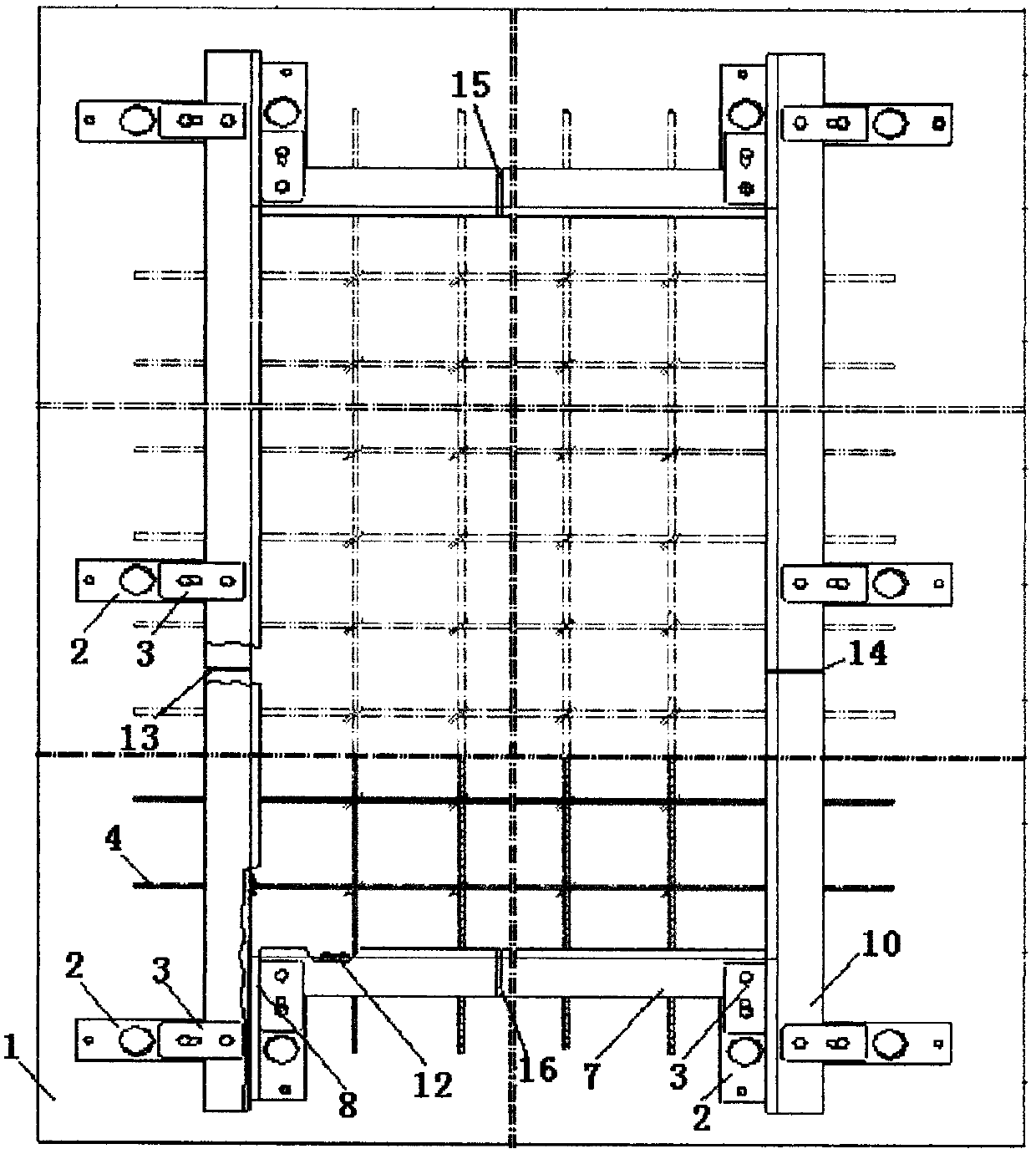

InactiveCN102071796AHigh mechanized production efficiencyEasy to manufactureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShear wallBearing capacity

The invention discloses a template for construction, which comprises groove-shaped modules (1), and bolts or pins (2). The template for construction is spliced by a plurality of mutually connected groove shaped modules (1) through the bolts or pins (2), wherein a connecting block (3) arranged at a corner of the template has an L-shaped or groove-shaped section; the connecting blocks (3) are arranged at internal corners and external corners of the template for construction, have strong rigidity, can connect the templates in different directions into a whole; and the L-shaped and groove-shaped connecting blocks (3) arranged at the internal corners of the template can plug gaps on the end parts of the groove-shaped modules (1) to prevent concrete from flowing out. The template for construction is easy to manufacture and convenient to assemble and disassemble, has high rigidity, high bearing capacity and long service life, and can be used in construction of concrete uprights, shear walls and beams; and the connecting blocks (3) can be used for connecting corners of an upright template, a shear wall template and a beam template.

Owner:吴方伯

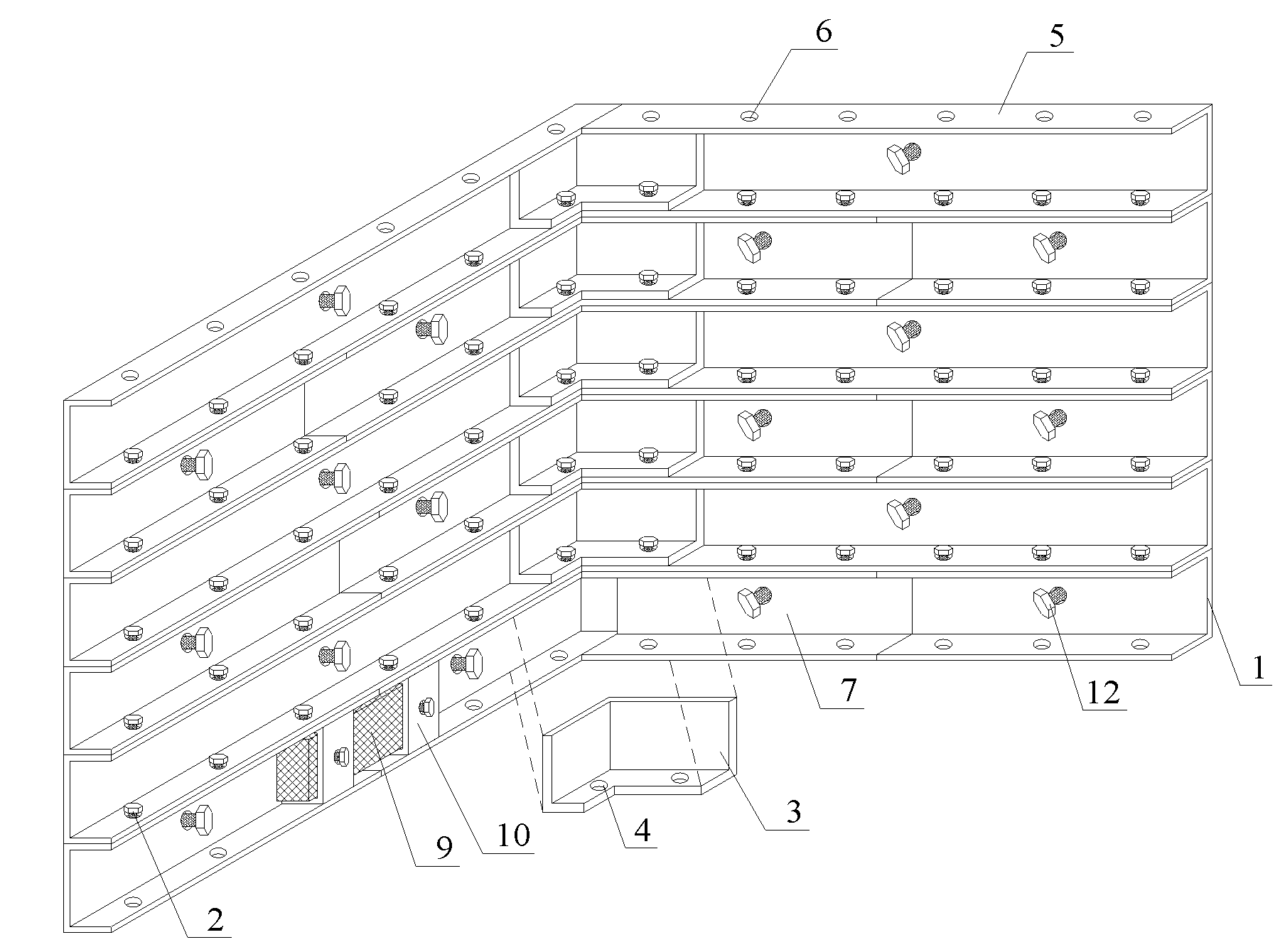

Template for construction

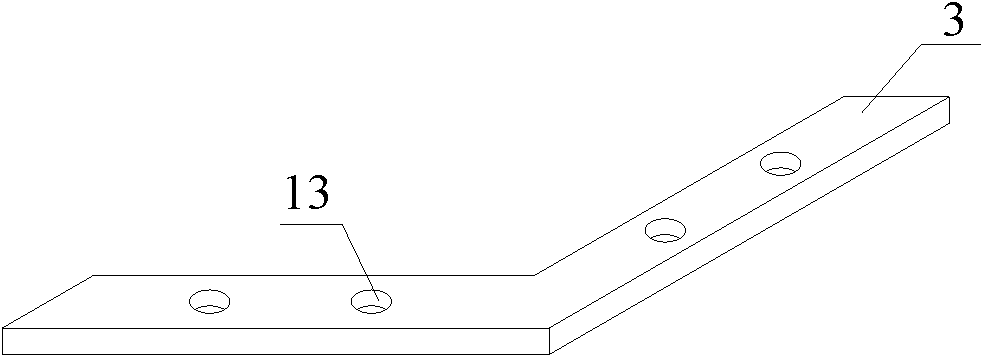

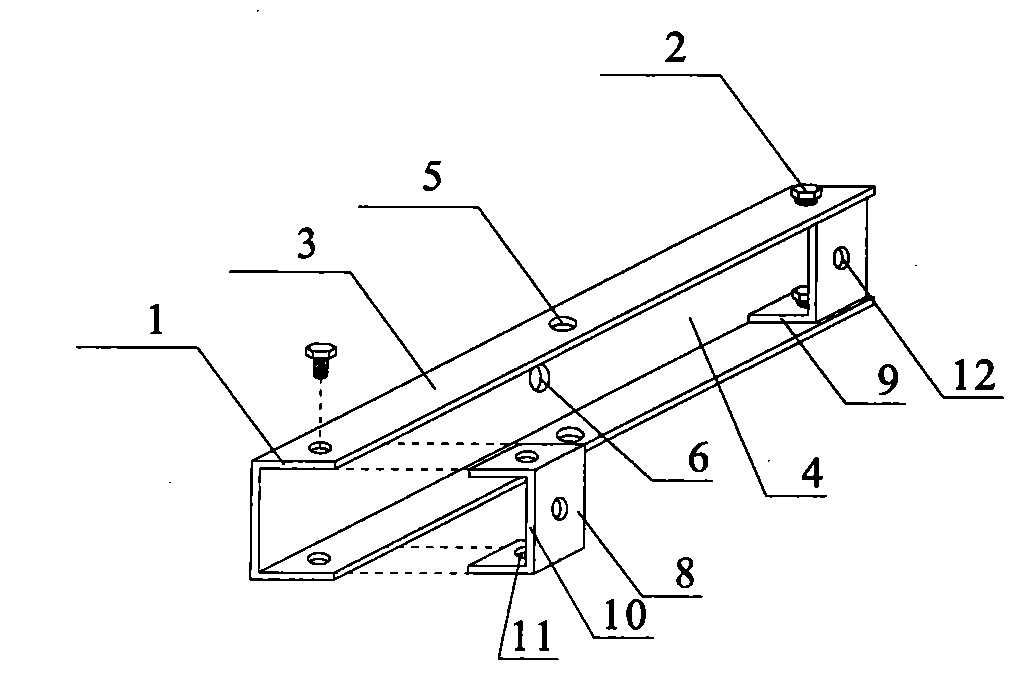

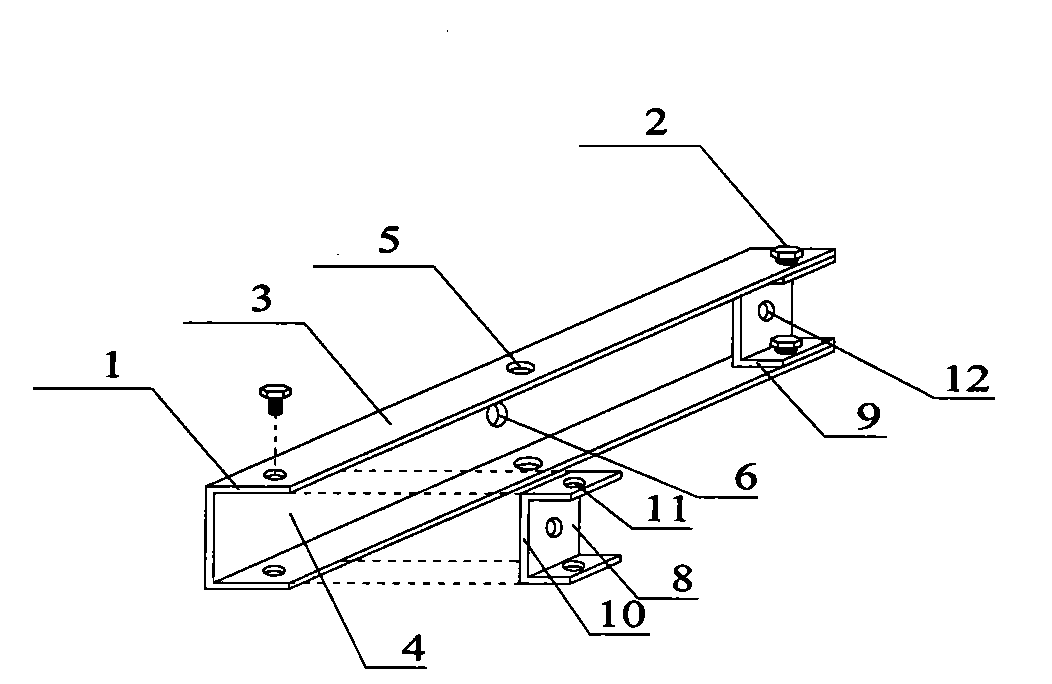

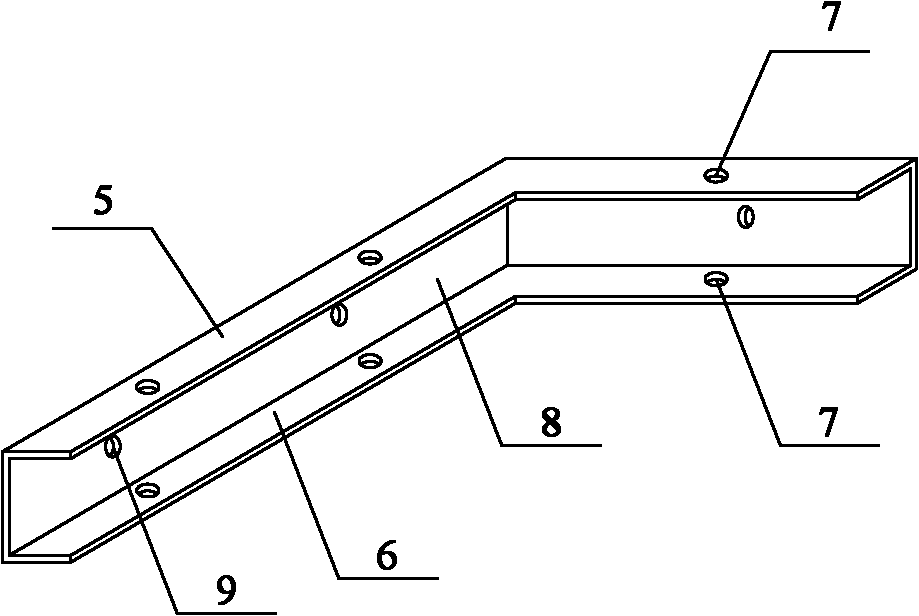

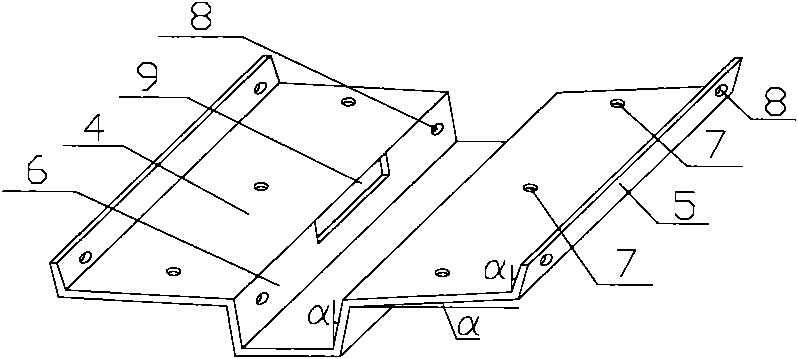

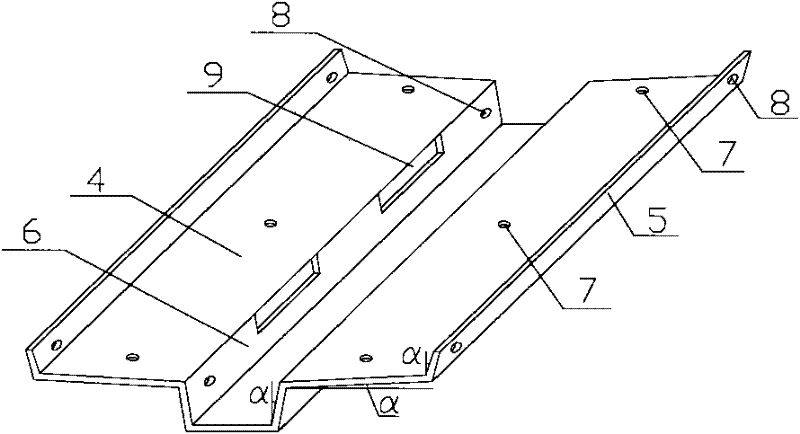

ActiveCN102071802AHigh mechanized production efficiencyEasy to manufactureAuxillary members of forms/shuttering/falseworksForm treatmentFlangeBearing capacity

The invention discloses a template for construction, which comprises groove-shaped modules (1), and pins (2). The template for construction is spliced by a plurality of mutually connected groove-shaped modules (1) through the pins (2), wherein connecting plates (3) are arranged at corners of the template, holes (13) on the connecting plates (3) correspond to holes on flanges (5)of the groove-shaped modules; the pins (2) pass through the holes (13) and the holes (6) to connect and fix the connecting plates (3) and the groove-shaped modules (1); the connecting plates(3) are arranged at internal corners and external corners of the template for construction; n-shaped plugs (4) are arranged on the end parts of the groove-shaped modules (1) at the internal corners, and holes (14) are formed on plugs (4); and the plugs (4) and the connecting plate (3) are connected by the pins (2) to prevent concrete from leaking from the end parts of the groove-shaped modules. The template for construction is easy to manufacture and convenient to assemble and disassemble, has high rigidity, high bearing capacity and long service life, and can be used in construction of concrete uprights, shear walls and beams; and the connecting plates (3) can be used for connecting corners of an upright template, a shear wall template and a beam template.

Owner:吴充

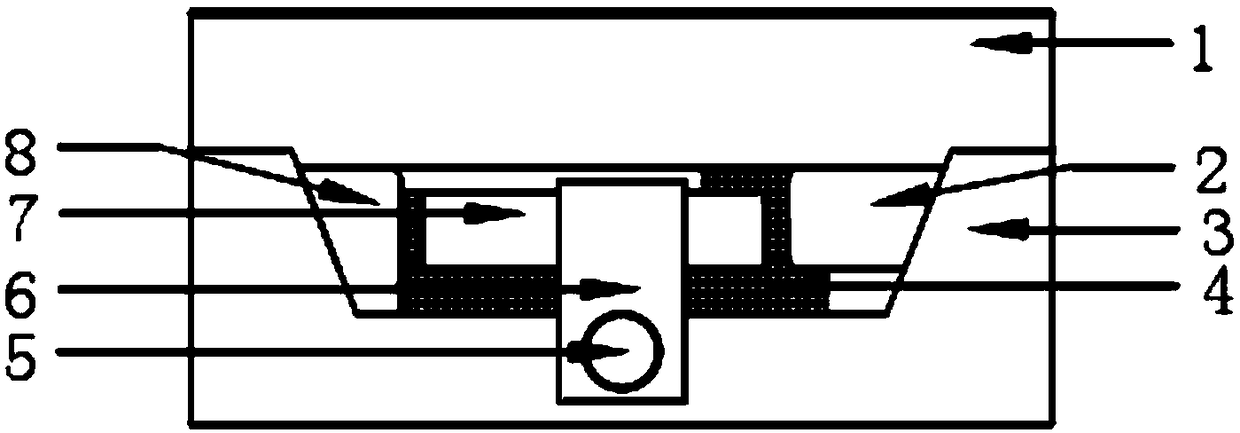

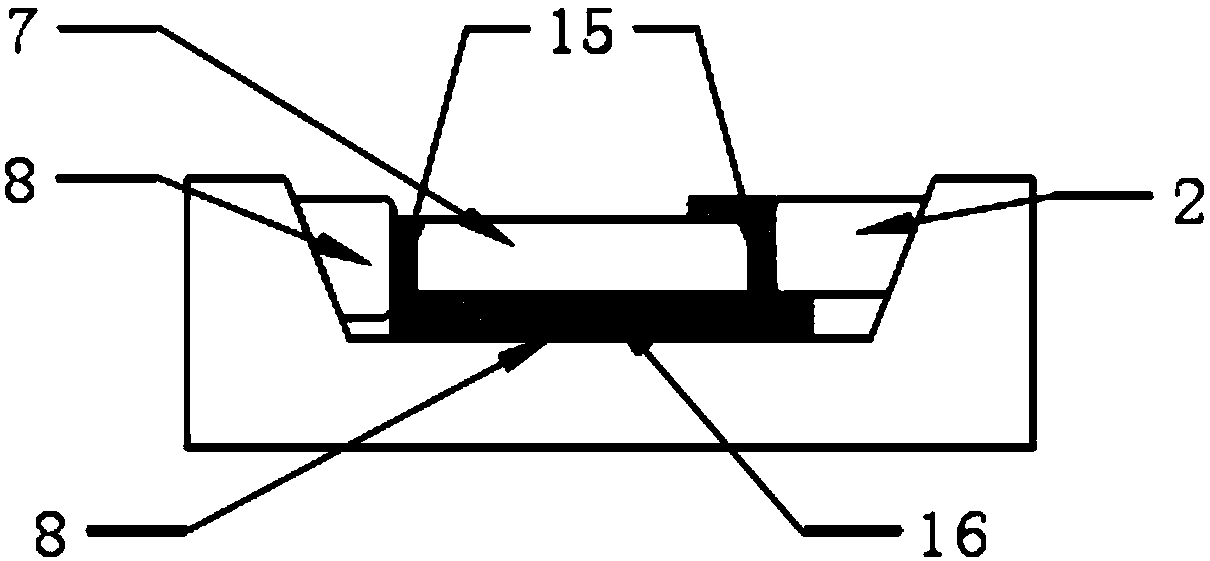

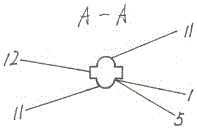

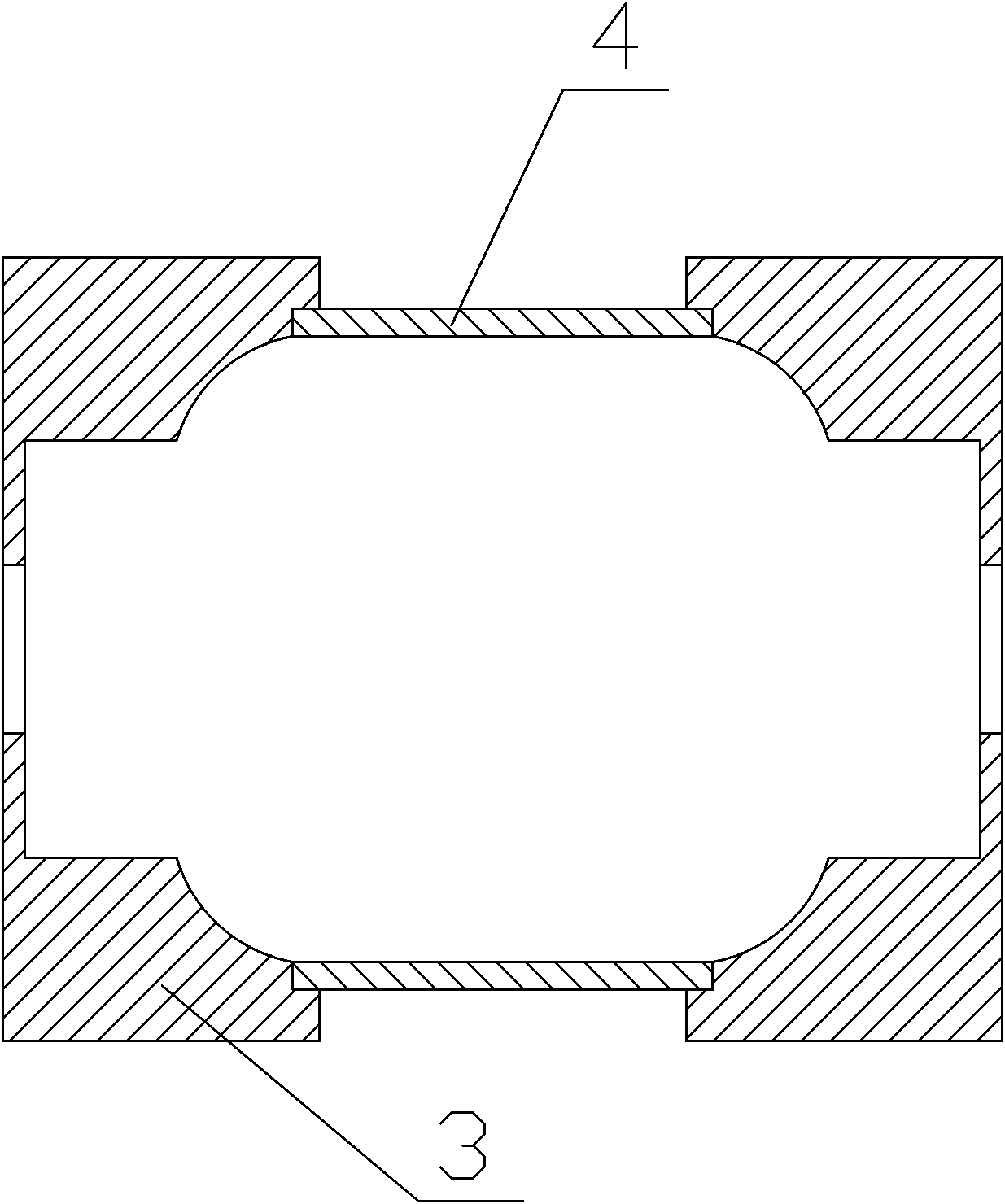

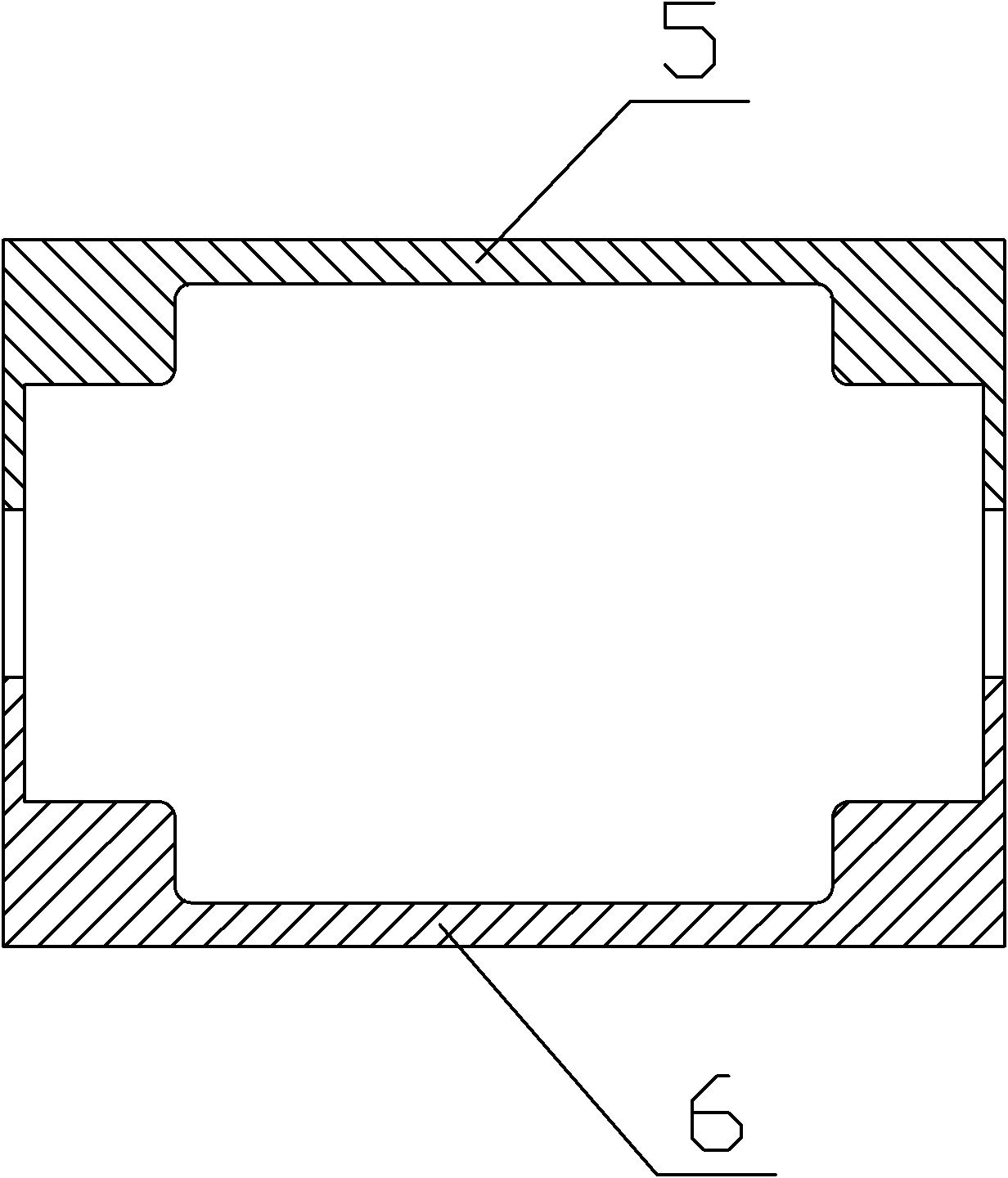

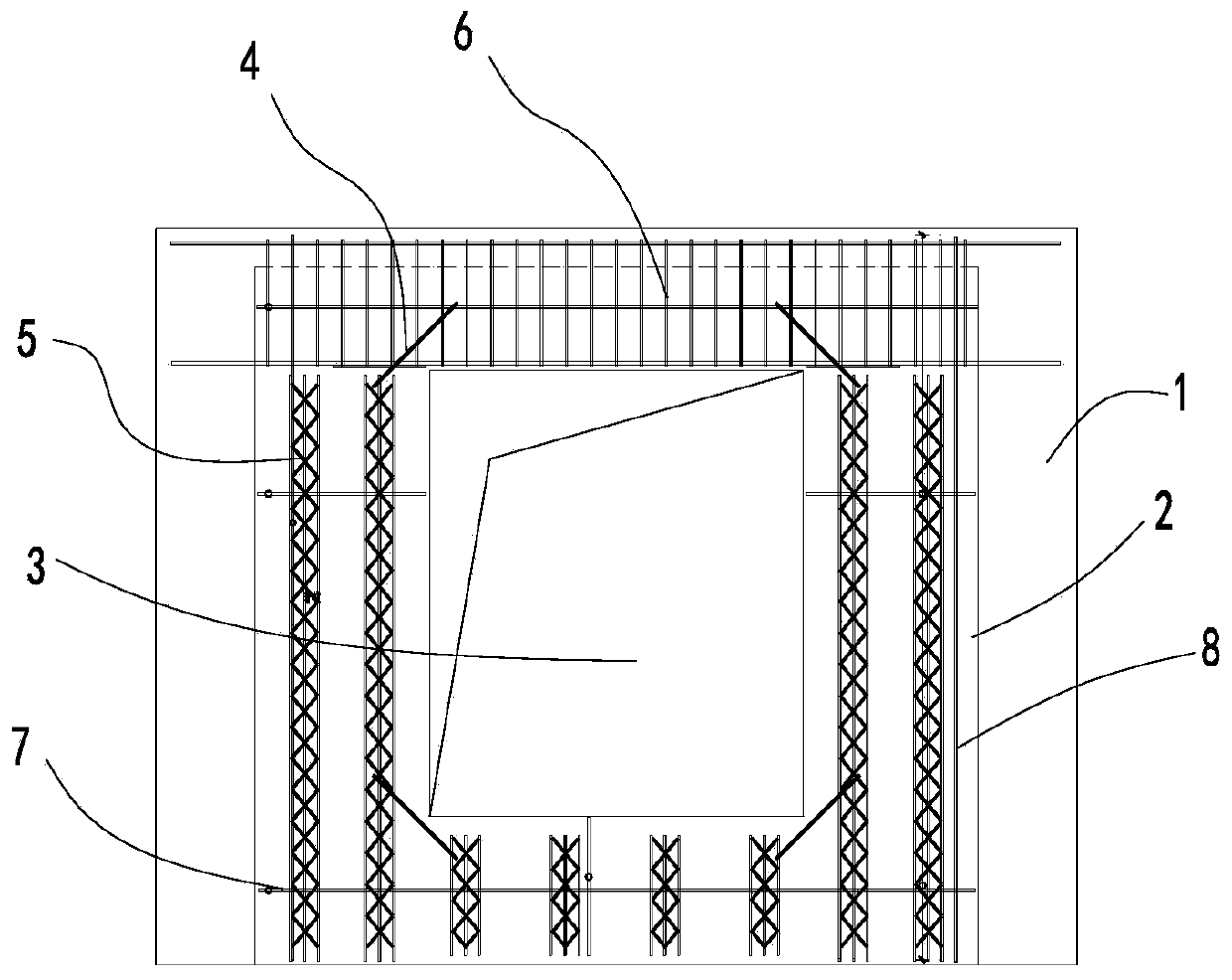

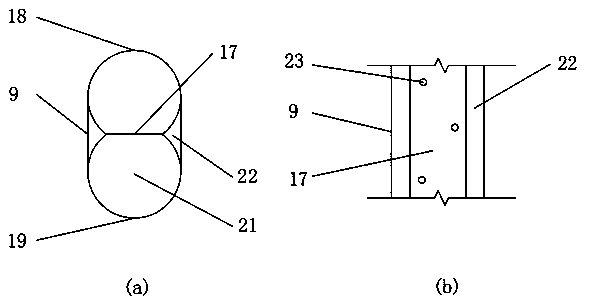

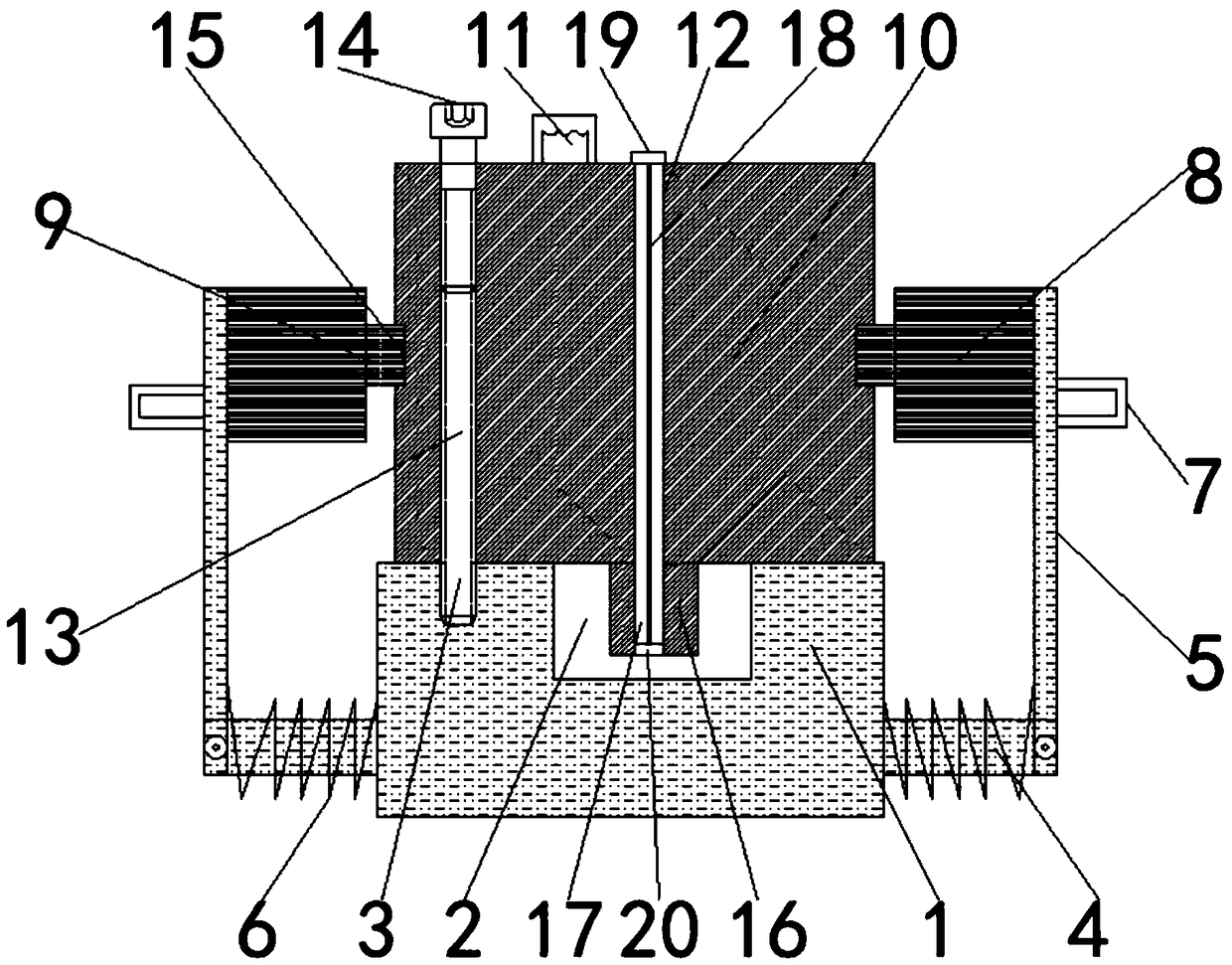

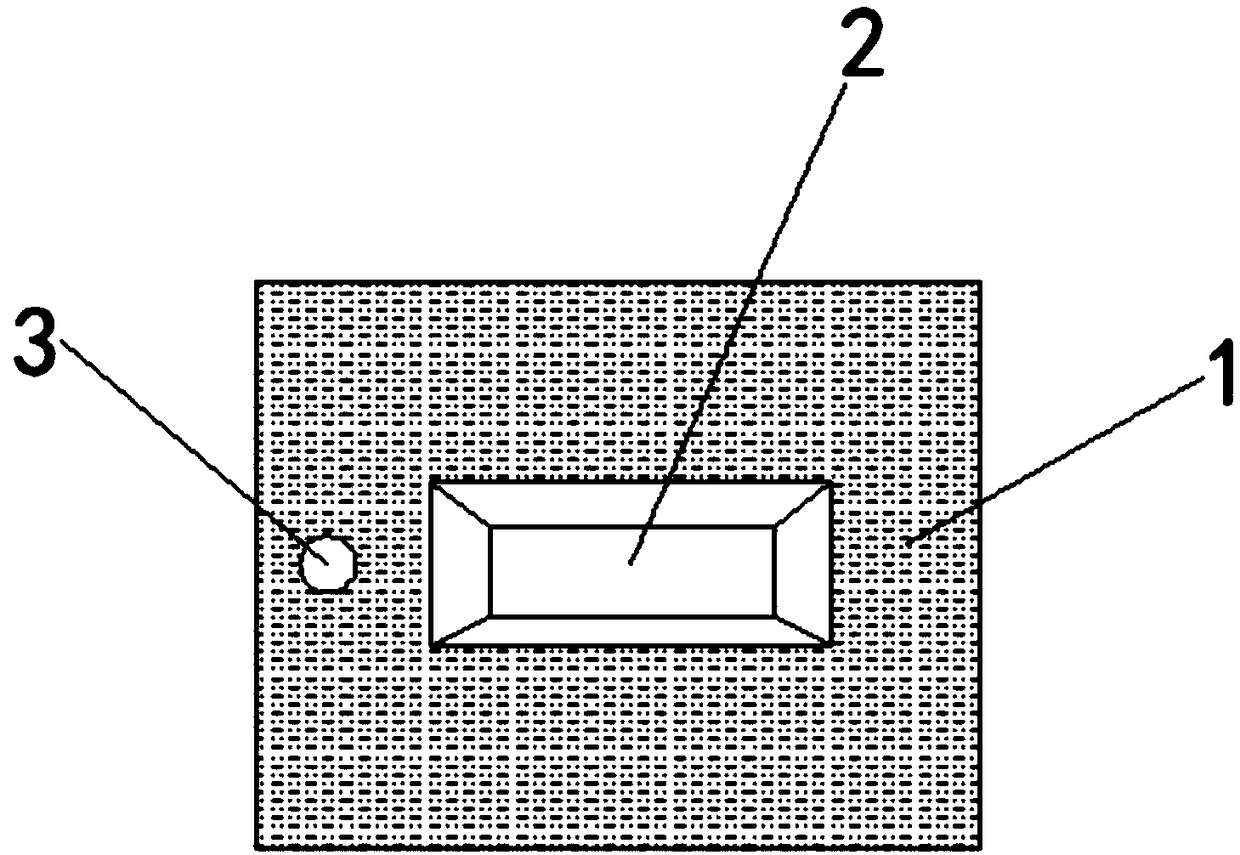

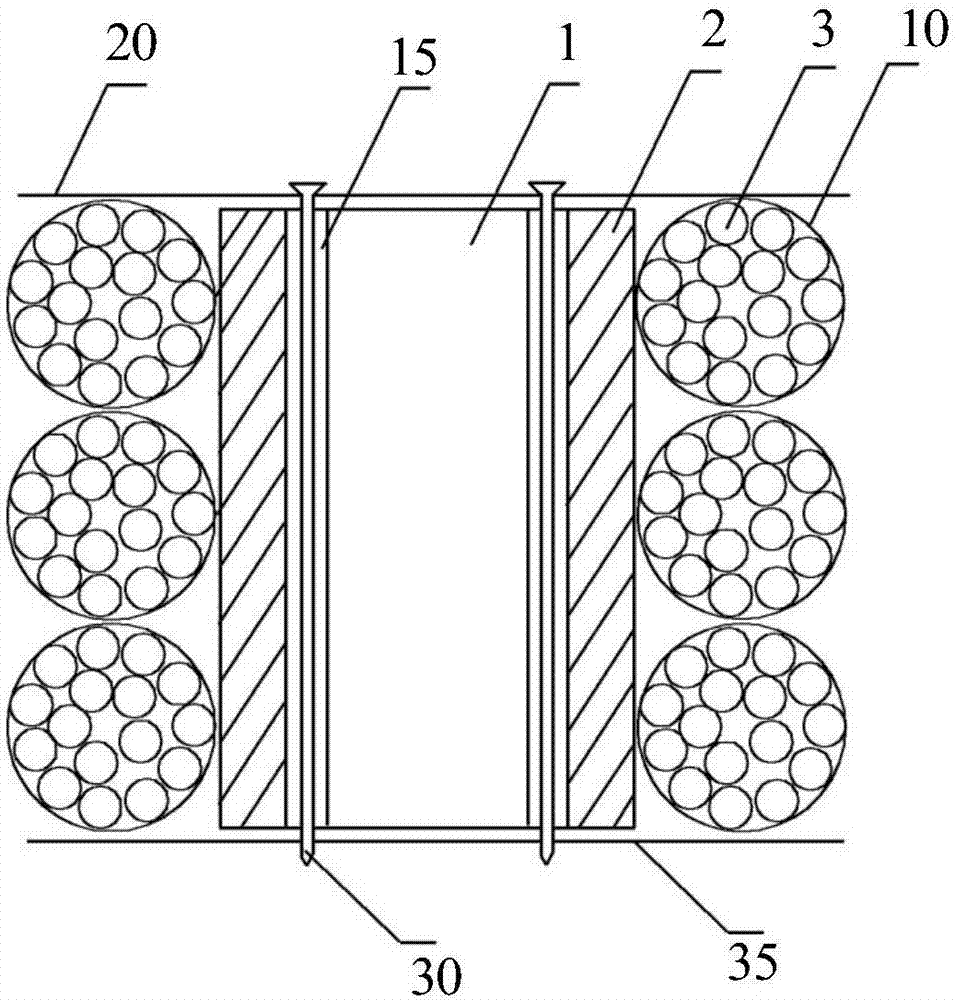

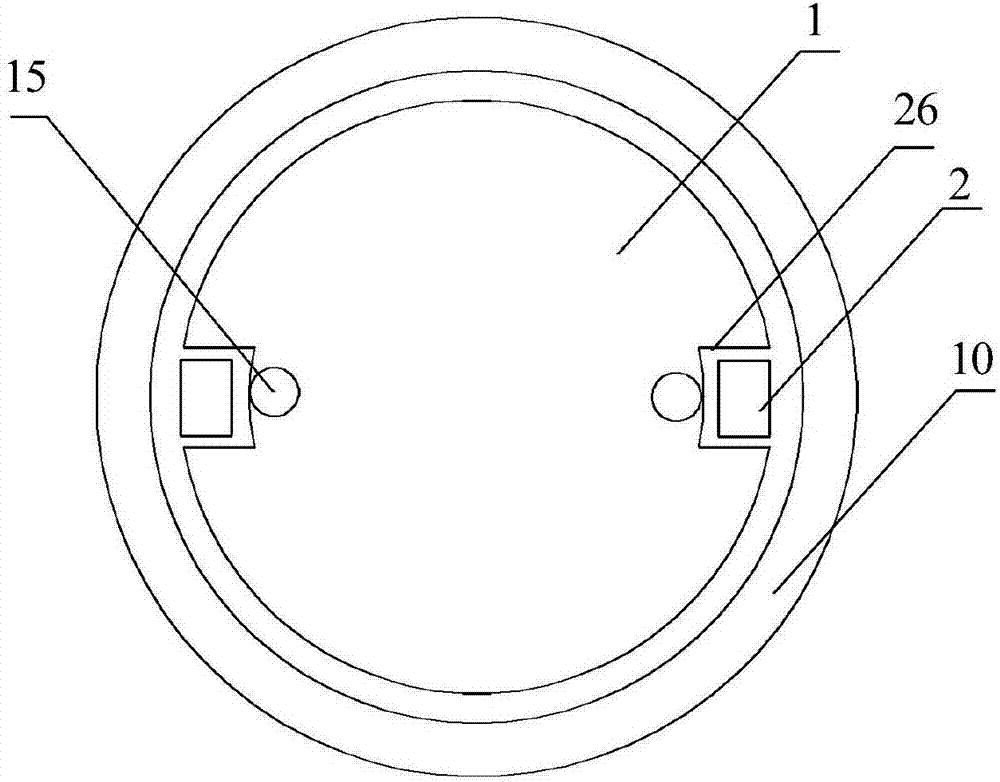

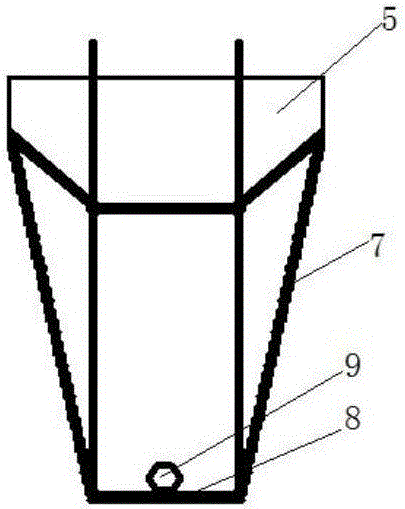

Mold for preparing reinforced structure of composite

The invention provides a mold for preparing a reinforced structure of a composite. The mold comprises a male mold (1), a right sliding block (2), a female mold (3), core mold barrier strips (6), a fastening bolt (5), a core mold (7) and a left sliding block (8) and is characterized in that flanges (14) are arranged at the left side and right side of the female mold (3), and bevel vertical columns(10) are arranged at the four corners of the female mold (3) and are matched with slideways (17) at the four corners of the male mold; the matching surfaces of the left sliding block (8), the right sliding block (2) and the female mold (3) are at a certain angle; the core mold (7) is arranged between the two sliding blocks and is matched with the sliding blocks to form an internal cavity of a component (4); the female mold (3), the left sliding block (8), the right sliding block (2) and the core mold (7) form a molding space of the component (4); and the core mold barrier strips (6) are arranged at the two ends of the core mold (7). When a prepreg-infiltration technology is used for preparing the reinforced component of the CMC (ceramic matrix composite), the mold can be used for compression molding of a reinforced structure prefab and provides a blank for forming the reinforced component of the CMC.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

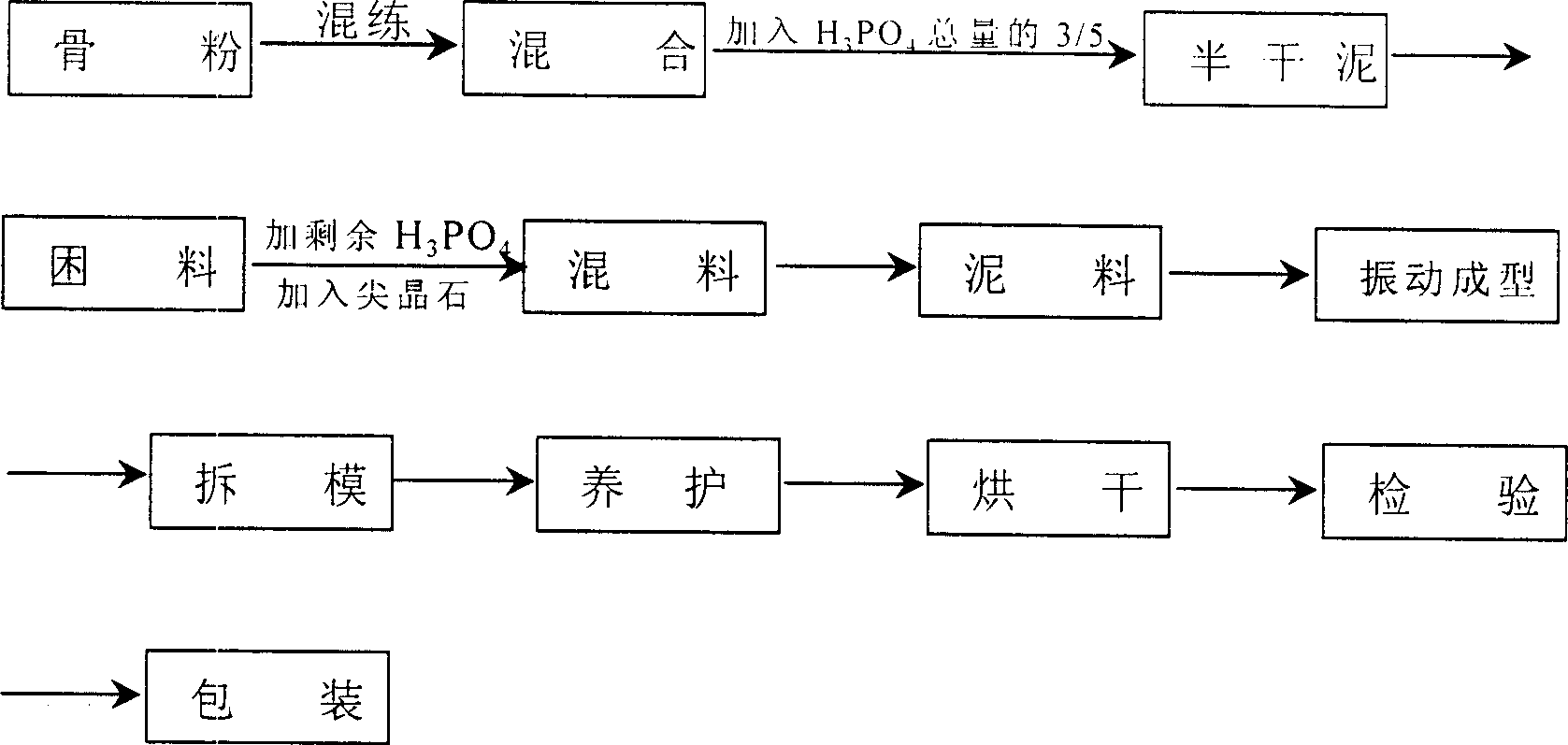

Phosphoric acid and spinel combined high aluminia pouring material

The present invention belongs to the field of refractory material, specially, it is suitable for producing phosphoric acid combined high-aluminium pouring material. It is characterized by that it uses electrocast spinel as coagulation accelerator or phosphoric acid combined pouring material, its main raw material is a high-grade high-alumina, and its secondary raw material is electrocast magnesia-alumina spinel and phosphoric acid. Said inention is easy to construct and easy to remove form, and has higher strength, after the form of removed for 3 days, it is water resistant.

Owner:UNIV OF SCI & TECH BEIJING

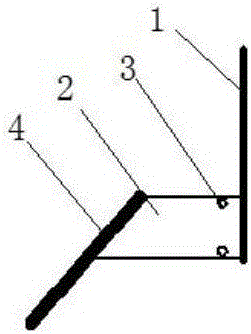

Washroom water-proof structure and construction method

InactiveCN104060737AWon't breakImprove waterproof performanceFloorsForms/shuttering/falseworksFloor slabStructural engineering

The invention discloses a washroom water-proof structure and a construction method. The washroom water-proof structure comprises a structural floor slab (1) and a washroom lower plate (2); when the washroom lower plate (2) is manufactured on the structural floor slab (1), an inclined surface is formed on the periphery of the washroom lower plate (2); the inclined surface comprises a folded plate inclined surface (3) and a slightly inclined surface (5) near a structural wall (9); a masonry reverse ridge (8) is arranged on the folded plate inclined surface (3); the structural wall (9) is cast on the edge of the slightly inclined surface (5). According to the washroom water-proof structure, the inclined surface is formed on the periphery of the washroom lower plate, so that form removal is easy, and the structural floor slab cannot be damaged after form removal; the masonry reverse ridge is arranged on the folded plate inclined surface to enable the slope of the inclined surface to be less susceptible to leakage, thereby having an obvious water-proof effect.

Owner:THE THIRD CONSTR & ENG OF CCFED

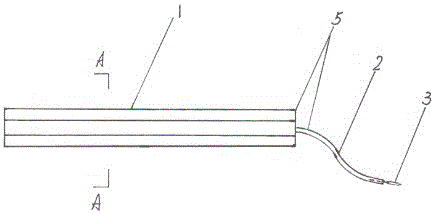

Geometrical shape concrete formwork sealing device

InactiveCN106545162ASimple structureNovel structureAuxillary members of forms/shuttering/falseworksEngineeringMechanical engineering

The invention discloses a geometrical shape concrete formwork sealing device. The geometrical shape concrete formwork sealing device comprises a bar-shaped air bag, an air conveying pipe and a charging connector. One end of the air conveying pipe and one end of the bar-shaped air bag are bonded, and the other end of the air conveying pipe and the charging connector are in bell-and-spigot joint. The geometrical shape concrete formwork sealing device is simple and reasonable in structure, good in sealing effect and high in practicability.

Owner:曹龙

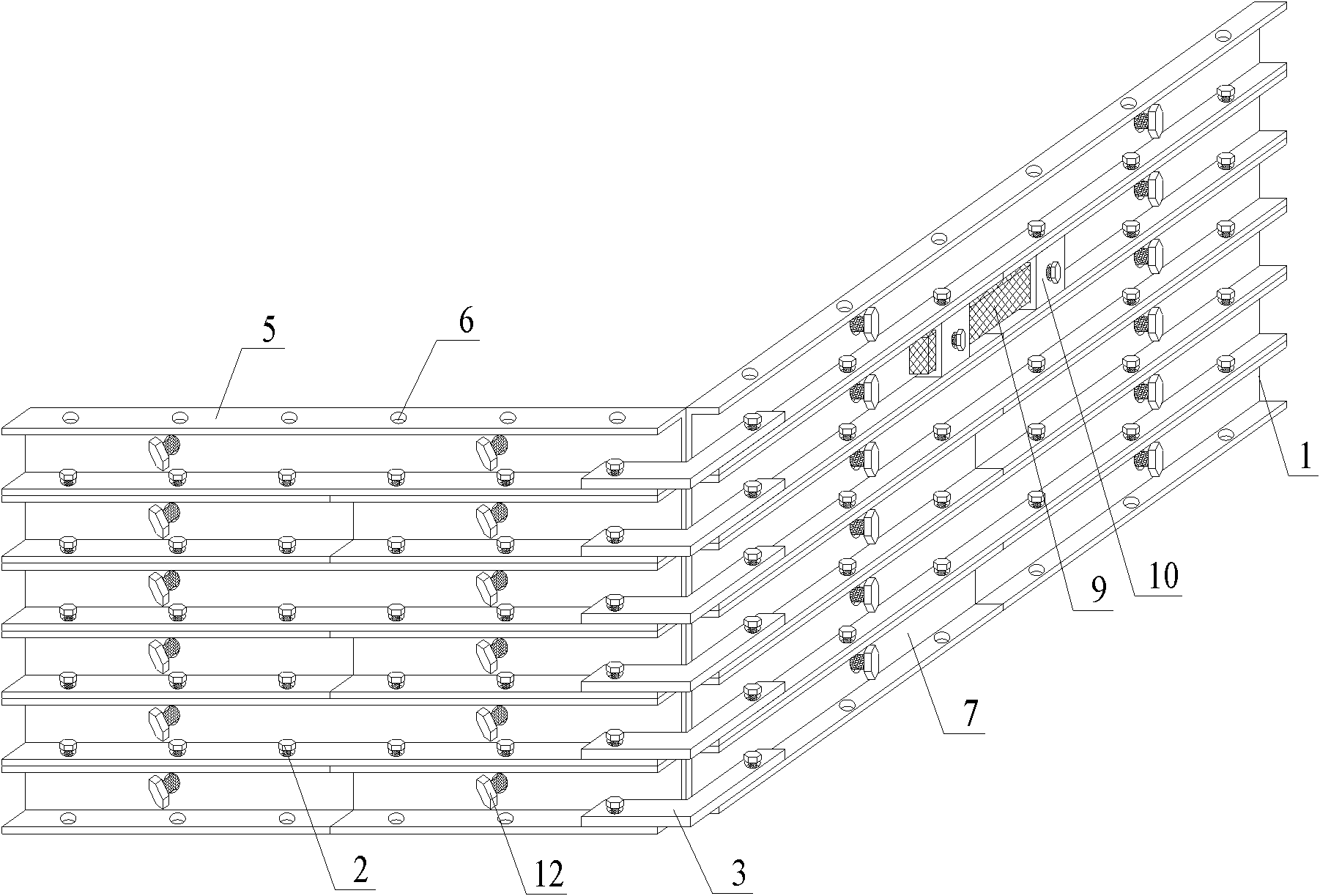

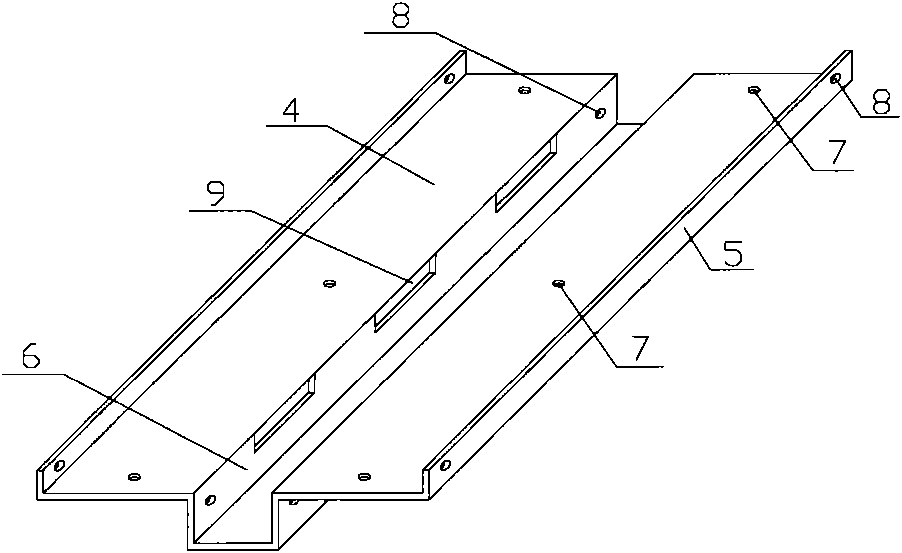

Template for buildings

InactiveCN102121308AHigh mechanized production efficiencyEasy to manufactureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabConcrete beams

The invention discloses a template for buildings. The template comprises a groove-shaped module (1), a bolt (2) or plug, a connecting strip (7) and a connecting strip positioning part (8), wherein the connecting strip positioning part (8) is connected with the groove-shaped module (1) through the bolt (2) or plug; bolt holes (5) are formed on flanges (3) of the groove-shaped module (1), and holes (11) are also formed on flanges (9) of the connecting strip positioning part (8); the connecting strip positioning part (8) is sleeved in a groove on the end part of the groove-shaped module (1), so that the holes (11) on the two flanges (9) of the connecting strip positioning part (8) correspond with the bolt holes (5) on the two flanges (3) of the groove-shaped module (1) respectively; and the bolt (2) or plug passes through the bolt holes (5) and the holes (11), so that the connecting strip positioning part (8) is connected with the groove-shaped module (1). The template for buildings is easy to manufacture and convenient to assemble and disassemble, has the advantages of large rigidity, high bearing force and long service life, and can be used in building construction of concrete beams, upright posts, shear walls and floor slabs.

Owner:吴方伯

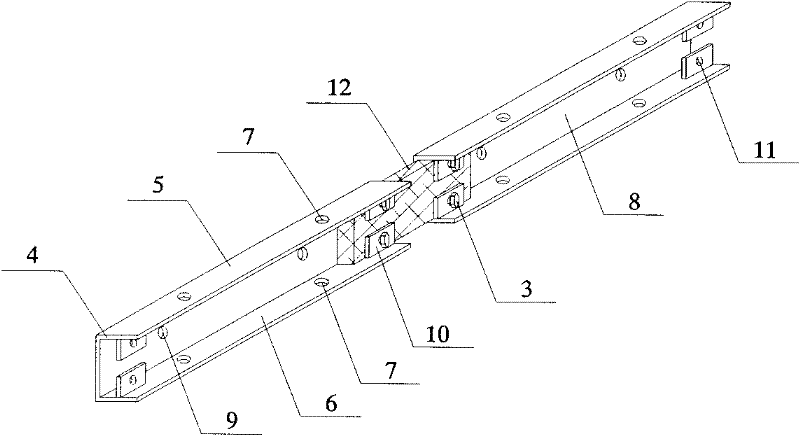

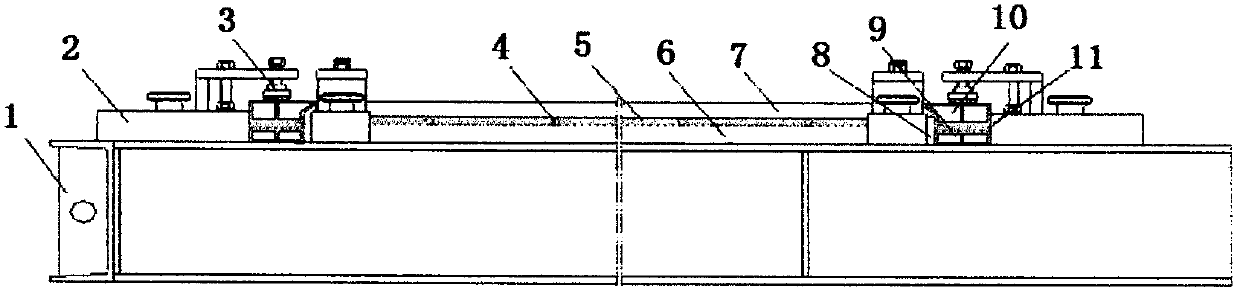

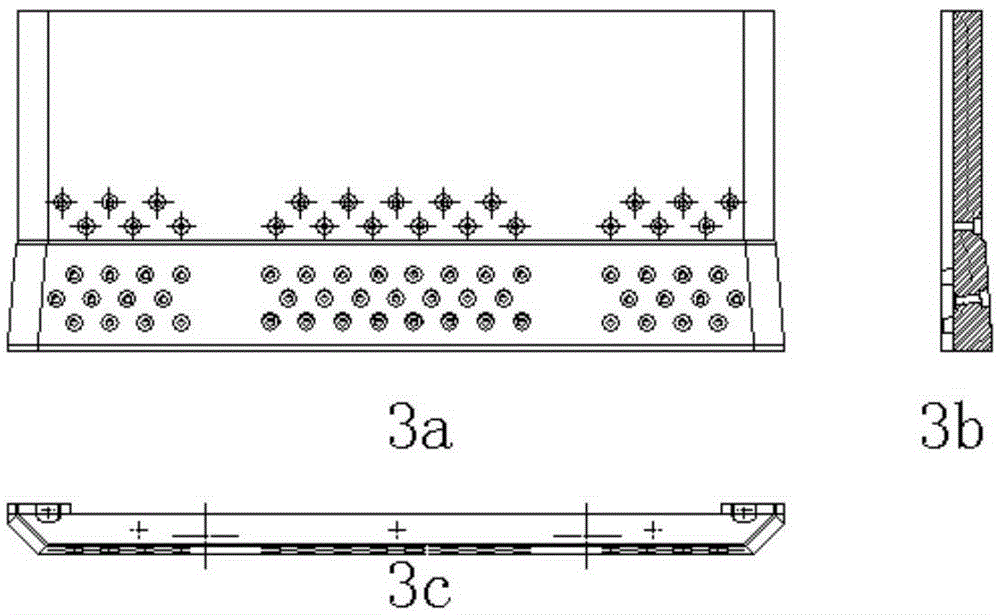

beam formwork for building

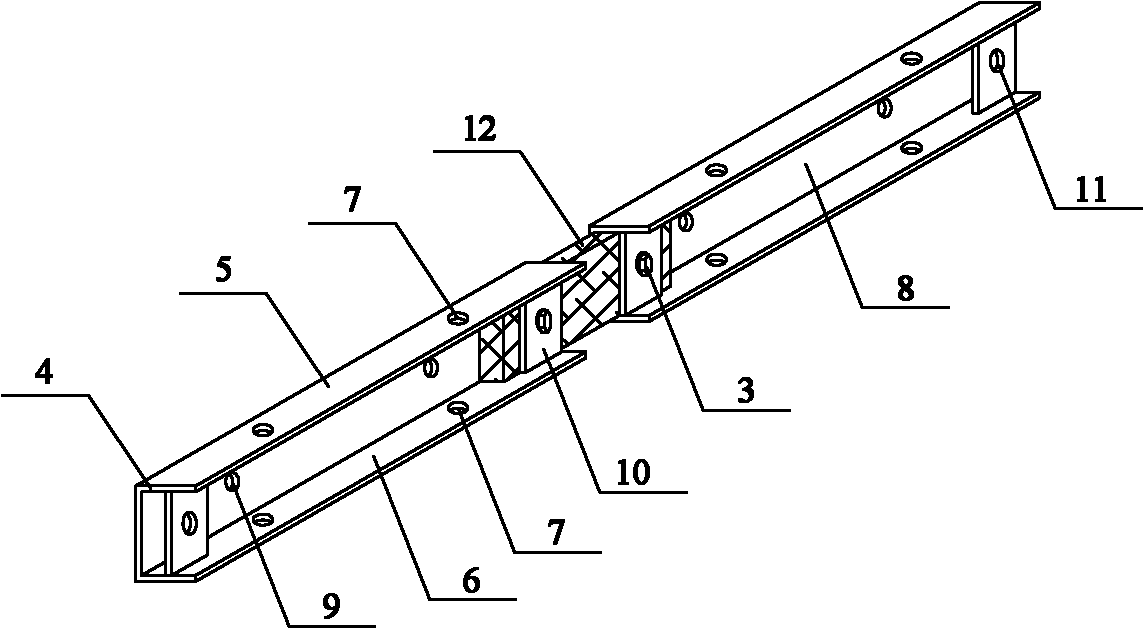

InactiveCN102268921AImprove bearing capacitySimplify the construction processForms/shuttering/falseworksArchitectural engineeringLarge capacity

The invention discloses a beam formwork for construction, which comprises a bottom formwork (1) and a side formwork (2). Bottom formwork (1) and side formwork (2) are assembled by trough-shaped modules (4) through bolts (3) or bolts or screws. Modules (4) are longitudinally connected by connecting strips (12). Modules (4) end There is a connecting strip locator (10) at the top, and the connecting strip (12) is located between the side plate (8) of the module (4) and the connecting strip locating piece (10). Holes (7) are arranged on the top plate (5) and the base plate (6) of the module (4), holes (9) are arranged on the side plate (8), and holes (11) are arranged on the connecting bar positioning piece (10). When assembling the beam formwork for construction, the bolts (3) or bolts or threaded fasteners are passed through the holes (7) on the modules (4), and the modules (4) are connected to form the bottom formwork (1) and the side formwork (2); The side formwork (2) is tied through the hole (9) on the module (4) with a transverse tie piece (14) to form a beam formwork for the overall building. The beam formwork used in the building has high rigidity, high bearing capacity, long service life, simple construction process, and mechanized production of modules.

Owner:吴方伯

Construction method of double-limb thin-walled pier of bridge

InactiveCN109356030AFast constructionSimple demouldingBridge structural detailsBridge erection/assemblyRebarThin walled

The invention relates to a construction method of a double-limb thin-wall pier of a bridge and mainly aims at solving the problem of slow construction speed in prior construction of the two-limb thin-wall pier of the bridge. The method comprises the following steps of: pier body reinforcement installation: wherein, the root part of the pier body main reinforcement extends into a cap part, straightthread rolling is carried out on a connecting end of the main reinforcement in a ground processing site by using a heading machine, a sleeve is connected with the threaded connecting end; rollover formwork assembly: wherein, the formworks is raised by using a tower crane, and the horizontal joint and vertical joint of the internal and external formworks are made into flat joints. Rubber stop grout is filled during installation; installation of internal and external operation platforms and a protection system; pier body concrete is lifted and put into the formworks, manual vibration is carriedout by using a plug-in vibration bar, when the concrete is poured, horizontal distribution in layers is carried out; concrete curing; the formworks are removed and turned up and circulated to the topof the pier; after completion of a first cycle of construction, a next cycle, which includes steel bar binding, formwork lifting and concrete pouring, is carried out. The method has the advantage offast construction speed.

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD

Method for manufacturing shape memory polymer core mold by winding composite material component

The invention discloses a method for manufacturing a shape memory polymer core mold by winding a composite material component. The method comprises the following steps of: 1, uniformly mixing hydrogenated epoxy resin, hexanediol diglycidyl ether and maleic anhydride according to the molar ratio of 0.5-1.0:0-0.4:2.0, and adding the mixture into a vacuum drying box to remove bubbles to obtain a hydrogenated epoxy resin system; 2, casting the hydrogenated epoxy resin system into a cylindrical mold, placing the cast mold in an oven to be cured, after cooling the mold to room temperature, demolding to obtain a hydrogenated epoxy resin blank; and 3, selecting a core mold shaping mold according to the shape of the required core mold, assembling the hydrogenated epoxy resin blank and the core mold shaping mold, deforming the hydrogenated epoxy resin blank into the shape of the core mold through a blow-moulding process, and cooling the hydrogenated epoxy resin blank to obtain the shape memory polymer core mold. The shape memory polymer core mold manufactured by the method is low in cost, high in efficiency and short in manufacturing period, can be repeatedly used and has obvious economic benefit; and demolding is convenient to perform.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

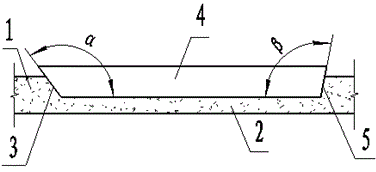

Light compound side fascia and its manufacturing method

ActiveCN100385083CReasonable structureImprove performanceConstruction materialMouldsHigh intensityRebar

The invention relates to a lightweight compounded outer wallboard and the manufacturing method thereof. And it is compounded of fiber or wire fabric reinforced cement slab and bearing layer, where the bearing layer is made of reinforcing fabric reinforced light aggregate concrete, one or two sides of the bearing layer are combined with cement slabs and a cavity in the bearing layer is enveloped by light aggregate concrete and full of heat insulator. And its manufacturing method comprises a process as follows: A. placing cement slabs on one or two sides in a die space; B. placing reinforcing fabric provided with heat insulator in the middle by the cement slabs in the die space; C. pouring light aggregate concrete in the die space to bury the reinforcing fabric; and D. staying, curing and hardening and then demoulding to make it. And the method is simple, practical, high-efficiency and it has advantages of lightweight, high intensity, strong bearing capacity, good heat insulating property, seismic resistance, seepage prevention, etc.

Owner:广州益群板业有限公司

Building template

InactiveCN102359265AEasy to manufactureEasy to assembleForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabReinforced concrete

The invention discloses a building template. The building template comprises grooved modules (1) and screws (2) or bolts, wherein the grooved modules (1) are connected with each other by the screws (2) or bolts; more than two connected grooved modules (1) are spliced with each other to form an integral template; and the building template is provided with anti-slurry-leakage mold sleeves (10) at the longitudinally spliced portions of the grooved modules (1). During splicing the building template, the anti-slurry-leakage mold sleeves (10) are sleeved into end portion webs (4) of the grooved modules (1); and the grooved modules (1) are arranged in an orderly way; and the screws (2) or bolts penetrate through holes (5) at wing edges (3) of the grooved modules (1) to connect the two adjacent grooved modules (1) in sequence so that the integral building template is formed. The building template disclosed by the invention has the advantages of low manufacturing cost, convenience in detaching the mold and cycle use; and the slurry leakage problem during depositing concrete is largely improved so that good construction quality can be guaranteed. The template can be used for building construction of reinforced concrete beams, uprights, shear walls and floor slabs.

Owner:吴方伯

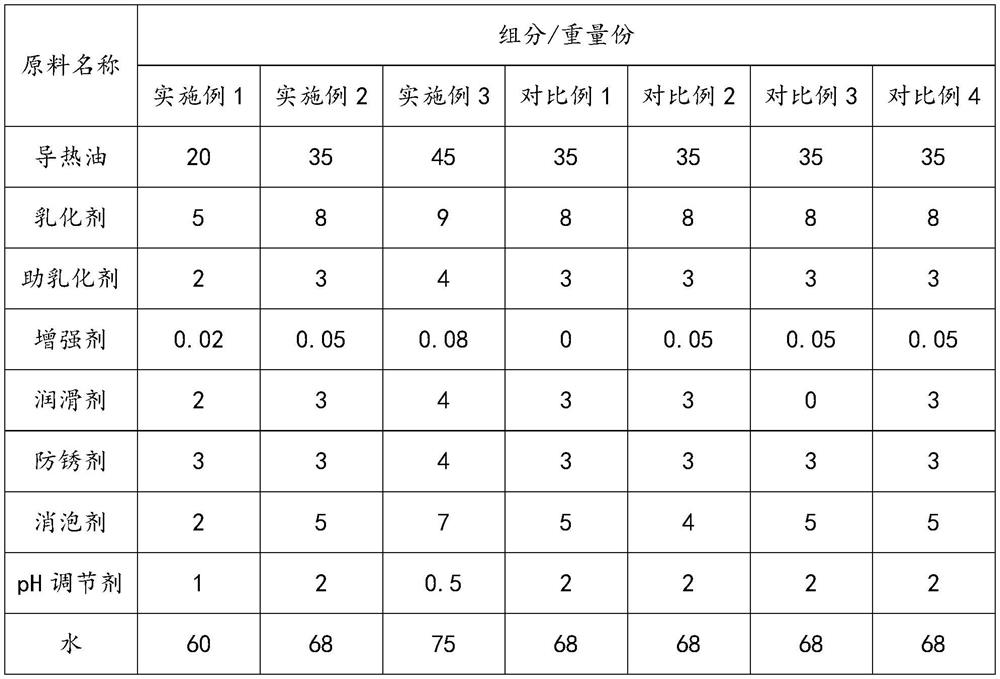

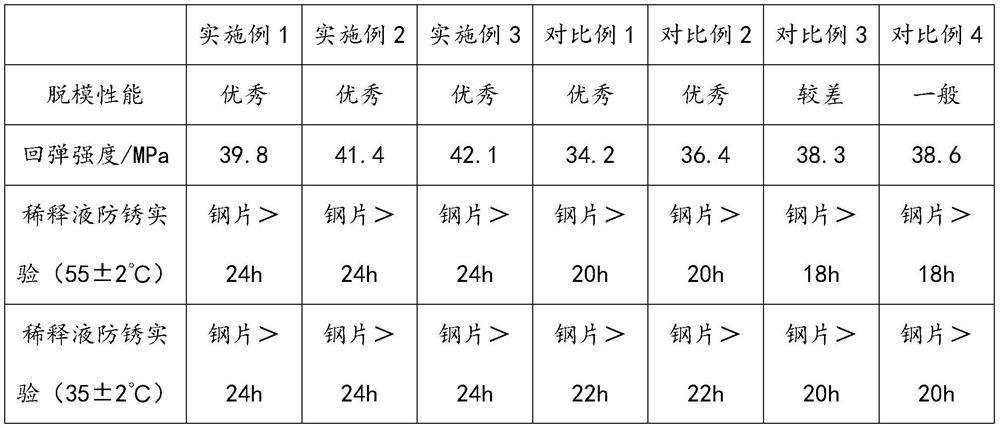

Reinforced concrete release agent and preparation method thereof

ActiveCN112708493AImprove adhesionHelp formSolid waste managementLubricant compositionCalcium silicateReinforced concrete

The invention relates to the technical field of building admixtures, in particular to a reinforced concrete release agent and a preparation method thereof. The concrete release agent is prepared from completely emulsified oil and a reinforcing agent, the completely emulsified oil is prepared from heat conduction oil through emulsification under participation of an emulsifier, wherein the co-emulsifier comprises an emulsifier and a co-emulsifier; and the reinforcing agent is active calcium silicate hydrate. The invention provides the reinforced concrete mold release agent, which can improve the mold release strength of concrete and the adhesion of the mold release agent on a template, improve the rain wash resistance of the mold release agent, reduce the adhesion amount during mold release and eliminate bubbles on a concrete / template interface.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

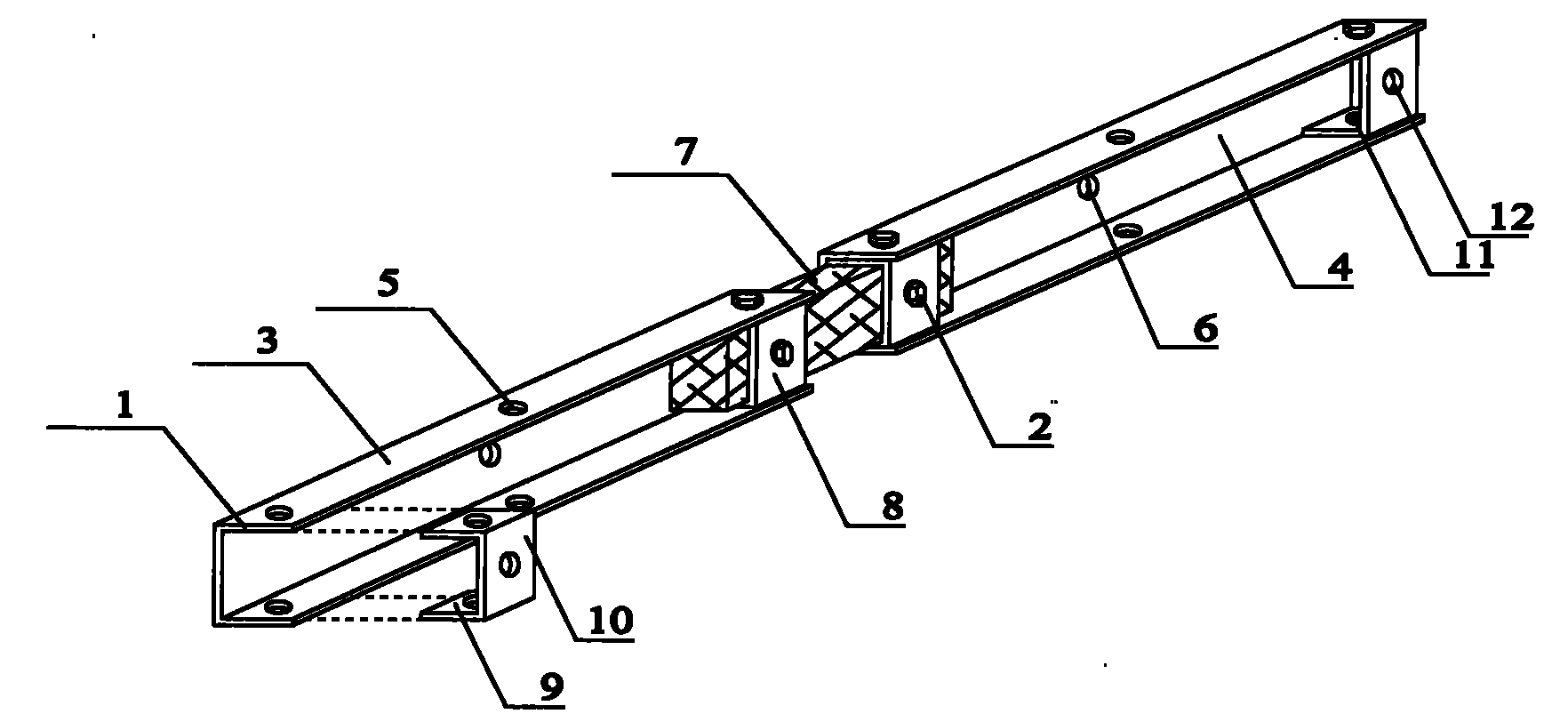

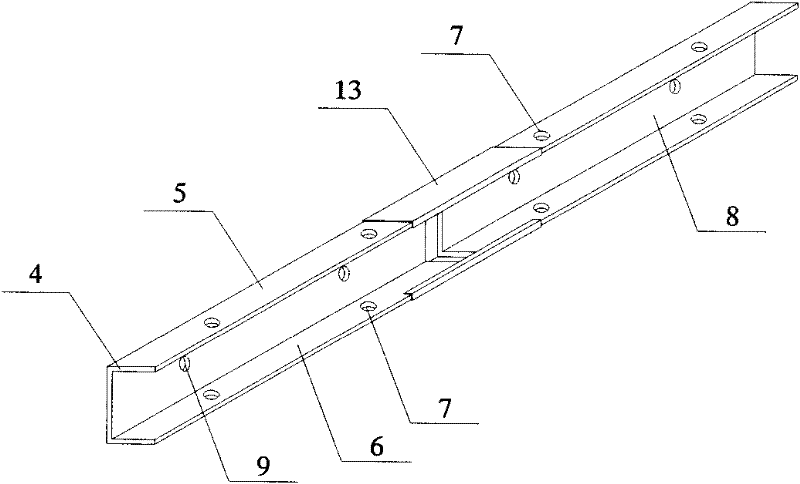

Beam template for building

InactiveCN102191859AImprove bearing capacitySimplify the construction processForms/shuttering/falseworksEngineeringBearing capacity

The invention discloses a beam template for a building. The beam template for the building comprises a bottom template (1) and lateral templates (2), wherein the bottom template (1) and the lateral templates (2) are formed by splicing two or more than two groove-shaped modules (4) which are connected mutually; the lateral templates (2) are tied by a transverse tie piece (14); a positioning sleeve (15) is arranged on the transverse tie piece (14); holes (7) are formed on a top plate (5) and a bottom plate (6) of the modules (4); and holes (9) are formed on a lateral plate (8). When the beam template is assembled, bolts (3) or pins pass through the holes (7) on the modules (4), and the two adjacent modules (4) are connected to form the bottom template (1) and the lateral templates (2); and the transverse tie piece (14) passes through the holes (9) on the modules (4) to tie the lateral templates (2) to form the integral beam template for the building. The integral beam template for the building has high rigidity, high bearing capacity, long service life and simple constructional processes, the modules (4) can be produced mechanically, and the quality of construction is convenient to control.

Owner:吴方伯

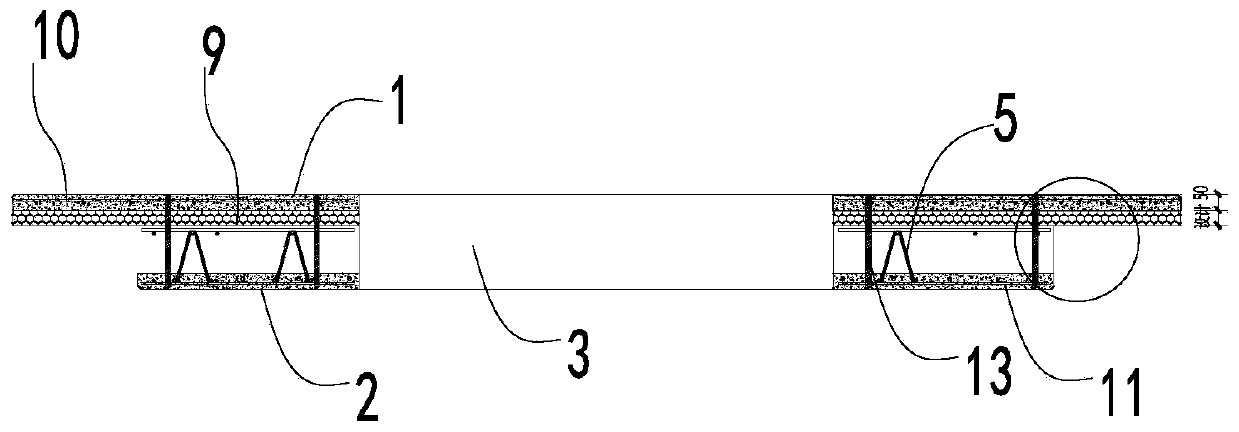

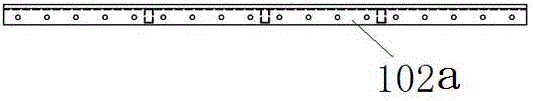

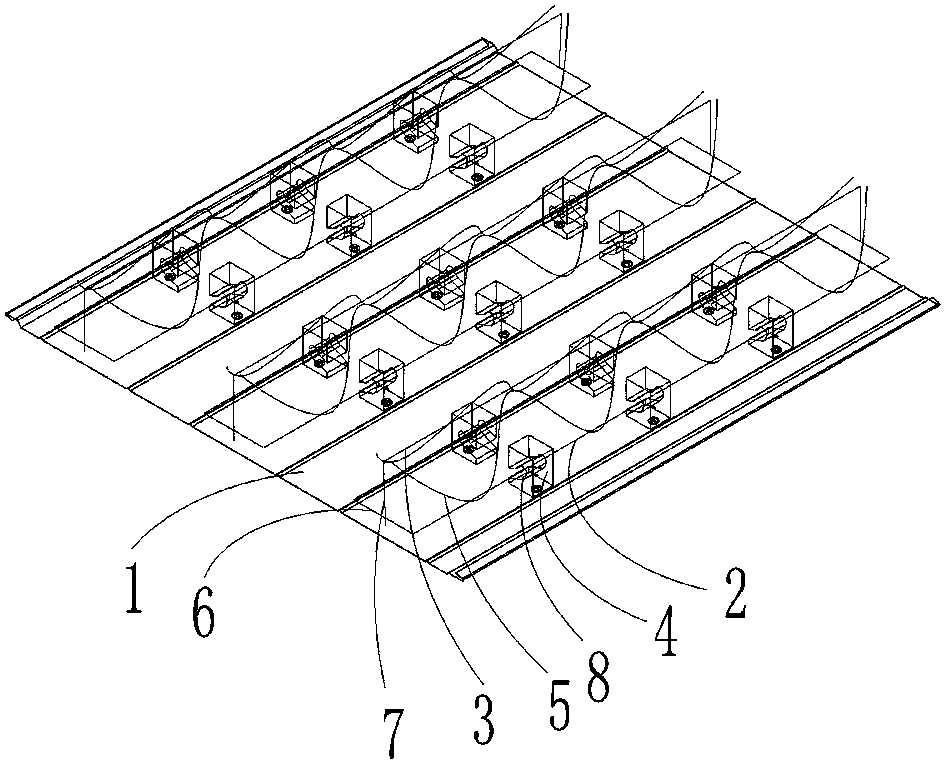

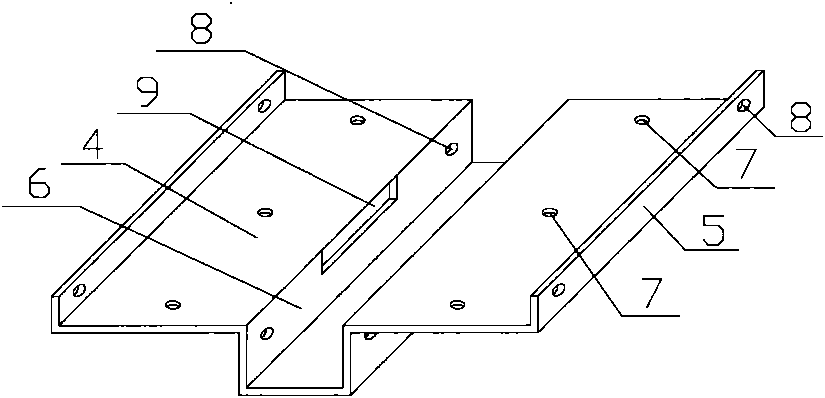

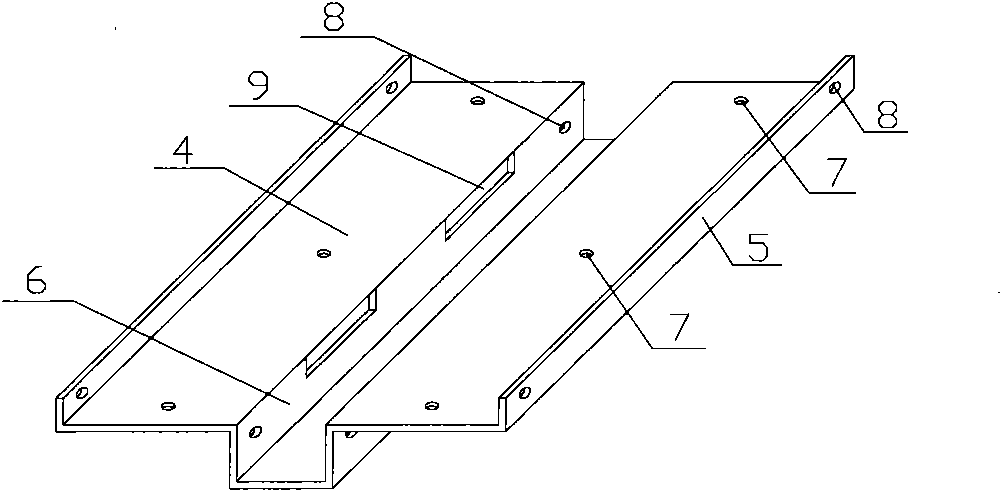

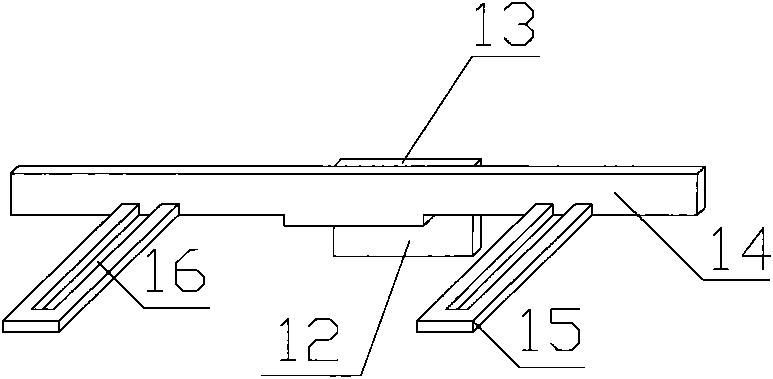

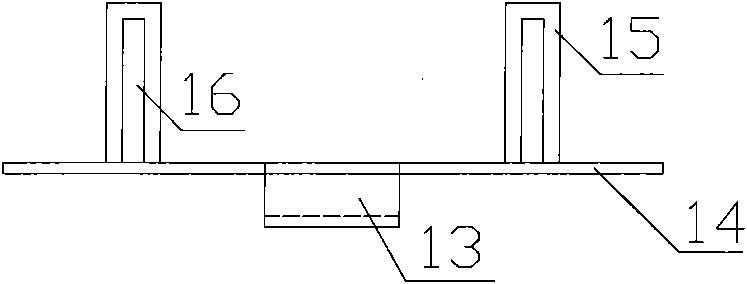

Sandwich thermal insulation non-load-bearing wallboard with holes and production process thereof

PendingCN110103316ASimple demouldingAvoid timeMouldsBuilding componentsBlade plateThermal insulation

The invention discloses a sandwich thermal insulation non-load-bearing wallboard with holes and a production process thereof. The sandwich thermal insulation non-load-bearing wallboard with the holescomprises an inner blade plate, an intermediate post-pouring cavity layer, an insulating layer and an outer blade plate arranged sequentially from the inside to the outside. The holes are correspondingly formed in the inner blade plate and the outer blade plates; the intermediate post-pouring cavity layer is provided with intermediate reinforcing bar meshes; reinforcing bar frameworks are embeddedat the upper portion of the holes; and the reinforcing bar frameworks are arranged at the intermediate post-pouring cavity layer and the inner blade plate to form a superimposed connecting beam. Theproduction process comprises the following steps of firstly, making the inner blade plate, and then making the outer blade plate; turning the inner blade plate 180 degrees; pressing the inner blade plate on the outer blade plate of newly laid with an insulation plate; and carrying out maintenance and demoulding treatment. In the production process, the area of the inner blade plate is less than that of the outer blade plate, and the collision between hot and cold broken bridge connecting pieces and a truss reinforcing bar is reduced or avoided, therefore, the inner blade plate is produced before the outer blade plate, so that the production of a wallboard and the demoulding of the outer blade plate are convenient.

Owner:美好建筑装配科技有限公司

Cast in situ concrete tool type steel frame wood plastic template system and construction method thereof

InactiveCN105952140AImprove the efficiency of manual constructionShorten the construction periodForming/stuttering elementsForm treatmentRebarRc frames

A cast in situ concrete tool type steel frame wood plastic template system comprises a tool type steel frame wood plastic template, a tool type angle steel frame column template, a tool type variable column hoop, a tool type beam template support, a rapid support, and a support top connecting seat; said members are mutually connected to form the cast in situ concrete tool type steel frame wood plastic template system; the cast in situ concrete tool type steel frame wood plastic template system construction method comprises a steel bar concrete frame structure construction process and a steel bar concrete shear wall structure construction process; the steel frame wood plastic template system comprises the following processes: design, formwork, casting, and dismounting. The cast in situ concrete tool type steel frame wood plastic template system is standard, rapid in formwork, early in dismounting, high in efficiency, high in safety factor, economical and practical, low in carbon consumption, environment friendly, can save resources, and the recycle number can be above 500 times; even if the steel back frame cannot be restored, the cast in situ concrete tool type steel frame wood plastic template system can be fully recovered for producing steel; the system and method are low in comprehensive usage cost.

Owner:ANYANG INST OF TECH +1

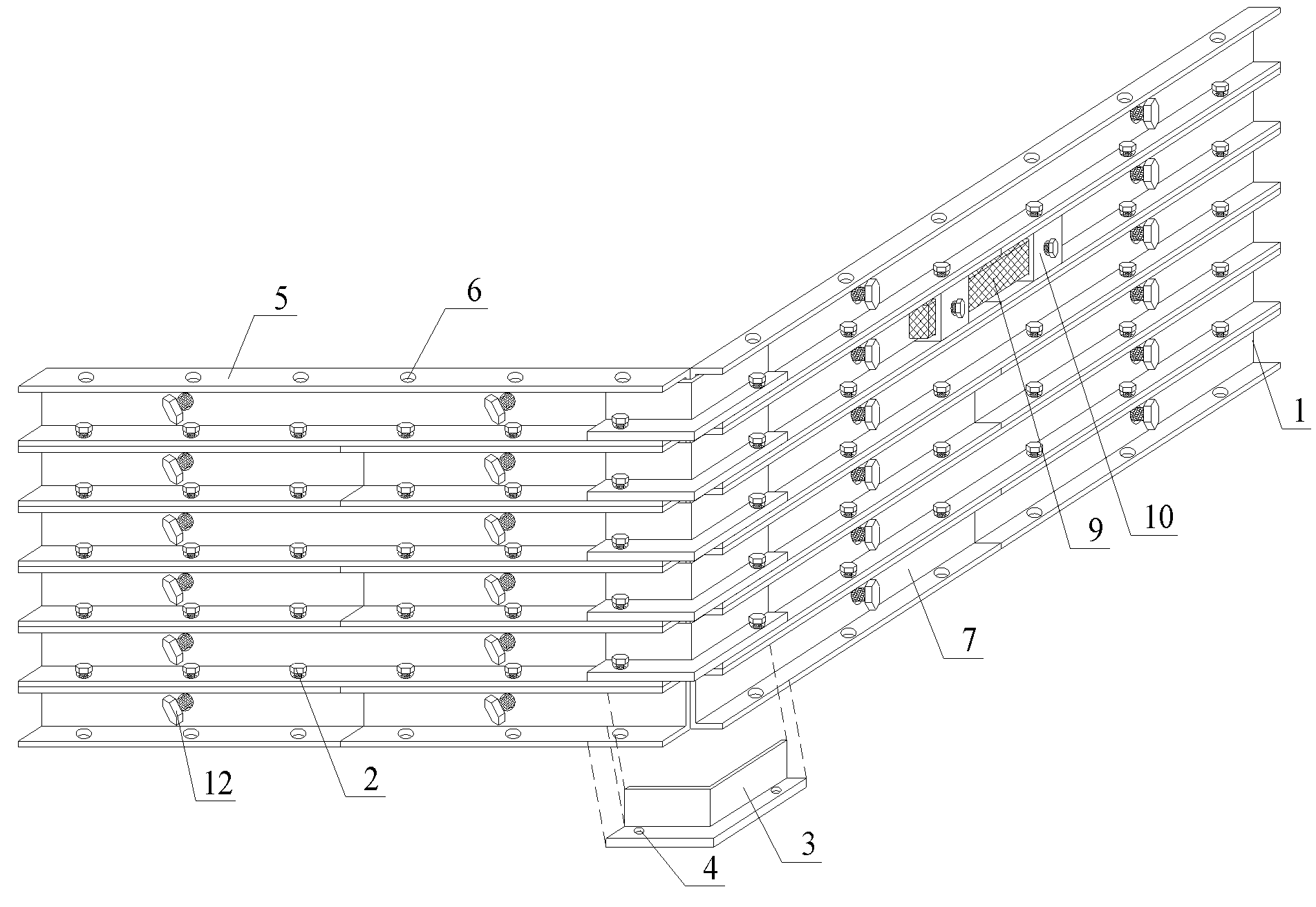

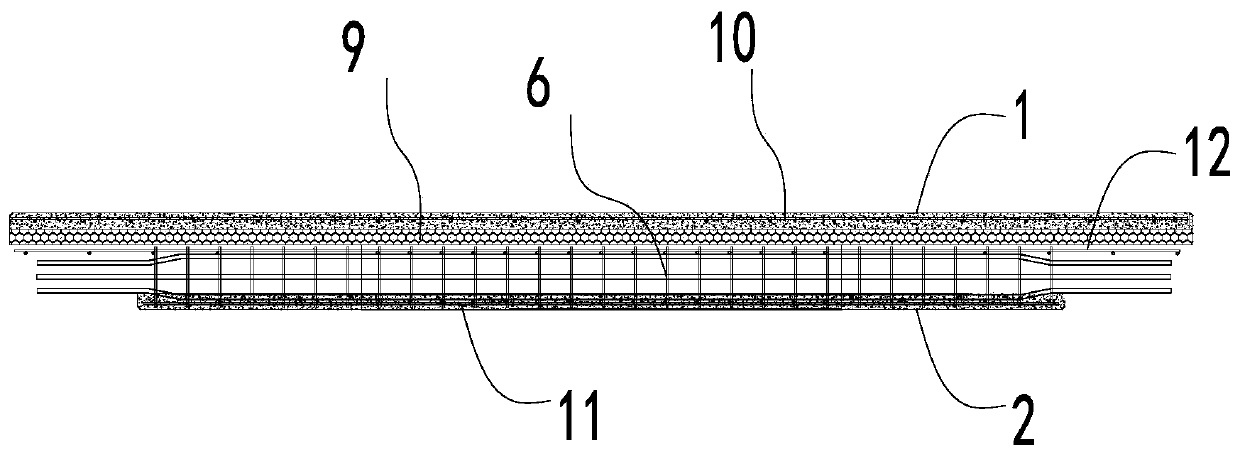

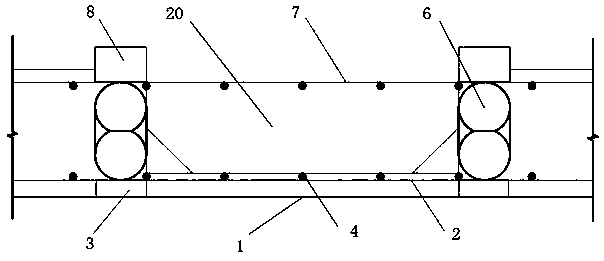

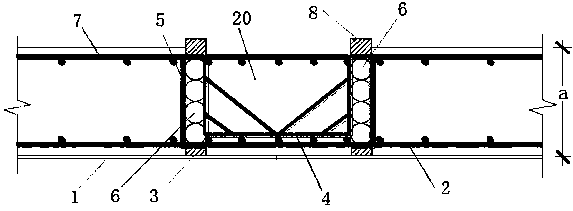

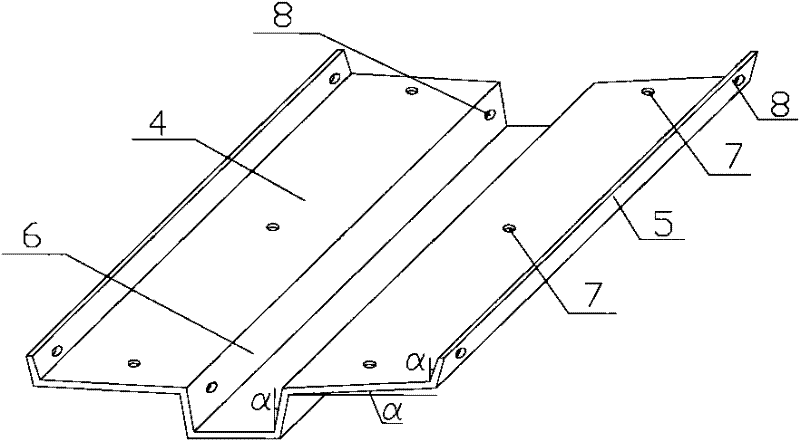

A detachable base form steel truss floor deck and its assembly method

ActiveCN105089192BEasy to removeImprove economyFloorsForms/shuttering/falseworksAgricultural engineeringRebar

The invention relates to a floor deck, in particular to a detachable bottom mold reinforced truss floor deck and an assembly method thereof, belonging to the field of steel structures. Including the bottom formwork, the bottom formwork is provided with more than one set of steel bar truss assemblies, the steel bar truss assemblies include lower chord reinforcement bars and upper chord reinforcement bars, and the lower chord reinforcement bars are positioned by positioning blocks fixed on the bottom formwork, the An upper chord reinforcing bar is provided in the middle above the lower chord reinforcing bar, and a web reinforcing bar is arranged between the upper chord reinforcing bar and the lower chord reinforcing bar. A detachable base form steel bar truss floor deck and an assembly method thereof are compact in structure, simple in manufacture, excellent in use performance, and convenient in assembly and disassembly.

Owner:浙江东南网架股份有限公司

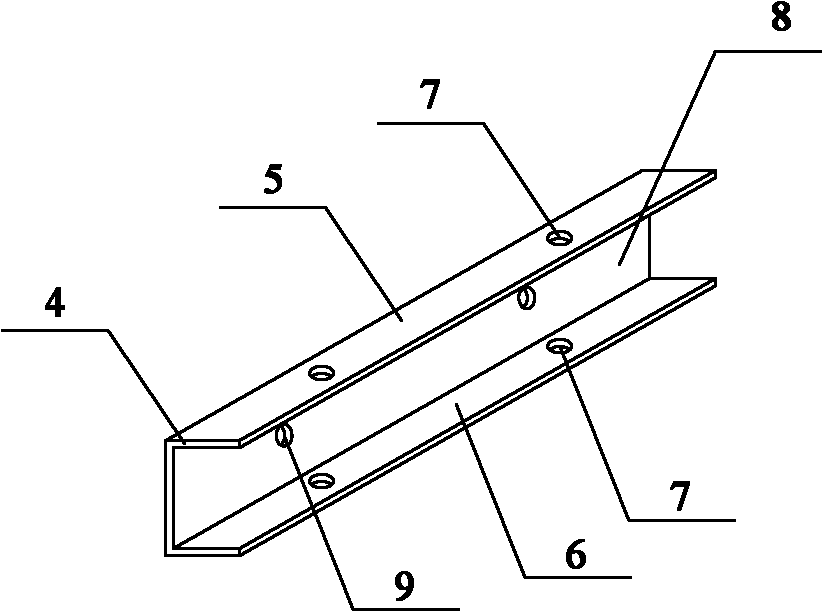

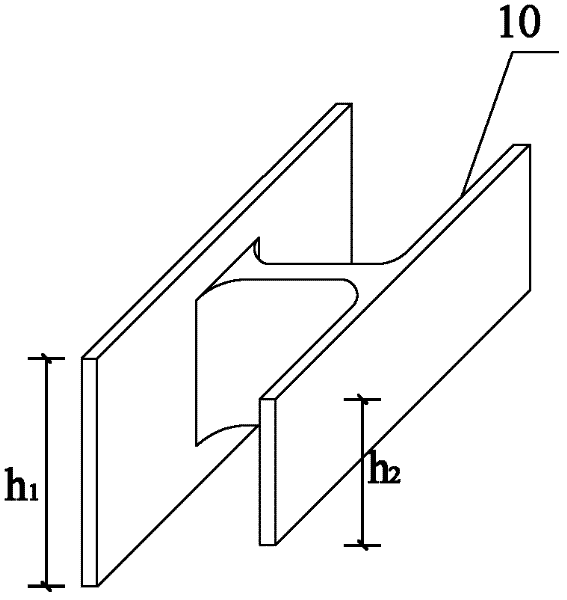

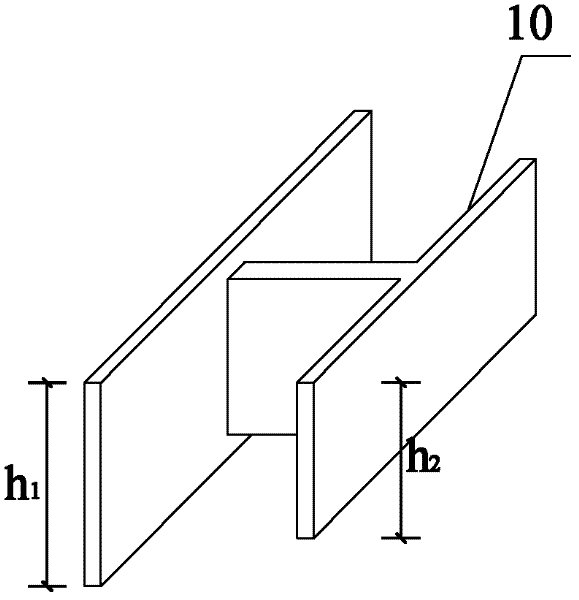

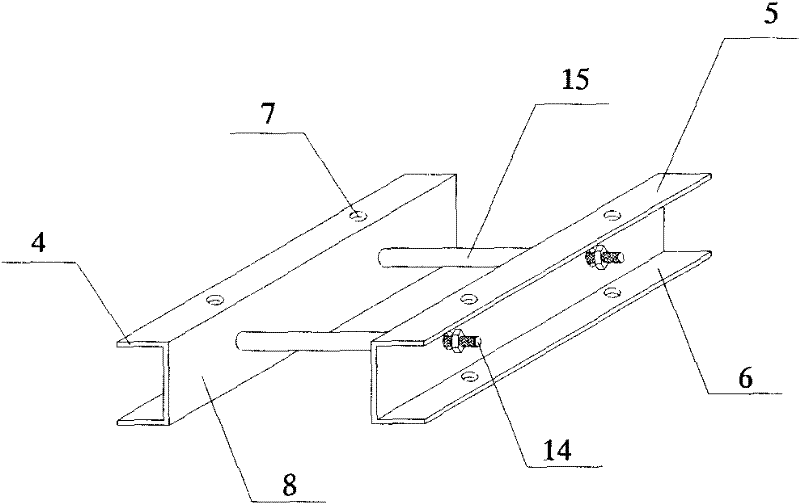

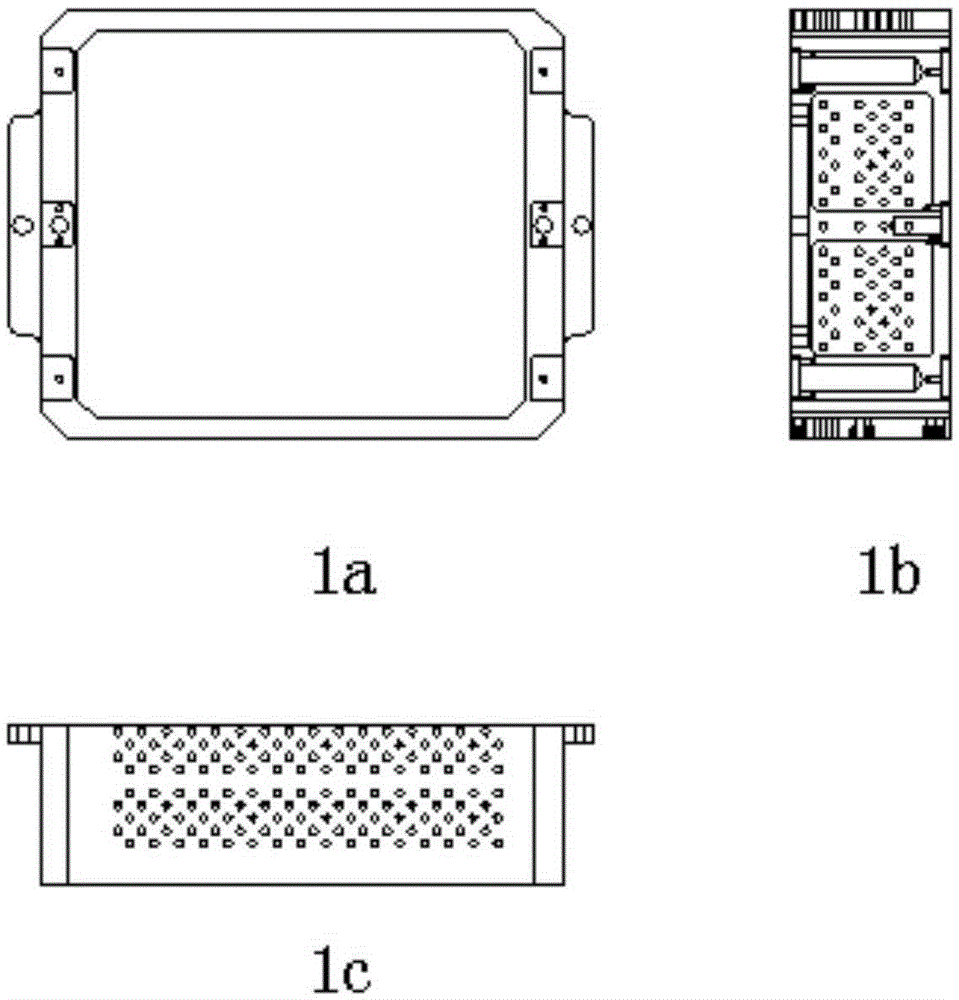

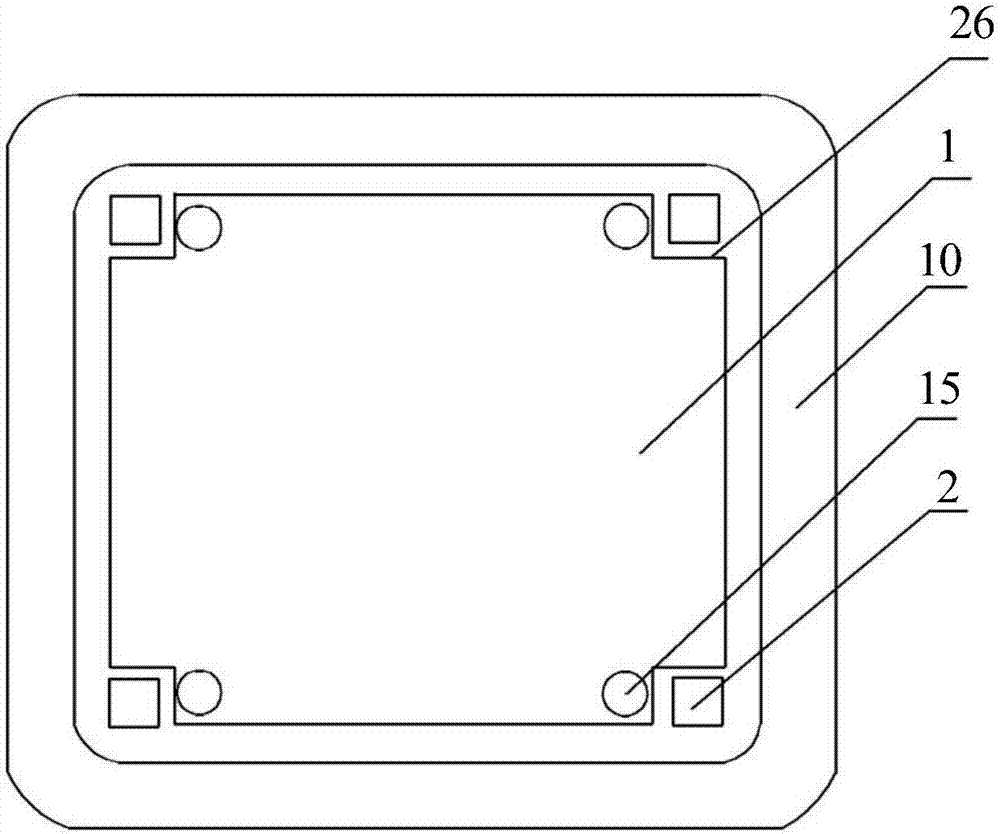

Ribbed precast component template for buildings

The invention discloses a ribbed precast component template for buildings. The template is formed by assembling one or more modules (1) comprising bottom plate bottom dies (4), bottom plate side dies (5) and longitudinal rib side dies (6). Die removing bolt holes (7) or connecting bolt holes (8) are arranged on the bottom plate bottom dies (4), bottom plate side dies (5) or longitudinal rib side dies (6); and through holes (9) are arranged on the longitudinal rib side dies (6). When the template is assembled, the modules (1) are butted and are connected by connectors (10) with such fasteners as bolts (3), latches or screw threads, and end blocks (2) are connected with the modules (1) to form the integral ribbed precast component template. The template has high rigidity and bearing capacity, long service life and simple construction procedures, and the modules (1) can be mechanically produced, thus being convenient for controlling the construction quality.

Owner:吴方伯

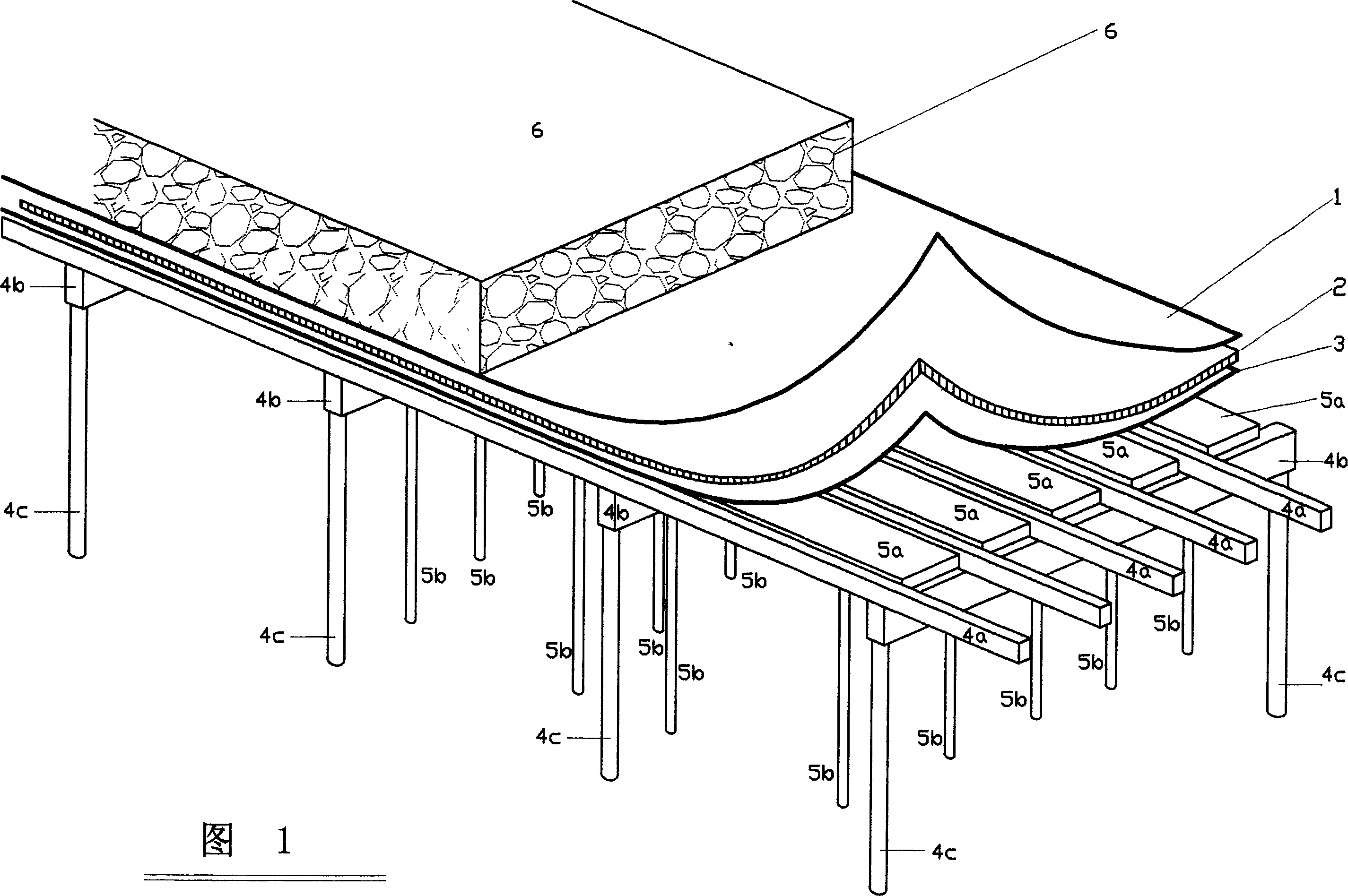

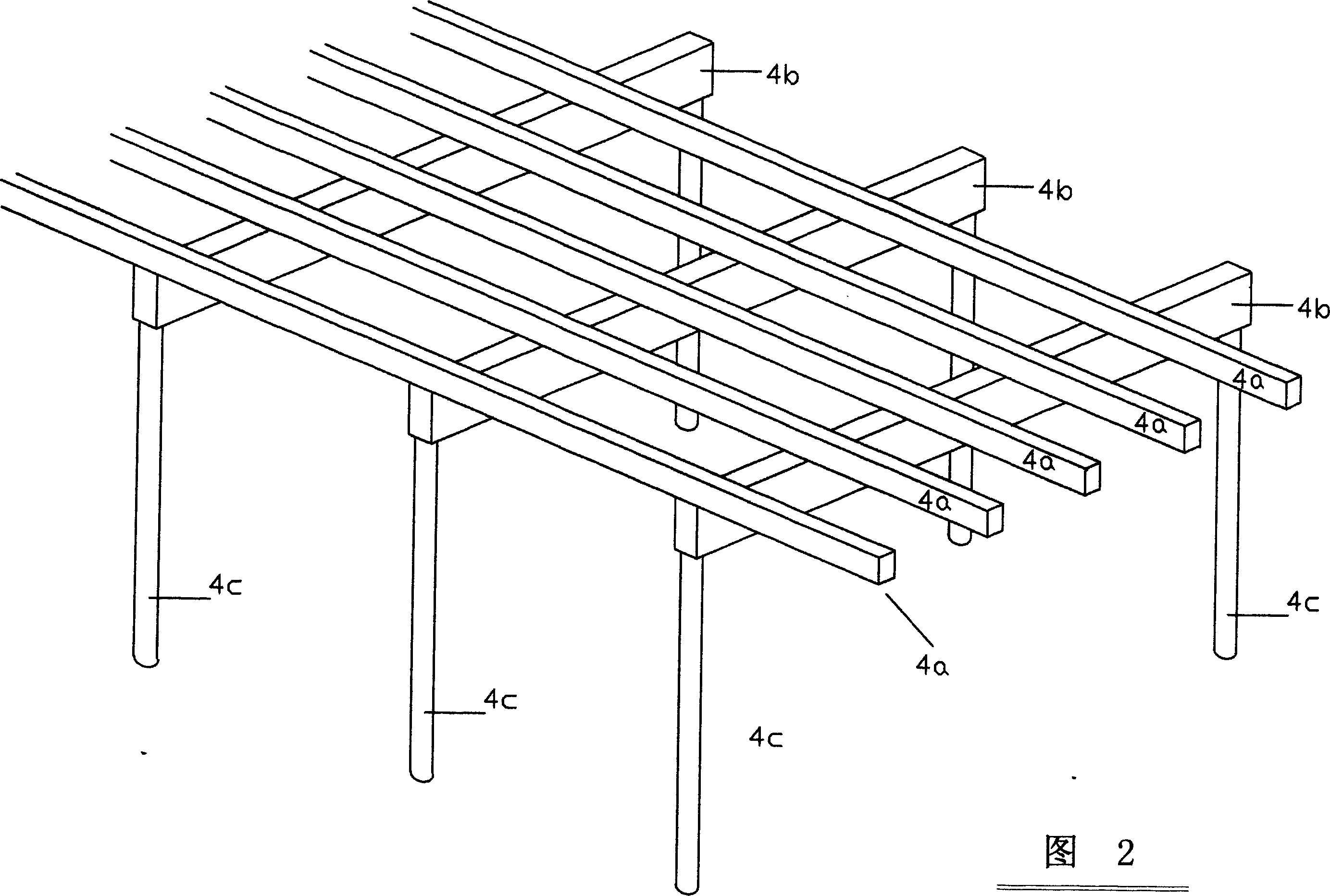

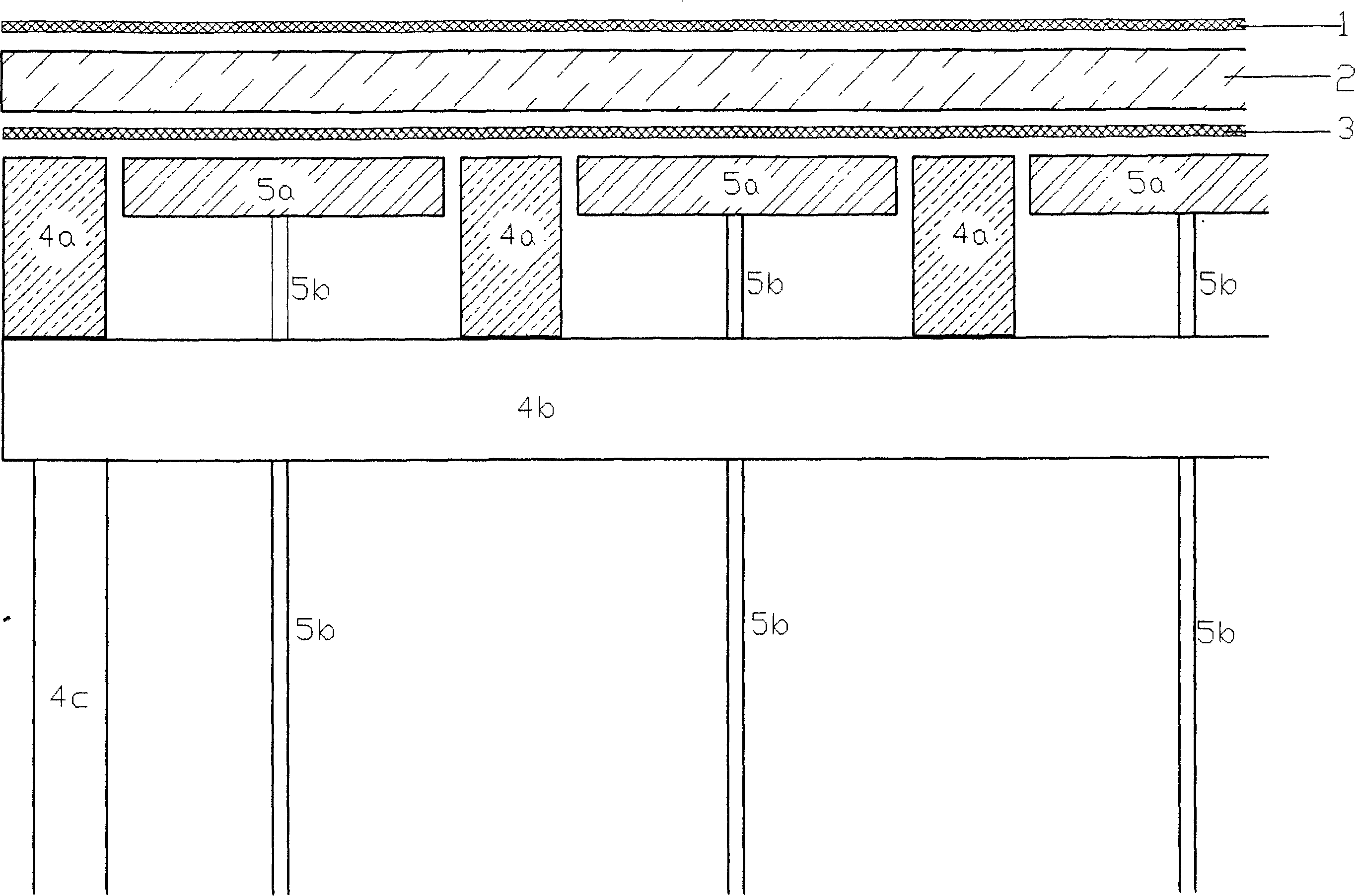

Template engineering construction technology employing coiled material

InactiveCN1769622AIncrease stiffnessSimple demouldingForming/stuttering elementsSupporting systemArchitectural engineering

The invention discloses a coil mould construction technique, which comprises the following parts: coil mould and support system, wherein the support system contains fixation support system and temporary support system; the mould support system is fixed basically, whose support force is more than the sum of static load and construction load, which avoids the waste of resource. The invention reduces the impaction of support system from vibrating force, which forms 'temporary composite board' of three overlapping coils in the new casting concrete and pressing condition.

Owner:孙长顺

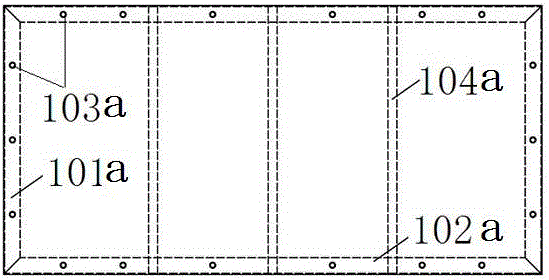

Concrete prefabricated part laminated plate production die parts and manufacturing method as well as concrete prefabricated part laminated plate production die

InactiveCN110815517ALow amortization expenseHigh strengthMouldsManufactured materialMechanical engineering

The invention belongs to production dies, and particularly relates to concrete prefabricated part laminated plate production die parts and a concrete prefabricated part laminated plate production diemanufacturing method as well as a concrete prefabricated part laminated plate production die. The concrete prefabricated part laminated plate production die parts comprise a template, a side die fixing magnetic box, a die pressing plate, a lower die end die aluminum profile, an upper die end die aluminum profile, a self-adhesive strip and a connecting piece, wherein the template is a plate-shapedpart, the lower die end die aluminum profile is a strip part with a Chinese character "lv"-shaped cross section, the size of the two Chinese characters "kou" of the Chinese character "lv" of the crosssection of the lower die end die aluminum profile is consistent, and the upper die end die aluminum profile is a strip part with a trapezoidal cross section. The concrete prefabricated component laminated plate production die has the remarkable effects that the die with the main material being aluminum is adopted, the weight is light, a production site worker can manually move the die, the convenience and flexibility are achieved, the cost of die raw materials is low, and the die is suitable for large-scale production.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

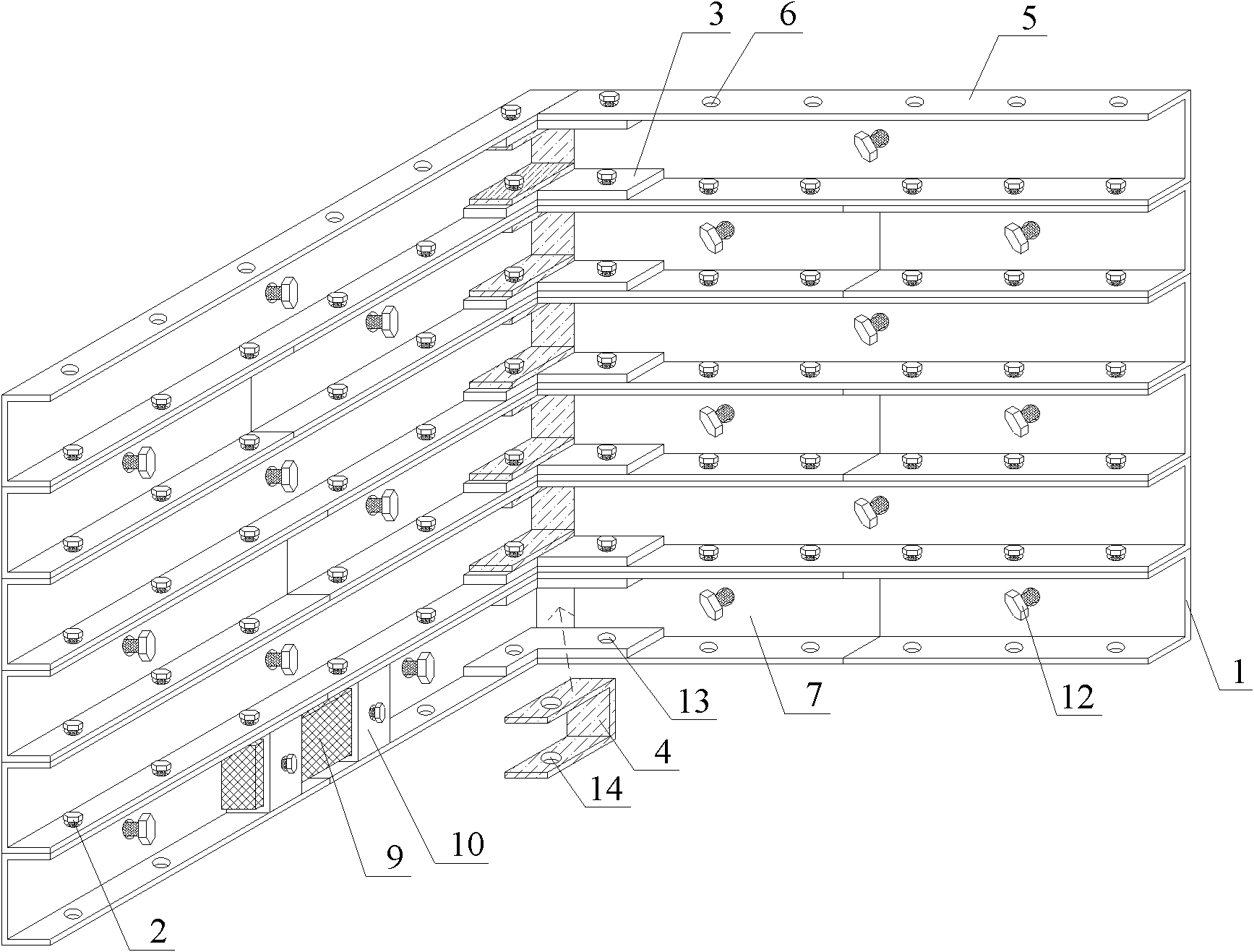

Ribbed precast component template for buildings

The invention discloses a ribbed precast component template for buildings, comprising modules (1) and end blocks (2). The template is characterized in that the template is formed by assembling two or more modules (1) which are connected by connectors (10); The modules (1) comprise bottom plates (4), side plates (5) and longitudinal ribs (6); die removing bolt holes (7) or connecting bolt holes (8) are arranged on the bottom plates (4), side plates (5) or longitudinal ribs (6); and through holes (9) are arranged on the longitudinal ribs (6). When the template is assembled, the modules (1) are butted and are connected by such fasteners as bolts (3), latches or screw threads, and the end blocks (2) are connected with the modules (1) to form the integral ribbed precast component template. The template has high rigidity and bearing capacity, long service life and simple construction procedures, and the modules (1) can be mechanically produced, thus being convenient for controlling the construction quality.

Owner:吴充

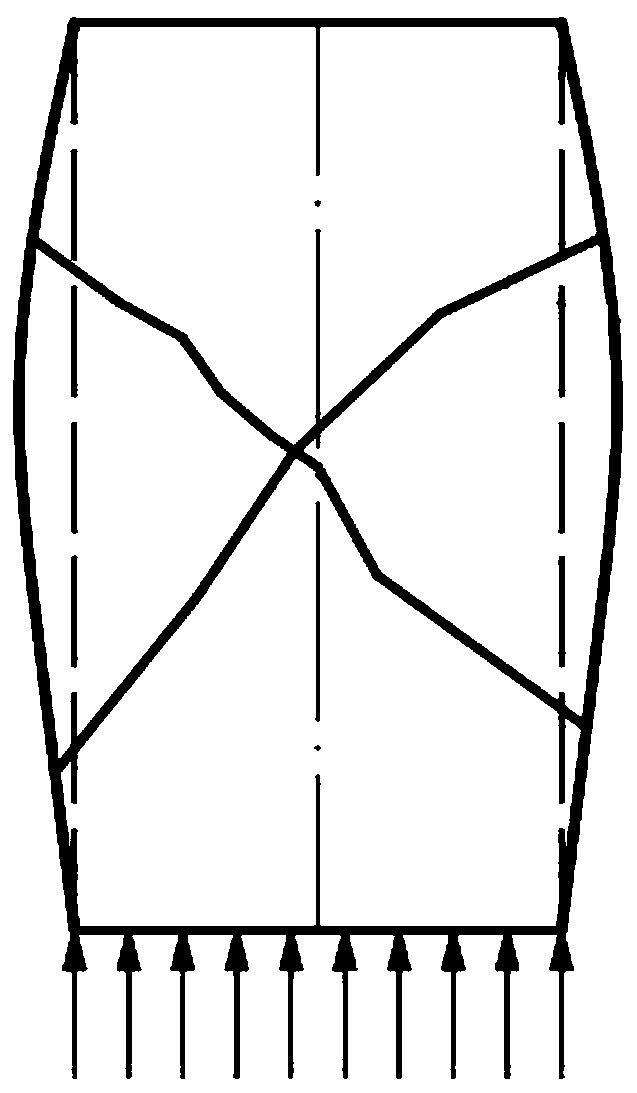

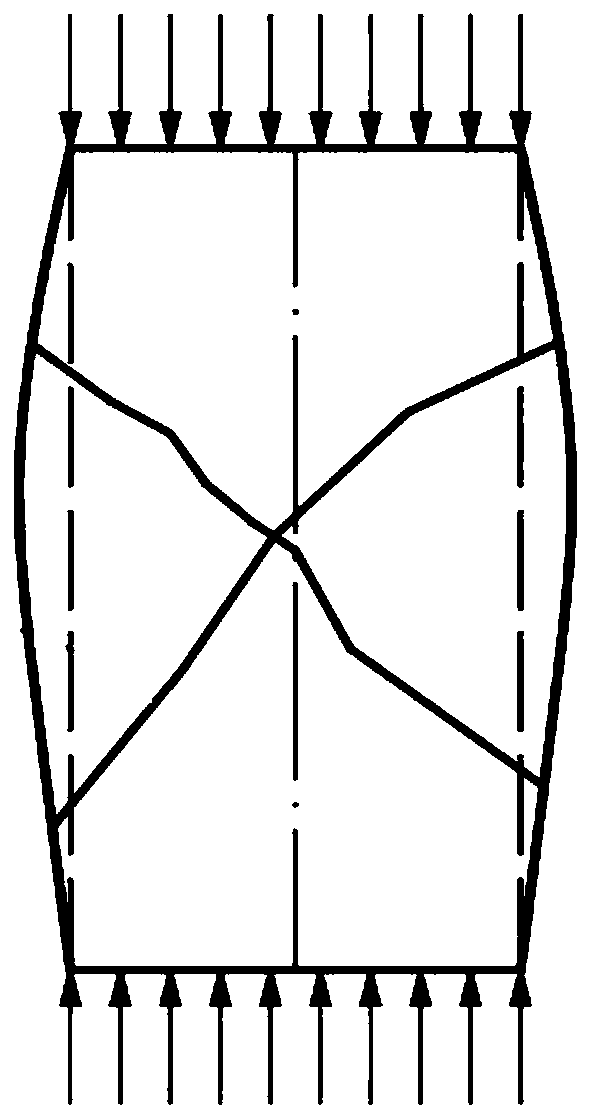

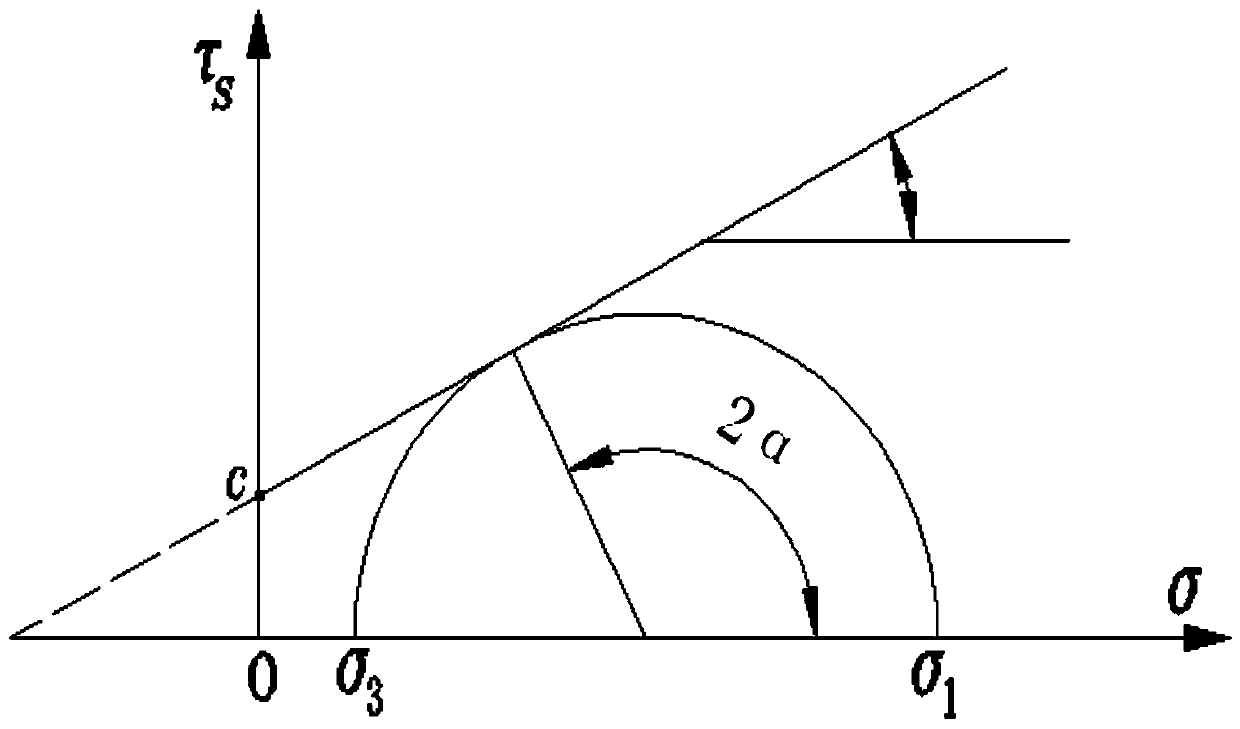

Mud-containing fault material test piece strength parameter and water rock coupling weakening testing method

InactiveCN110398416AGet weakening rateAccess to native state mechanical propertiesPreparing sample for investigationMaterial strength using tensile/compressive forcesAxial pressureNatural state

The invention discloses a mud-containing fault material test piece strength parameter and water rock coupling weakening testing method and relates to the field of mechanical properties of rock masses.In the test method, a test sample is sampled first and then prepared, and a test is carried out according to the following steps: S1. taking several test samples, and applying different confining pressure on the test samples; S2. respectively applying an axial pressure on the test samples in S1, and carrying out a triaxial compression destruction test in a natural state; S3. applying a hole pressure to the test samples in S2, and separately carrying out a triaxial compression destruction test for the test samples; and S4. recording the peak strength, axial strain and lateral strain during destruction of the tests, and calculating a strength parameter and a weakening rate. The purpose of the invention is to propose a whole set of methods to quantitatively reveal the water-rock coupling weakening effect of a fault material of a high arch dam abutment, so as to provide a basis for the evaluation of the overall stability of a high arch dam project. At the same time, this method is suitable for simulating the water-rock coupling weakening effect of a fault material of a dam abutment and a dam foundation, and the method is also suitable for analyzing a water-rock coupling test of a fault material of a deep buried tunnel and a high slope.

Owner:SICHUAN UNIV

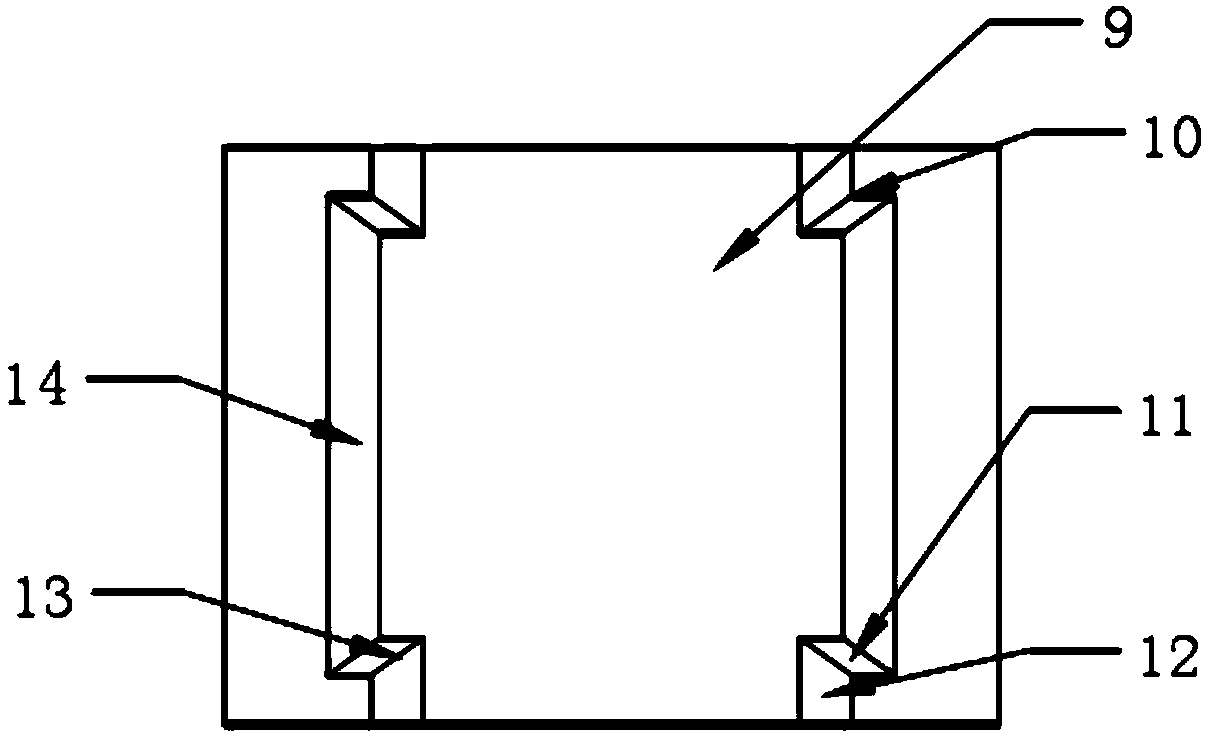

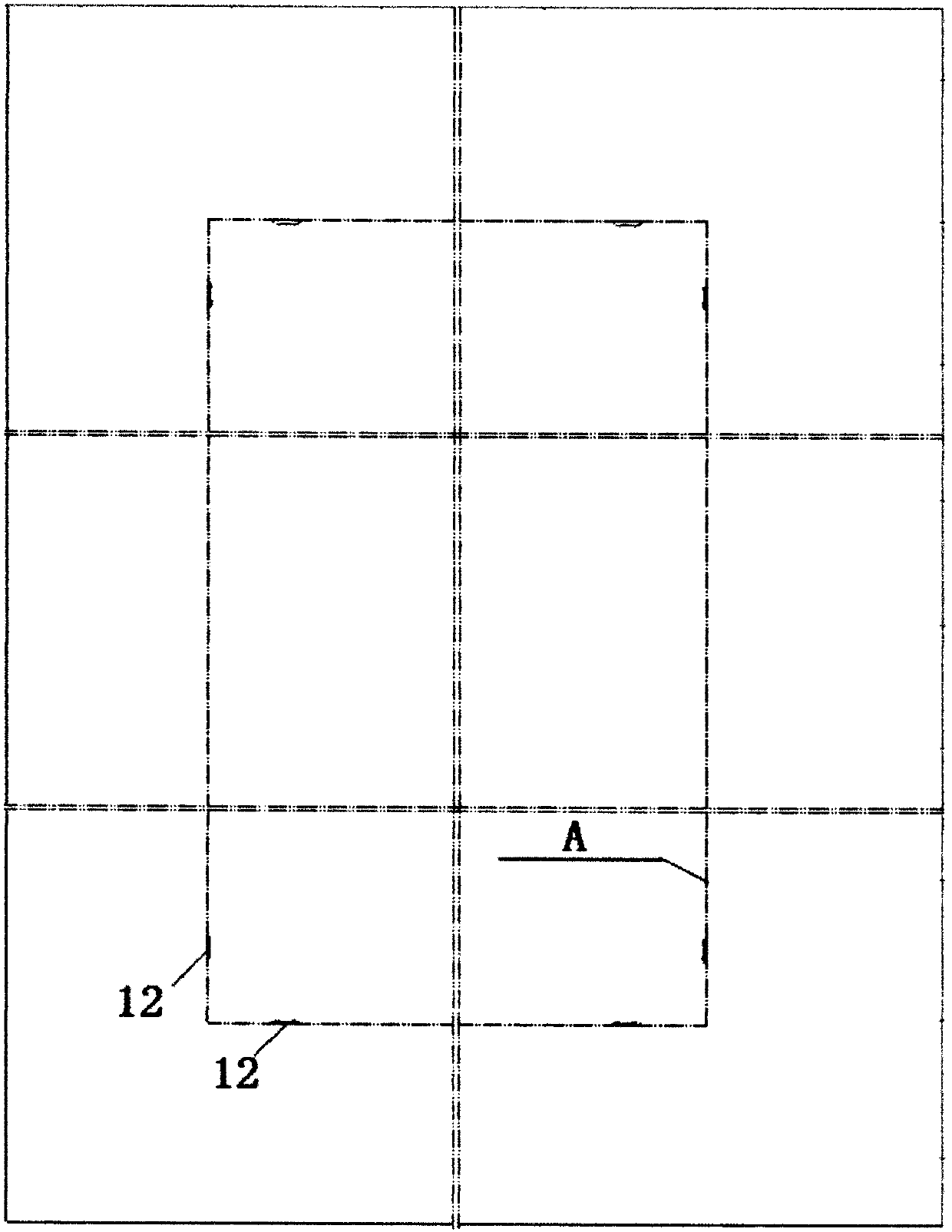

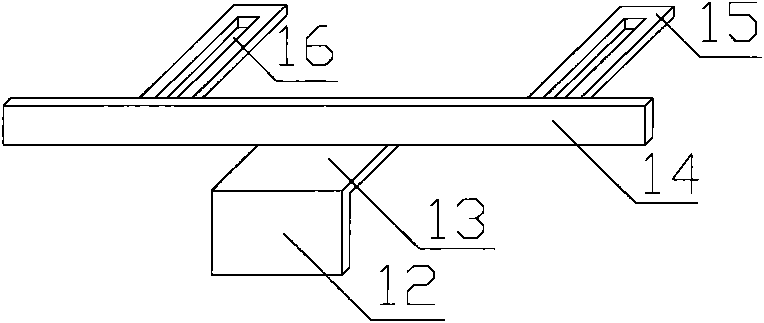

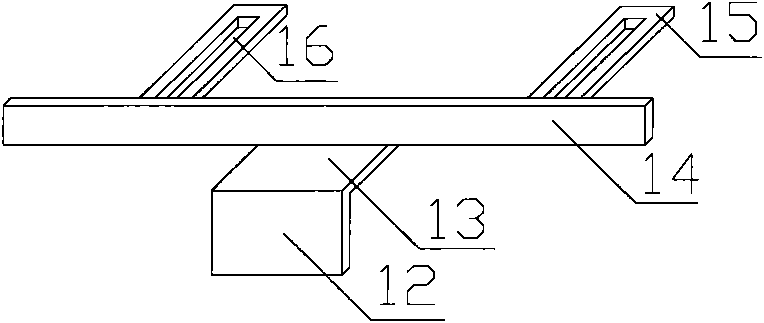

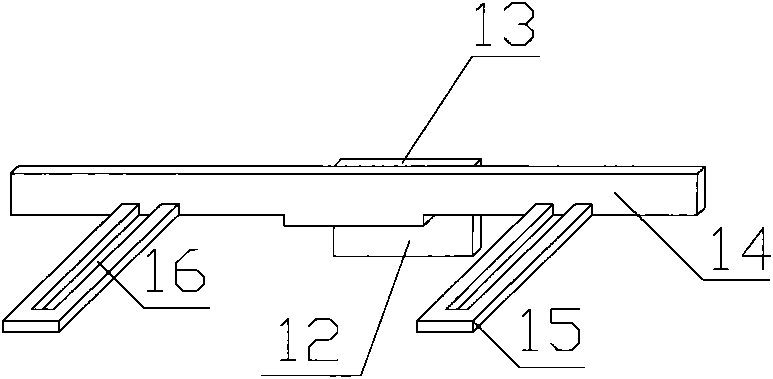

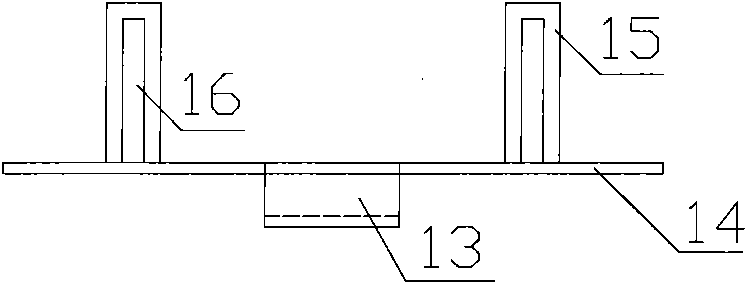

Ribbed precast component template for buildings

The invention discloses a ribbed precast component template for buildings, comprising modules (1) and end blocks (2). The template is characterized in that the template is formed by assembling more than two modules (1) which are connected by connectors (10). The end blocks (2) are formed by a rib vertical baffle (12), a rib horizontal baffle (13), a bottom baffle (14), an adjusting plate (5), and an adjusting hole (16), wherein the adjusting hole is arranged on the adjusting plate. When the template is assembled, the modules (1) are butted and are connected by such fasteners as bolts (3), latches or screw threads, and the end blocks (2) are connected with the modules (1) to form the integral ribbed precast component template. The template has high rigidity and bearing capacity, long service life and simple construction procedures, and the modules (1) can be mechanically produced, thus being convenient for controlling the construction quality.

Owner:吴充

Post-cast strip inflatable arc angle rectangular flexible pipe side mold support construction method

ActiveCN109025294AReduce the number of supportsReduce the number of units usedBuilding material handlingBuilding insulationsEngineeringRebar

The invention relates to a post-cast strip side mold support construction method; an inflatable arc angle rectangular flexible pipe is arranged in a gap between an upper layer steel bar and a lower layer steel bar in the post-cast strip position; in inflation, the arc angle rectangular flexible pipe is extruded by the upper and lower layer steel bars so as to fill the gap caused by the steel bars;the soft pipe is inflated to form an air column so as to space the concrete; the cross section outer contour of the arc angle rectangular flexible pipe is an arc-shaped rectangular shape; the arc angle rectangular is a rectangular with four arc-shaped corners, and is an axially symmetrical and centrosymmetric geometric figure; the arc angle rectangular flexible pipe comprises a soft pipe outer wall and a soft pipe inner wall; the soft pipe outer wall cross section is the cross section contour of the arc angle rectangular flexible pipe, i.e., an arc angle rectangular; the soft pipe inner wallcomprises an upper pipe inner wall, a lower pipe inner wall and a common inner wall; the area enclosed by the upper pipe inner wall and the lower pipe inner wall is an air pump pressurization area; anarea enclosed by the soft pipe outer wall, the lower portion of the upper pipe inner wall and the upper portion of the lower pipe inner wall is an air connection area; the common inner wall has a constant pressure hole. The method employs the inflatable arc angle rectangular flexible pipe support, is good in moulding effect, high in construction quality, and high in efficiency.

Owner:FUJIAN JIANGXIA UNIV

Ribbed prefabricated member template for building

The invention discloses a ribbed prefabricated member template for a building. The ribbed prefabricated member template for the building is spliced by using one or more modules (1), wherein the modules (1) comprise a bottom plate bottom module (4), a bottom plate side module (5) and a longitudinal rib side module (6). The bottom plate bottom module (4), the side plate side module (5) or the longitudinal rib side module (6) of the modules (1) is provided with a stripping bolt hole (7) or a connecting bolt hole (8), and the longitudinal rib side module (6) is provided with a through hole (9). When the ribbed prefabricated member template is spliced, the modules (1) are butted and placed, the plurality of modules (1) are connected by using fasteners such as bolts (3) or inserted pins or screw threads through connectors (10), and end plugging blocks (2) are connected with the modules (1) to form the integrated ribbed prefabricated member template. The ribbed prefabricated member template for the building has high rigidity, high bearing capacity, long service life and simple construction process; and the modules (1) can be mechanically produced, so the control of construction quality is convenient.

Owner:吴方伯

Automatic clamping and positioning rolled steel casting mold

InactiveCN108788017AAchieve positioningSimple structureFoundry mouldsFoundry coresCasting moldSteel casting

The invention relates to the technical field of molds and discloses an automatic clamping and positioning rolled steel casting mold. The automatic clamping and positioning rolled steel casting mold comprises a lower mold base. The top of the lower mold base is provided with a casting groove. The position, far away from the casting groove, of the top of the lower mold base is provided with a bolt positioning hole. The bottoms of the left side and the right side of the lower mold base are both fixedly provided with connection rods. The ends, far away from the lower mold base, of the connection rods are movably connected with guide columns. Springs surrounding the outer surfaces of the connection rods are fixedly connected between the lower mold base and the guide columns. The tops of the inner sides of the guide columns are fixedly provided with positioning blocks. The inner sides of the positioning blocks are fixedly provided with positioning protruding points. The top of the lower moldbase is connected with an upper mold base in a buckled manner. The top of the upper mold base is further provided with a bolt through hole. The left side and the right side of the upper mold base areboth provided with positioning grooves. The clamping and positioning structure of the mold is simple, mold dismounting is convenient, a great amount of time is saved, and by means of a movable mold core, the mold can be used for casting of different types of rolled steel.

Owner:应城市砺安智能科技有限公司

Amf sand box polyurethane lining mold and its manufacturing process

ActiveCN103770260BSmall sizeSolve the problem of different shrinkageMoulding flasksCompound (substance)Engineering

The invention relates to a polyurethane lining die of an AMF sand box. The polyurethane lining die of the AMF sand box comprises a sand box, a die base, a long-side baffle plate, a short-side baffle plate, a sand shooter hole die and an exhaust hole die, wherein the sand box is fixedly mounted at the upper end of the die base; the long-side baffle plate and the short-side baffle plate are symmetrically and fixedly mounted in a cavity defined by the sand box; the sand shooter hole die is mounted on the long-side baffle plate; a plurality of hoisting handles convenient for hoisting and moving are symmetrically manufactured around the die base; concave grooves for positioning and embedding the baffle plates are formed in the middle part of the die base, so as to ensure accurate mounting positions of the long-side baffle plate and the short-side baffle plate; a straight positioning iron block and an L-shaped positioning iron block are respectively arranged on the surface of the die base, outside the concave grooves. According to the polyurethane lining die of the AMF sand box, the polyurethane lining is integrally poured, so that the finished product of polyurethane has an accurate dimension, and the problem of different shrinking percentage of polyurethane holes in different positions can be solved; the polyurethane lining is adhered by a chemical manner, thus improving the adhering force between the polyurethane and a metal sand box.

Owner:ZHIHENG TIANJIN IND

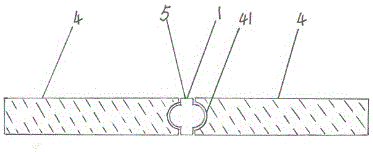

Mold for concrete preformed hole and construction method

PendingCN106869495AMove quicklySimple demouldingForms/shuttering/falseworksBuilding material handlingBuilding constructionCivil engineering

Owner:龚正圣

Constructional column improved casting method

ActiveCN106481082AEnsure pouring qualityReduce labor intensityBuilding material handlingEngineeringRebar

A constructional column improved casting method comprises steps of manufacturing a knife switch and a hopper, in which a discharging port is formed on a wooden template of a constructional column casting surface, notches are processed on two sides of the upper port of the discharging port, a vertical groove mounted on a sealing surface of a concrete casting top and having a groove bottom formed in the middle of the discharging port, and a through hole is formed under the vertical groove, inserting a knife switch arm into the vertical groove, in which a cutter plate is tightly applied to the inner wall surface of the wooden template, and a U-shaped bolt is inserted into two perforations of the cutting arm to fix the knife switch, placing a discharging end of a feeding tank of the hopper on the discharging port of the wooden template, in which an upright surface formed by two triangular reinforced frameworks is tightly applied to the outer wall surface of the wooden template, a top hook is hung on the notches on two sides of the wooden template, and an L-shaped bolt is inserted into a nut and the through hole to fix the hopper, casting concrete to constructional column space of the wooden template via the feeding tank until concrete stops entering, detaching the U-shaped bolt, hammering a knife switch handle from bottom to top until a cutting plate turns 90-degree, and getting the L-shaped bolt down and detaching the hopper. The constructional column improved casting method is safe, convenient and economical, and great casting quality can be achieved.

Owner:YUNNAN CONSTR INVESTMENT HLDG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com