LED filament light bulb

A technology of LED filament and LED light source, applied in the field of lighting, can solve the problems of polluted LED filament, high production cost, large light decay, etc., and achieve the effects of improving heat dissipation capacity, convenient and quick installation, and improving aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

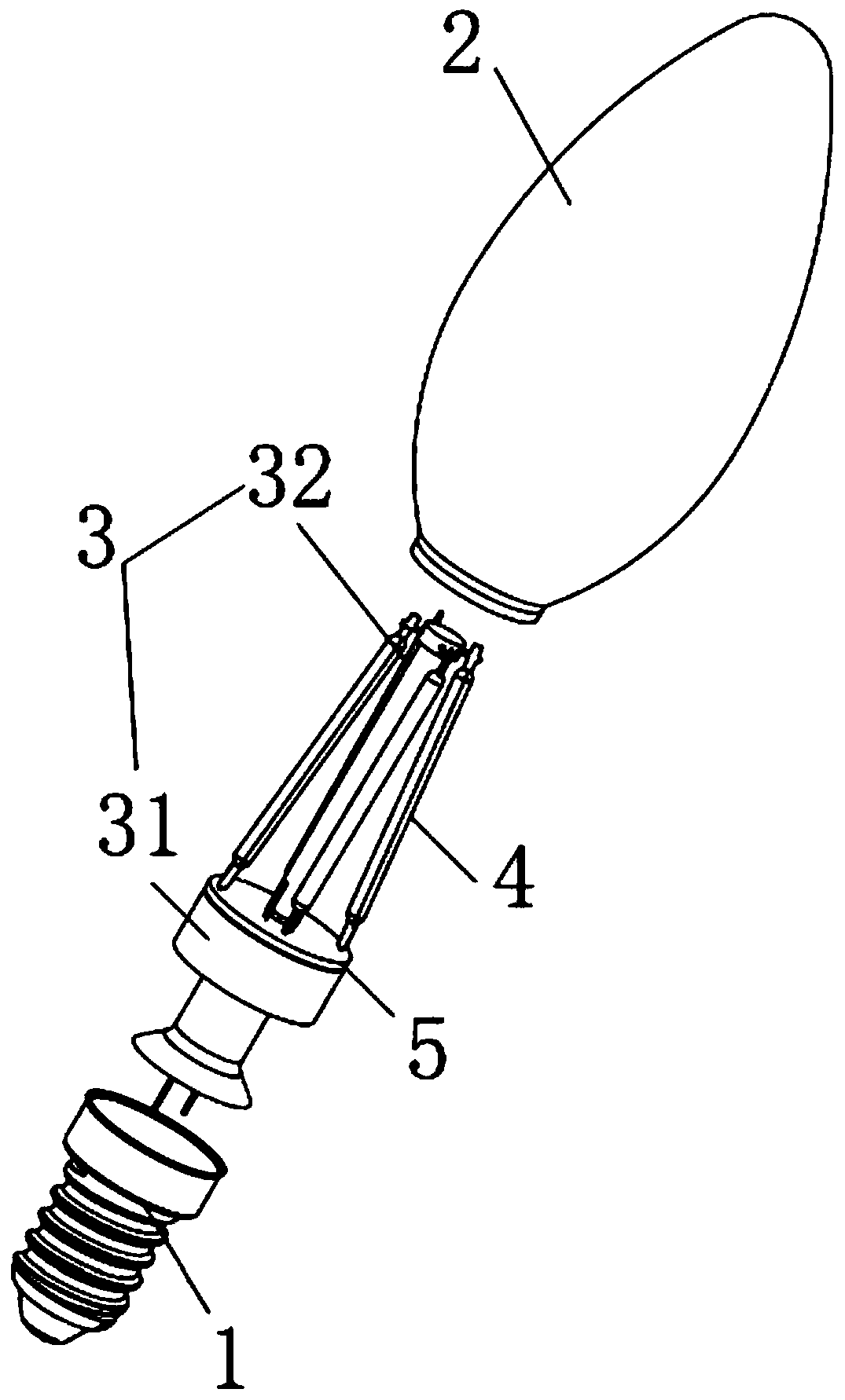

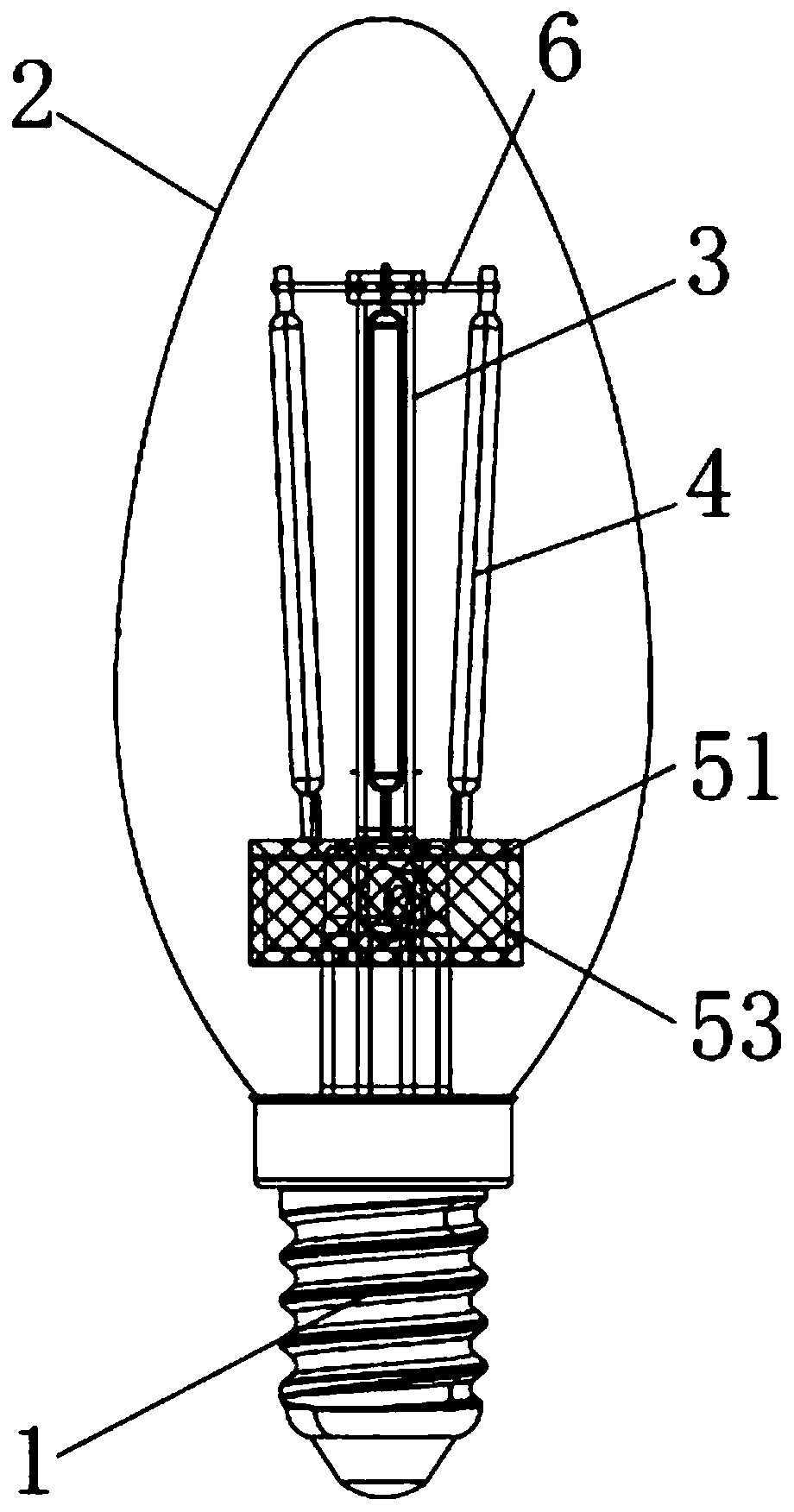

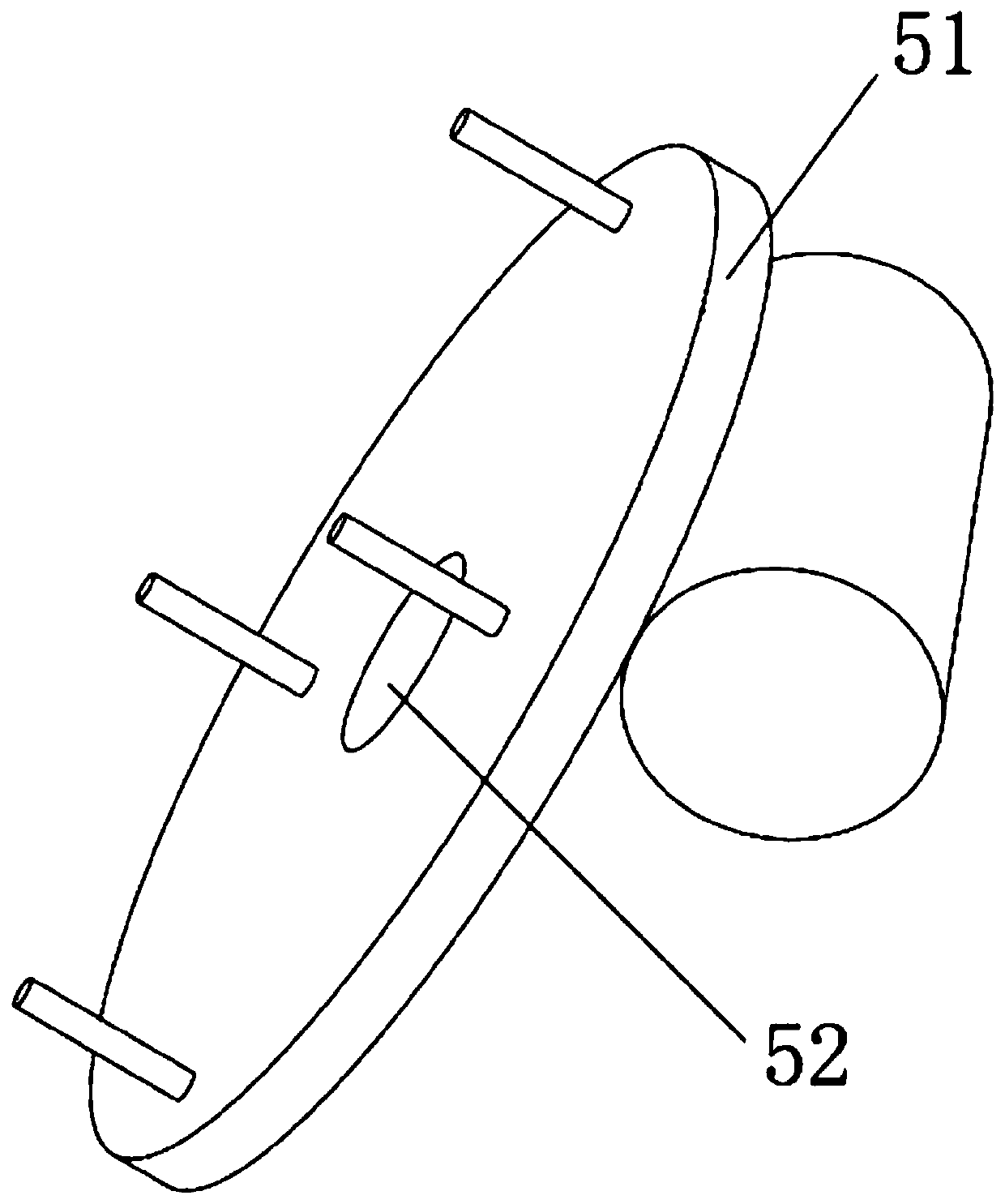

[0025] like Figure 1-3 As shown, an LED filament light bulb includes a lamp cap 1, a bulb shell 2 connected to the lamp cap 1, a stem 3 extending into the bulb shell 2, an LED light source 4 located in the bulb shell 2, The power supply 5 connected to the LED light source 4 and the protective gas inside the bulb; the LED light source 4 is installed on the stem 3, and the power supply 5 is installed on the stem 3 and located Inside the bulb 2, the bulb and the stem form an airtight cavity; the protective gas is located inside the airtight cavity, and includes a mixture of oxygen and helium, wherein the volume of oxygen occupies 1-50% of the total volume of shielding gas.

[0026] The lamp holder 1 is used to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com