Template system for retaining wall and construction method for retaining wall

A formwork system and retaining wall technology, which is applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of inconvenient scaffolding and large retaining walls that cannot be formed at one time, so as to increase the overall stability and facilitate disassembly flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

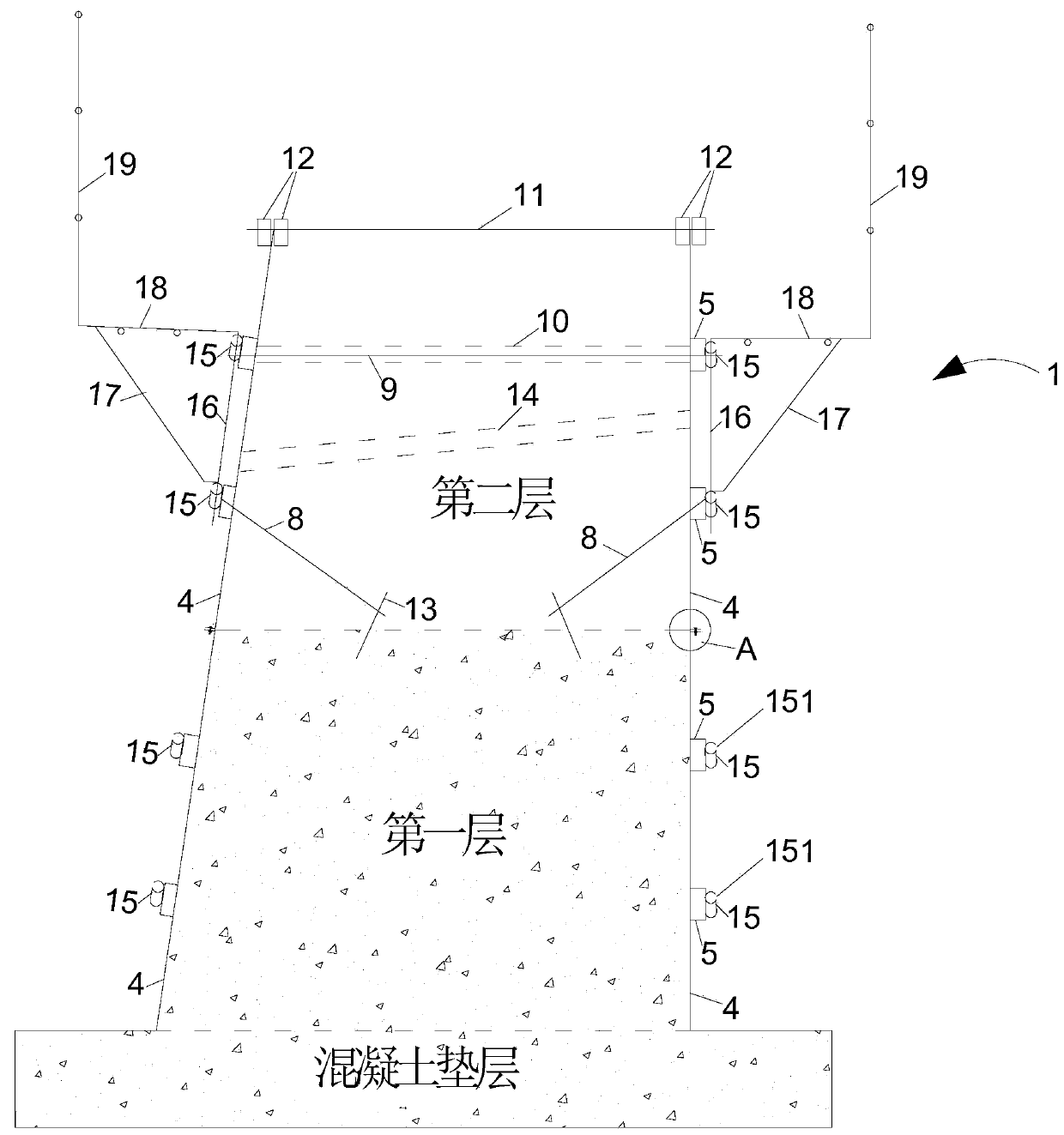

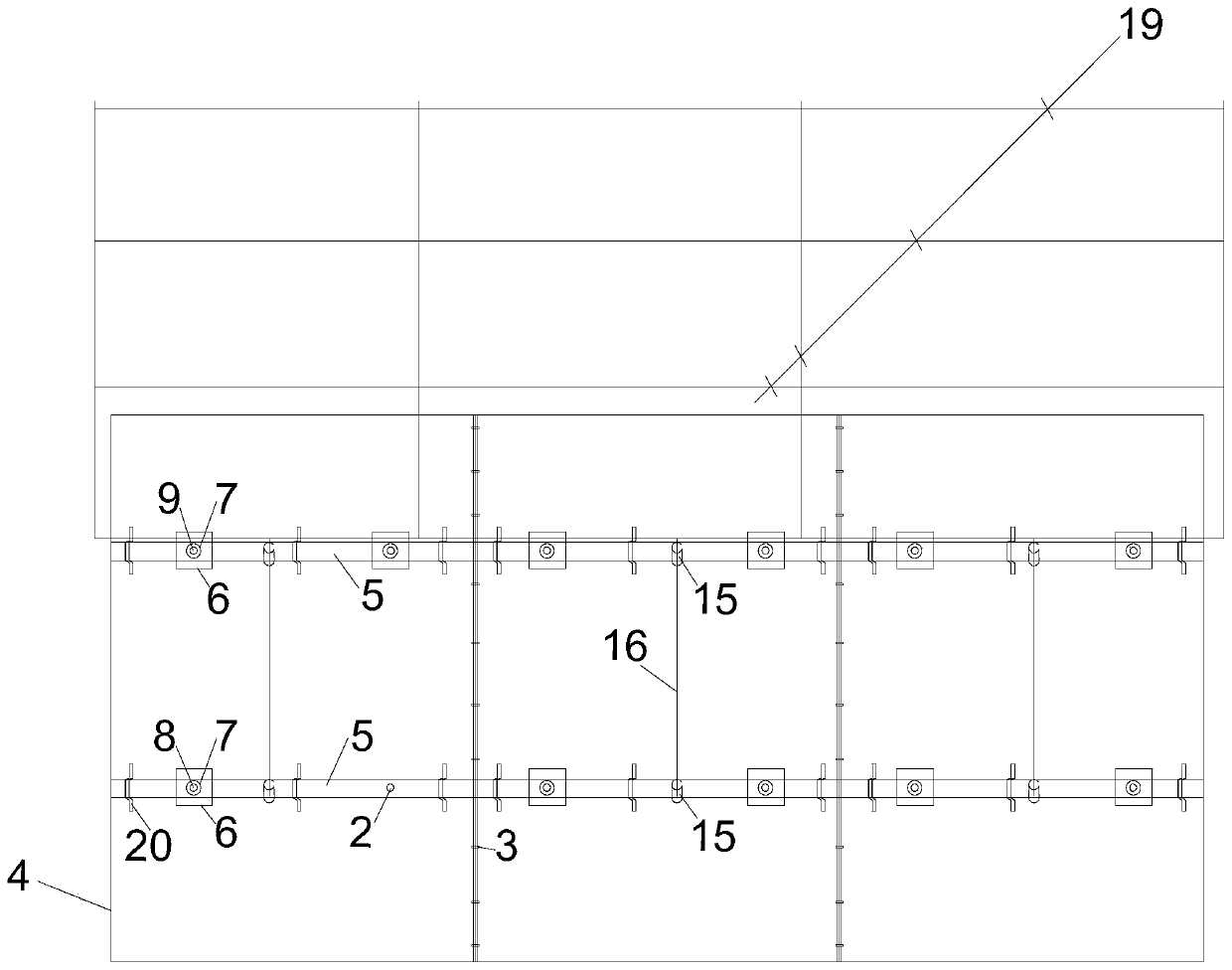

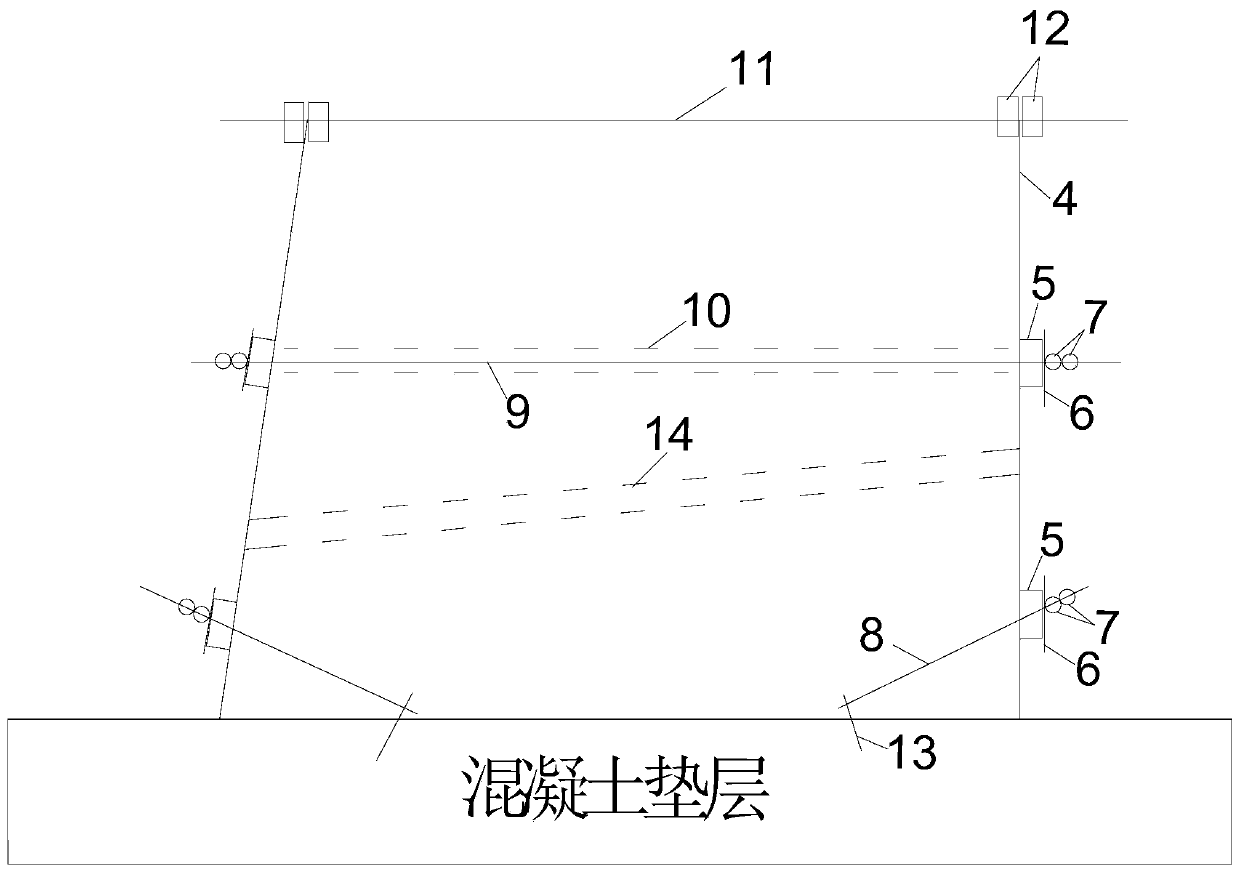

[0040] Such as figure 1 and figure 2 As shown, the formwork system for the retaining wall of this embodiment includes two formwork units 4 and an operating platform 1 corresponding to the formwork units 4, the two formwork units 4 are arranged at intervals along the thickness direction of the retaining wall, and the two formwork units The pouring space of the retaining wall layer is formed between the inner surfaces of the units 4; the operation platform 1 is set on the corresponding formwork unit 4, and the operation platform 1 forms a formwork unit for pouring the retaining wall layer of this layer and erecting the upper layer of retaining wall layer 4 work sites.

[0041] The formwork unit 4 is composed of multiple small steel formworks sequentially connected along the length direction of the retaining wall. The size parameters and assembly forms of the steel formwork are highly selective, and can be prefabricated and assembled flexibly according to the actual situation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com