Template for construction

A formwork technology for construction, which is applied in the direction of construction, building structure, formwork/formwork components, etc., and can solve problems such as failure to meet construction requirements, consumption of forest resources, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

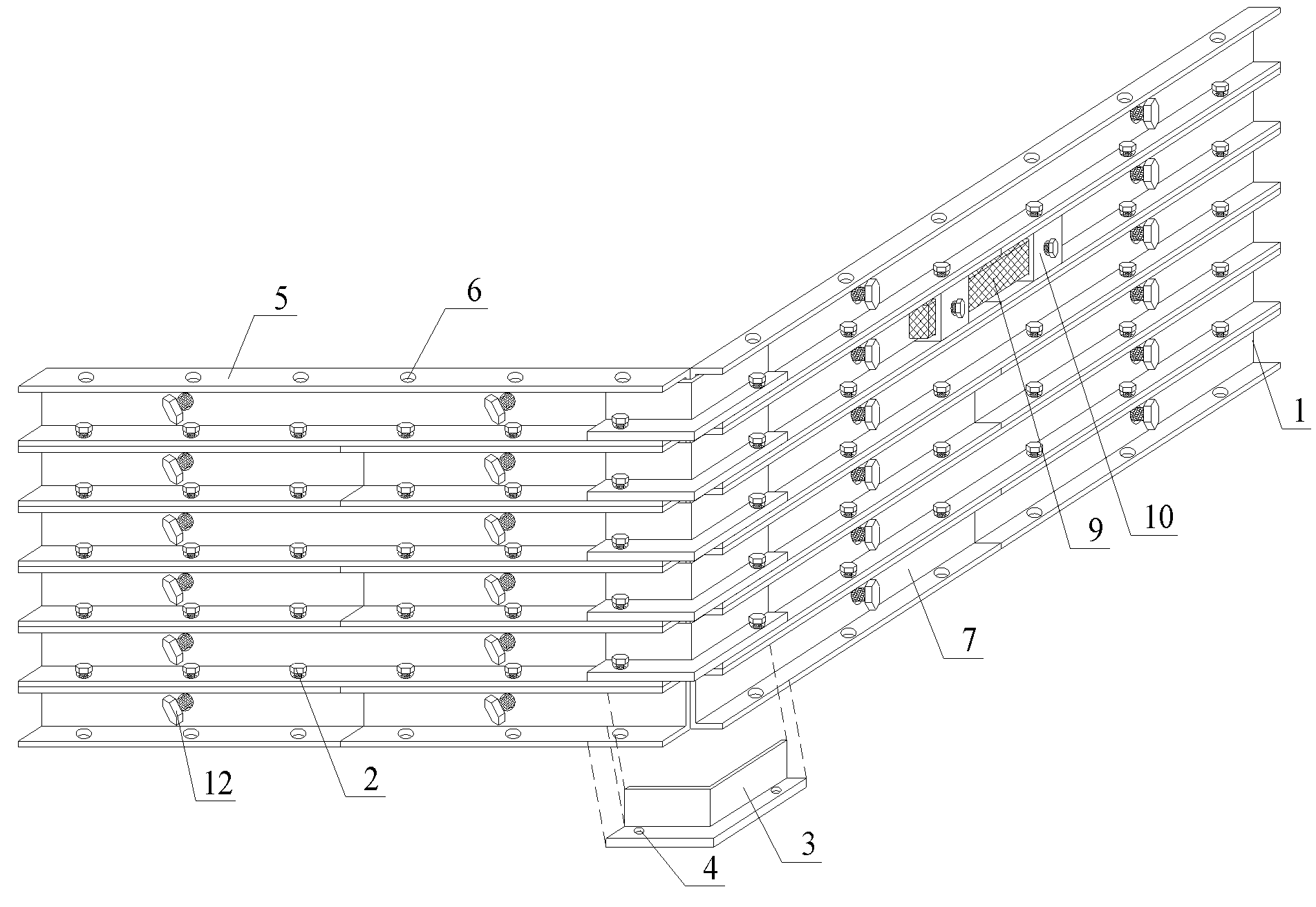

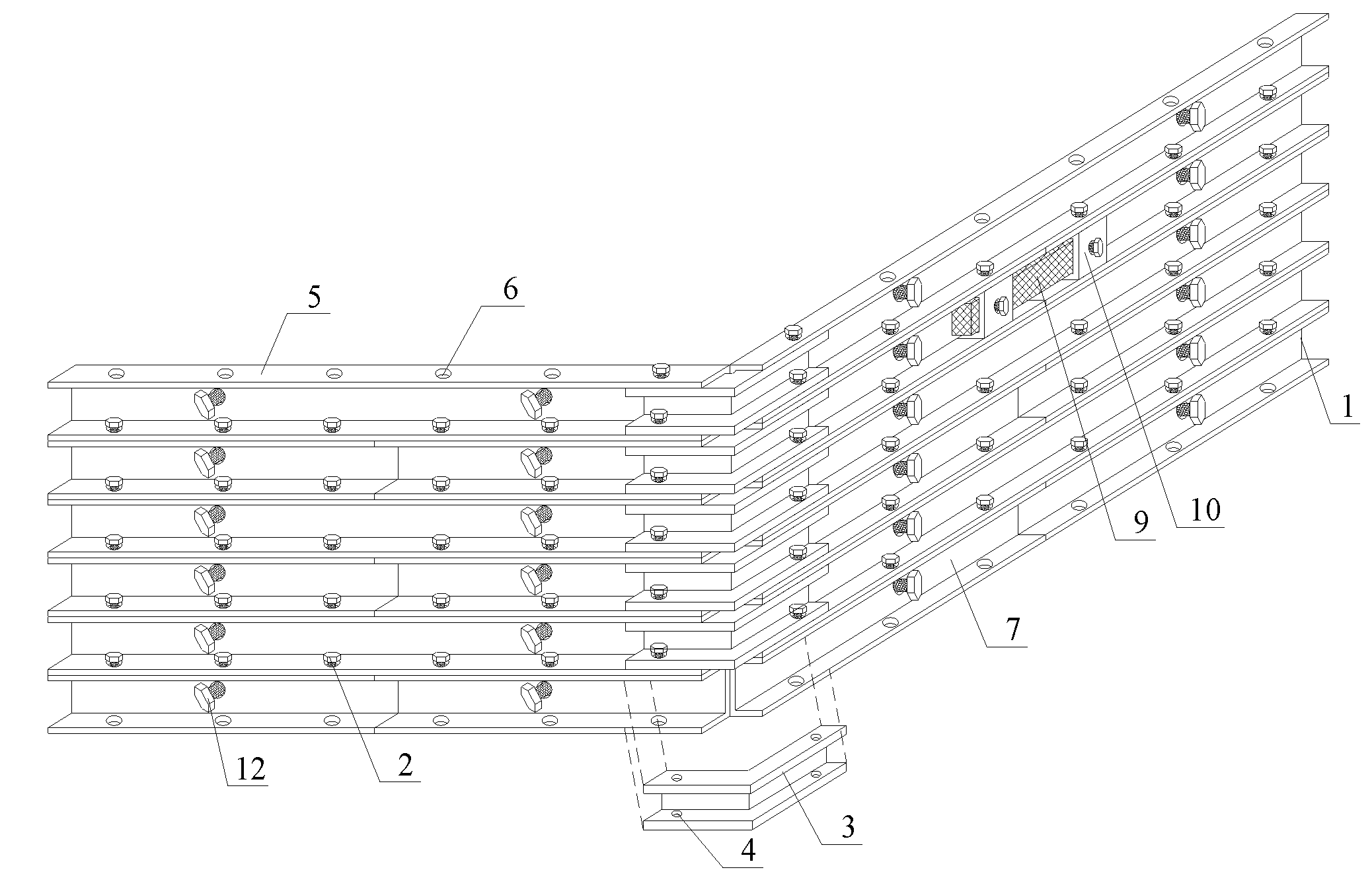

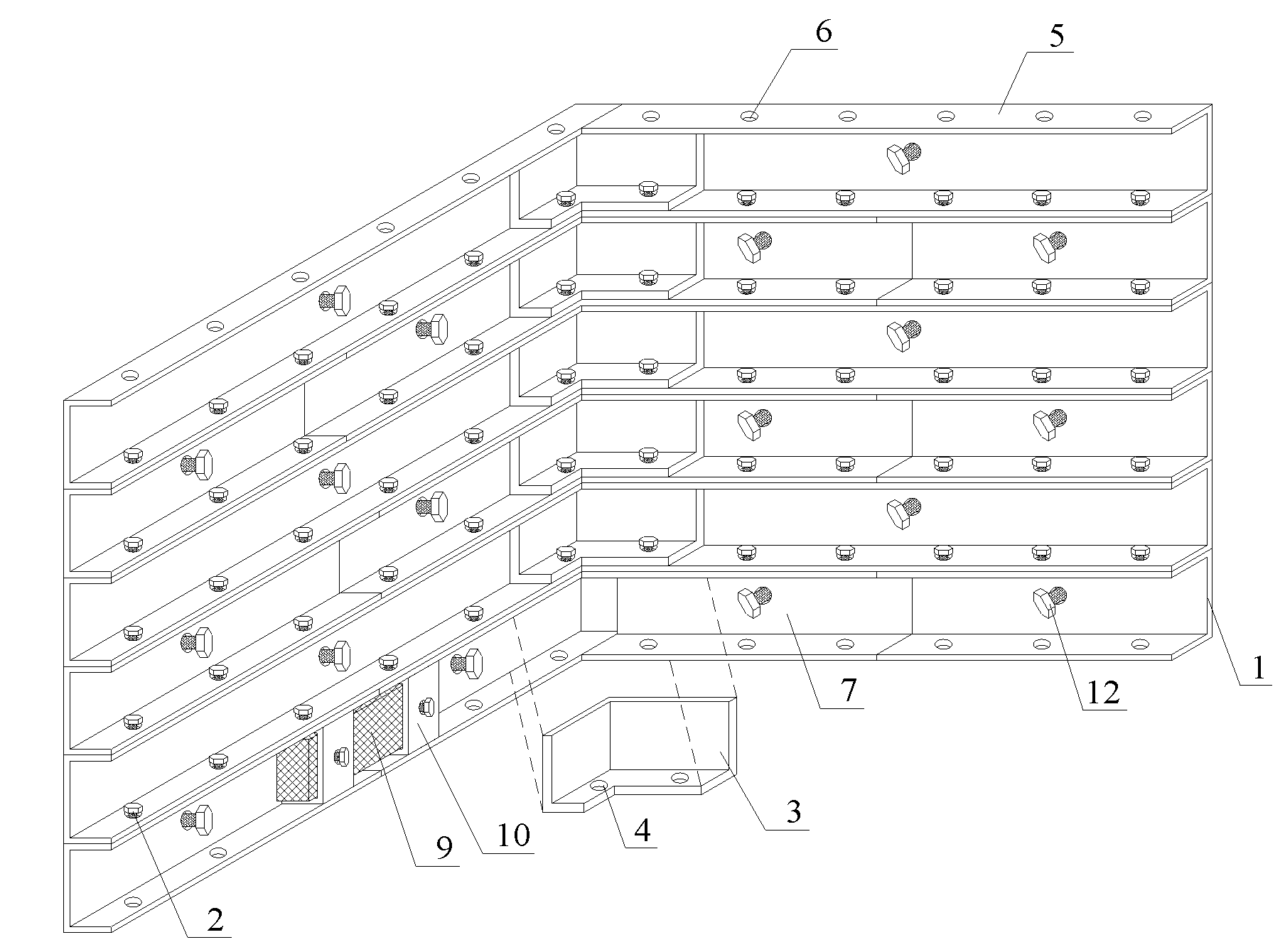

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] The invention is attached Figure 1-18 As shown, a formwork for construction includes a trough-shaped module 1, bolts or bolts 2, and the construction formwork is assembled by a plurality of trough-shaped modules 1 connected to each other through bolts or bolts 2. The present invention is characterized in that The cross section of the connecting block 3 provided at the corner of the building formwork is L-shaped or groove-shaped. Both the inner corner and the outer corner of the building formwork are provided with connecting blocks 3, the connecting block 3 has strong rigidity and strength, and can connect the formworks in different directions into a whole to ensure the connection strength at the corners of the formwork. At the same time, L-shaped and trough-shaped connecting blocks 3 are arranged at the inner corners of the formwork, and the gap at the end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com