Constructional column improved casting method

A technology of structural columns and gate knives, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of increasing labor intensity, affecting concrete strength, and large initial investment, so as to reduce labor intensity of workers and ensure pouring quality , the effect of conforming to the size of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

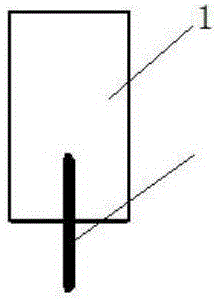

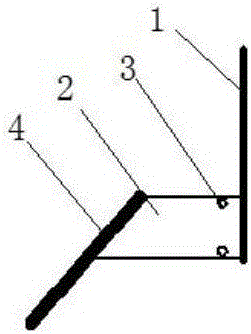

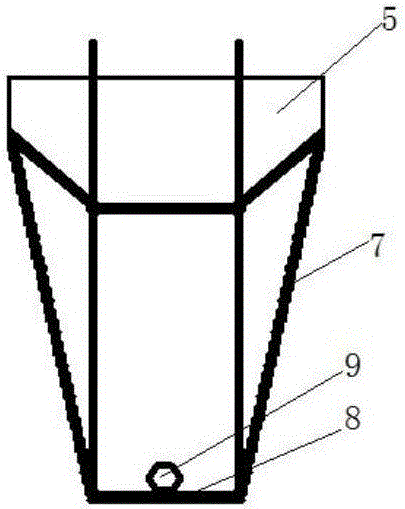

[0019] The invention relates to an improved pouring method of a structural column, in which a gate knife and a hopper are prefabricated. like figure 1 , figure 2 As shown, the gate knife includes a rectangular knife plate 1, a vertical plate-type knife arm 2 welded vertically to the middle of the bottom end of the knife plate, the outer end of which is a beveled edge, and an oblique handle 3 welded to the beveled edge of the outer end of the knife arm. Two perforations 4 are processed at the inner end of the arm. Both the knife plate and the knife arm are made of steel plate, and the handle can be made of steel bar or steel pipe. like image 3 , Figure 4 As shown, the hopper includes a trapezoidal inclined-bottom feeding chute 5 gradually closed toward the discharge end, two interconnected triangular steel skeletons 6 supporting the chute, the vertical surface formed by the two triangular steel skeletons and the discharge of the feeding chute. The surface is even, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com