A construction method of a high-level water tower for a large-volume multi-zone water tank

A construction method and large-volume technology, applied to the configuration of water supply tanks, towers, water supply devices, etc., can solve the problems that a single water tank cannot meet the requirements of various water qualities, the difficulty of supporting formwork on the concrete pool wall, and the difficulty of construction, etc., to achieve The pouring quality is easy, the construction speed is fast, and the formwork is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

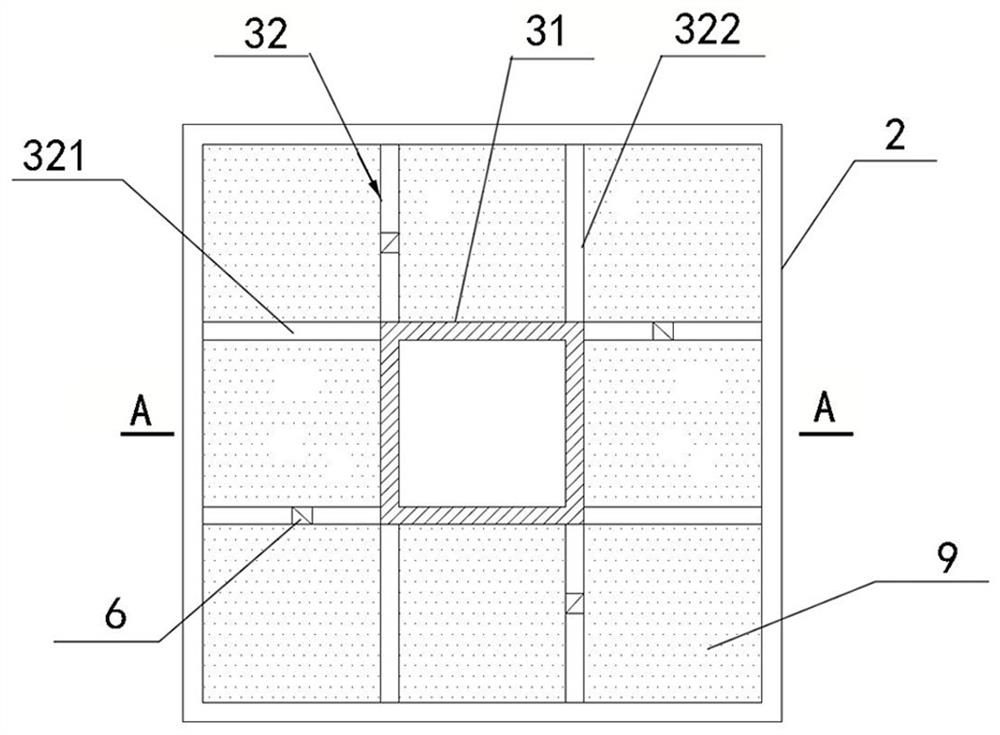

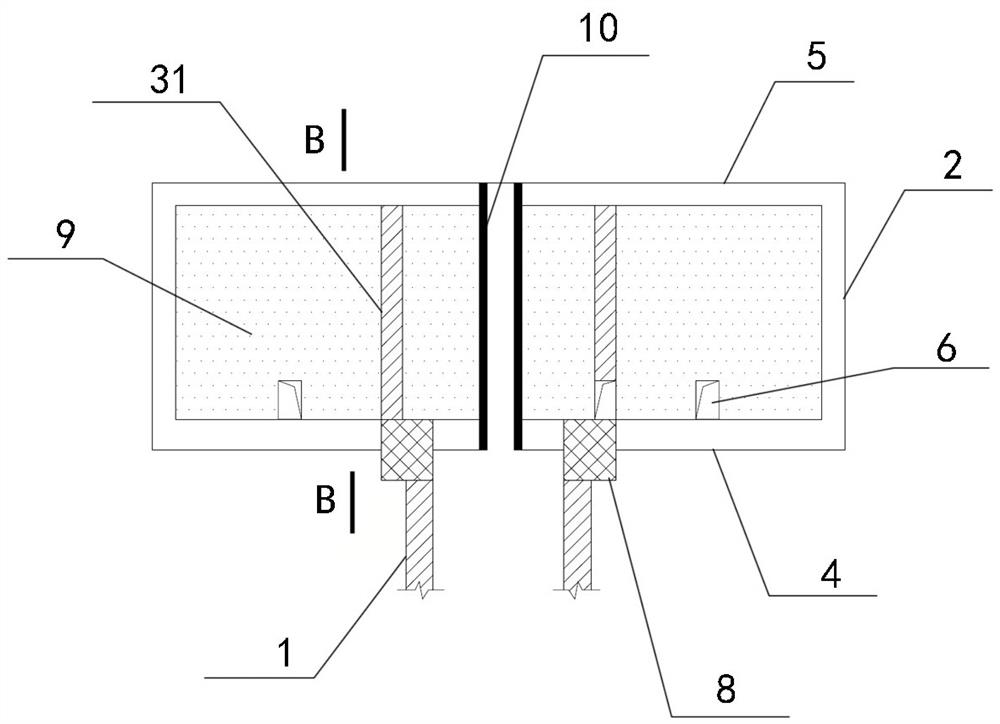

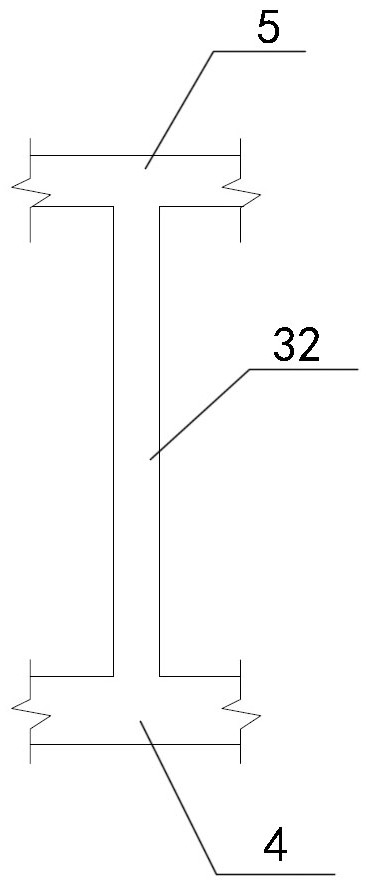

[0046] Such as Figure 1~4As shown, a high-level water tower with a large-volume multi-section water tank includes a water tank and a supporting structure (1). The water tank includes an outer wall of the water tank (2), a top plate of the water tank (5) and a bottom plate of the water tank (4). The outer wall of the water tank (2) and the inner cylinder partition (31) are all square, and the inside of the water tank, the top plate of the water tank (5) and the bottom plate of the water tank (4) are provided with an inner cylinder surrounded by the inner cylinder partition (31). A compartment partition (32) is arranged inside the water tank, between the inner cylinder partition (31) and the outer wall of the water tank (2), and the compartment partition (32) includes a horizontal compartment partition (321) and a vertical compartment partition (322) . Divide the inner area of the water tank between the outer wall of the water tank (2) and the next wall of the inner cylinder...

Embodiment 2

[0054] Such as Figure 6 As shown, in order to enrich the building facade requirements, the outer wall (2) of the water tank is a regular octagon, and the others are the same as the first embodiment.

Embodiment 3

[0056] Such as Figure 7 As shown, in order to further enrich the building facade requirements, the outer wall (2) of the water tank is octagonal, and the width of two opposite faces is greater than that of other faces. And the cell partition (32) in one direction is canceled, and only a horizontal cell partition (321) is provided between the inner tube partition (31) and the outer wall (2) of the water tank at this time. Others are the same as embodiment one.

[0057] In addition to the conventional cast-in-place concrete construction for the above-mentioned large-volume multi-cell water tank high-level water tower, the priority construction steps are as follows:

[0058] Step 1, construction foundation and support structure (1);

[0059] Step 2, prefabricating the outer wall of the water tank (2), the inner cylinder partition (31) and the compartment partition (32) on the ground, and assembling them into a lattice structure;

[0060] Step 3, hoisting the lattice structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com