Sandwich thermal insulation non-load-bearing wallboard with holes and production process thereof

A production process and non-load-bearing technology, which is applied in the field of sandwich insulation non-load-bearing wallboard and its production process, can solve the problems of difficulty, falling off, long-term bare leakage, etc., and achieve the effects of saving construction period, avoiding slurry leakage and avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

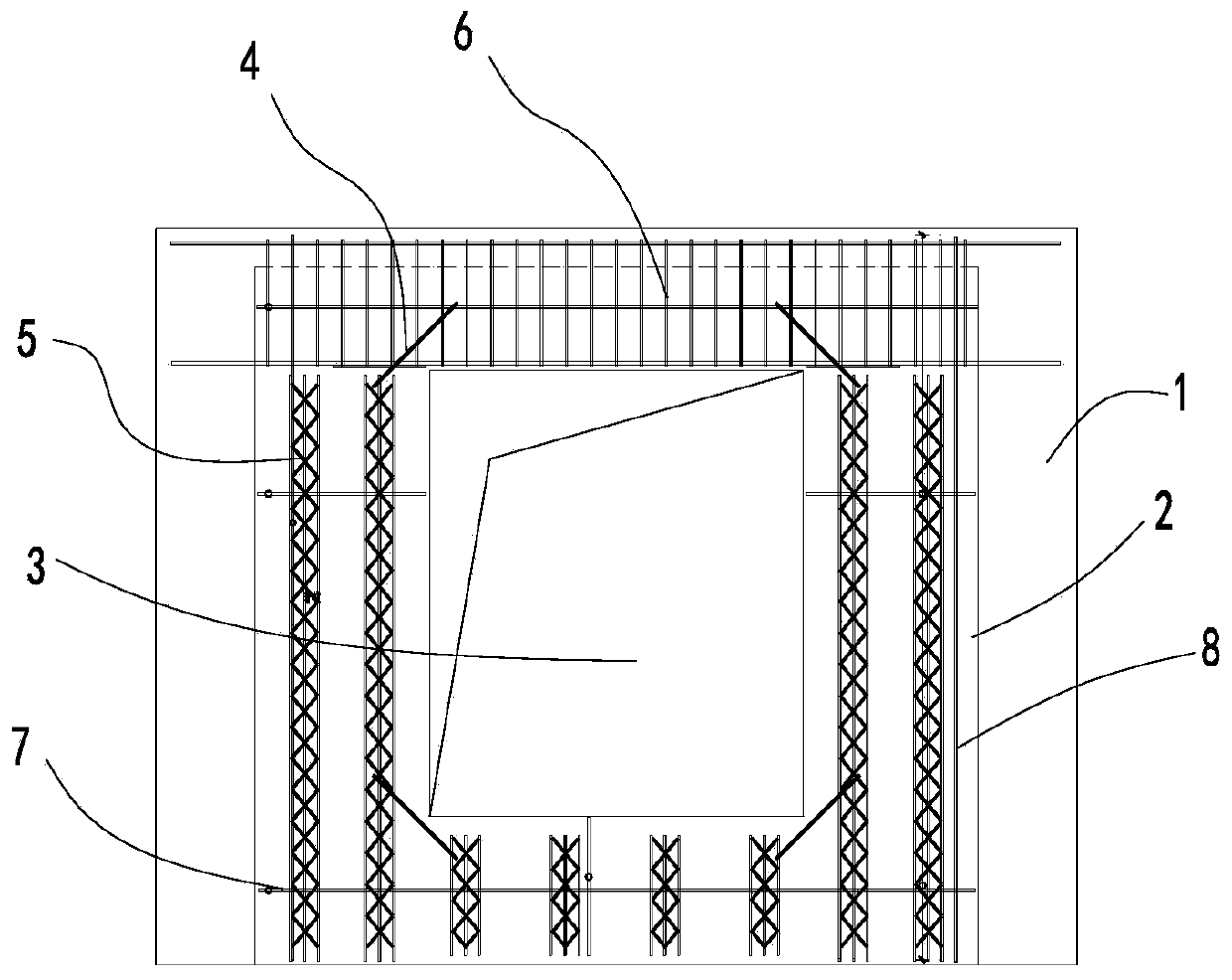

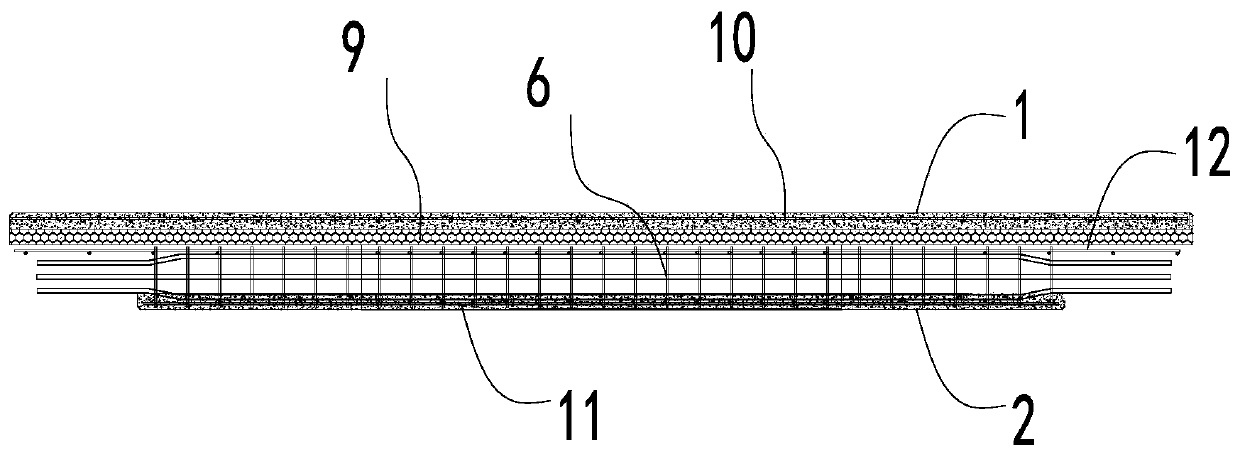

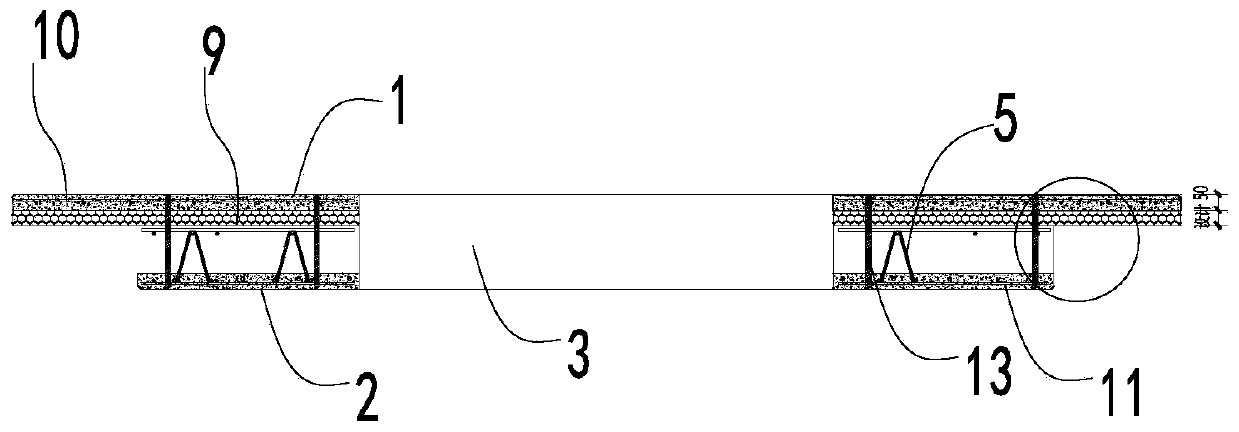

[0035] Such as Figure 1-4 As shown, the present embodiment provides a sandwich thermal insulation non-load-bearing wallboard with a hole, which includes an inner leaf plate 2, a post-cast cavity layer in the middle, an insulating layer 9, and an outer leaf plate 1 arranged sequentially from the inside to the outside. The inner leaf plate 2 and the outer leaf plate 1 are correspondingly provided with openings 3, and the middle post-cast cavity layer is provided with a middle steel mesh 12, and the middle steel mesh 12 is connected with the inner leaf plate 2 through the truss steel bar 5, The inner leaf plate 2, the insulation layer 9 and the outer leaf plate 1 are connected by a cold and hot bridge breaker connector 13, and a steel skeleton 6 is pre-embedded above the opening, and the steel skeleton 6 is located in the middle of the cavity layer after pouring and the inner leaf plate to form a laminated connecting beam.

[0036] Specifically, the two sides of the two ends of...

Embodiment 2

[0050] The structure of the sandwich thermal insulation non-load-bearing wallboard with openings in the second embodiment is the same as that in the first embodiment. The main difference lies in the production process, which is mainly reflected in the placement sequence of the hot and cold bridge connectors. The connectors in this embodiment are After the concrete is poured, the hot and cold bridge break connectors are arranged, and the cold and heat break bridge connectors can pass through the insulation layer and the outer blade plate when the inner leaf plate is turned over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com