Mold for concrete preformed hole and construction method

A construction method and concrete technology, which is applied in the fields of formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc., which can solve problems such as time-consuming, labor-intensive and costly, absence of plastic pipes, and plastic pipe deviations , to achieve the effect of fast moving speed, small friction coefficient and strong mutual suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

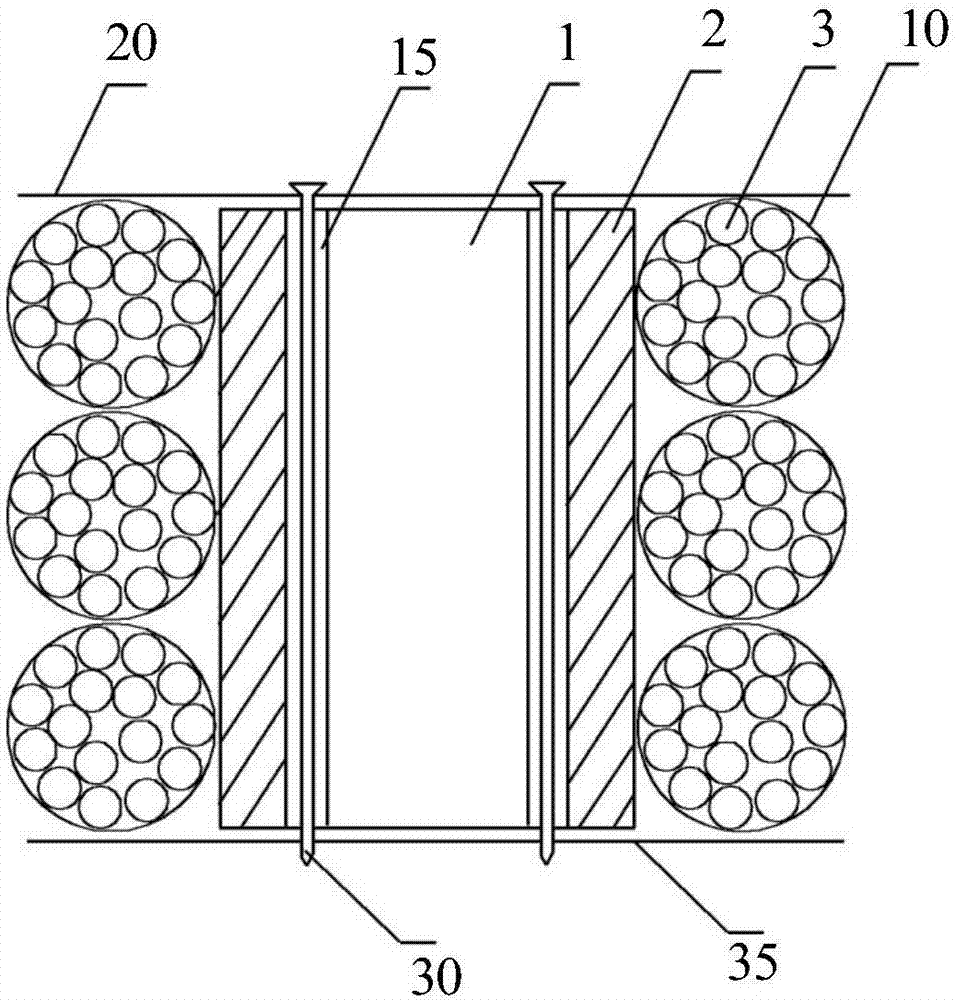

[0057] Such as figure 1 As shown, the box body 1 is placed horizontally on the template 35, and the box body is made of iron; the two sides of the box body 1 are provided with a circular tube-shaped positioning hole 15 penetrating from top to bottom; The side of the positioning hole 15 is provided with a permanent magnet 2, and the permanent magnet is a strong magnet; the nylon hose or rubber tube 10 with steel balls is attached to the side of the permanent magnet; the cover plate 20 is pressed on the On the box body 1, the nylon hose or the rubber tube, the iron nail 30 passes through the cover plate 20, passes through the positioning hole 15, and the tip of the iron nail is inserted into the template 35 to fix the nylon hose or rubber tube and the box body above the template.

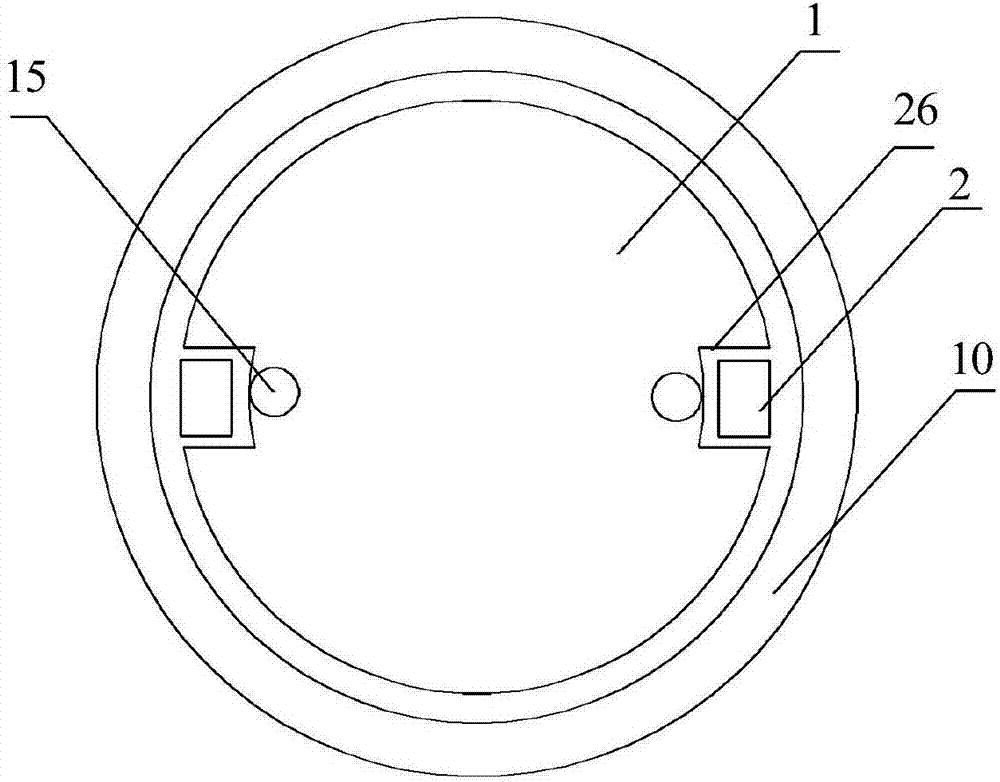

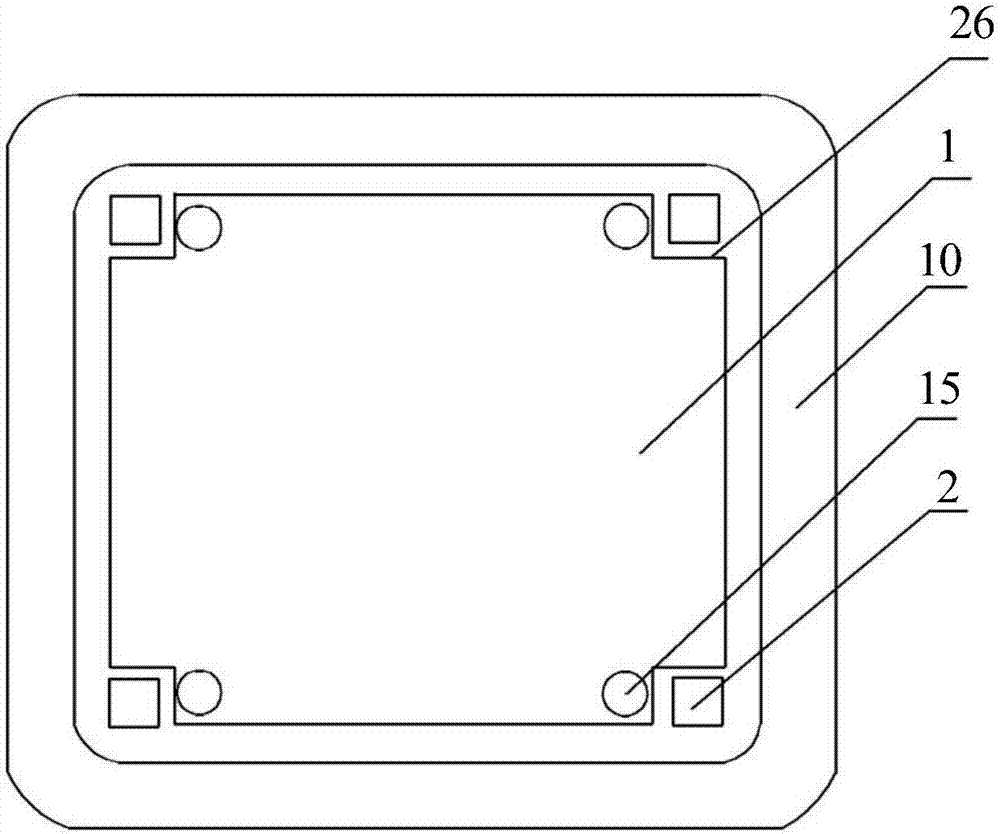

[0058] Such as figure 2 , image 3 Shown, the positioning hole 15 that offers on the box body 1, the groove 26 that positioning hole limit is established, is placed with permanent magnet 2 in the ...

Embodiment 2

[0065] Such as Figure 4 As shown, the side of the steel pipe 4 is connected with a permanent magnet 2; the side of the permanent magnet is adsorbed with a nylon hose or a rubber tube 10 with a steel ball 3; the positioning rod 16 is located in the steel pipe 4; the positioning rod The lower end of the lower end is against the top of the main bar 22 of the reinforcement cage; the external thread on the top of the positioning rod 16 is engaged with the internal thread of the steel pipe 4; in order to facilitate the adjustment of the height of the steel pipe, an inner hexagonal groove is provided on the top of the positioning rod , when you need to adjust the height of the steel pipe, you only need to insert the extended inner hexagonal wrench into the hexagonal groove of the positioning rod. rise or fall accordingly.

[0066] Such as Figure 5 Shown, location bar 16 is located at steel pipe 4 li, and permanent magnet 2 is located at the outside of steel pipe, and nylon hose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com