Reinforced concrete release agent and preparation method thereof

A concrete release agent, enhanced technology, applied in the petroleum industry, climate sustainability, sustainable waste treatment, etc., can solve the problems of affecting the appearance of concrete, concrete surface damage, air bubbles cannot be discharged, etc., to increase the resistance to rain erosion properties, eliminate air bubbles, and improve the apparent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

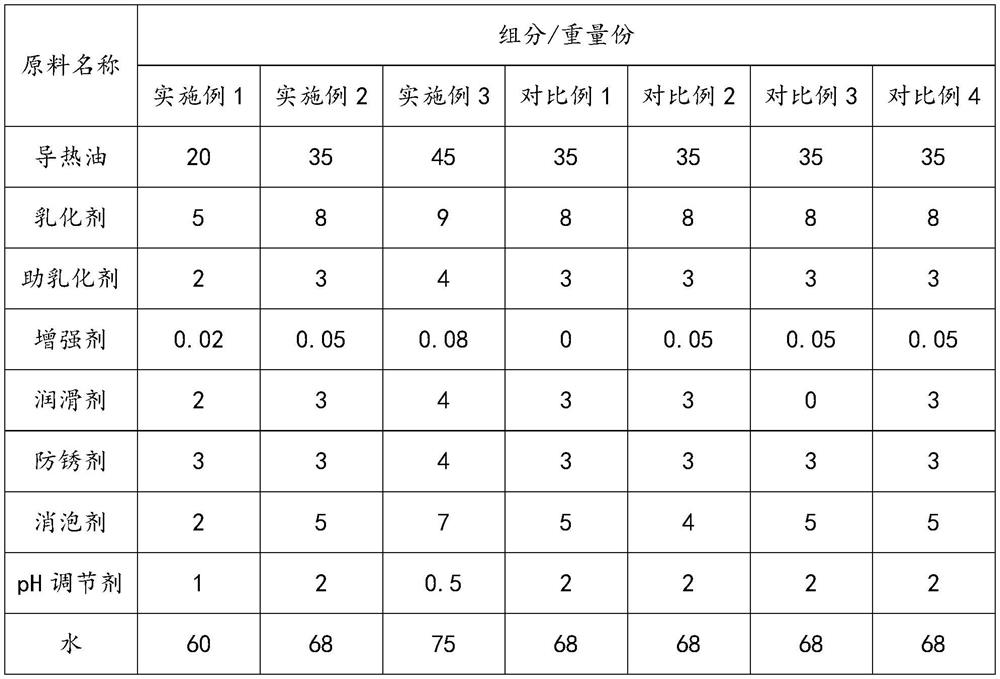

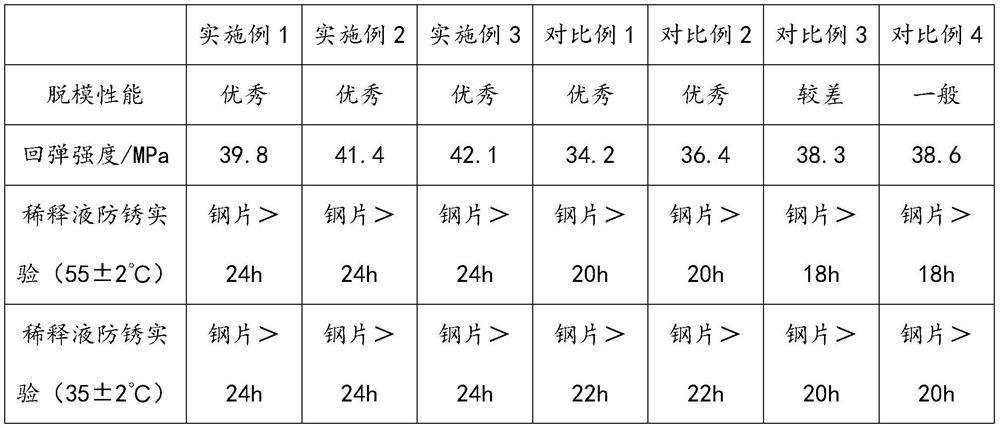

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of reinforced concrete release agent, and its specific steps are as follows:

[0032] Step 1: First mix water, heat transfer oil and surfactant in a certain proportion, and stir in a mixer at a speed of 1000-3000r / min for 20-30min to obtain emulsified oil;

[0033] Step 2: Add emulsifier and co-emulsifier to the emulsified oil obtained in Step 1, and stir for 30-50 minutes under the condition of 800-2000r / min to obtain completely emulsified oil;

[0034] Step 3: Add a certain proportion of enhancer, lubricant, antirust agent, defoamer to the fully emulsified oil obtained in step 2, and stir for 10-20min under the condition of 800-2000r / min to obtain the decomposed oil without adjusting the pH value. molding agent;

[0035] Step 4: adding a certain amount of pH regulator to the release agent obtained in step 3, and adjusting the pH value of the release agent to between 6-7 to obtain a reinforced concrete release agent;...

Embodiment 1

[0043] In terms of parts by mass, the specific steps are as follows:

[0044] Add 25 parts of heat transfer oil, 60 parts of water, 2 parts of sorbitan monostearate, and 3 parts of polyoxyethylene sorbitan tristearate into the reaction kettle, and stir for 20 minutes at 2000 r / min. An emulsified oil is obtained.

[0045] Add 1 part of diethylbutyl succinate and 1 part of diethylbutyl glutarate into the reaction kettle and stir for 30 minutes under the condition of 1000 r / min to obtain completely emulsified oil.

[0046] Add 0.02 parts of activated calcium silicate hydrate, 1 part of water-soluble fatty acid amide, 1 part of synthetic ester, 1 part of fatty acid, 2 parts of alcohol amine, and 2 parts of polyether modified silicone oil into the reactor, and stir at 1000r / min 10min.

[0047] Add 1 part of 2-amino-2-methylpropanol into the reaction kettle, stir slowly, adjust the pH value of the release agent to 7, and configure it as a concrete release agent for aluminum formwo...

Embodiment 2

[0050] In terms of parts by mass, the specific steps are as follows:

[0051] Add 35 parts of heat transfer oil, 68 parts of water, 3 parts of sorbitan monostearate, and 5 parts of polyoxyethylene sorbitan tristearate into the reaction kettle, and stir for 25 minutes at 2000 r / min. An emulsified oil is obtained.

[0052] Add 1 part of diethylbutyl succinate and 2 parts of diethylbutyl glutarate into the reaction kettle and stir for 40 minutes under the condition of 1000r / min to obtain completely emulsified oil.

[0053] Add 0.05 parts of activated calcium silicate hydrate, 3 parts of water-soluble fatty acid amide, 1 part of fatty acid, 2 parts of sodium nitrite, and 5 parts of polyether modified silicone oil into the reaction kettle, and stir for 15 minutes at 1000 r / min.

[0054] Add 2 parts of 2-amino-2-methylpropanol into the reaction kettle, stir slowly, adjust the pH value of the release agent to 7, and configure it as a concrete release agent for aluminum formwork.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com