Patents

Literature

53results about How to "Quick demolition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

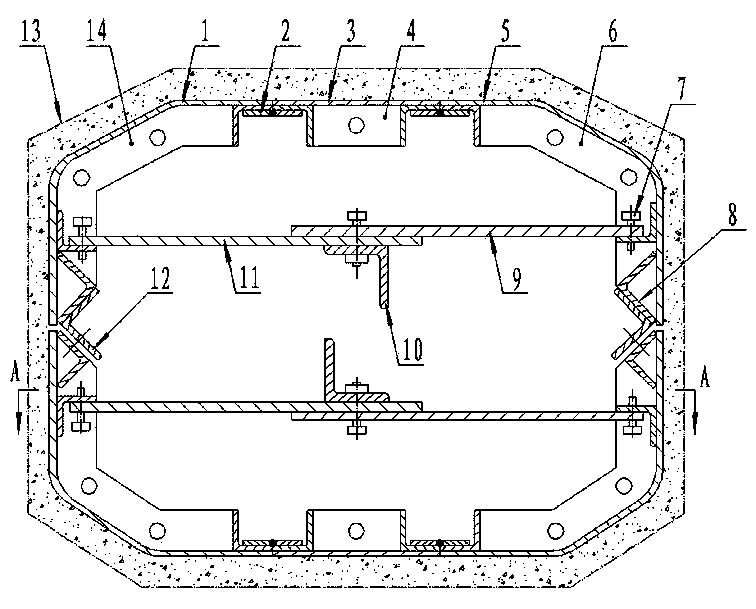

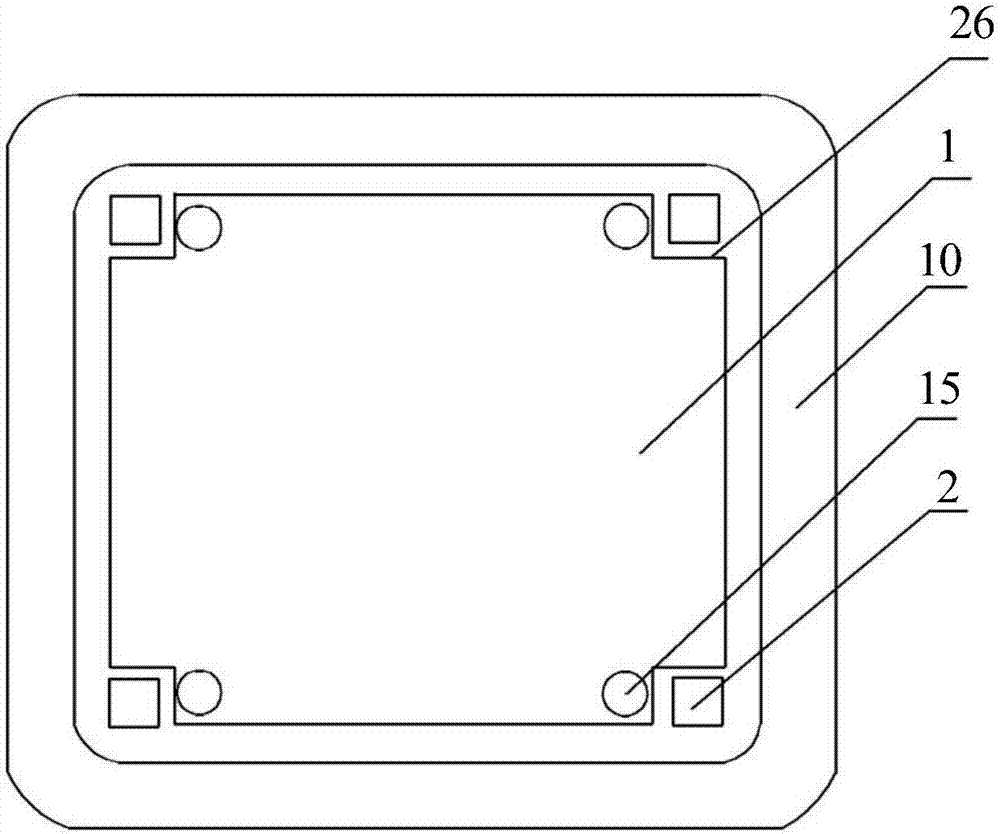

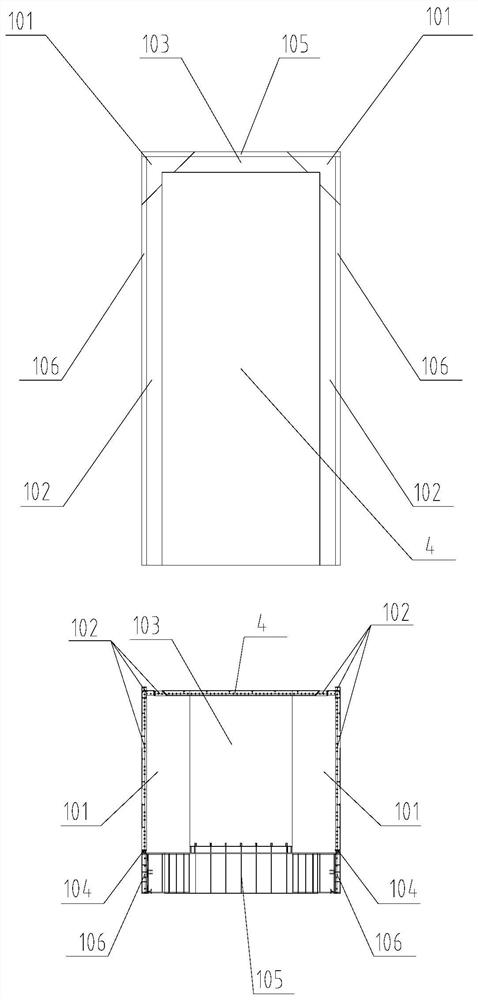

Integral hydraulic formwork applied to box culvert prefabrication

ActiveCN110394885AGuaranteed installation qualityQuick demolitionMouldsAuxillary shaping apparatusHigh surfacePrefabrication

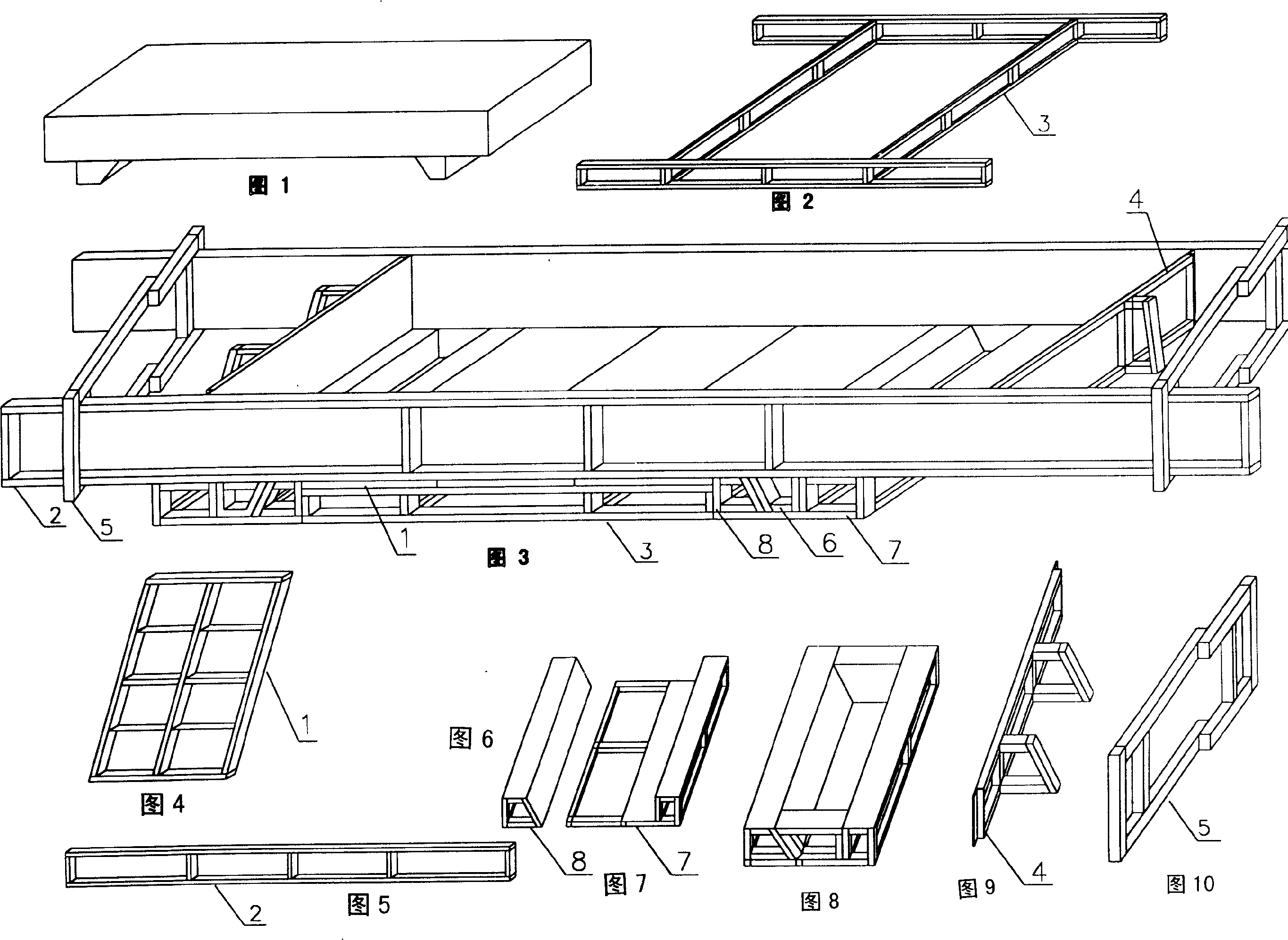

The invention belongs to the field of box culvert pouring, and provides an integral hydraulic formwork applied to box culvert prefabrication. The integral hydraulic formwork comprises an internal formwork component, a bottom formwork component, an external formwork component, an end formwork component and a retaining formwork component; the internal formwork component includes internal formworks and an internal top formwork; the internal formworks include the first internal formwork and the second internal formwork; the bottom formwork component includes a bottom formwork; the external formwork component includes external formworks; the external formworks include the first external formwork and the second external formwork; the retaining formwork component includes a first retaining formwork and a second retaining formwork; the end formwork component includes a convex end formwork and a concave end formwork; and the space enclosed by the first external formwork, the second external formwork, the first internal formwork, the second internal formwork, the internal top formwork, the bottom formwork, the first retaining formwork, the second retaining formwork, the convex end formwork and the concave end formwork is used for pouring concrete. By mean of the integral hydraulic formwork applied to box culvert prefabrication, the prefabrication quality is high and stable, the adopted set shaped steel formwork has high surface rigidity, is not prone to deforming, and has good flatness.

Owner:INNER MONGOLIA ROAD & BRIDGE

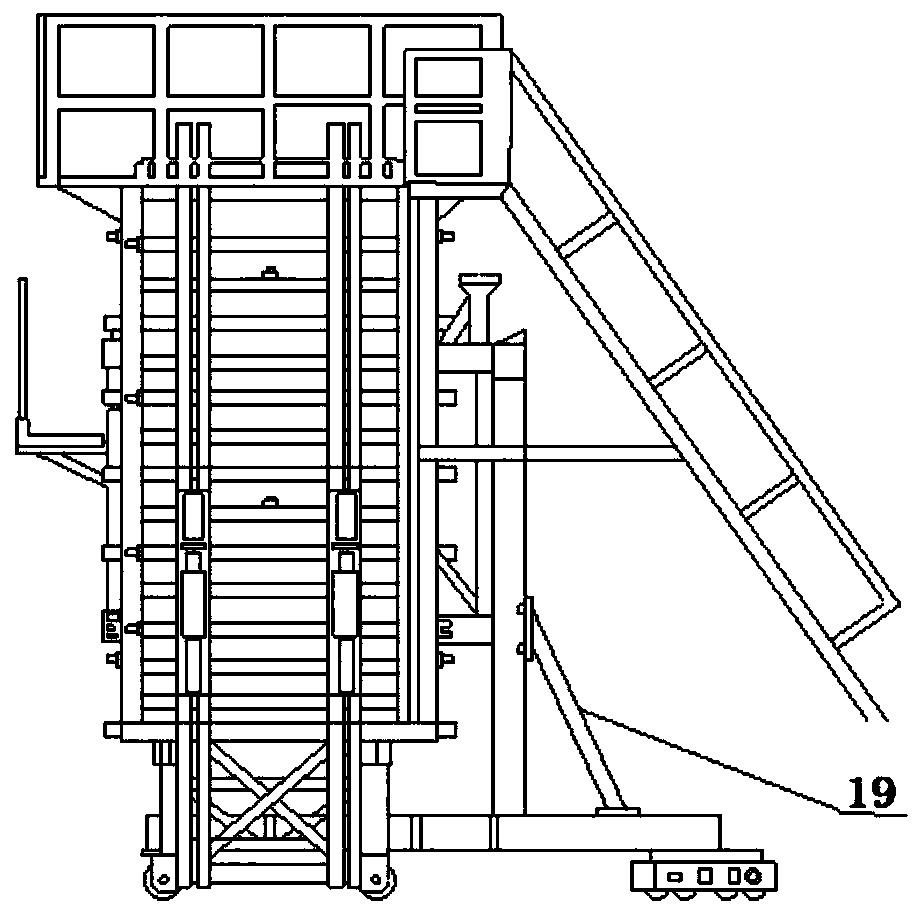

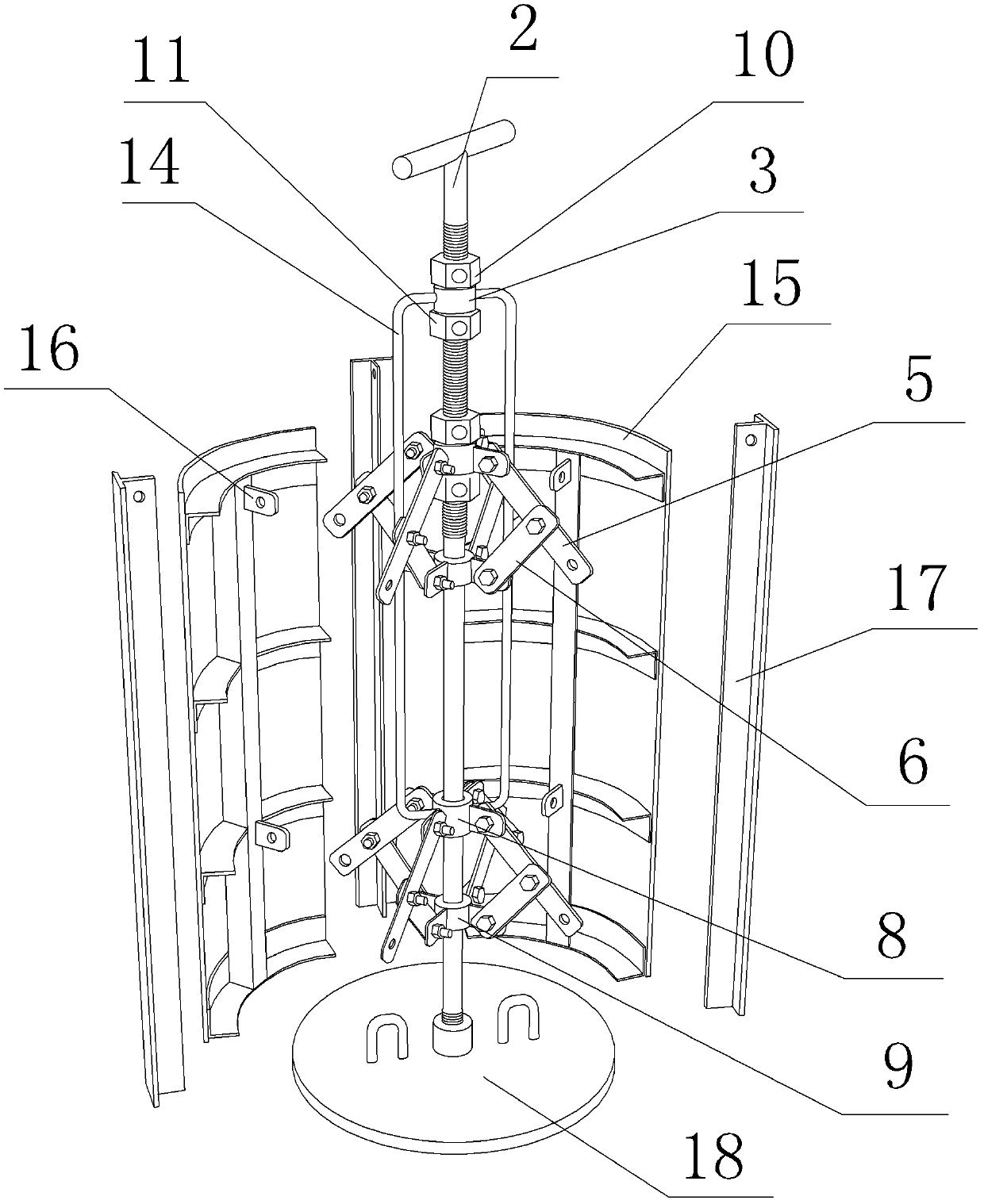

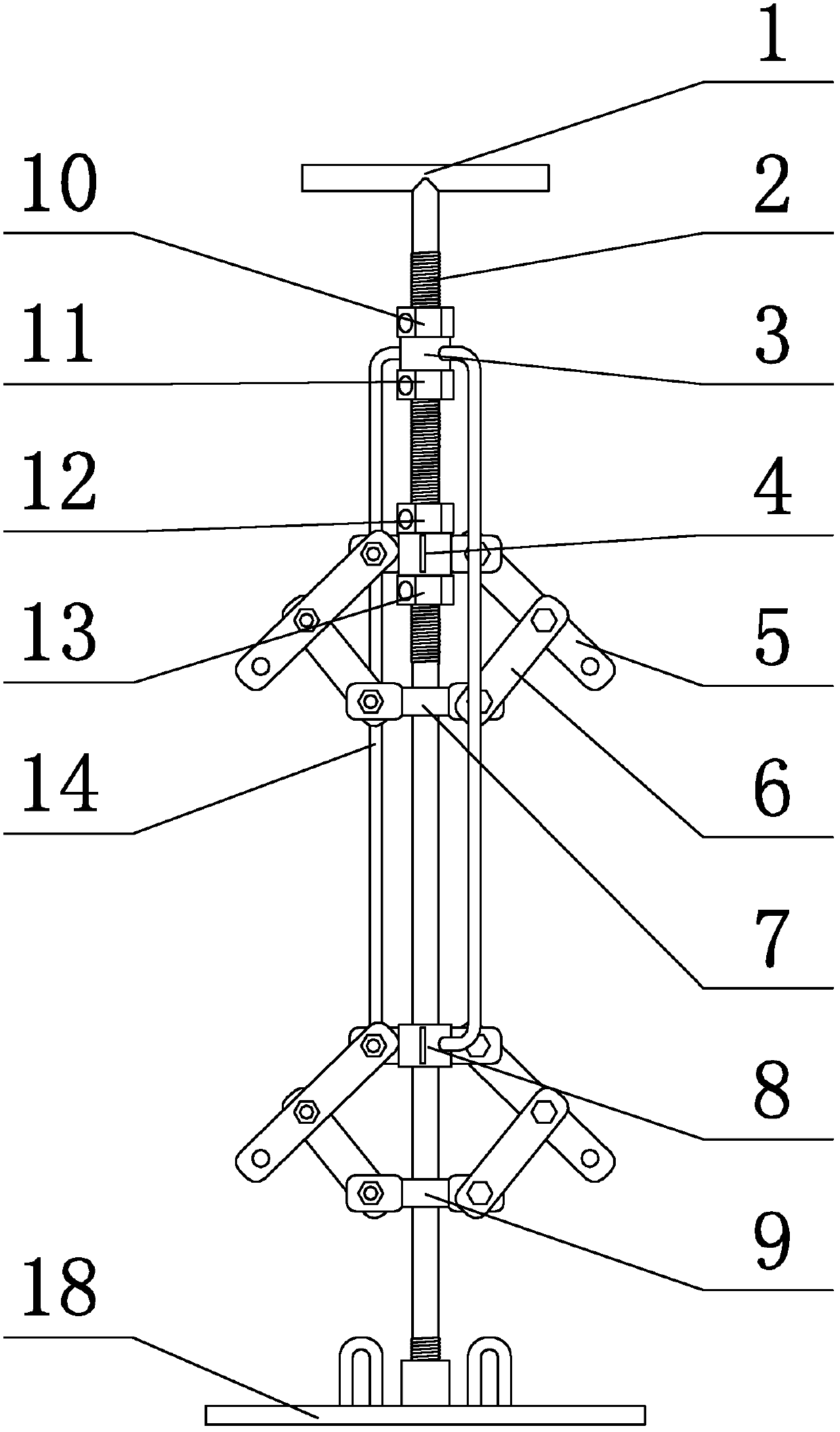

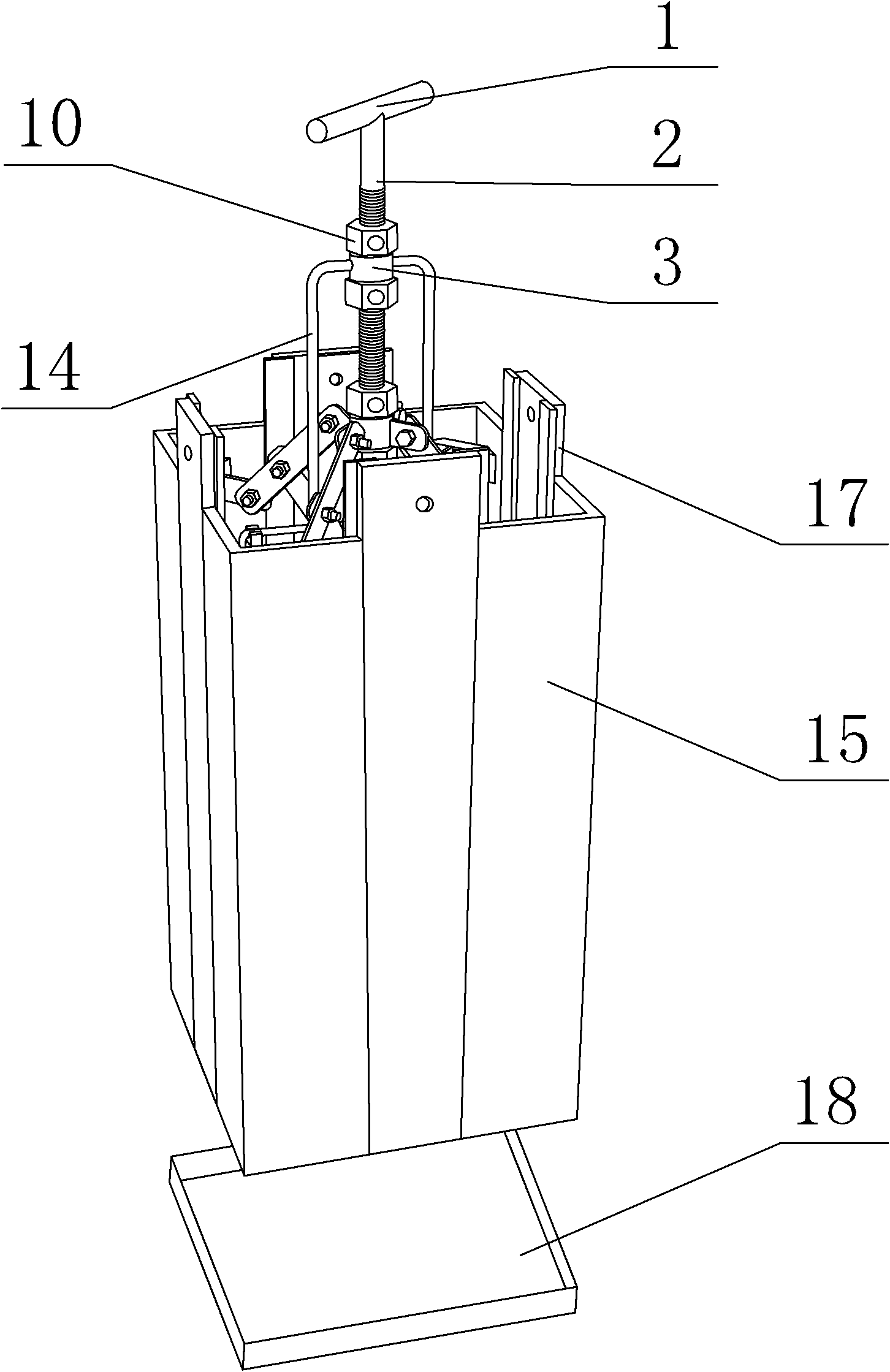

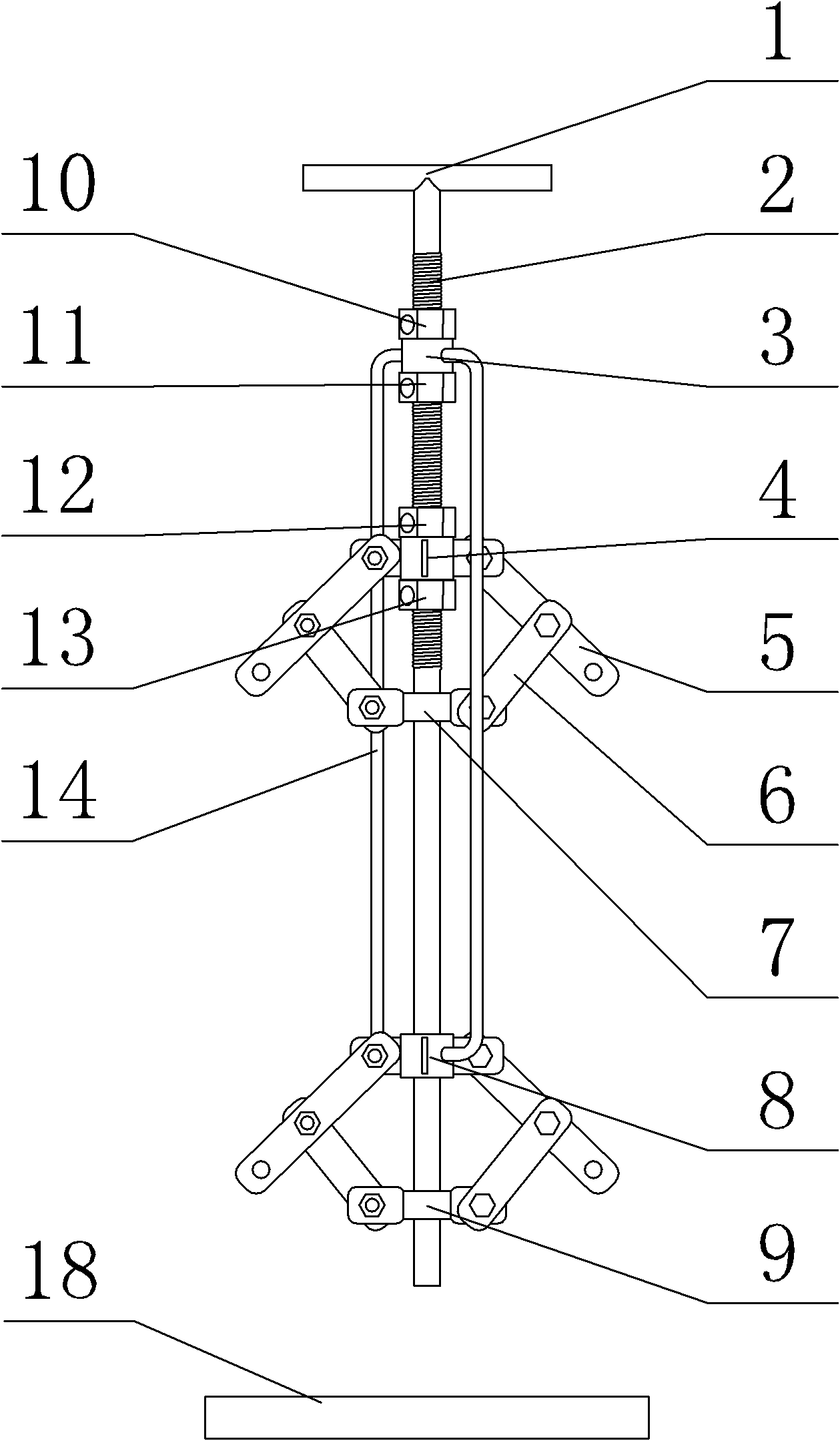

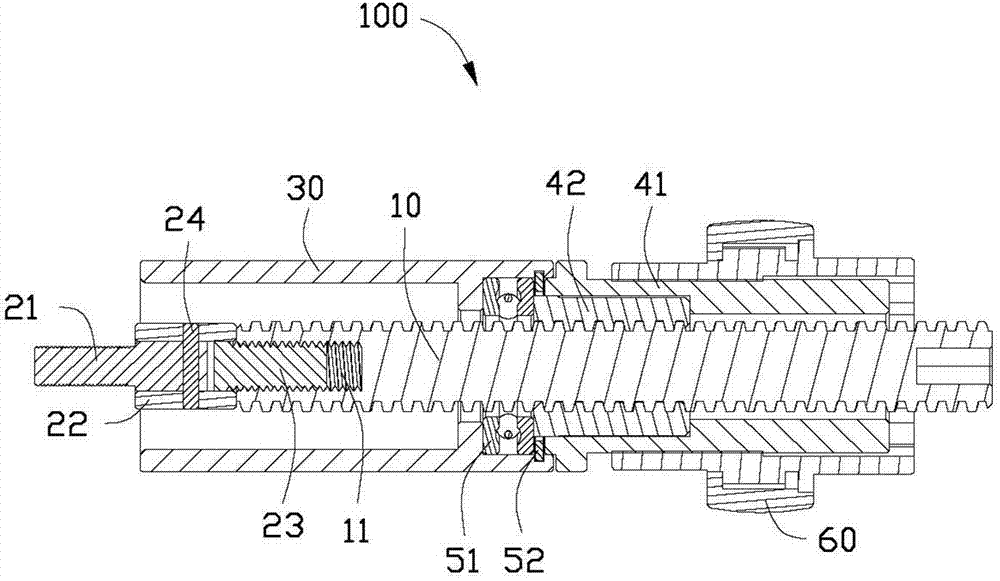

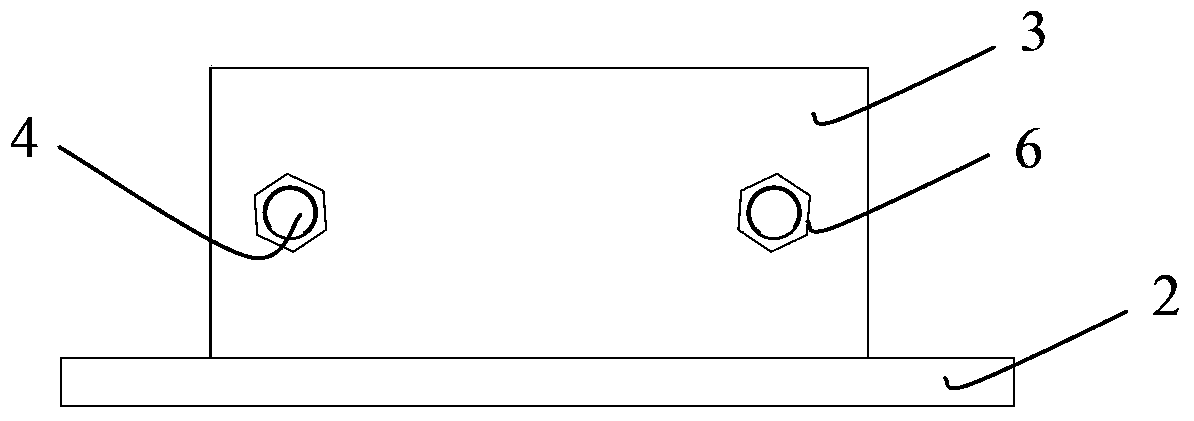

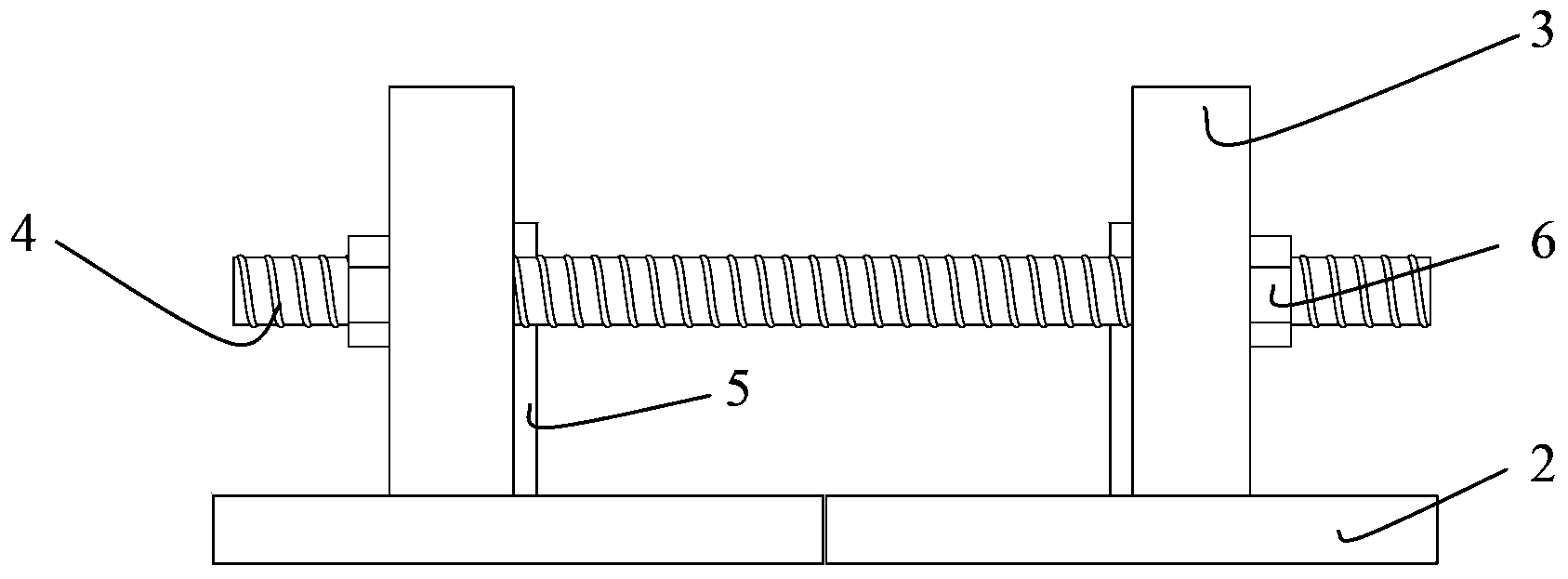

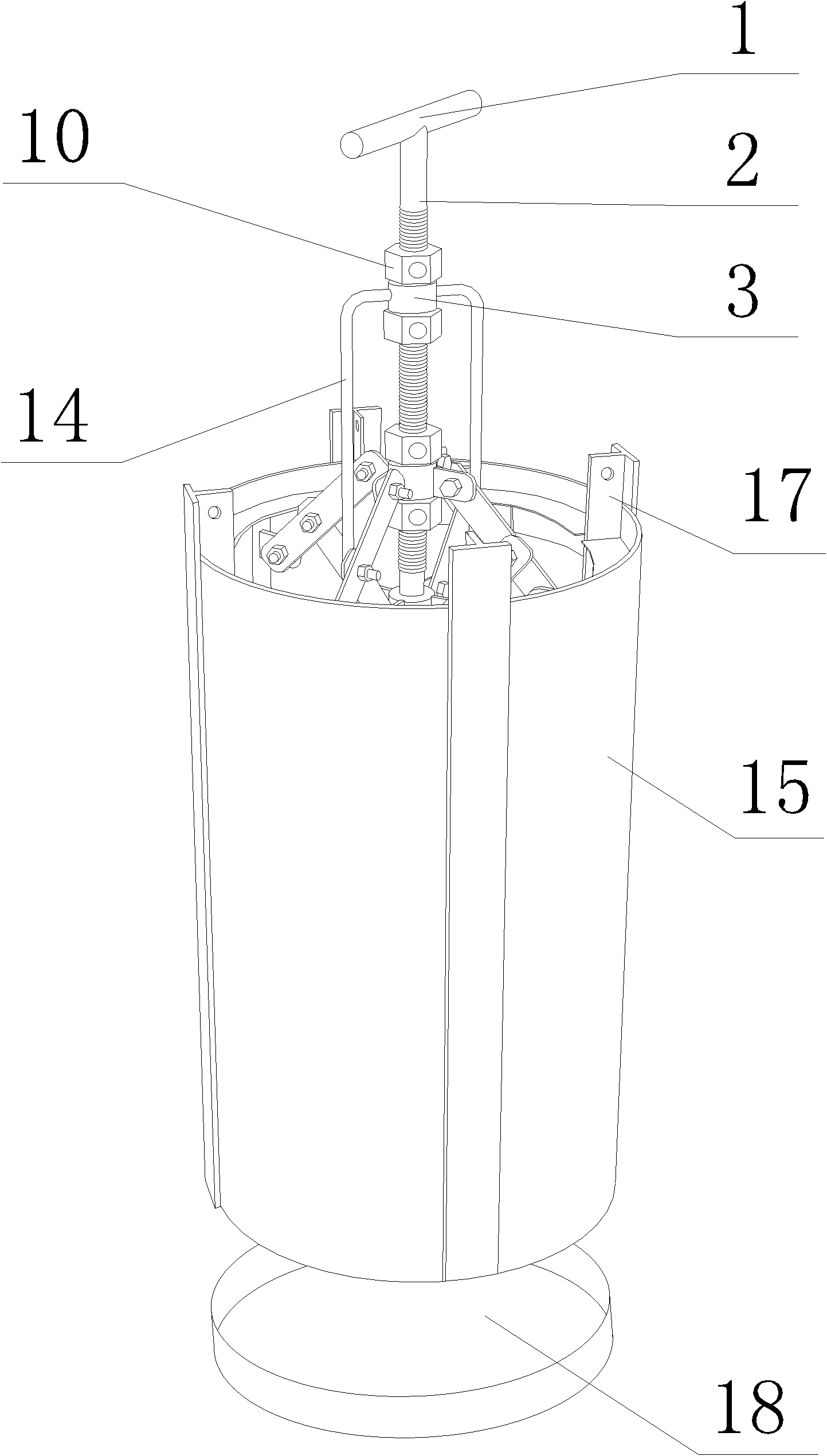

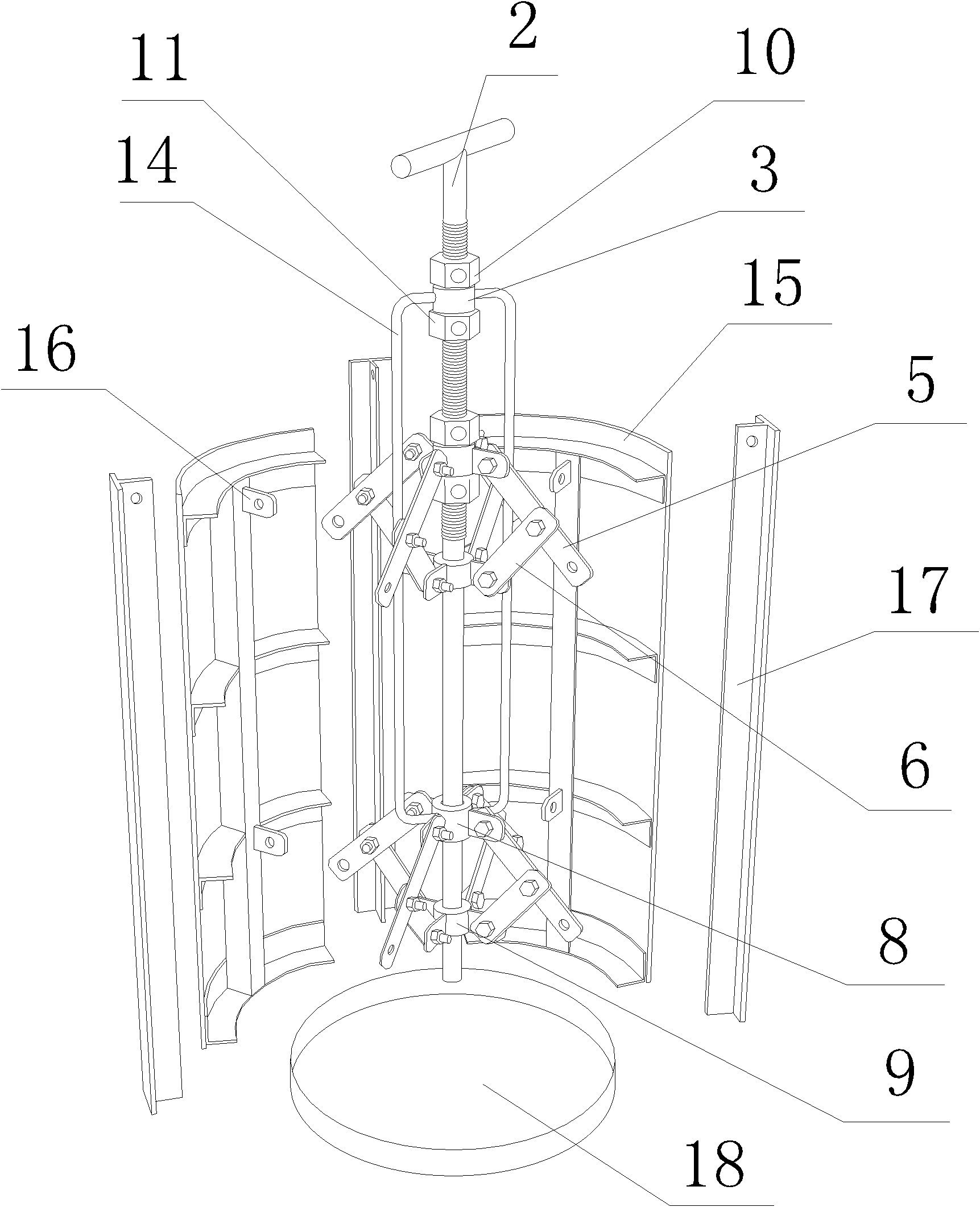

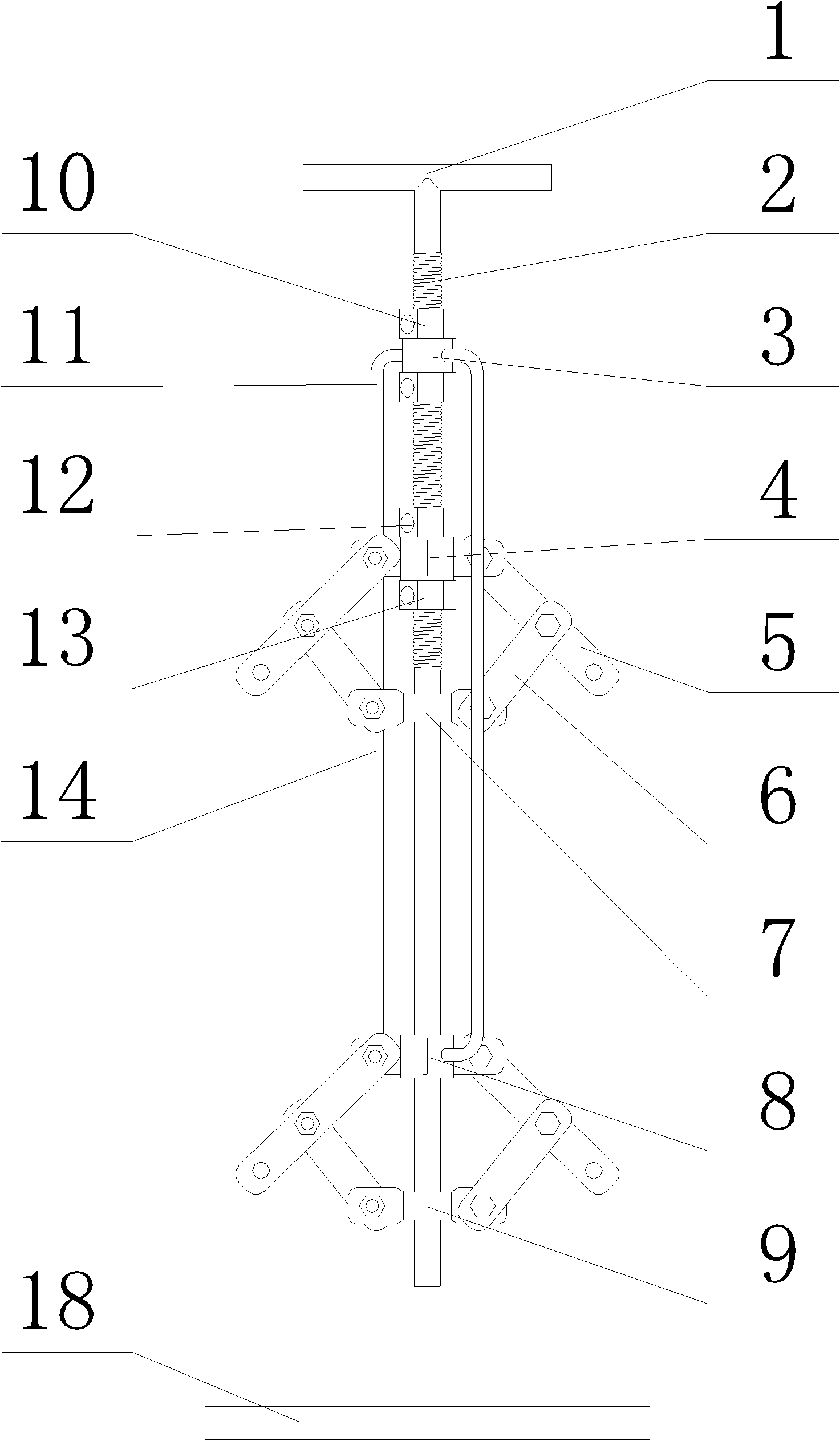

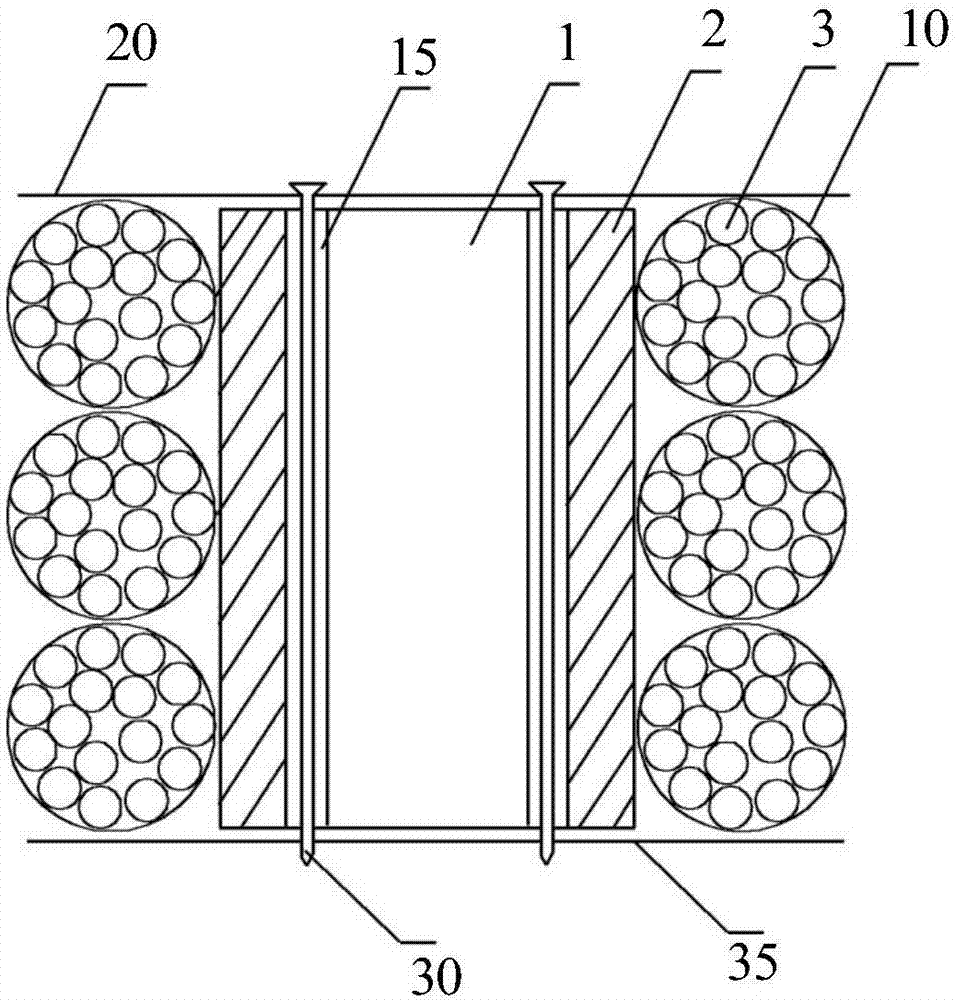

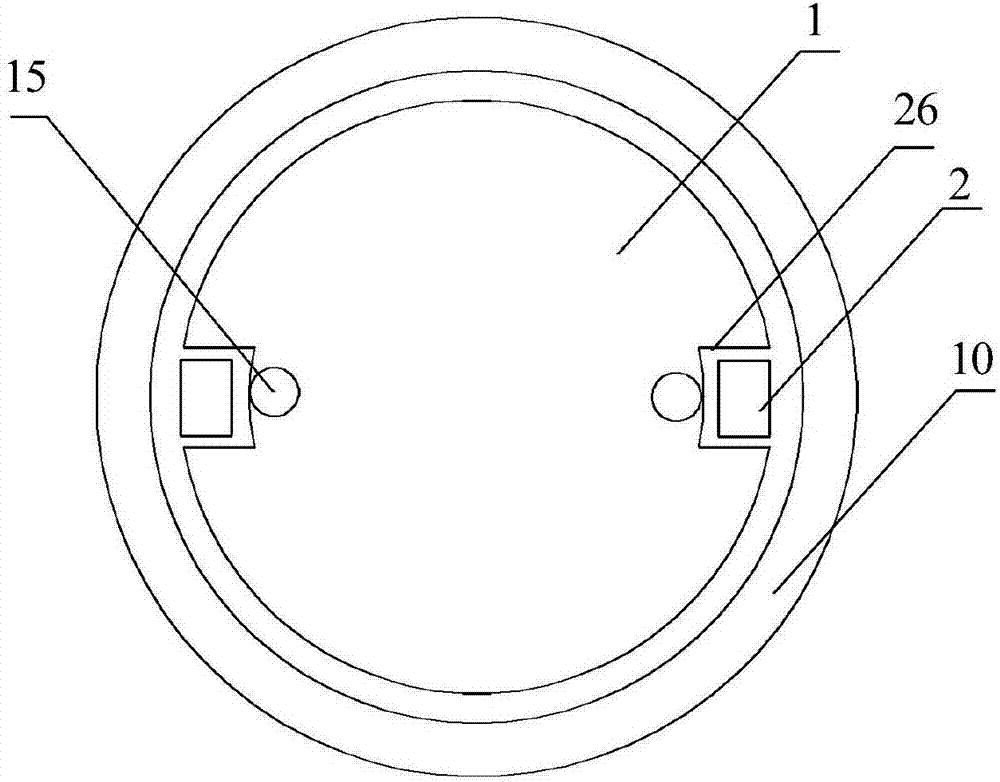

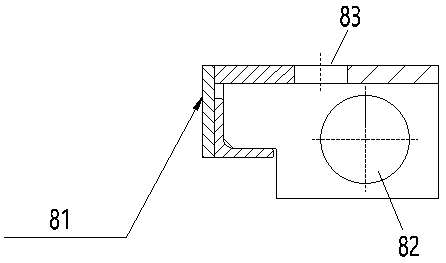

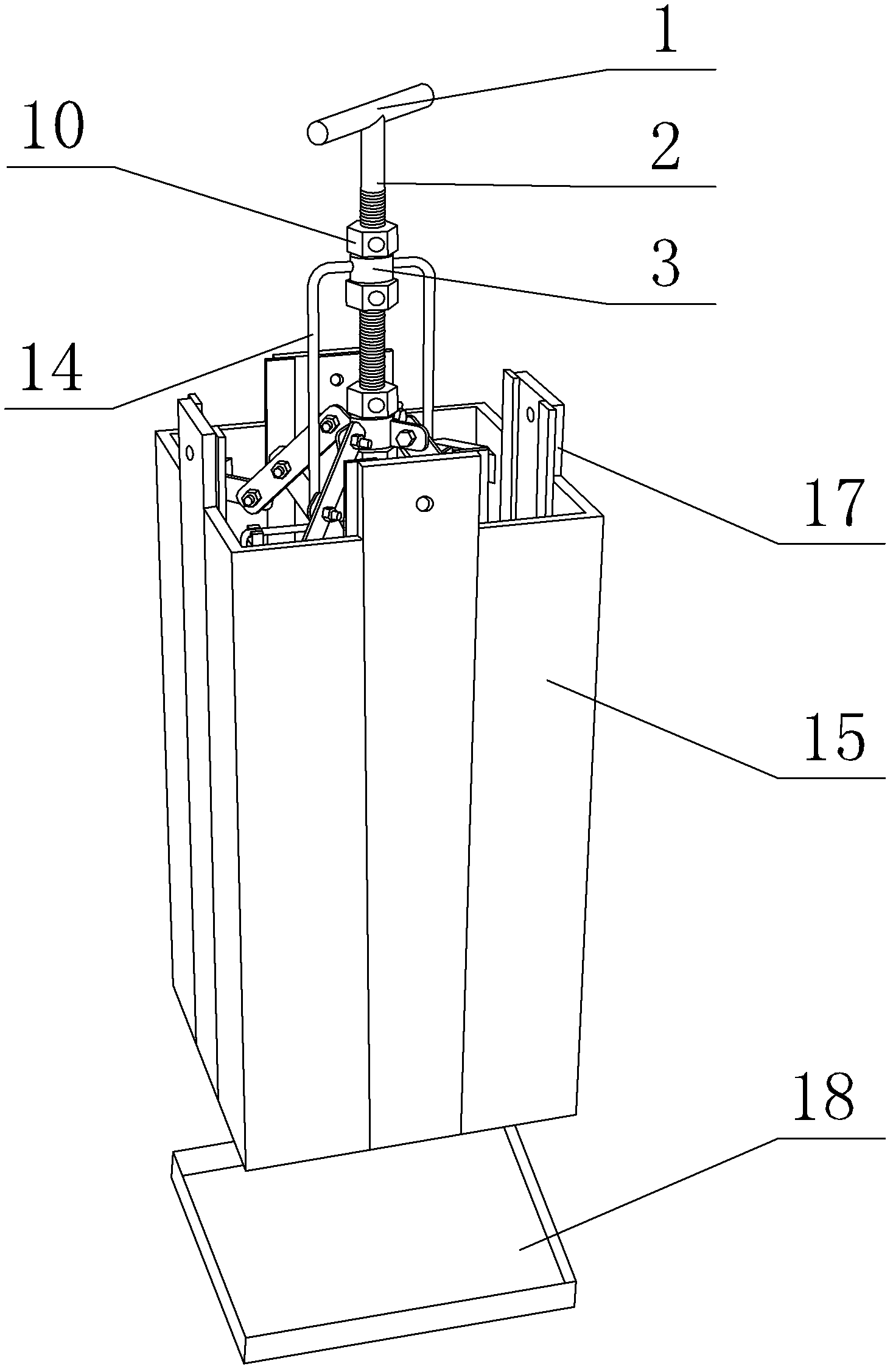

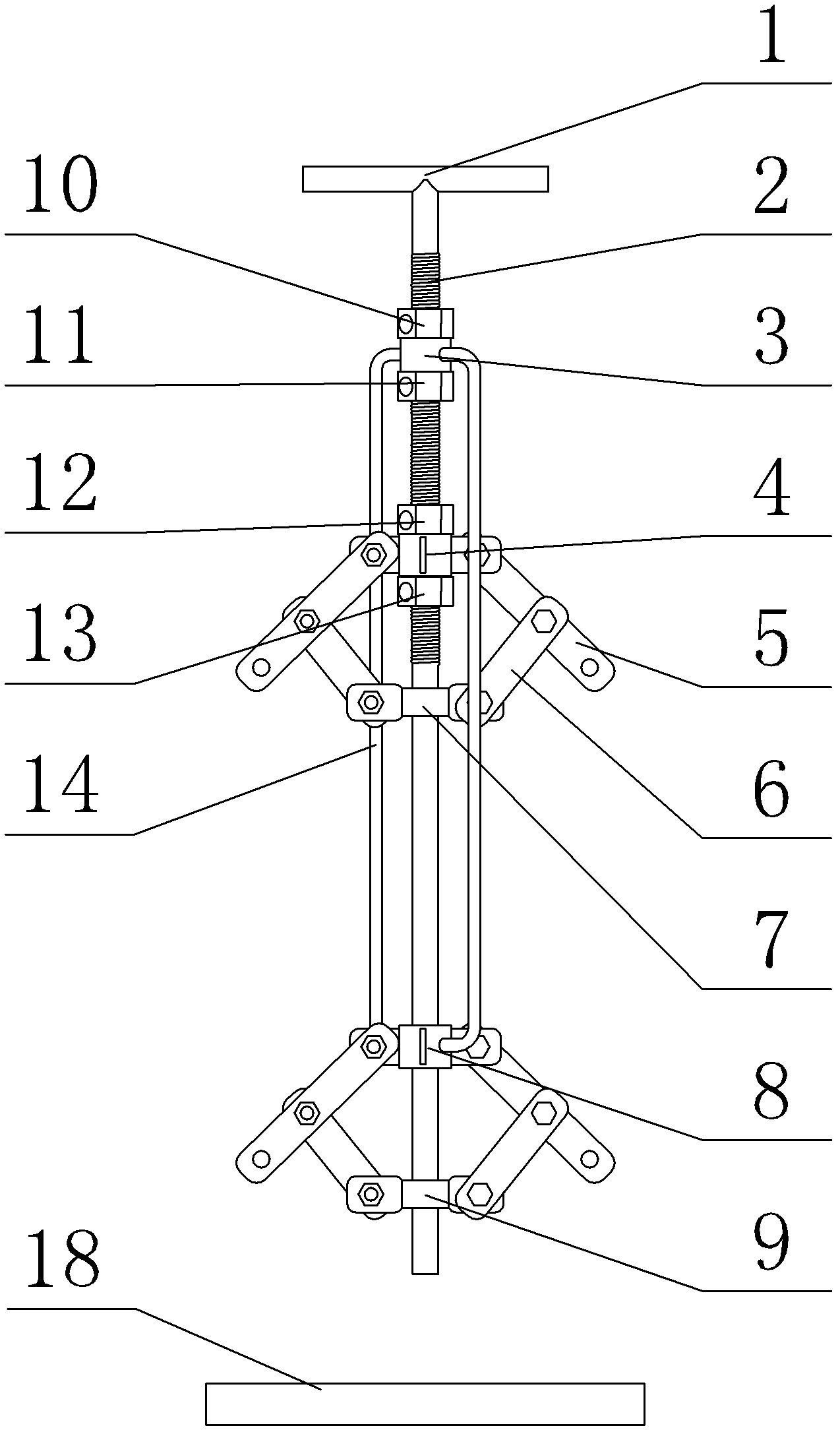

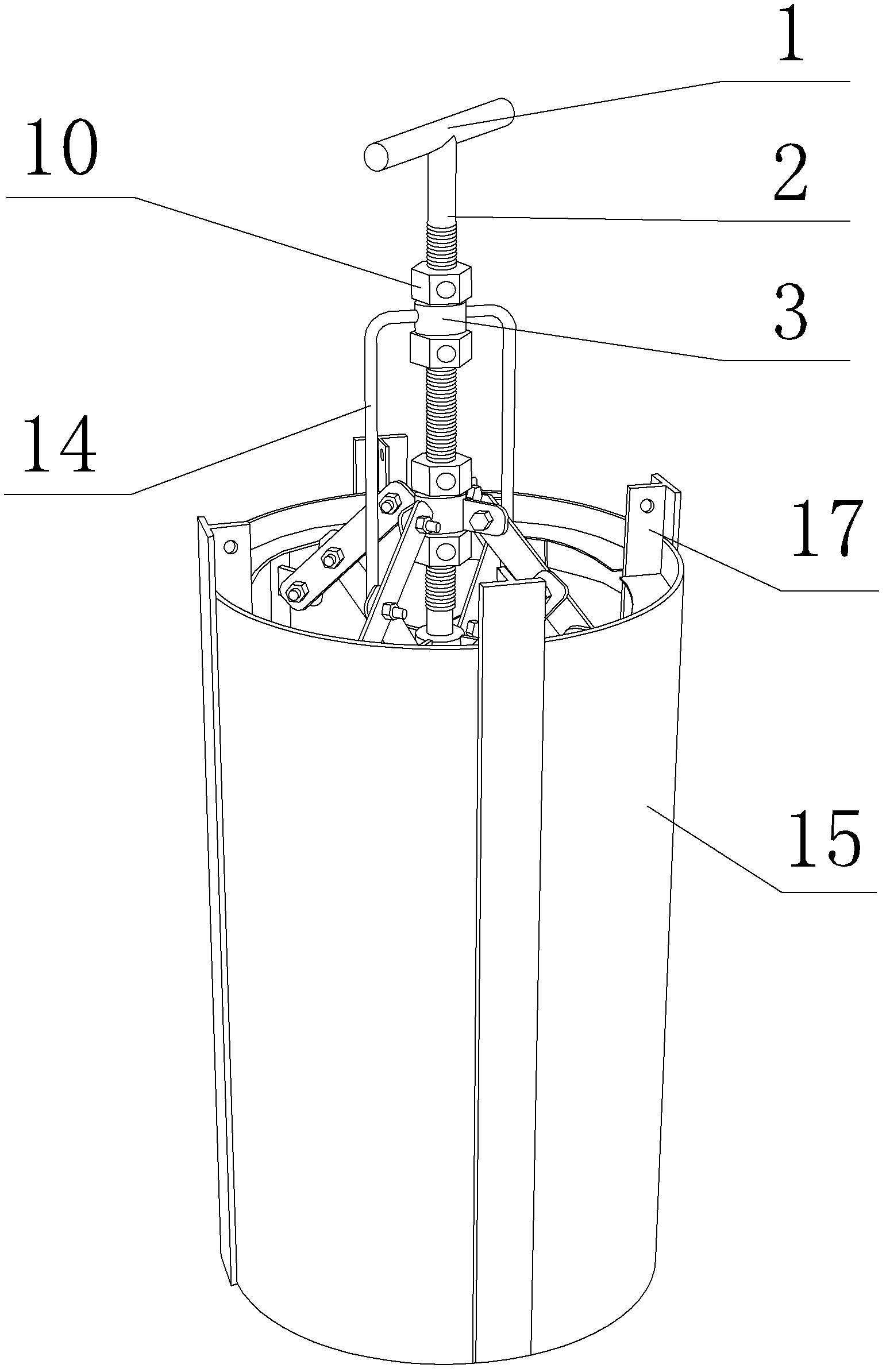

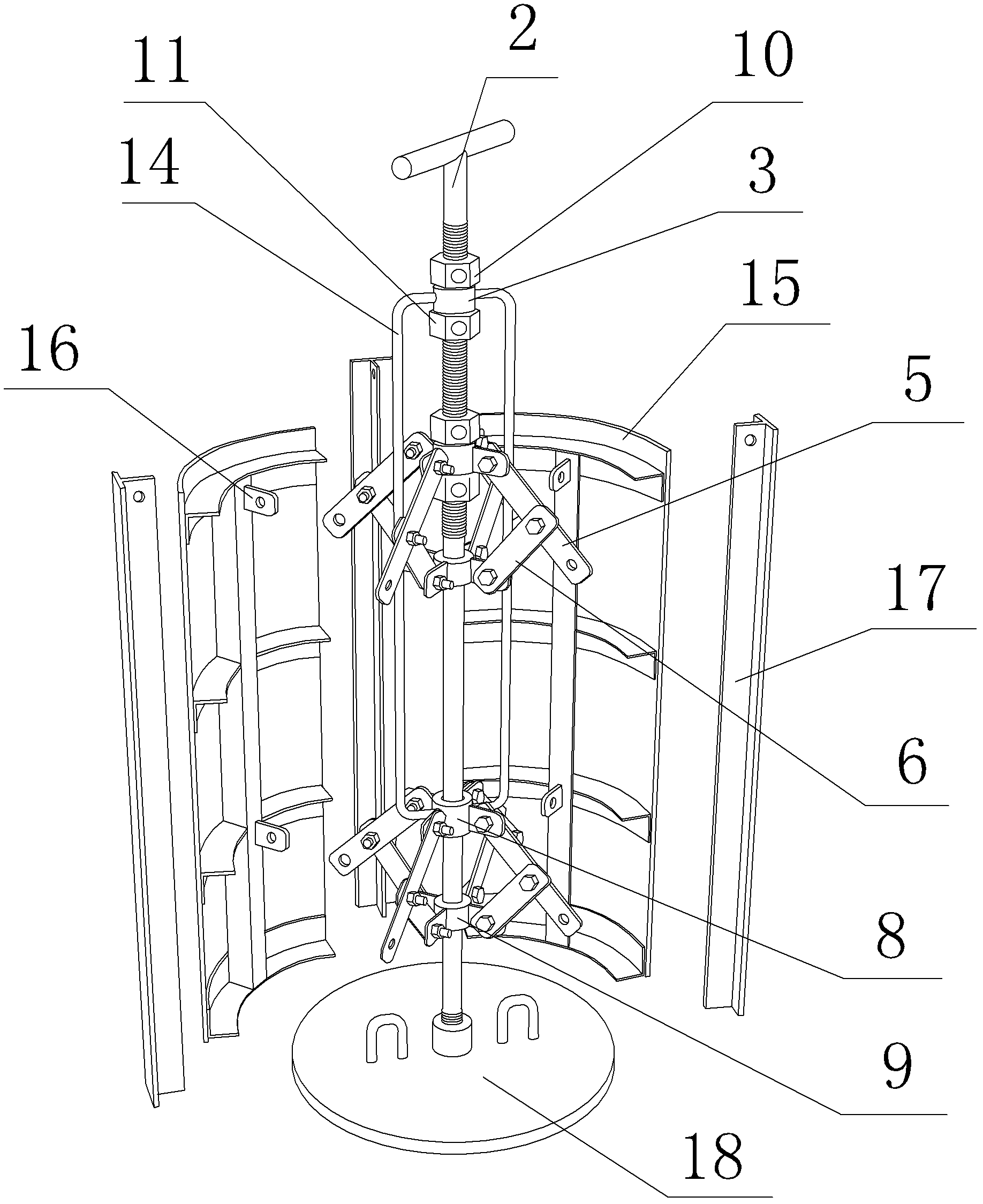

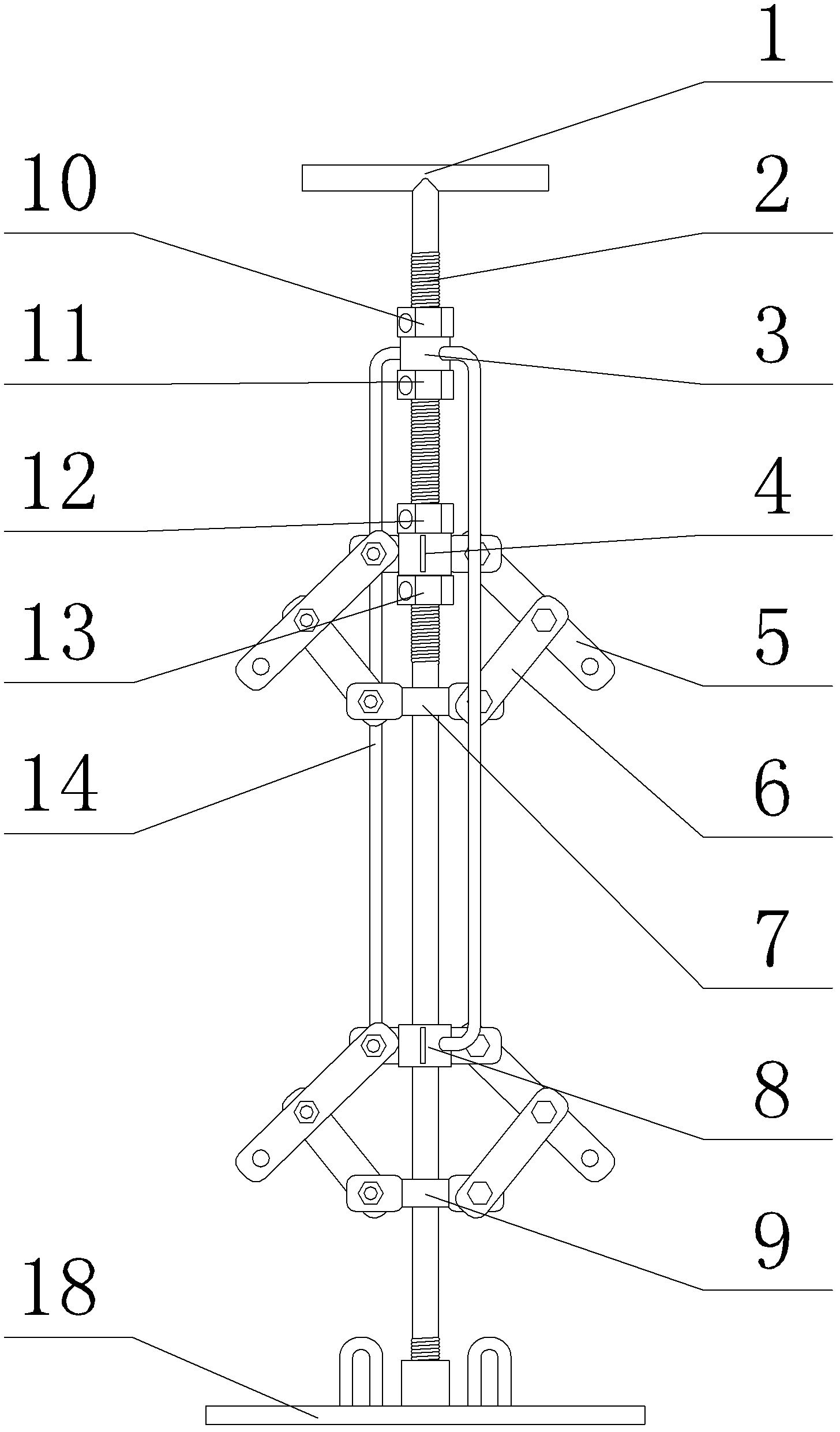

Equipment base pre-reservation round anchor bolt hole die

ActiveCN102433989AFlexible supportFlexible demolitionForms/shuttering/falseworksEngineeringScrew thread

The invention relates to a round hole die of an equipment base pre-reservation anchor bolt hole, in particular to an equipment base pre-reservation round anchor bolt hole die, which is characterized in that the equipment base pre-reservation round anchor bolt hole die comprises a center shaft, a first bracing and shrinking device, a second bracing and shrinking device, four templates and four joint sealing plates, wherein the four templates are all in an arc shape and uniformly distributed along a circumference, each joint sealing plate is inserted between two adjacent templates, the four templates and the four joint sealing plates enclose to form a cylindrical space, first template supports on the four templates are all articulated to the first bracing and shrinking device, second template supports on the four templates are all articulated to the second bracing and shrinking device, the lower part of the center shaft, the first bracing and shrinking device and the second bracing and shrinking device are all arranged in the cylindrical space enclosed by the four templates and the four joint sealing plates, the upper part of the center shaft is arranged above the cylindrical space and is provided with outside threads, and a handle is arranged at the upper end of the center shaft. The die is simple to operate and rapid to disassemble and can be used repeatedly.

Owner:CHINA FIRST METALLURGICAL GROUP

Shaping mold for reserved hole in concrete wall

InactiveCN101131042AIncrease stiffnessImprove deformation abilityForms/shuttering/falseworksScrew threadBuilding construction

The present invention discloses one kind of mold used in building construction for setting the reserved holes in concrete wall. The mold includes one mold frame comprising formworks and one inside formwork supporting device. The formwork supporting device includes one middle screw bolt with alternately arranged forward threads and backward threads connected to the upper and lower sides of the mold frame for regulating the mold height, and one four-rod link drive mechanism connected to the right and left sides of the mold frame for regulating the mold width. In addition, the mold frame has also reinforcing ribs and thus enhanced rigidity and certain deforming ability. The setting mold has high rigidity, easy assembling and disassembling, reuseability, low cost and capacity of raising construction efficiency.

Owner:RONGHUA CONSTR GRP CO LTD

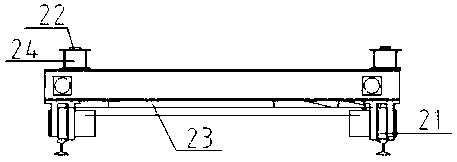

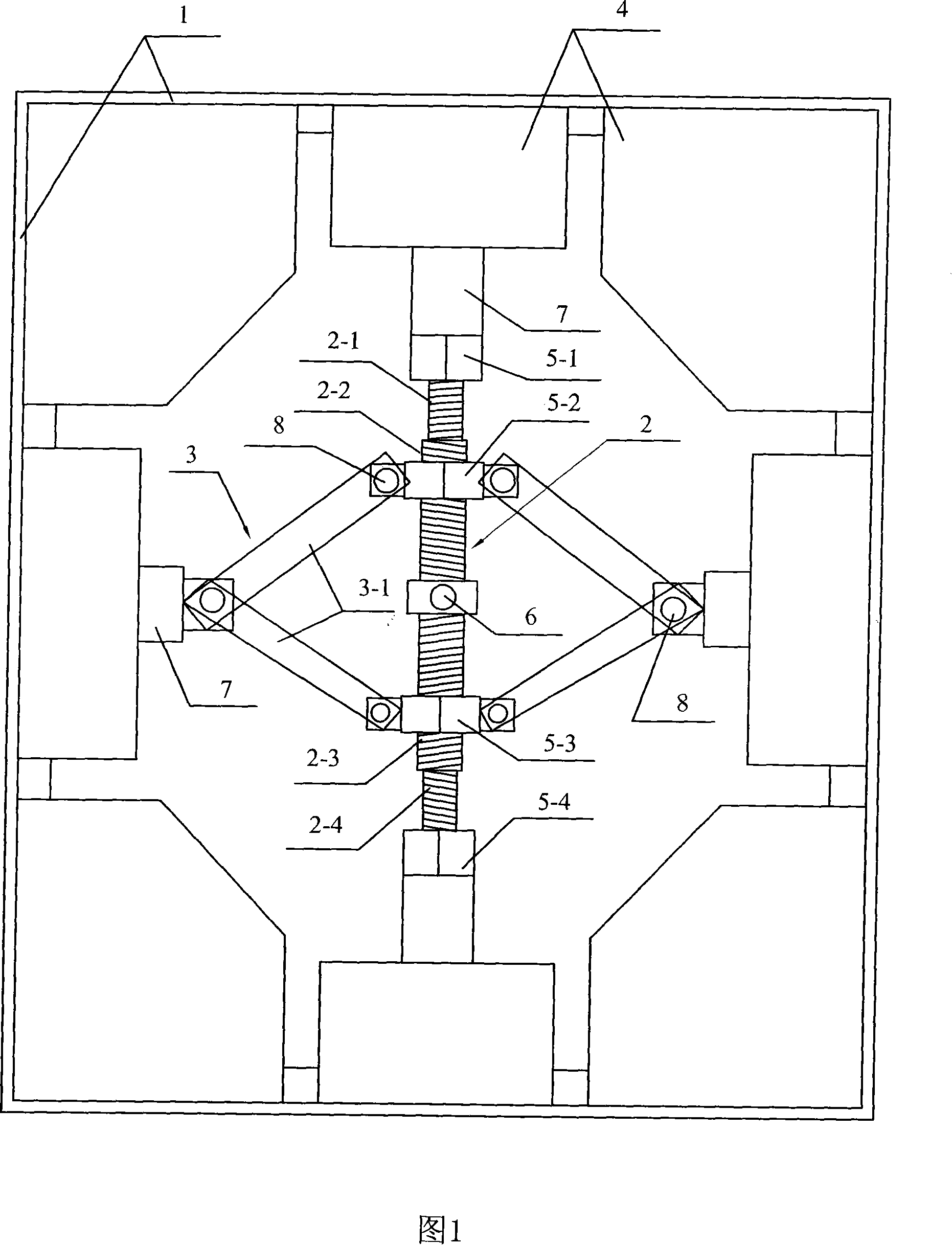

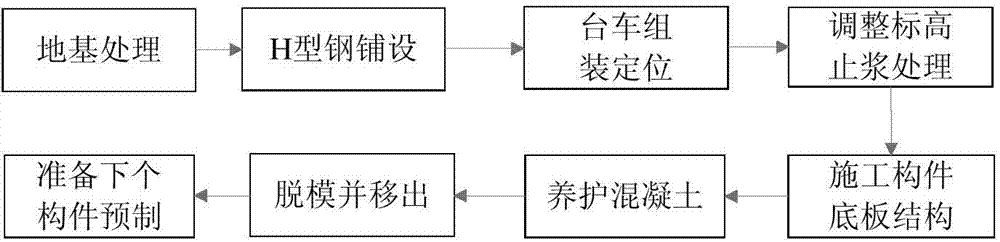

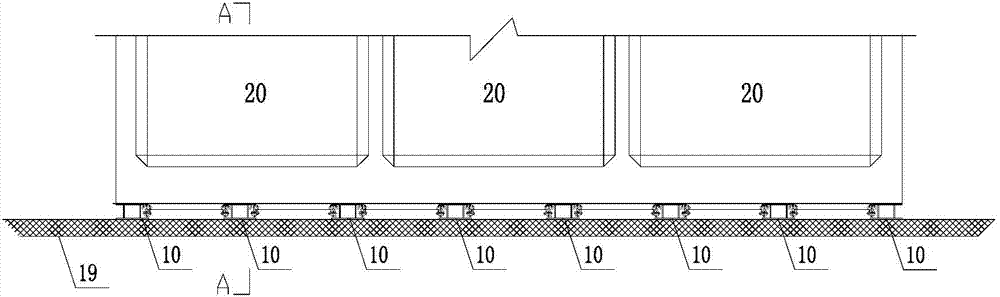

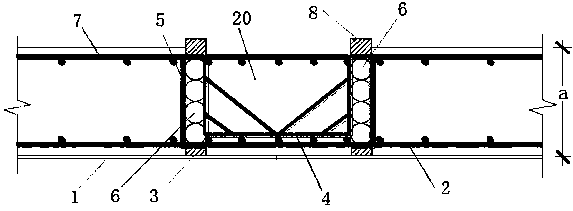

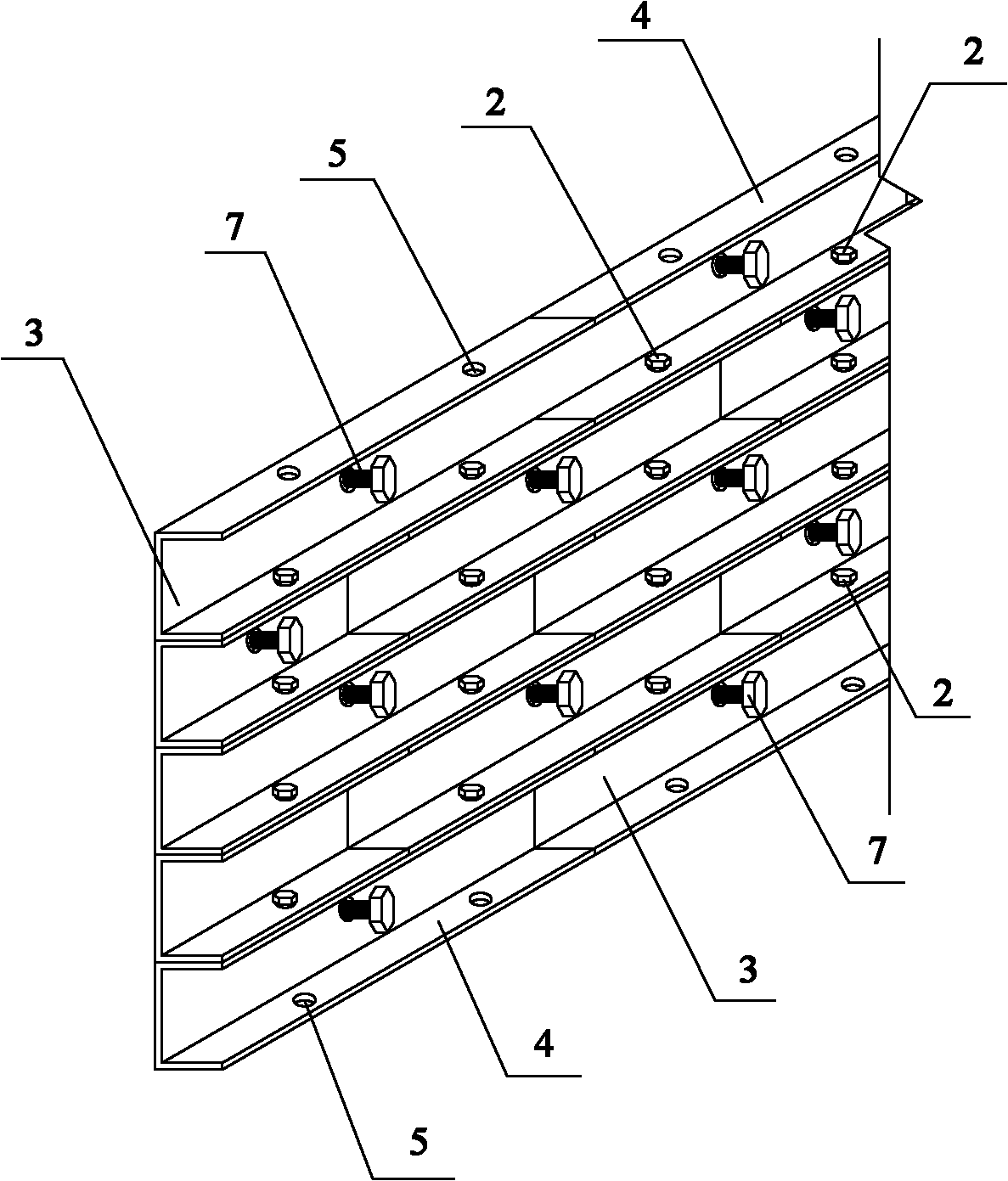

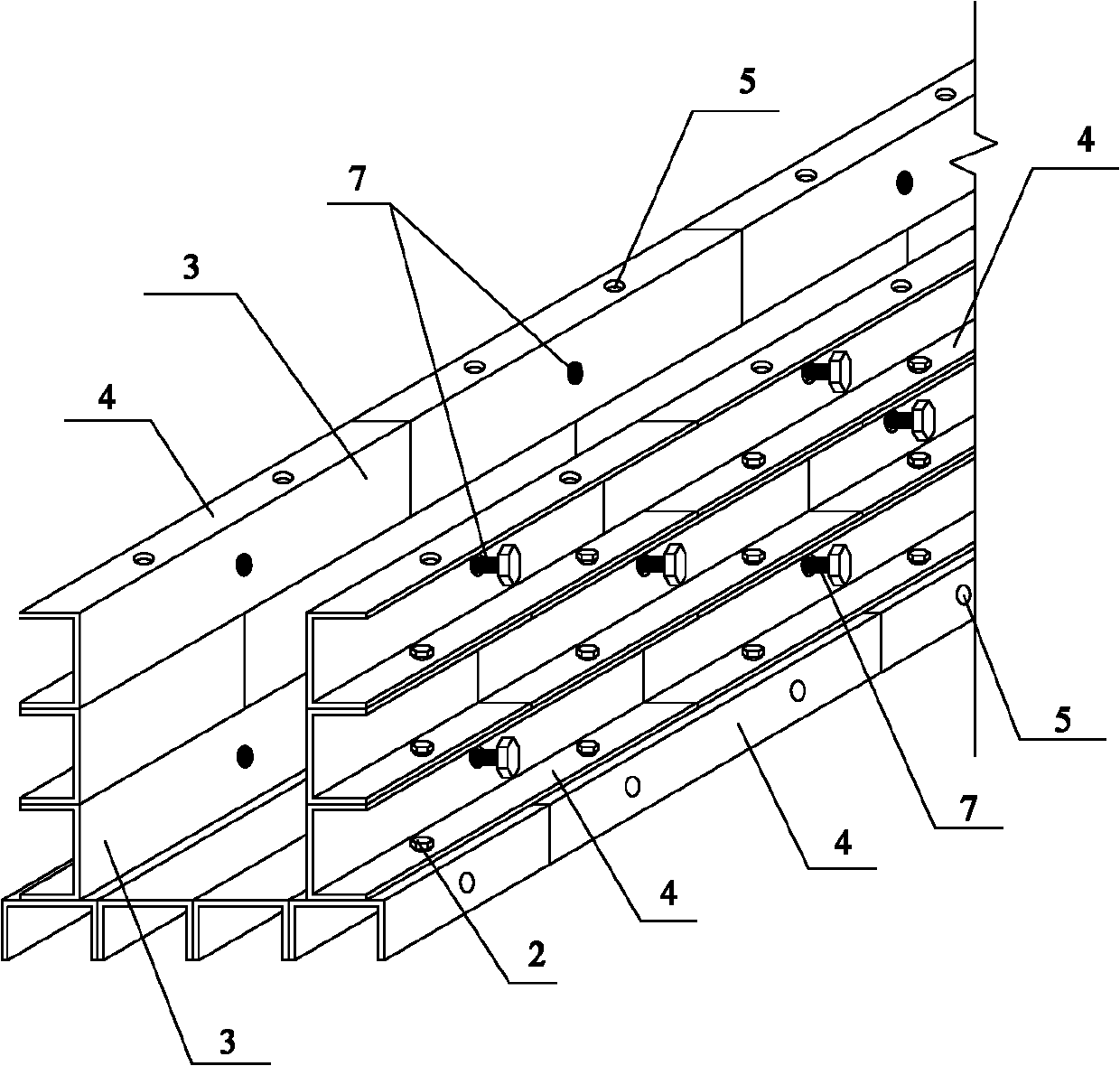

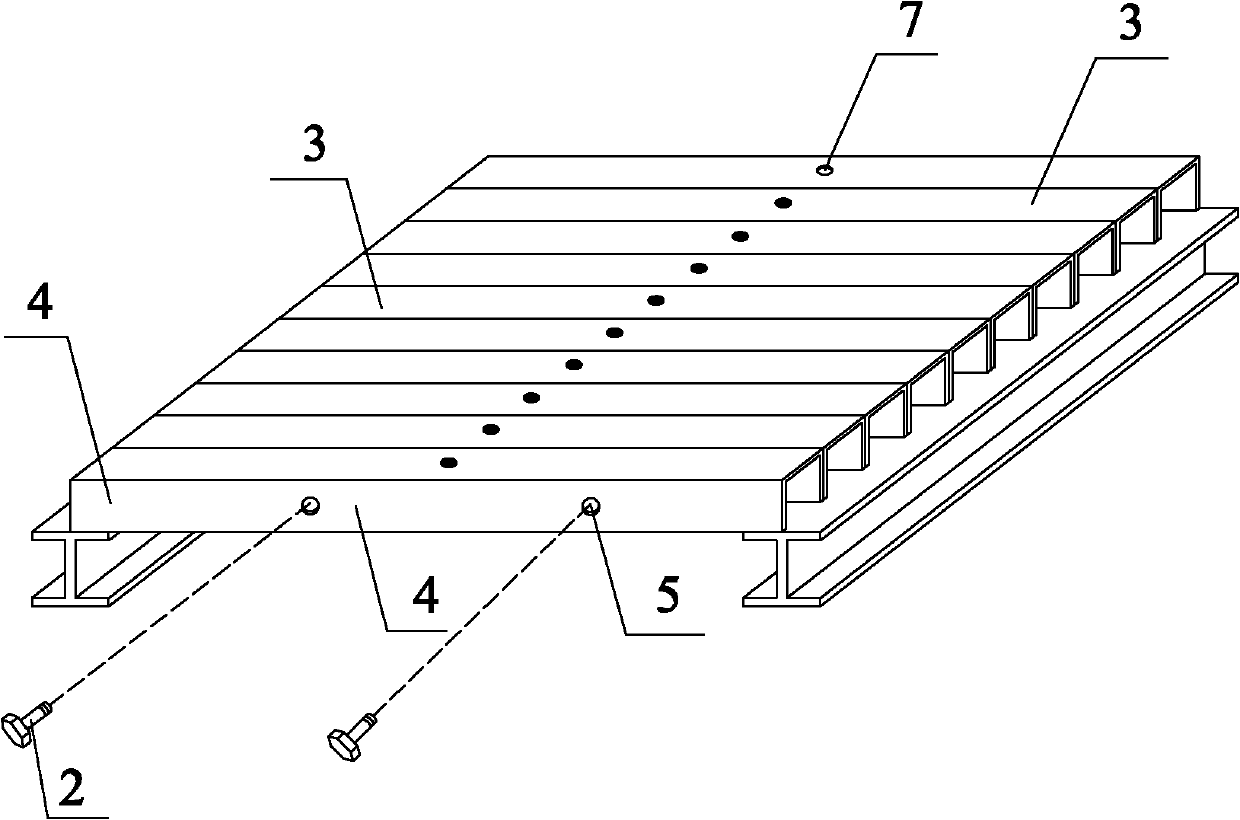

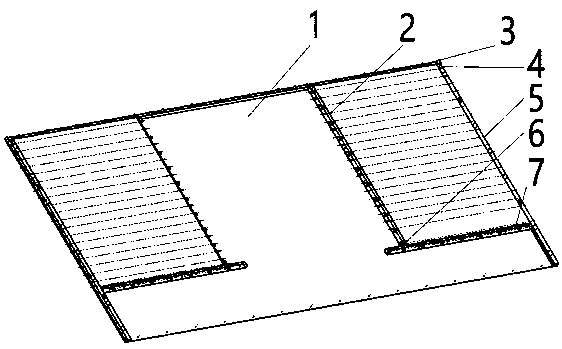

Movable bottom formwork trolley system suitable for large concrete prefabricated component and method for prefabricating base plate of large concrete component

ActiveCN104727229ATaking into account the transferQuick assemblyBridge erection/assemblyBuilding material handlingStructural engineeringRelease agent

The invention provides a movable bottom formwork trolley system suitable for a large concrete prefabricated component. The movable bottom formwork trolley system comprises multiple movable bottom formwork trolleys and multiple H-bars. A locating groove is formed between the adjacent H-bars. The movable bottom formwork trolleys are arranged in the locating grooves. Each movable bottom formwork trolley comprises multiple bottom formwork trolley units which are connected in series and at least one bottom formwork steel plate with the surface coated with release agent, wherein the bottom formwork steel plates are independent of the bottom formwork trolley units. Each bottom formwork trolley unit comprises multiple sets of bearing devices, multiple pairs of traveling wheels and a formwork lifting device. The formwork lifting devices are connected with the bearing devices, located below the bottom formwork steel plates and used for lifting or descending the bottom formwork steel plates, so that in concrete pouring process, the top surfaces of the bottom formwork steel plates and the top surfaces of wing plates of the H-bars are located on the same plane, and therefore a bottom formwork plate of the large concrete component can be formed. Through different splicing combinations, the prefabricated bottom formworks can be formed for the large concrete prefabricated component of different types and sizes, the bottom formwork can be quick spliced and detached and also can be used for transfer of the component is also considered.

Owner:中交四航局第五工程有限公司 +1

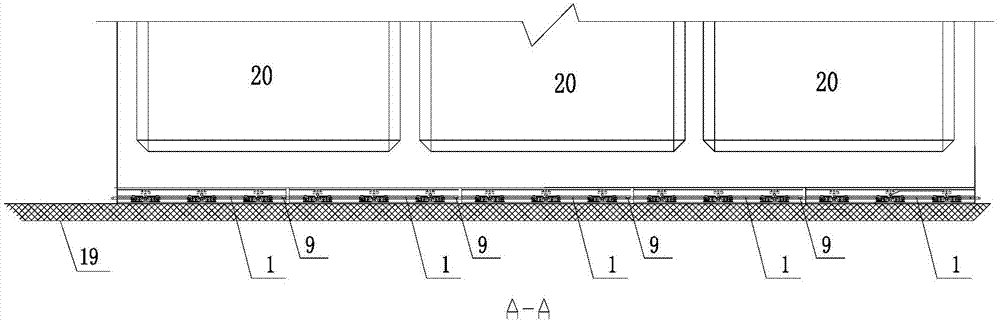

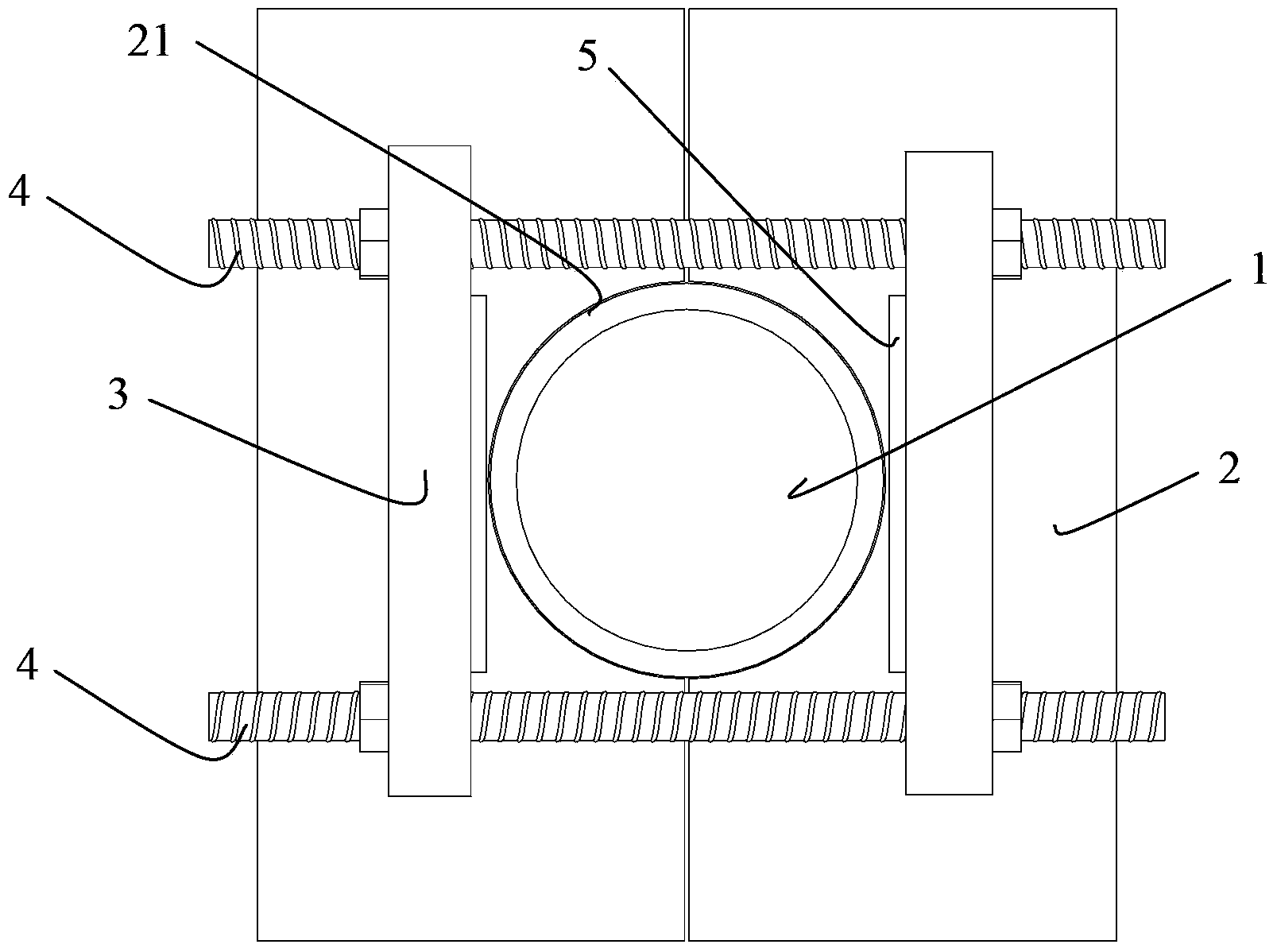

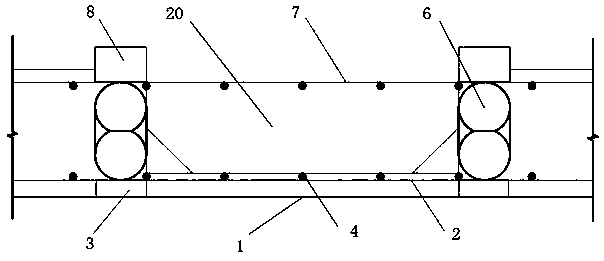

'n' shaped element mold for precasting reinforced concrete culvert

ActiveCN1843727AQuick demolitionImprove control accuracyMould separation apparatusMouldsRear quarterReinforced concrete

The invention relates to a prefabricated reinforced concrete culvert T-shape mould, which can solve the problems of hard installment, hard control on the verticality and surface smoothness; loose connection between plates, and concrete leakage, etc. The invention comprises a bottom support, a bottom plate mould, and side plate moulds, while said mould is rectangle whose two sides are mounted with side moulds (2); and two ends are mounted with support side moulds (4); two ends of side mould (2) are mounted with side plate fixed skeletons (5); side moulds () and the support side mould (4) and the side plate fixed skeleton (5) form special-shaped side mould; the baffle mould (6), chair-shaped bottom plate mould (7) and the trapezium bottom mould (8) form the bottom support mould; and the side mould forms the whole mould with bottom support mould. The invention has simple structure and easy installment, which can save cost and labor force, to improve the construction speed and quality.

Owner:刘山健

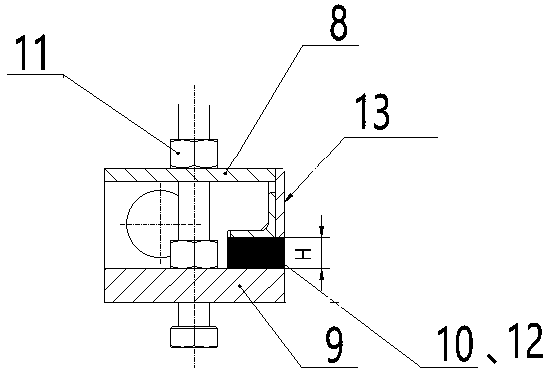

Reusable die for equipment foundation reserved square hole

ActiveCN102493480AFlexible demolitionQuick dismantlingForms/shuttering/falseworksFoundation engineeringEngineeringMechanical engineering

Owner:CHINA FIRST METALLURGICAL GROUP

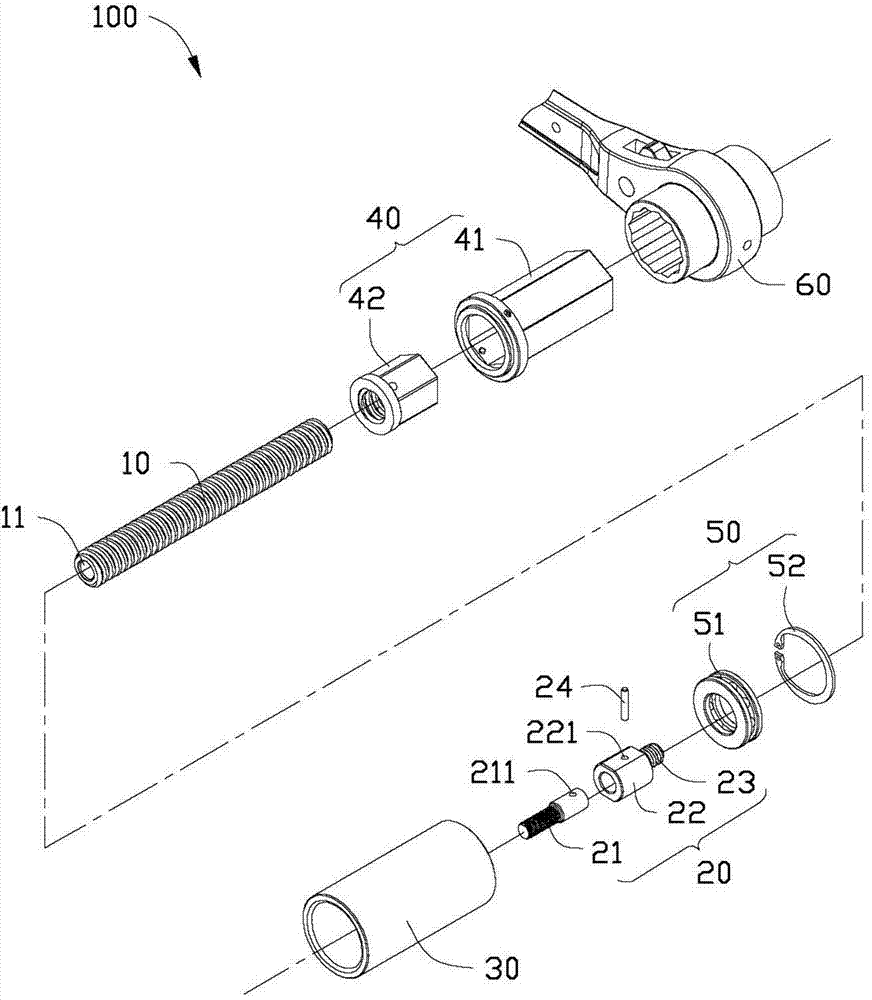

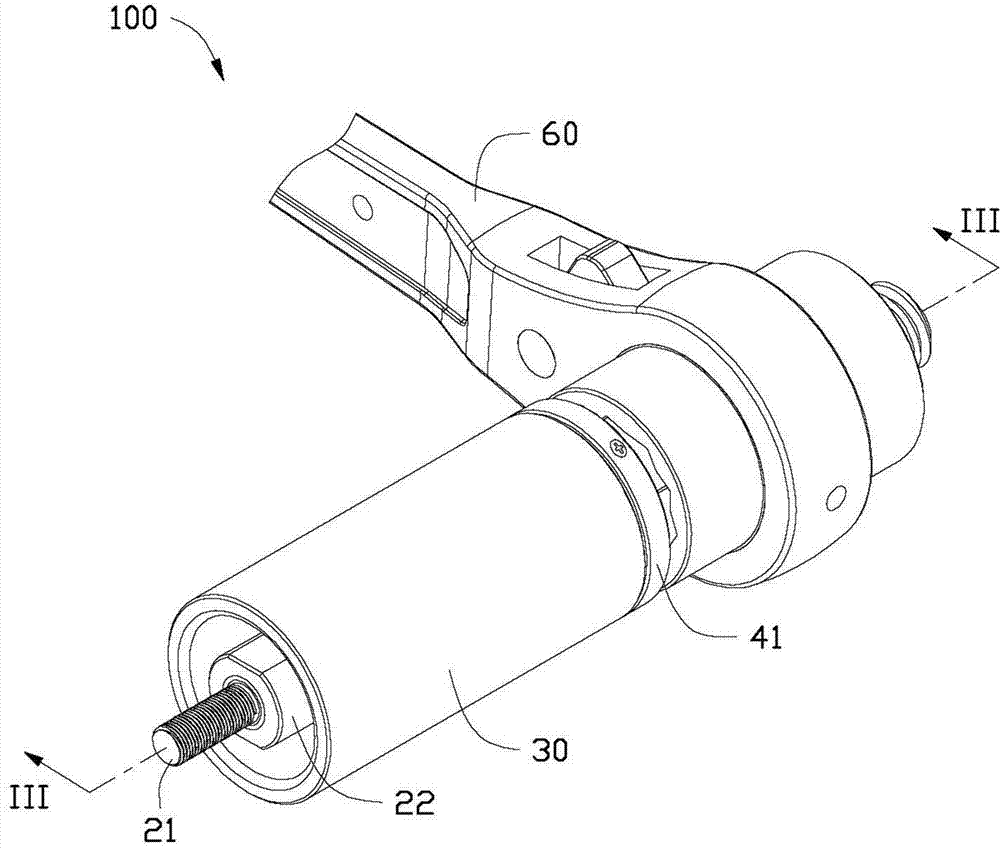

Drawing device

InactiveCN102814779ASimple structureEasy to operateMetal-working hand toolsEngineeringMechanical engineering

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

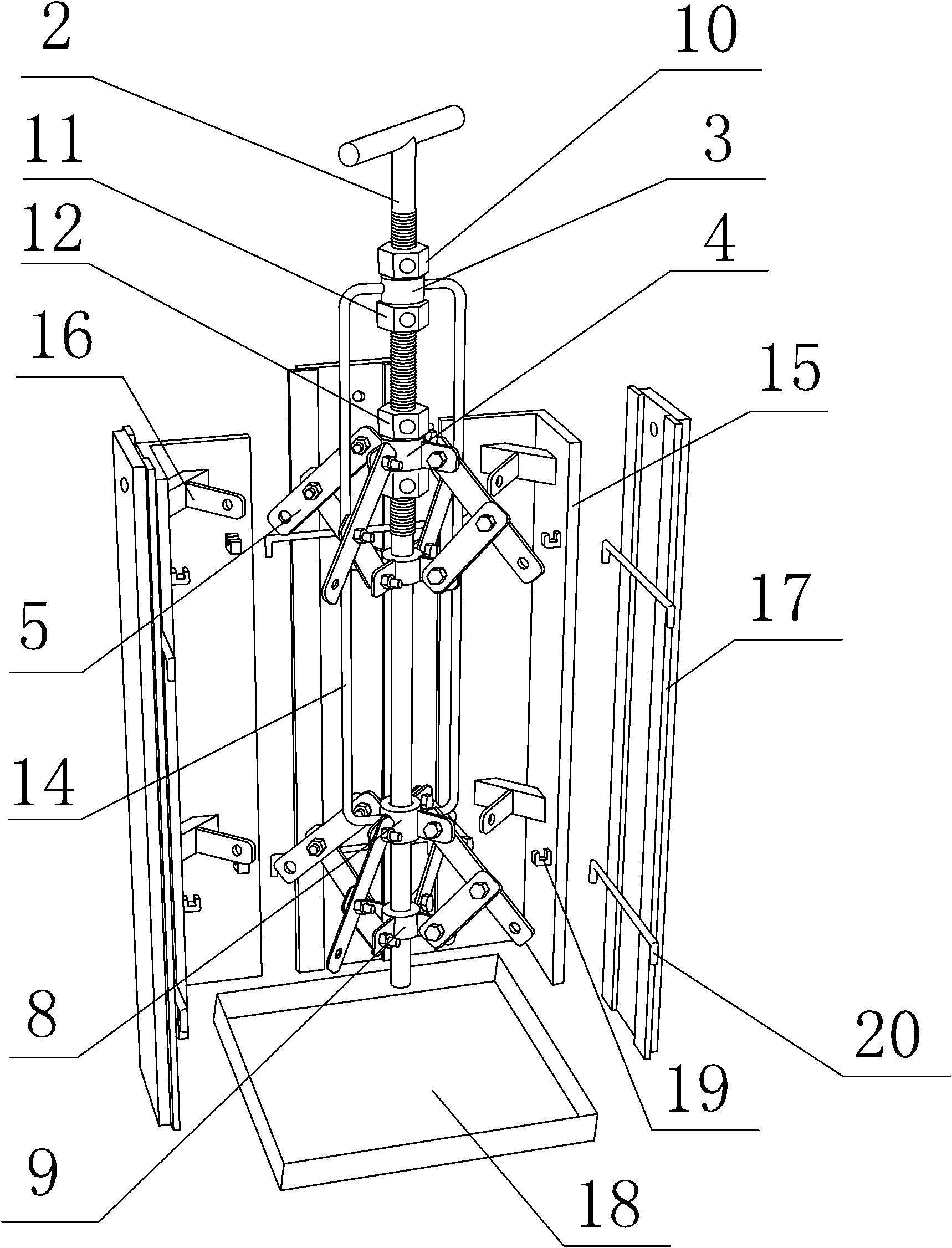

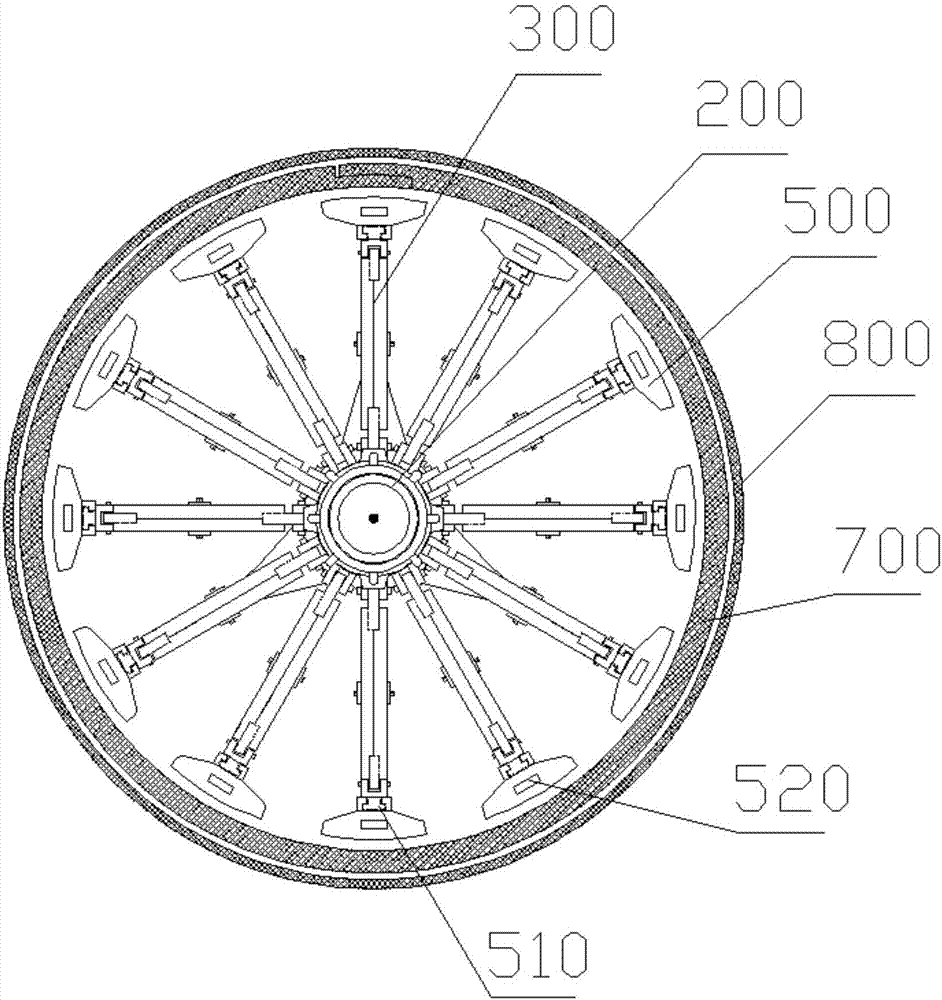

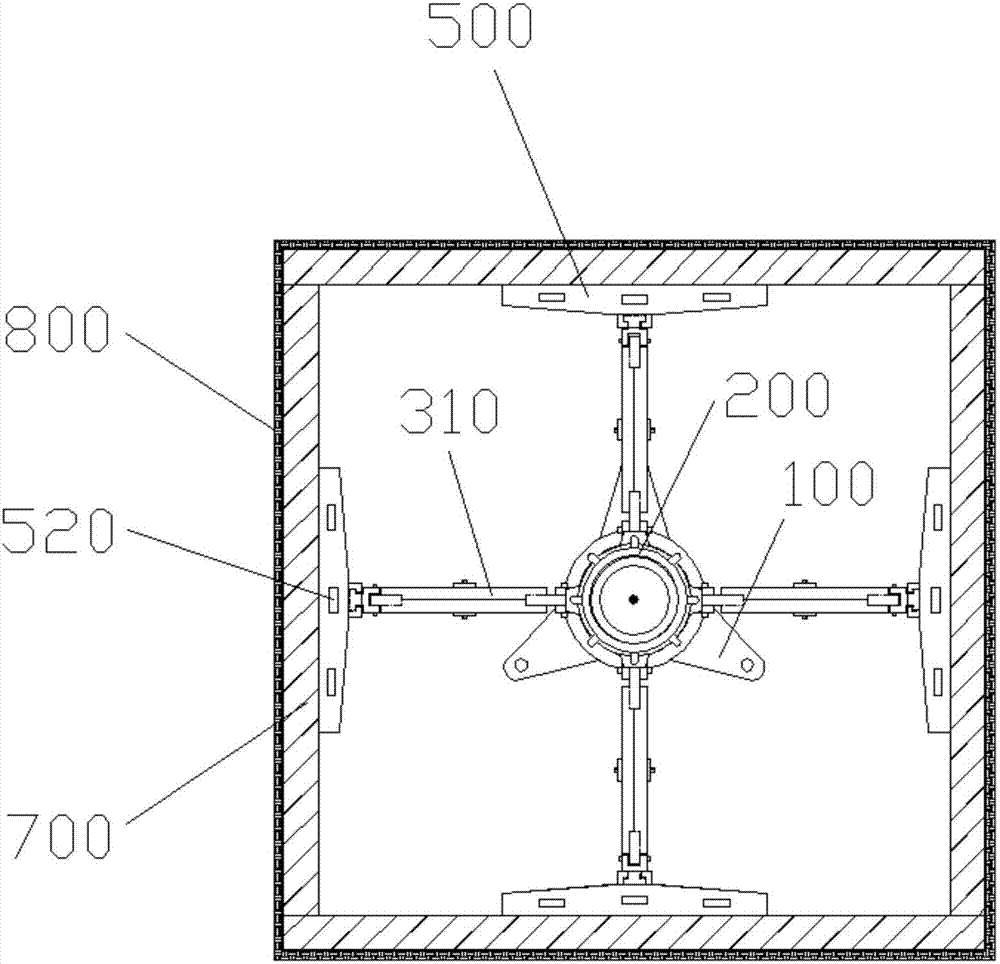

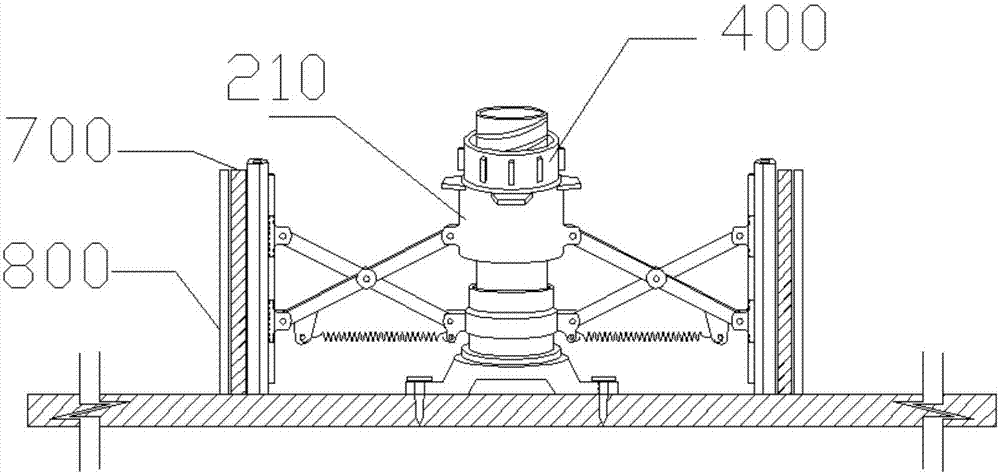

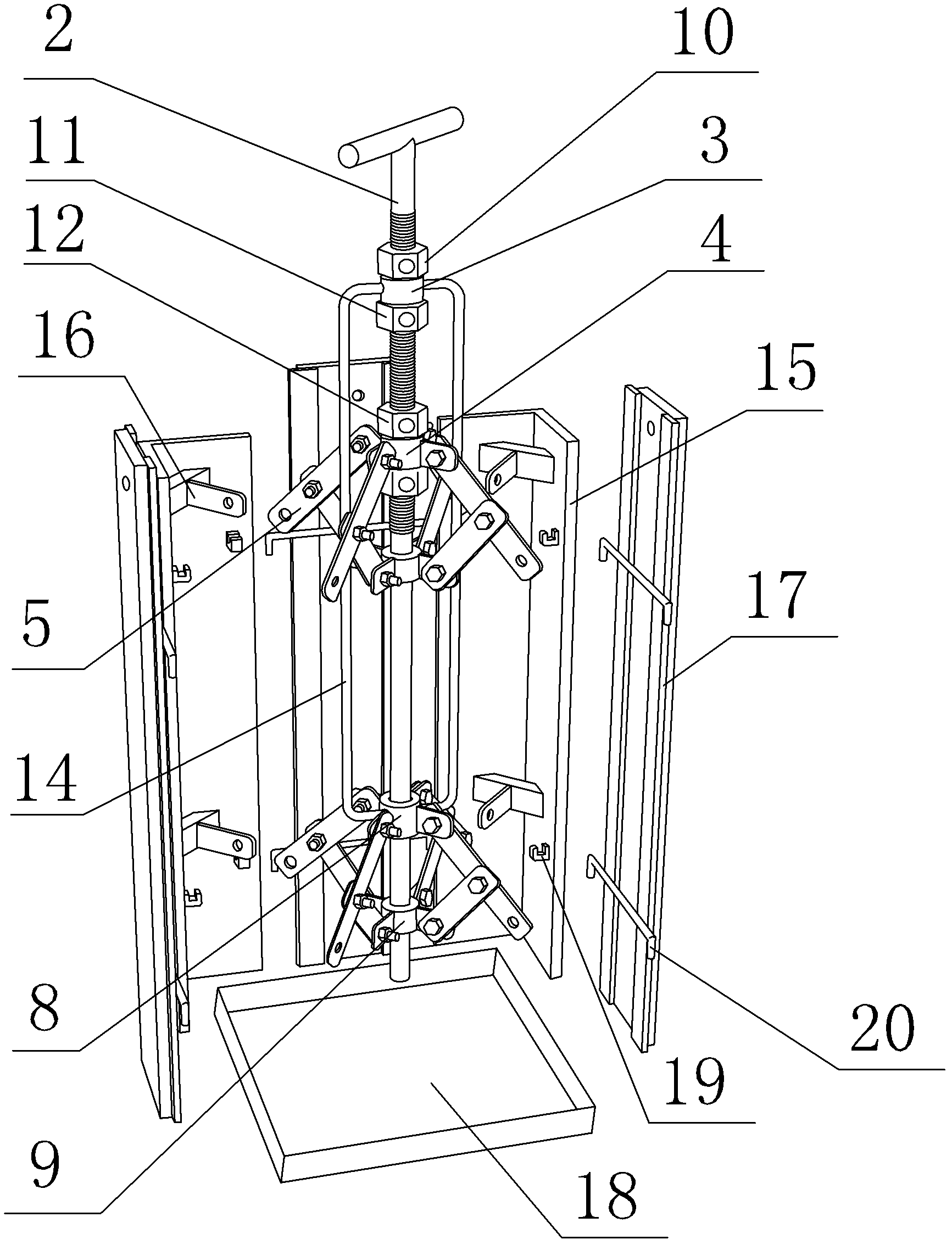

Multifunctional device for formworks with reserved holes

ActiveCN107965144AThe style is flexible and changeableSatisfy the formwork requirementsForms/shuttering/falseworksEngineering

The invention provides a multifunctional device for formworks with reserved holes. The multifunctional device for the formworks with the reserved holes comprises a supporting base, an umbrella-shapedsupport, a compression ring nut and vertical supporting plates, wherein the supporting base is used for fixing a formwork erecting device body and comprises a pedestal and a tubular vertical rod fixedto the pedestal; the umbrella-shaped support is used for providing hole formwork inner bracing and comprises a plurality of telescopic supporting arms which are connected with the tubular vertical rod and uniformly distributed along the circumference of the tubular vertical rod; the compression ring nut is used for adjusting the opening degree of the telescopic supporting arms; the vertical supporting plates are fixed to the tail ends of the telescopic supporting arms respectively and used for fixing a formwork body, and the vertical supporting plates are parallel to the tubular vertical rod.The multifunctional device for the formworks with the reserved holes can fit for the formworks with round holes, square holes and even polygonal holes, the assembly and disassembly operation is convenient, the device can be reused, wood waste is reduced, and the device is environmentally friendly.

Owner:CHINA FIRST METALLURGICAL GROUP

Leakage proof mould hoisting tool at root of residence pipeline and construction method thereof

ActiveCN103382771AAvoid water leakage hazardsFast constructionForms/shuttering/falseworksBuilding material handlingFloor slabResidence

The invention provides a leakage proof mould hoisting tool at the root of a residence pipeline and a construction method thereof. The construction method comprises the following steps: two templates are fabricated, and a semi-circle matched with the pipeline in outer diameter is cut in the middle of each template; a clamping piece is arranged at the position where each template is closely pasted with the semi-circle; the two templates are arranged at the root of the pipeline in a sleeving manner, and are closely pasted at the bottom of a floor slab; the clamp force is exerted to the two clamping pieces to enable the clamping pieces to clamp the pipeline, so that the fastening mounting of the templates is achieved. Two through holes are formed in the two ends of each clamping piece, and the clamping pieces are fixed in the through holes through the penetration of split bolts, and exert the clamp force to the two clamping pieces through the matching of the fastening of nuts. The method has the advantages that the construction speed is fast, and the mounting operation is convenient and quick. A person can perform independent operation below stairs, and can complete the mounting of a set of mould hoisting tool in a few minutes. After construction, the wall and the pipeline are clean and tidy, so that a person is not required to perform cleaning in the later period. During form removal, only one person is required to perform operation below stairs, so that the construction efficiency is improved, and the cost of labor is reduced.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

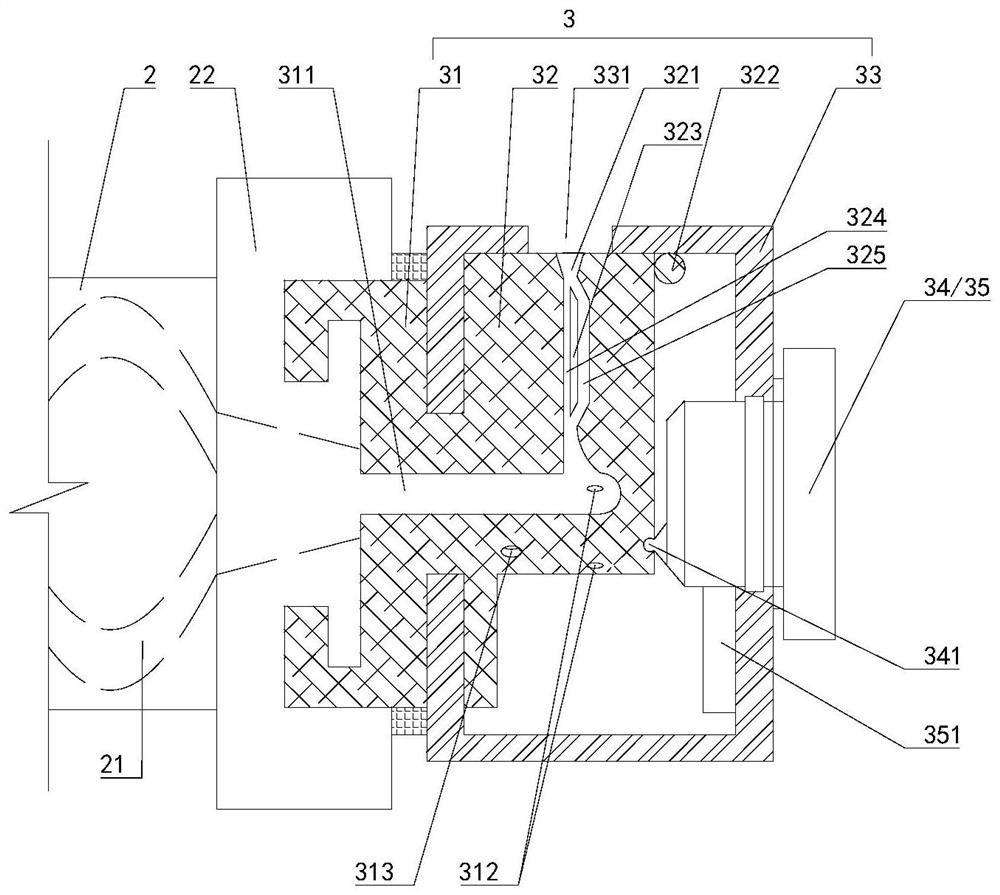

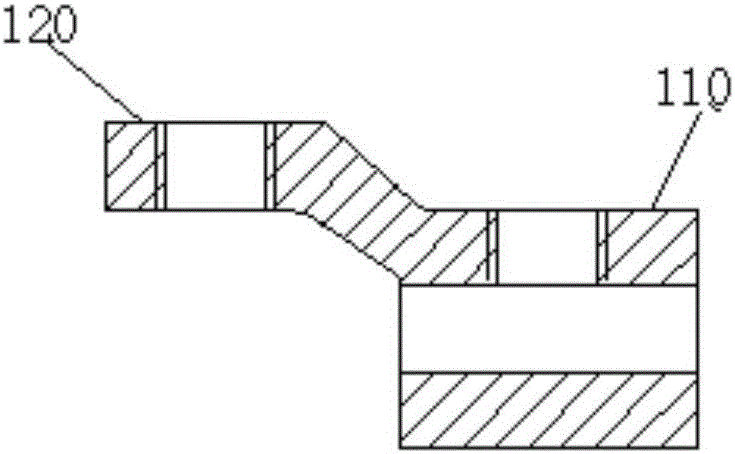

Spray maintenance telescopic spray head

ActiveCN111672647AReduce site occupancyReduce construction difficultyMovable spraying apparatusSpray nozzlesStructural engineeringWater supply

The invention provides a spray maintenance telescopic spray head. The spray maintenance telescopic spray head comprises a connecting pipe, the connecting pipe is connected with a water supply pipe, asliding body is slidably connected in the connecting pipe, under the action of water pressure, the sliding body partially extends out of the connecting pipe, under the action of no water pressure, thesliding body retracts in the connecting pipe, a water channel is arranged in the sliding body, a spray head device is rotatably connected to the tail end of the sliding body, the spray head device communicates with the water channel, and the spray head device swings left and right under the action of water pressure by taking a central shaft of the sliding body as a rotating shaft. According to the spray maintenance telescopic spray head, the technical effects that the site occupancy rate is greatly reduced, the construction difficulty and the construction cost are greatly reduced due to sitesaving, the telescopic swing spray head has no interference with formwork erecting and detaching of cast-in-place components, formwork erecting and detaching are conveniently and rapidly carried out,the construction efficiency is improved, the economic benefit is obvious, the spray area of the spray head is increased through the swing spray head, the spraying effect is better, the curing effect is improved, the strength of the components is guaranteed, and water resources are saved are achieved.

Owner:湖北省清江路桥建筑有限公司

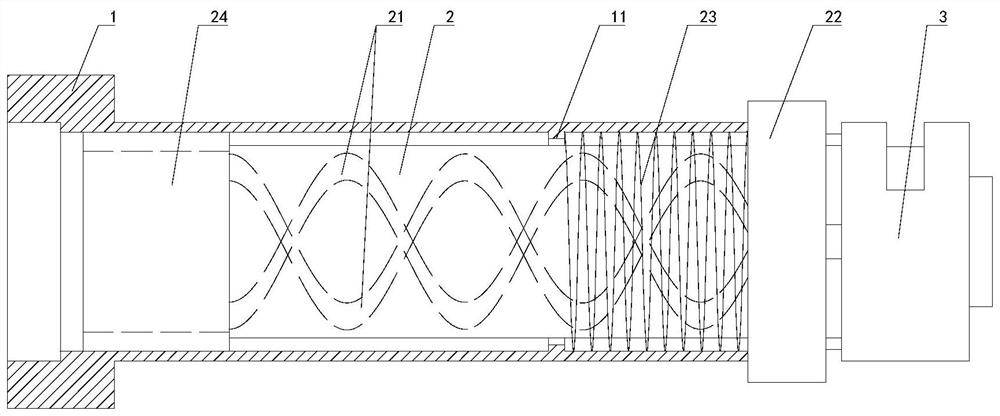

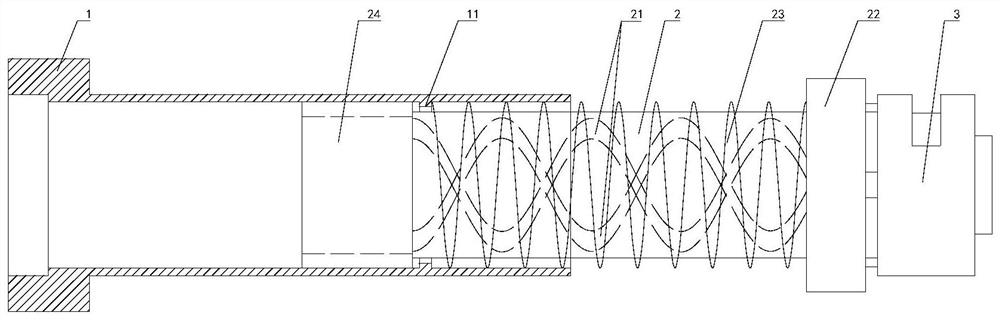

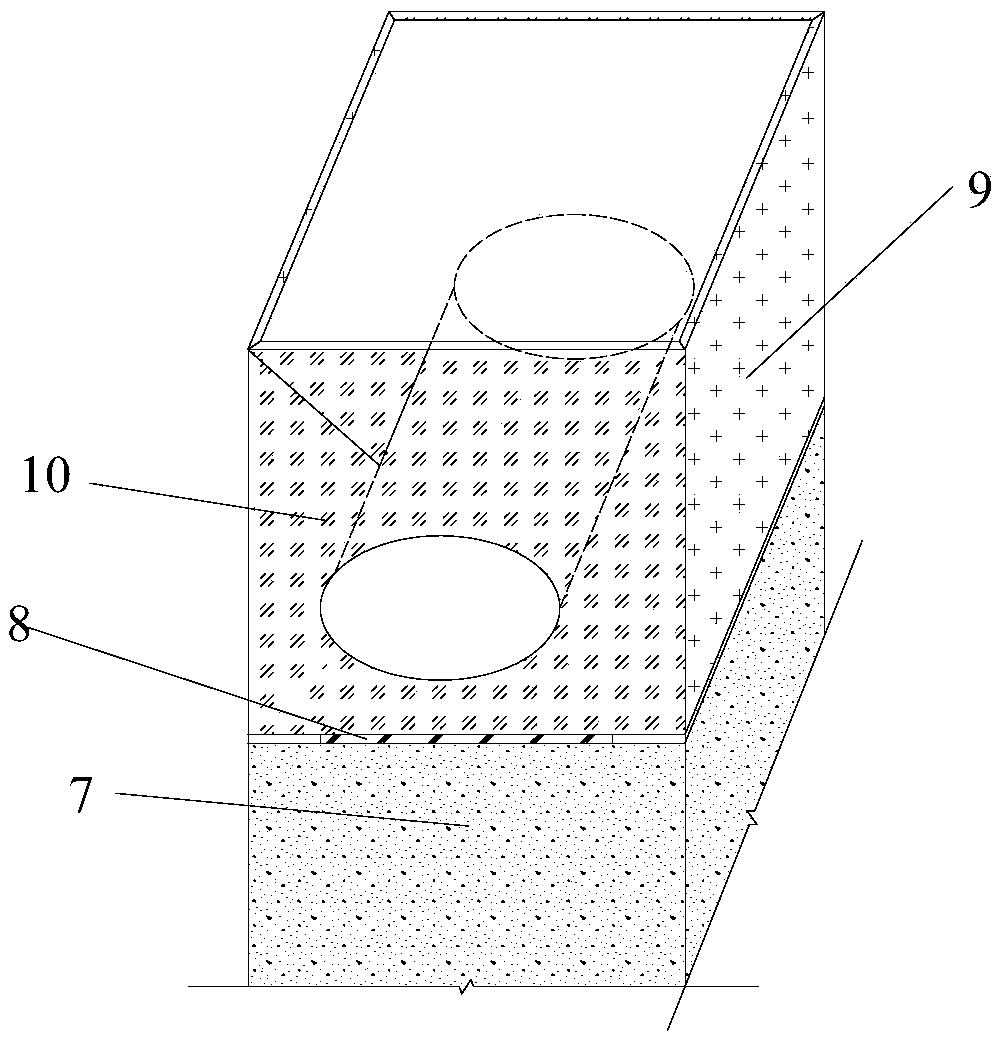

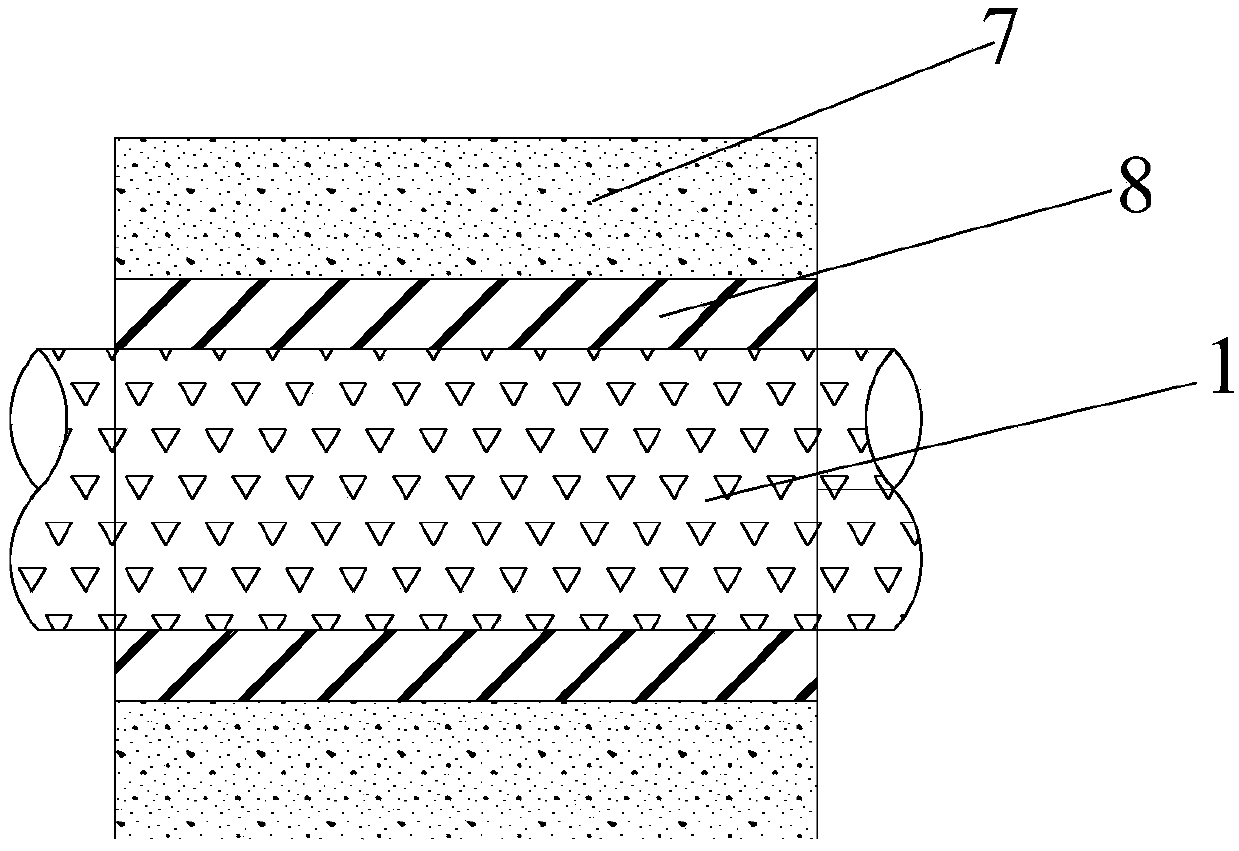

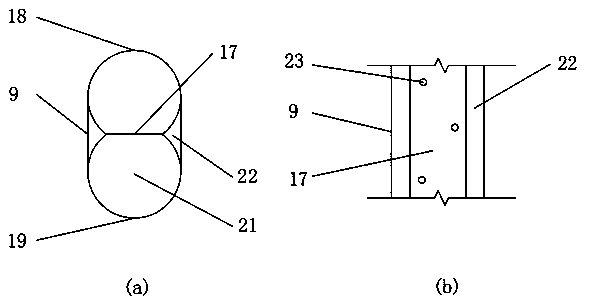

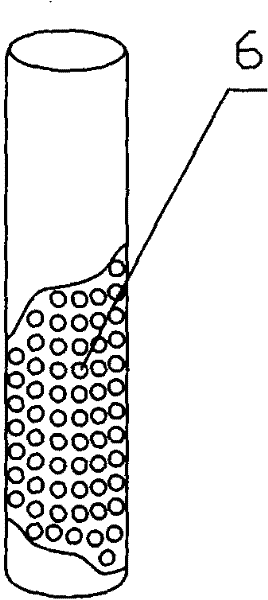

Movable die core of concrete core slab and box girder pouring die

InactiveCN103802204AQuick demolitionQuick ModelingCeramic shaping mandrelsCeramic shaping coresChinese charactersEngineering

The invention discloses a movable die core of a concrete core slab and box girder pouring die, belongs to a concrete pouring die and aims to provide a movable die core of a die, which is rapid and convenient in die assembly and disassembly and can prevent the inner surface of a pouring body being damaged. The movable die core of the concrete core slab and box girder pouring die comprises a die core which adopts a tubular structure. The die core is formed by oppositely closing half dies which are shaped like a Chinese character 'ao' or are in a semicircular shape. Each half die is formed by an intermediate plate (3), a left lateral plate (1), a right lateral plate (5), a plurality of left connecting rods (11), a plurality of right connecting rods (9) and pull rods (10), wherein the left lateral plate (1) and the right lateral plate (5) are respectively hinged to the left and right sides of the intermediate plate (3); the left connecting rods (11) are hinged to the left lateral plate (1), the right connecting rods (9) are hinged to the right lateral plate (5); the pull rods (10) are hinged to the corresponding left connecting rods (11) and right connecting rods (9). The movable die core of the concrete core slab and box girder pouring die has the advantages of high efficiency, low labor intensity, small drawing friction force, no damage to the inner surface of the pouring body and the like. The invention discloses a die for pouring a concrete core slab or a box girder.

Owner:GUIZHOU YONGHAO HEAT ENERGY EQUIP MFG

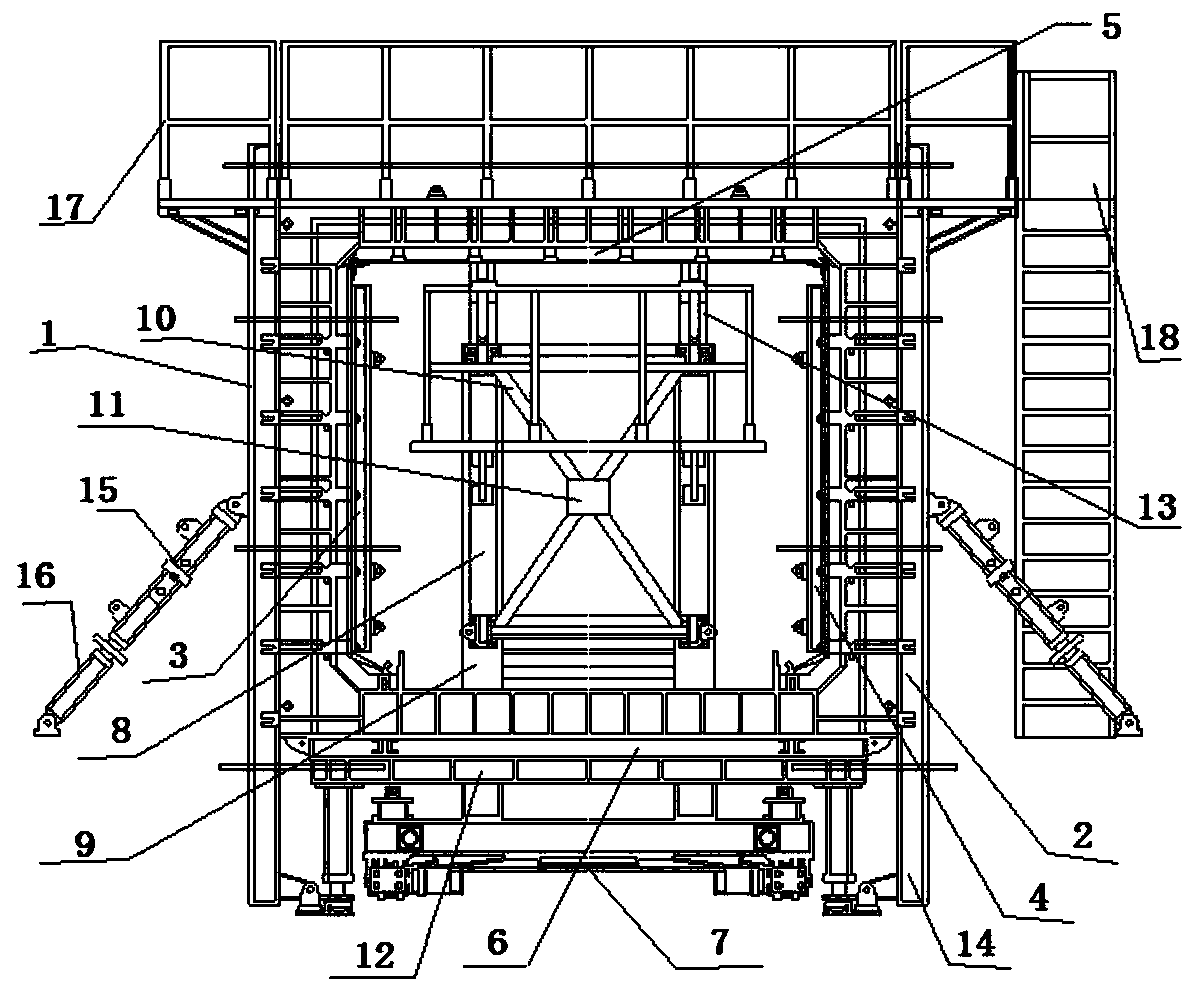

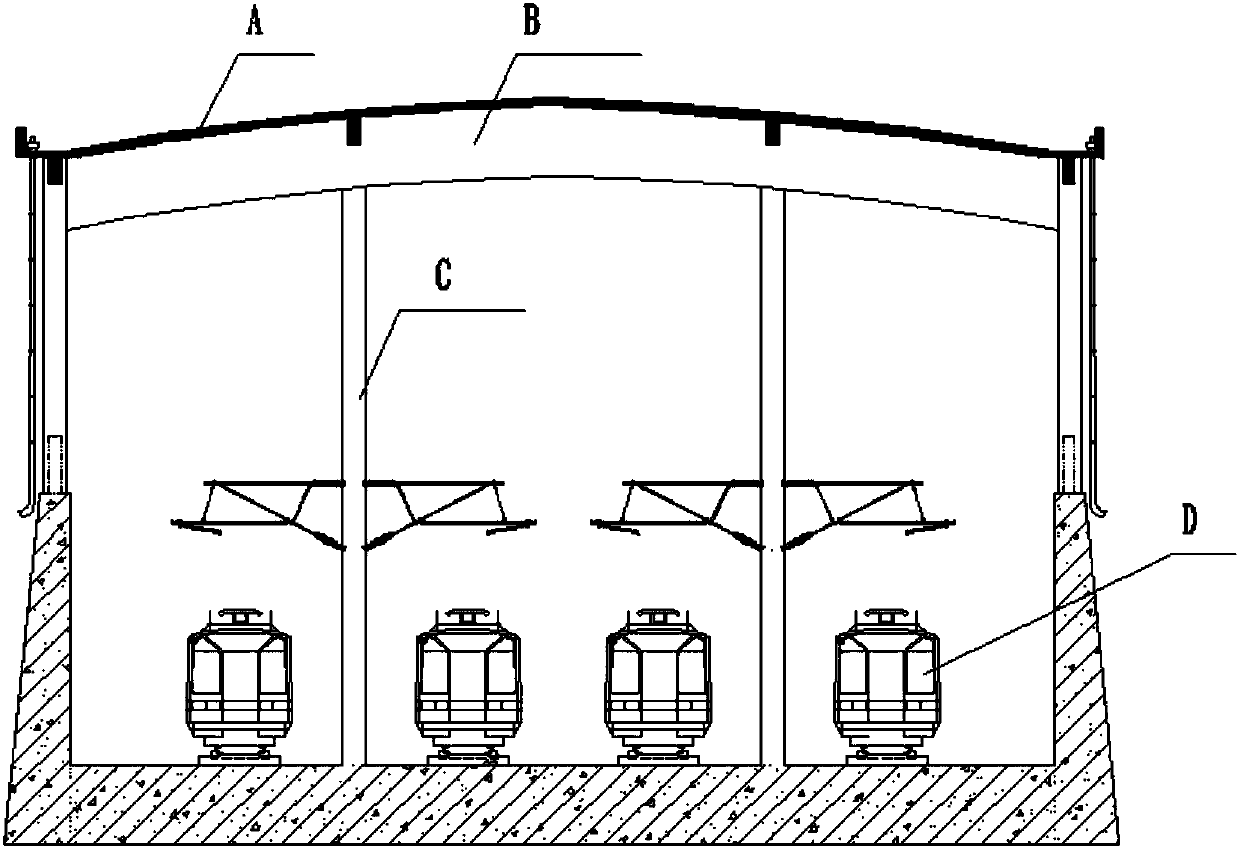

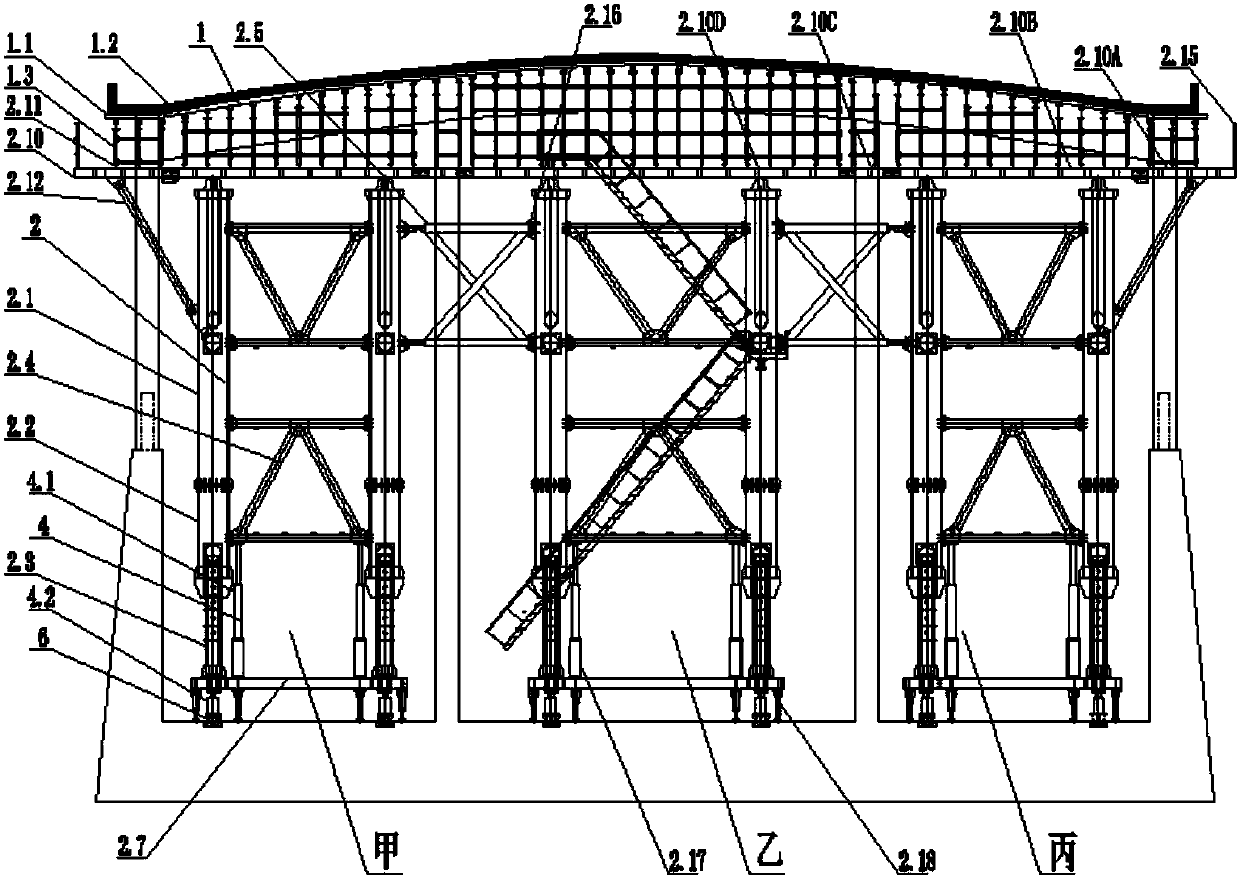

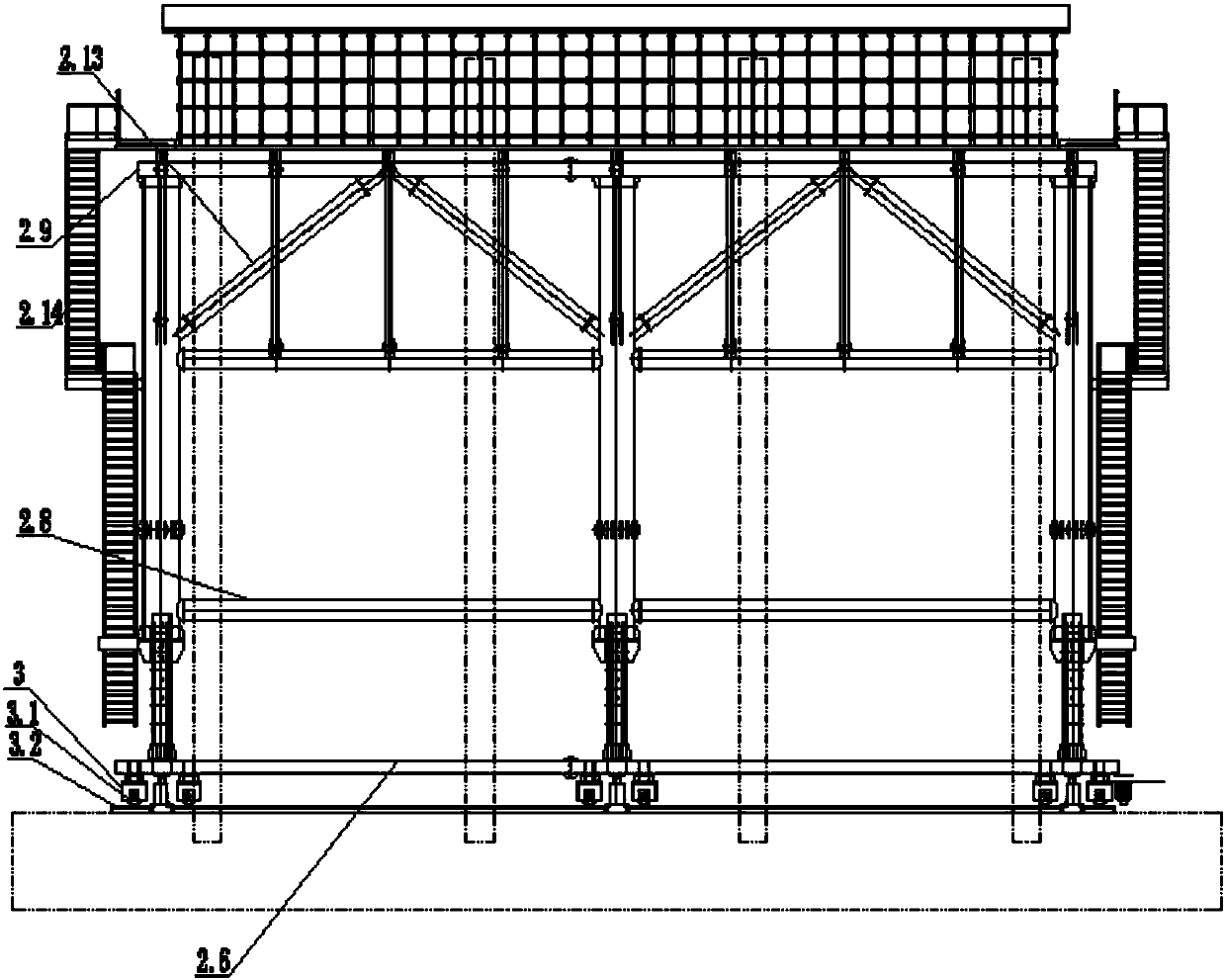

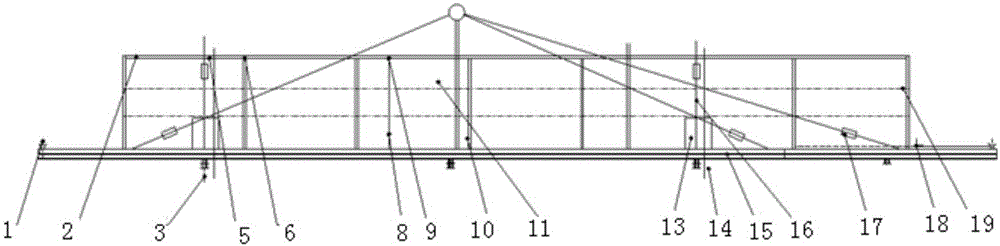

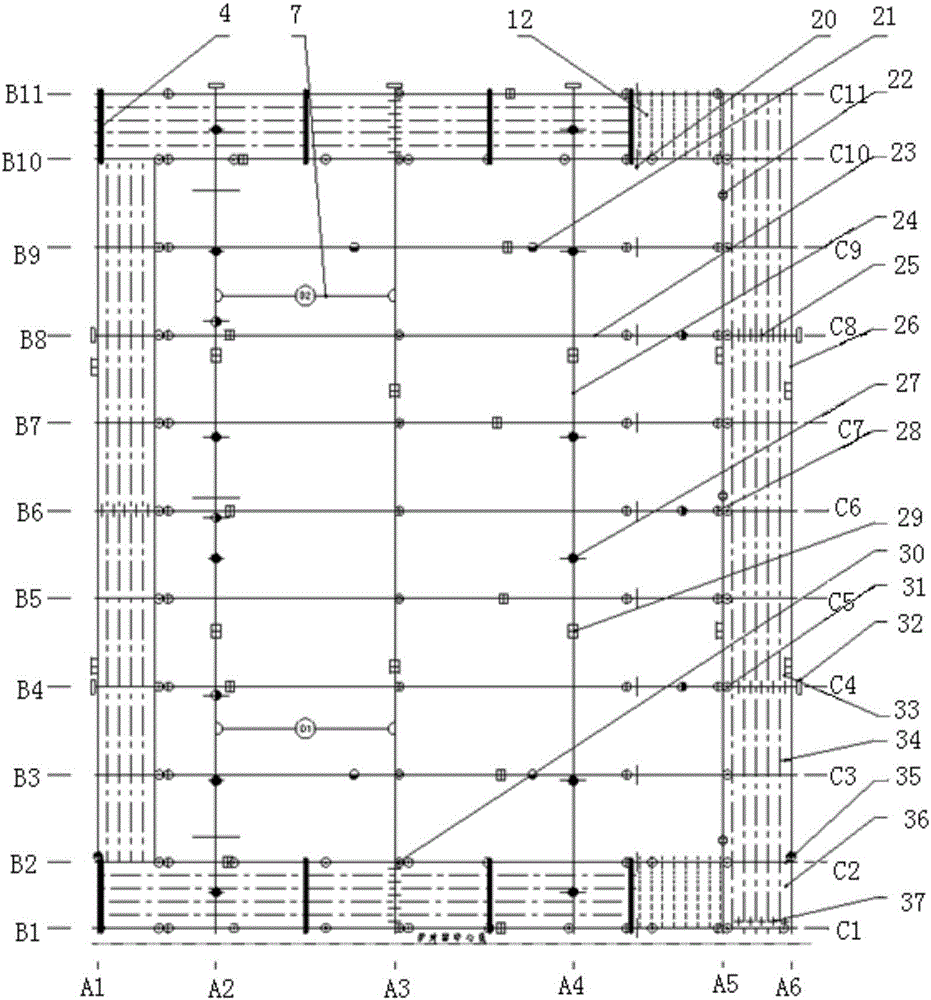

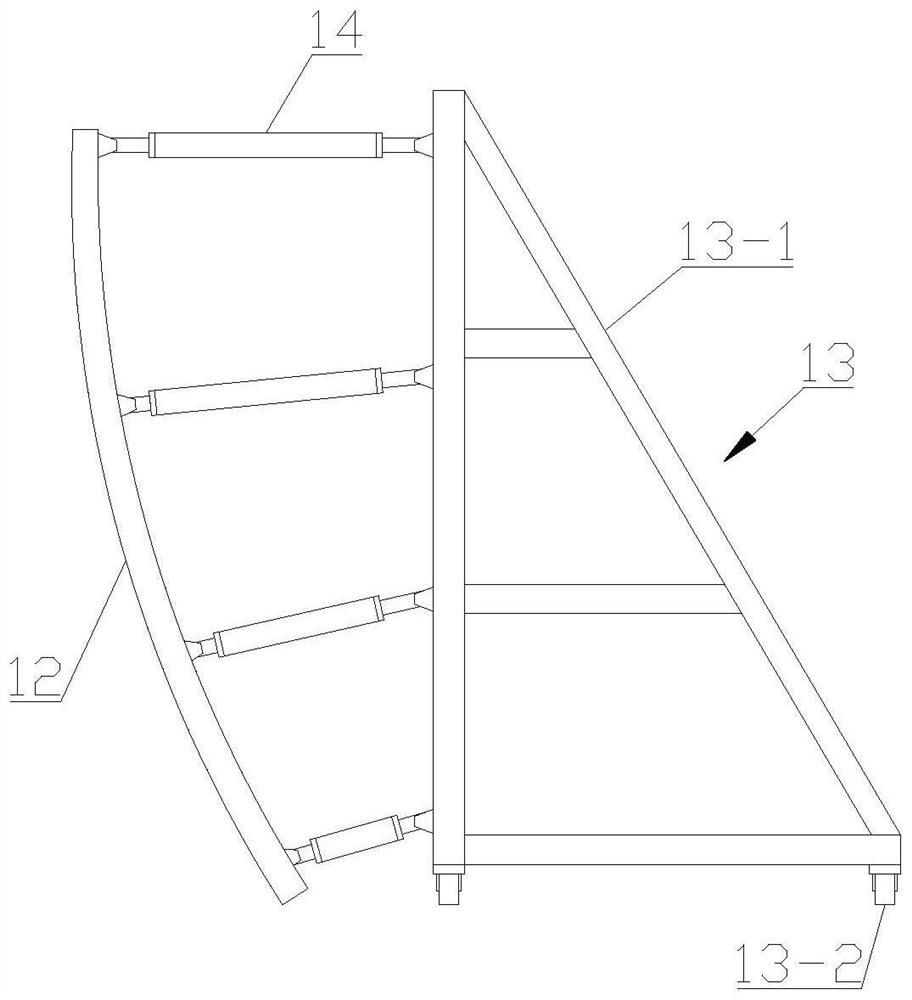

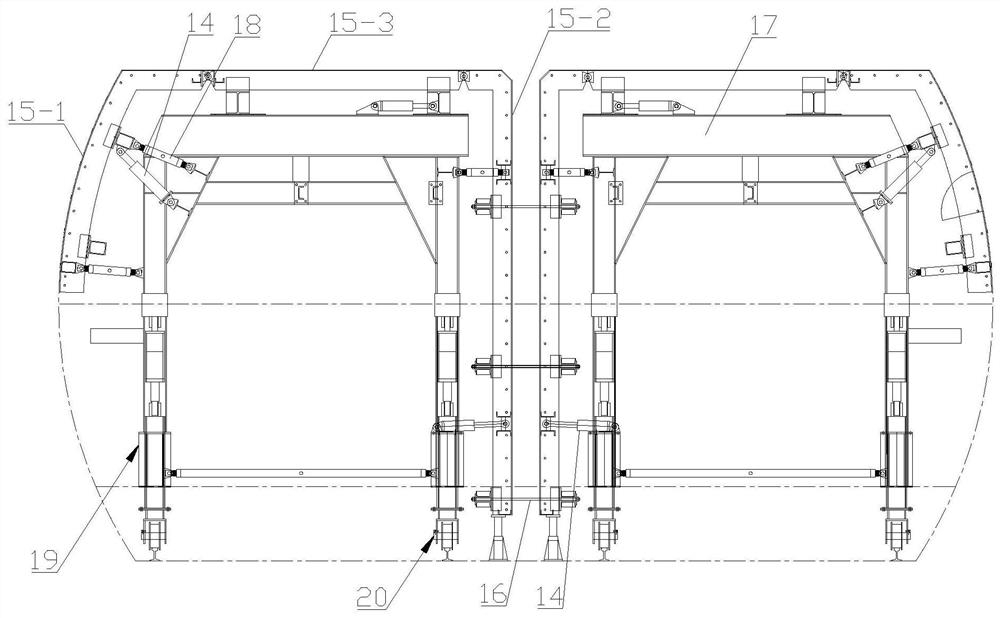

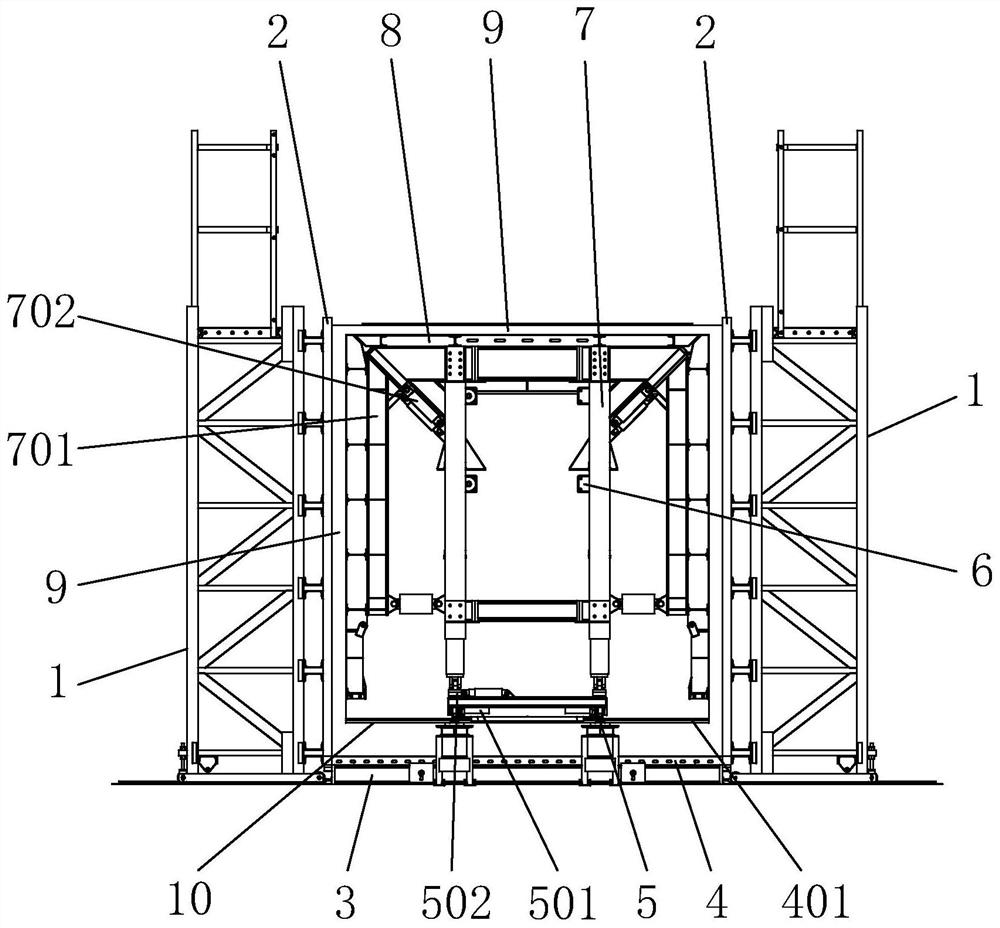

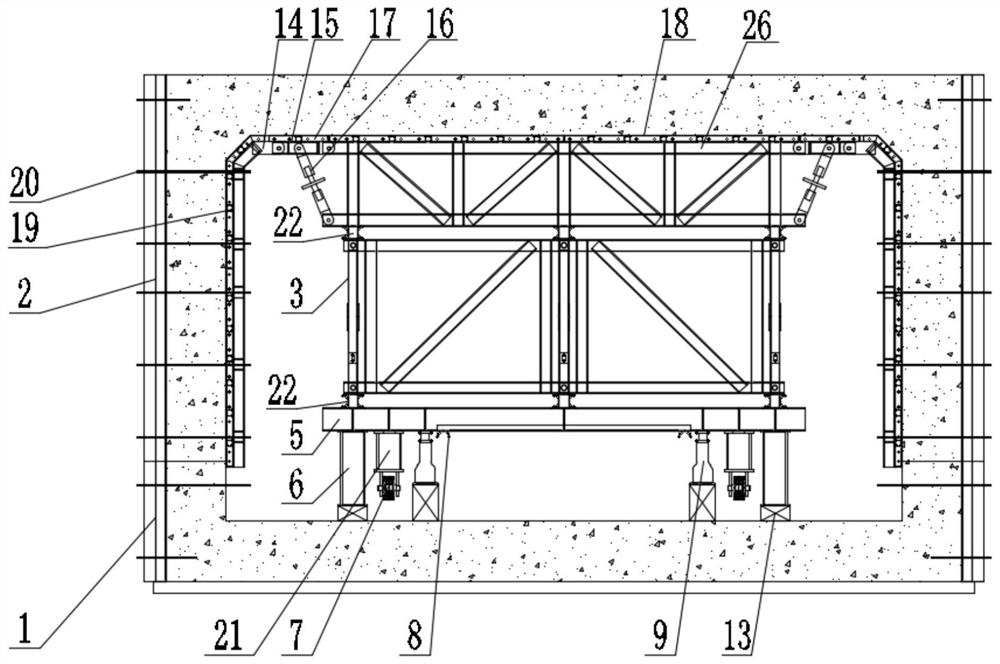

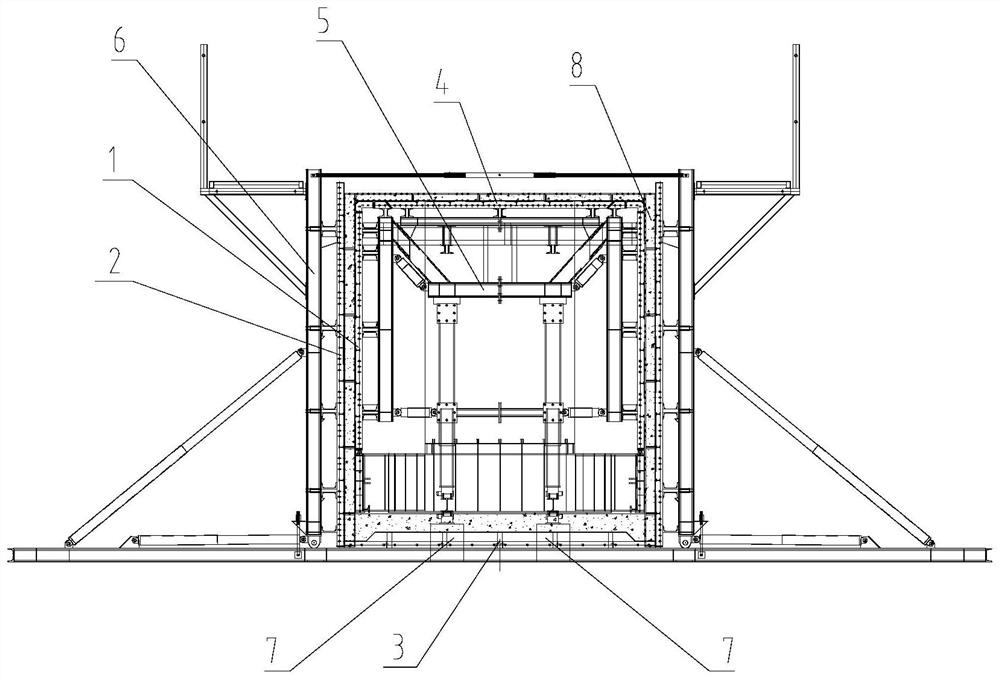

Station canopy construction movable framework and station canopy construction method

InactiveCN107939040AQuick demolitionQuick installationForms/shuttering/falseworksControl systemArchitectural engineering

The invention discloses a mobile formwork for station canopy construction and a construction method for a station canopy, comprising a left warehouse formwork, a middle warehouse formwork and a right warehouse formwork. The formwork includes the formwork system, gantry system, walking system, hydraulic system, control system and bottom support for the canopy of the construction station; the formwork systems of the left warehouse, middle warehouse and right warehouse formwork are in order connection; the formwork can be separated and adjusted, which can not only solve the problem that the ordinary integral formwork cannot pass through the column and beam structure, but also realize the function of the integral formwork, save time and effort, avoid delaying the construction progress, and solve the problem of It solves the problem that the quality of the traditional construction scheme of the station canopy is difficult to control. The technical scheme is applicable to the construction of rain-proof sheds for stations with various spans, and can ensure the construction quality of the canopy. The overall structure of the formwork is simple and simple, the stress is clear, and the safety is high.

Owner:SHANDONG TIEYING CONSTR ENG

A cross-channel-segment pipeline structure and a mounting method thereof

ActiveCN109594581AReduce the amount of aerial workAvoid unsafe factorsPipe supportsFoundation engineeringButtressEngineering

The invention relates to a cross-channel-segment pipeline structure and a mounting method thereof. The cross-channel-segment pipeline erection adopts a cross-channel-segment pipeline overhead structure. Anchor blocks are arranged at the two ends of the river channel, buttresses are arranged in the river channel at certain intervals. In the installation process of the cross-channel-segment pipeline, a door-shaped frame structure and a track reinforcing structure between the door frames are adopted for transportation. Traction is achieved through a winch and a steering pulley, splicing at jointsof the cross-channel-segment pipeline is implemented through with a pipeline connection construction platform, and formworks of the anchor blocks and the buttresses are erected through a hanging frame structure, a movable pouring and vibrating system structure and a fixed formwork structure. The structure provided by the invention can effectively solve the problem that pipeline erection encounters a river, the construction progress is accelerated and the construction efficiency is improved by adopting a fixed door-shaped track and transportation trolley combined pipe conveying technology, andthe formwork is quickly assembled and disassembled by adopting a cross-channel-segment pipeline anchor block and buttress fixed quick formwork erecting technology, so that repeated turnover use is realized, the material waste is reduced, and the cost is saved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Boiler furnace maintenance platform and rail support thereof

ActiveCN106379850AReduce weightQuick demolitionArc welding apparatusLifting devicesShaped beamBoiler furnace

The invention discloses a boiler furnace maintenance platform and a rail support thereof. The rail support comprises a rail base clamping plate and a rail connection pipe; the rail base clamping plate is provided with a rail base slideway which is matched with an I-shaped beam flange; bolt holes are formed in the rail base slideway; the rail base clamping plate is arranged on an I-shaped beam by arranging connection bolts in the bolt holes in a matched manner; a rail base clamping and connecting plate is arranged in the middle part of the rear part of the rail base slideway of the rail base clamping plate; inner pipe wall clamping grooves which are matched with the rail base clamping and connecting plate are formed in the inner wall of the rail connection pipe; outer pipe wall clamping grooves with an antiskid function are formed in the outer pipe wall of the rail connection pipe; and the rail connection pipe is arranged on the rear surface of the rail base slideway through the match of the inner pipe wall clamping grooves and the rail base clamping and connecting plate. Therefore, through the rail support disclosed by the invention, rails can be arranged on a platform body.

Owner:江苏能建机电实业集团有限公司

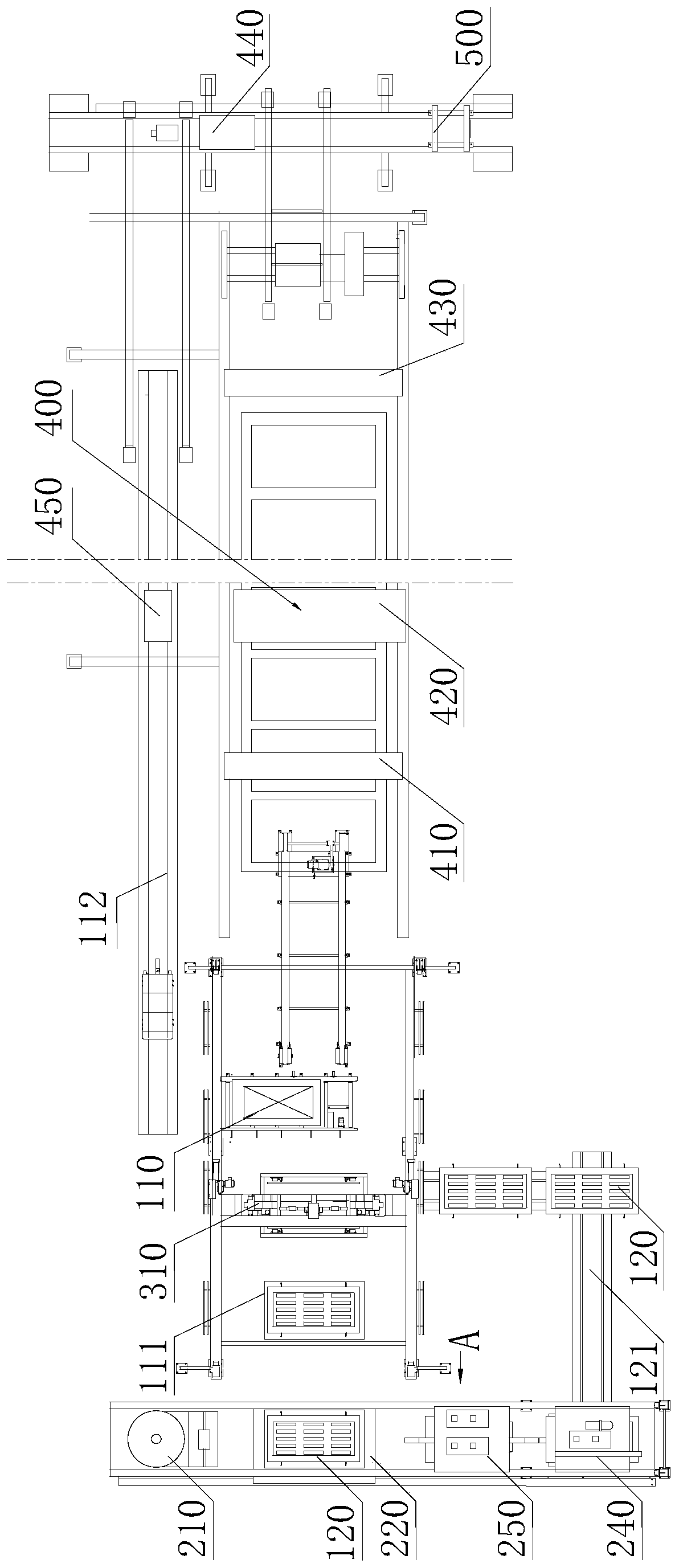

Production technology and equipment of concrete plate-shaped components

PendingCN110027083AQuick demolitionImprove turnover efficiencyCeramic shaping plantsMechanical engineeringMold removal

The invention provides a production technology and equipment of concrete plate-shaped components, and relates to the technical field of building material production equipment. The production technology comprises the following steps of batching, pouring and vibrating, demoulding, plate-shaped component curing and stacking; concrete pouring raw materials for manufacturing the plate-shaped componentsare obtained through batching; during pouring and vibrating, the materials are fed into molds, and vibrating is carried out after feeding is carried out, and the plate-shaped components are formed after vibrating is carried out; demoulding is to remove the plate-shaped components from the molds; plate-shaped component curing is to transport the plate-shaped components and a first tray to a curingkiln for curing; and the plate-shaped components are separated from the first tray, and the plate-shaped component are stacked. According to the production technology of the concrete plate-shaped components, the prepared concrete raw materials are put into the molds for pouring and vibrating is carried out at the same time, and after pouring is completed, the molds are removed before curing is carried out, so that the occupation of a large number of molds caused by traditional curing with molds is avoided, the problem of mold removal difficulty caused by hardening of the plate-shaped components after curing is solved, and the turnover efficiency of the molds is improved.

Owner:LANGFANG HESS BUILDING MATERIALS MACHINERY CO LTD +1

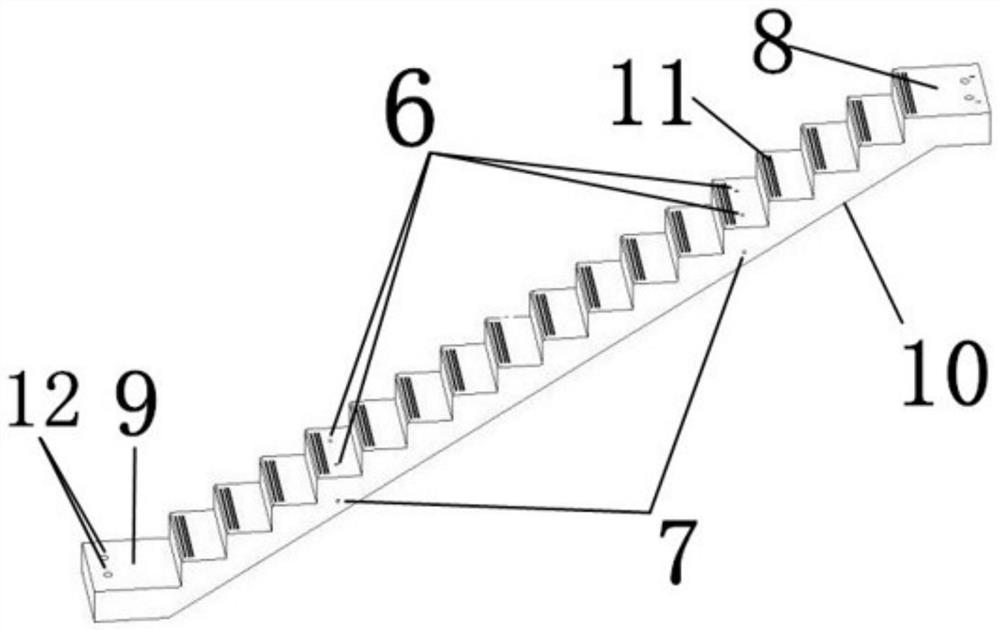

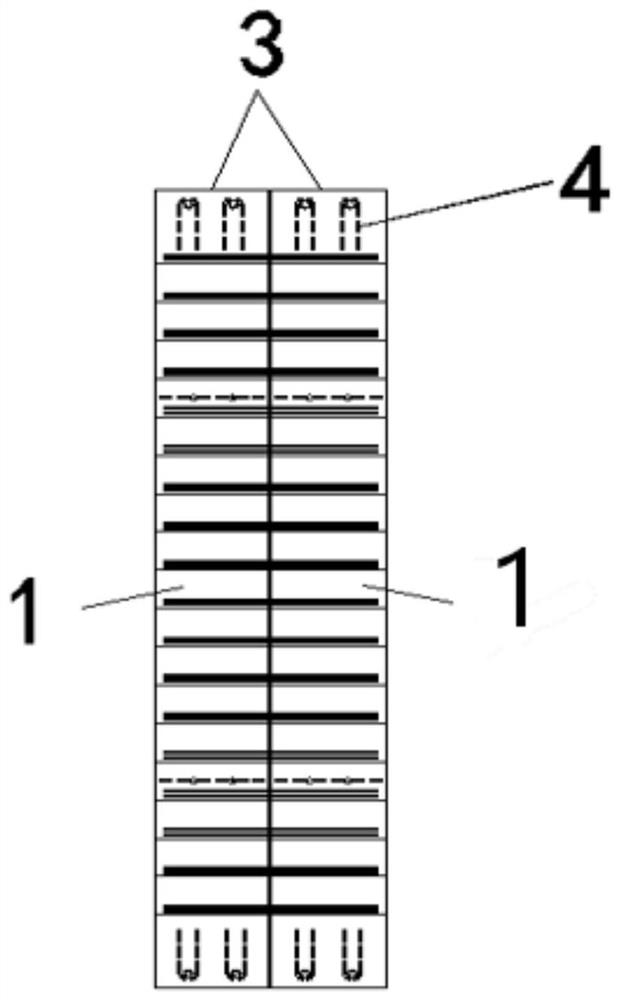

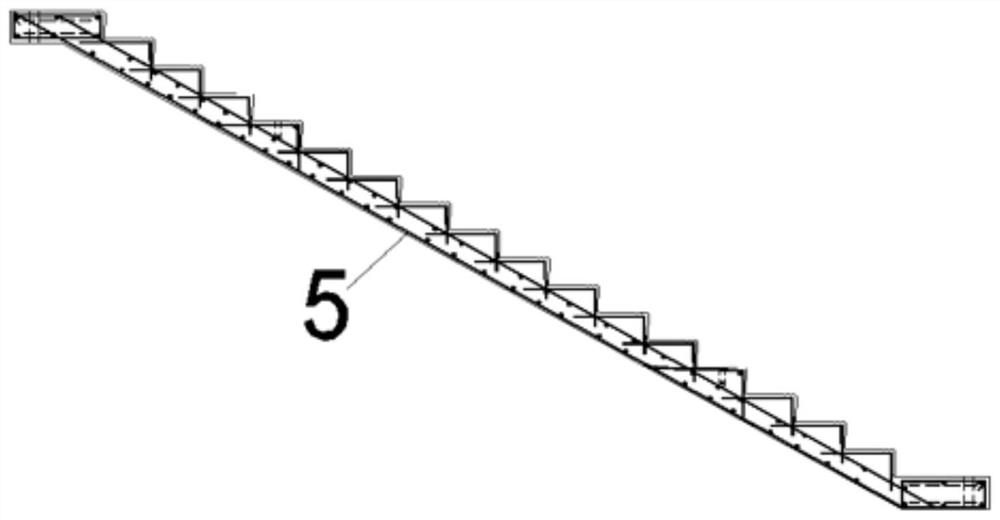

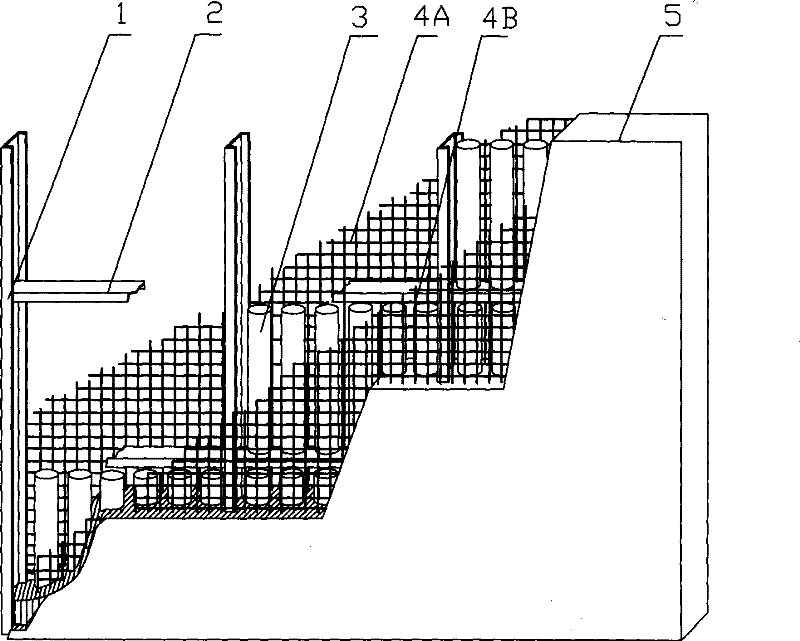

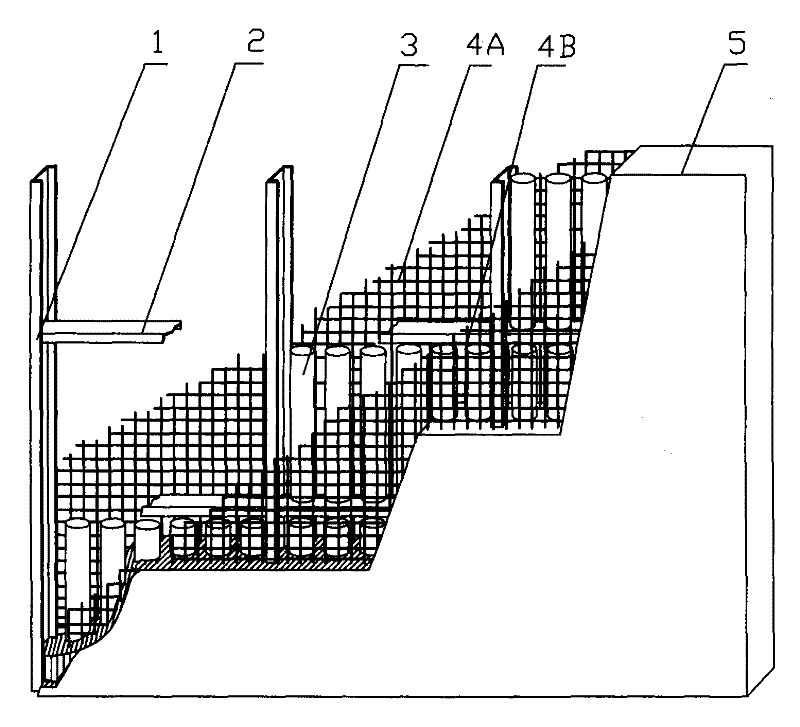

Separated precast prestressed concrete slab type stairway and production process thereof

PendingCN111958815AQuick demolitionAchieve thinningMouldsStairwaysPre stressArchitectural engineering

The invention relates to the technical field of prefabricated buildings, in particular to a separated precast prestressed concrete slab type stairway and a production process thereof. An existing slabtype stairway is large in dead weight and complicated in production process. The separated precast prestressed concrete slab type stairway comprises a stairway body, wherein the stairway body sequentially comprises an upper platform plate, stair section plates and a lower platform plate from top to bottom; prestressed reinforcing steel bars are arranged on the lower part in the stairway body along the length direction; reserved installation holes and reserved hole reinforcing ribs are respectively arranged on the surfaces of the upper platform plate and the lower platform plate; the stair section plates are provided with hoisting points and demoulding hoisting points; and the prestressed reinforcing steel bars are provided with reserved prestressed reinforcing steel bar plugging slots atreinforcing steel bar outlet holes of flat planels. Compared with a traditional precast stairway, 20 percent of concrete can be saved, 30 percent of reinforcing steel bars can be saved, the dead weight is light, fast production can be realized, and the separated precast prestressed concrete slab type stairway and the production process thereof have a favorable development prospect in the technicalfield of prefabricated buildings.

Owner:河南清水建设科技有限公司 +1

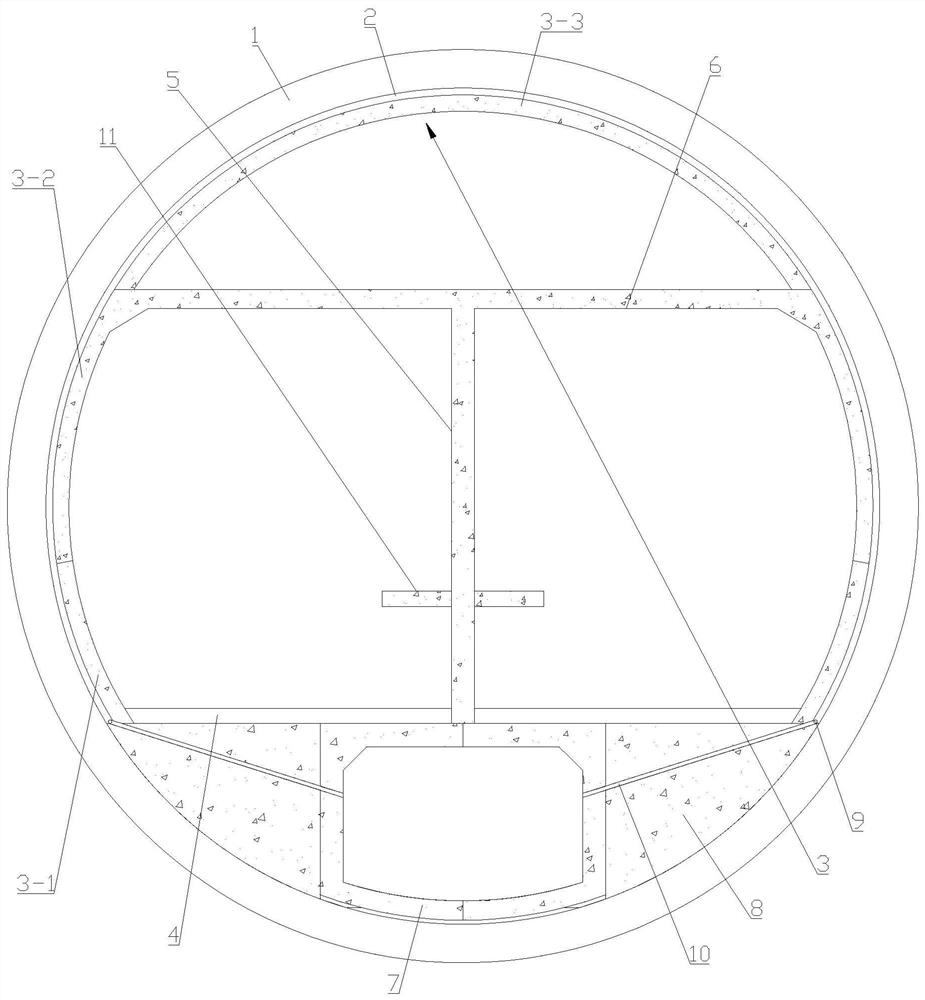

Isolation type double-lining shield tunnel construction structure and construction method

PendingCN113803088AAvoid destructive forceAvoid sharing rock pressureMining devicesUnderground chambersWater leakageArchitectural engineering

The invention discloses an isolation type double-lining shield tunnel construction structure and a construction method. The construction structure comprises a primary lining, an isolation buffer layer and a secondary lining, the bottoms of the two sides of the isolation buffer layer are each provided with water collecting pipes, and a plurality of water drainage pipes are arranged between the water collecting pipes and an opening piece box culvert; the construction method comprises the steps that 1, the primary lining and the opening piece box culvert are constructed; 2, a water collecting pipe and a water draining pipe are mounted; 3, an inverted arch filling layer is constructed; 4, the isolation buffer layer is constructed; 5, the secondary lining below a tunnel waist line is constructed; and 6, secondary linings between a middle partition wall, an air duct plate and the tunnel waist line and the air duct plate are constructed. According to the isolation type double-lining shield tunnel construction structure and the construction method, damage to a secondary lining structure caused by water leakage of the primary lining can be effectively reduced, the construction efficiency is improved, the air duct plate and the middle partition wall are constructed synchronously through a special formwork trolley, synchronous construction of residual structures can be achieved under the condition that material transportation is not affected. The isolation type double-lining shield tunnel construction structure and the construction method has the advantages of quick assembly, quick positioning, quick form removal and short process circulation time.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Post-cast strip inflatable arc angle rectangular flexible pipe side mold support construction method

ActiveCN109025294AReduce the number of supportsReduce the number of units usedBuilding material handlingBuilding insulationsEngineeringRebar

The invention relates to a post-cast strip side mold support construction method; an inflatable arc angle rectangular flexible pipe is arranged in a gap between an upper layer steel bar and a lower layer steel bar in the post-cast strip position; in inflation, the arc angle rectangular flexible pipe is extruded by the upper and lower layer steel bars so as to fill the gap caused by the steel bars;the soft pipe is inflated to form an air column so as to space the concrete; the cross section outer contour of the arc angle rectangular flexible pipe is an arc-shaped rectangular shape; the arc angle rectangular is a rectangular with four arc-shaped corners, and is an axially symmetrical and centrosymmetric geometric figure; the arc angle rectangular flexible pipe comprises a soft pipe outer wall and a soft pipe inner wall; the soft pipe outer wall cross section is the cross section contour of the arc angle rectangular flexible pipe, i.e., an arc angle rectangular; the soft pipe inner wallcomprises an upper pipe inner wall, a lower pipe inner wall and a common inner wall; the area enclosed by the upper pipe inner wall and the lower pipe inner wall is an air pump pressurization area; anarea enclosed by the soft pipe outer wall, the lower portion of the upper pipe inner wall and the upper portion of the lower pipe inner wall is an air connection area; the common inner wall has a constant pressure hole. The method employs the inflatable arc angle rectangular flexible pipe support, is good in moulding effect, high in construction quality, and high in efficiency.

Owner:FUJIAN JIANGXIA UNIV

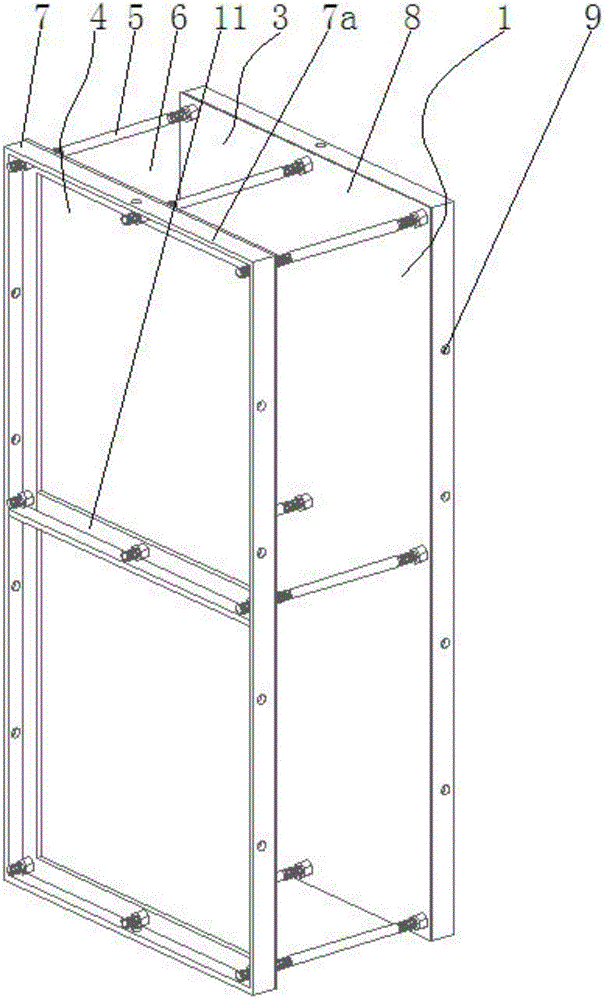

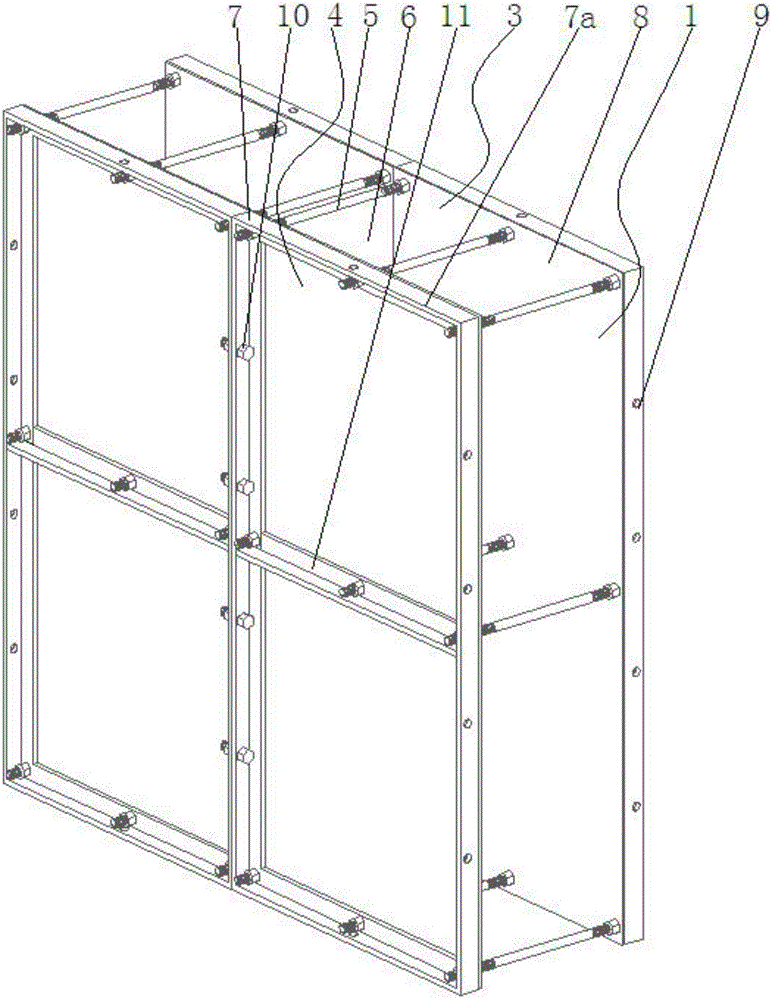

Construction template

InactiveCN102235087AIncrease stiffnessImprove bearing capacityForming/stuttering elementsArchitectural engineeringFlange

The invention discloses a construction template which comprises groove modules (1) and bolts (2) or latches, wherein two flanges (4) of each groove module (1) are respectively provided with a hole (5), and the holes (5) on the two flanges (4) are mutually aligned. When the template is assembled, a plurality of groove modules (1) are sequentially neatly arranged, so that the flanges (4) of two adjacent groove modules (1) are pressed against each other, and the holes (5) of the flanges are corresponding to each other; and the bolt (2) or latch after passing through the hole (5) is connected with an adjacent groove module (1) so as to form a construction template for concreting. The construction template can be applied to the cast-in-place concrete construction of beams, boards, columns and shear walls. The small-sized groove modules (1) in a unified form can be flexibly assembled into a beam / board / column / shear wall template in a required size according to the needs of construction, therefore, the construction template has the advantages of good flexibility, light weight and disassembling convenience; the construction template can be subjected to mechanized production, thereby facilitating the controlling of the construction quality, and improving the construction efficiency; and the construction template is made of hard materials, therefore, the construction template is large in rigidity, high in bearing capacity and good in overall performance.

Owner:吴方伯

Method for constructing circular hole of anchor bolt reserved by equipment foundation

ActiveCN102493643BFlexible demolitionQuick dismantlingForms/shuttering/falseworksFoundation engineeringEngineeringGap filling

This invention relates to a method for constructing a circular hole of an anchor bolt reserved by equipment foundation, which comprises the following steps: step 1, assembling a mould; step 2, bracing the mould; step 3, pouring concrete; step 4, detaching the mould and leaving a circular hole; and step 5, cleaning the hole so as to obtain the circular hole of the anchor bolt reserved by the equipment foundation, wherein the mould for reserving the circular hole by the equipment foundation comprises a central shaft, a first opening and contracting device, a second opening and contracting device, four templates, four gap filling boards; the four templates are arc-shaped and are evenly distributed along a circumference; the gap filling boards are inserted between the templates; and a cylindrical space is enclosed by the four templates and the four gap filing boards. The method disclosed by this invention is characterized by simple operation and quick mould detachment; and the mould can be reused.

Owner:CHINA FIRST METALLURGICAL GROUP

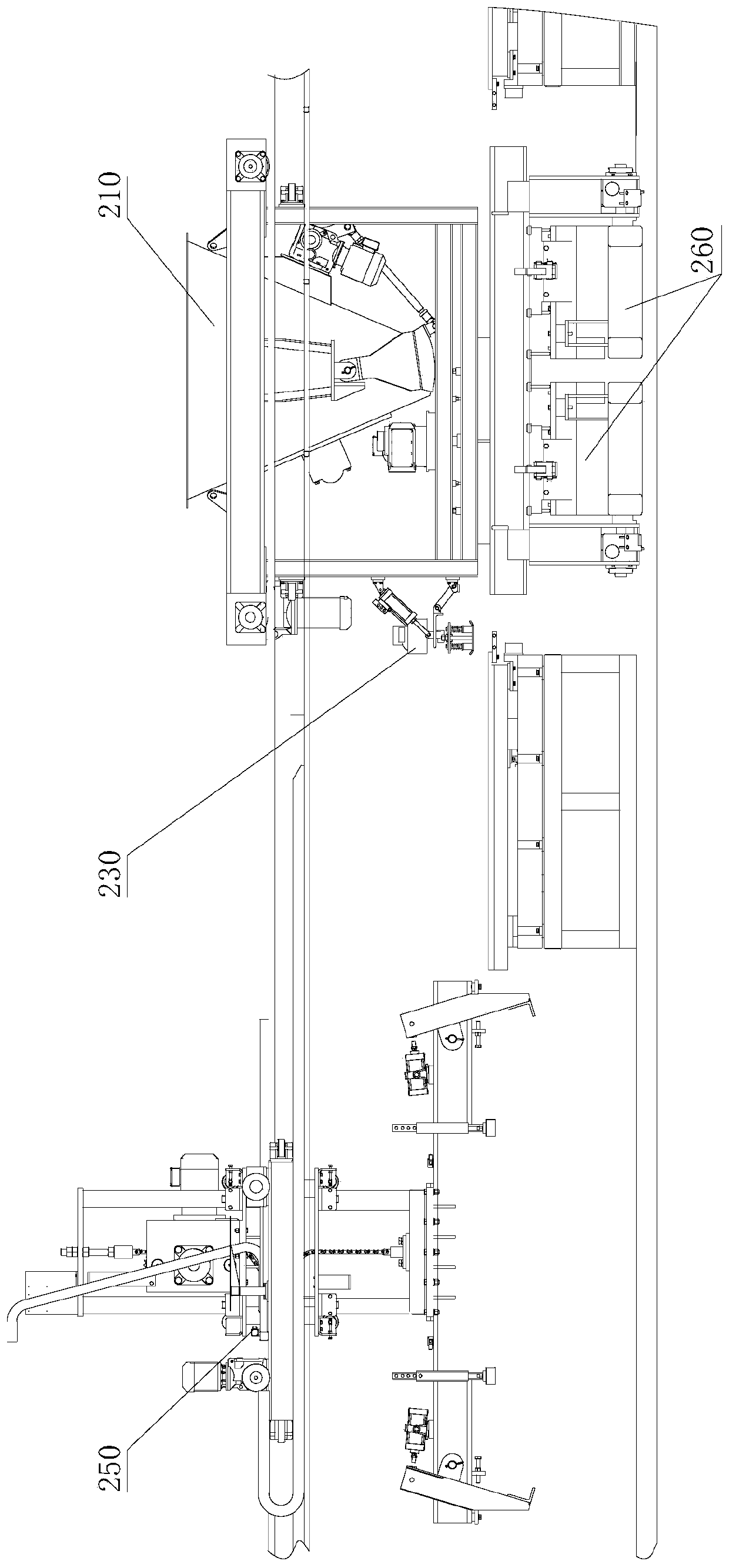

Prefabricated part formwork system and operation method thereof

PendingCN114182952AImprove appearance qualityImprove integrityForms/shuttering/falseworksBuilding material handlingArchitectural engineeringSteel frame

The invention discloses a prefabricated part formwork system which comprises an outer wall steel frame assembly and an outer wall body formwork, a bottom steel frame assembly and a bottom formwork lower formwork are arranged between the lower ends of the outer wall steel frame assembly, and the formwork system further comprises a rail located above the bottom formwork lower formwork. The track is connected with a movable seat capable of moving front and back through a walking mechanism, the movable seat is connected with an inner wall steel frame assembly through a jacking mechanism, and the two sides of the inner wall steel frame assembly are connected with inner wall side formworks through oblique guide mechanisms and driving mechanisms correspondingly. The invention further discloses an operation method of the prefabricated part formwork system, integrality is good, one-time pouring of the concrete can be achieved through all the formworks, construction joints are reduced, the construction efficiency is improved, and the construction cost is reduced. Through-wall opposite pulling is not needed, the structural appearance and the waterproof performance of the component are better, and the device has the advantages of being high in automation degree, rapid in formwork removal and the like.

Owner:JIANGXI GETO NEW MATERIALS CORP LTD

Mold for concrete preformed hole and construction method

PendingCN106869495AMove quicklySimple demouldingForms/shuttering/falseworksBuilding material handlingBuilding constructionCivil engineering

Owner:龚正圣

Prefabricated composite slab general combined assembling formwork and using method thereof

InactiveCN111070389AReduce manufacturing costImprove the speed of demoldingMouldsComposite slabMold removal

The invention discloses a prefabricated composite slab general combined assembling die and a using method thereof. The prefabricated composite slab general combined assembling die comprises a die table, composite slab forming dies formed by connecting first general edge formworks, second general edge formworks, third general edge formworks and net scale edge formworks in sequence are installed onthe die table, and at least one of the first general edge formworks, the second general edge formworks, the third general edge formworks and the net scale edge formworks serves as a rib outlet edge formwork. Each rib outlet edge formwork comprises an upper assembly and a lower assembly, wherein the upper assembly and the lower assembly are connected through fasteners, and a through-long rib outletgroove is reserved between the upper assembly and the lower assembly; and a first sealing bar is installed on the lower surface of the upper assembly, a second sealing bar is installed on the upper surface of the lower assembly, the thickness of the first sealing bar is larger than that of the second sealing bar, and the height of the rib outlet groove is smaller than the sum of the thickness ofthe first sealing bar and the thickness of the second sealing bar. In formwork changing, only the net scale edge formworks need to be replaced, and in formwork removing, only the net scale edge formworks and the upper assemblies of the rib outlet edge formworks need to be disassembled.

Owner:HUNAN SANXIN BUILDING IND

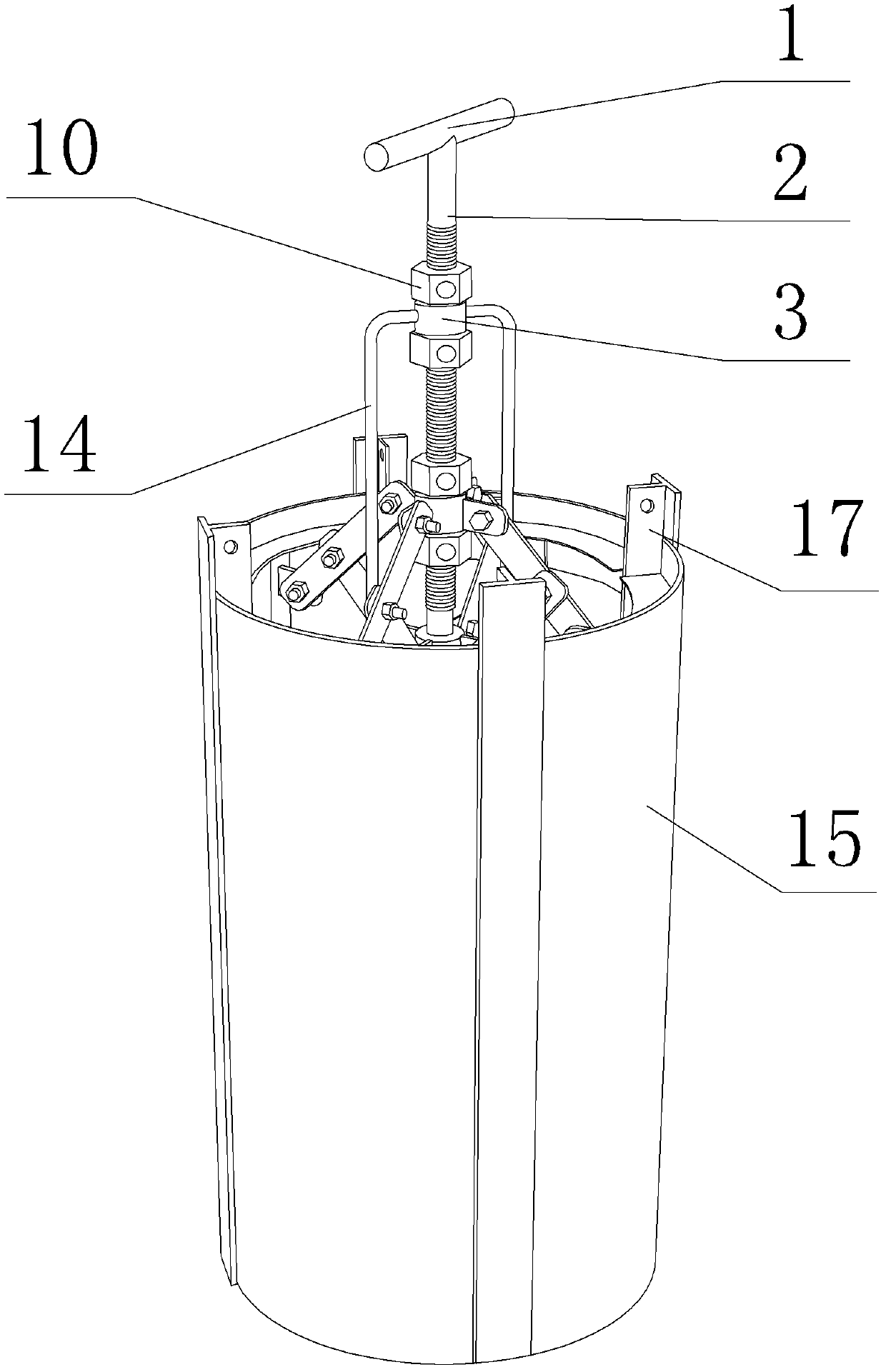

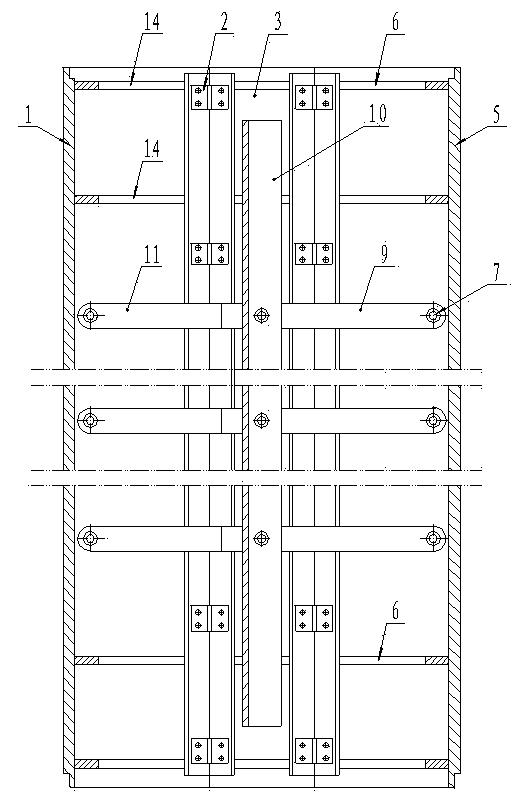

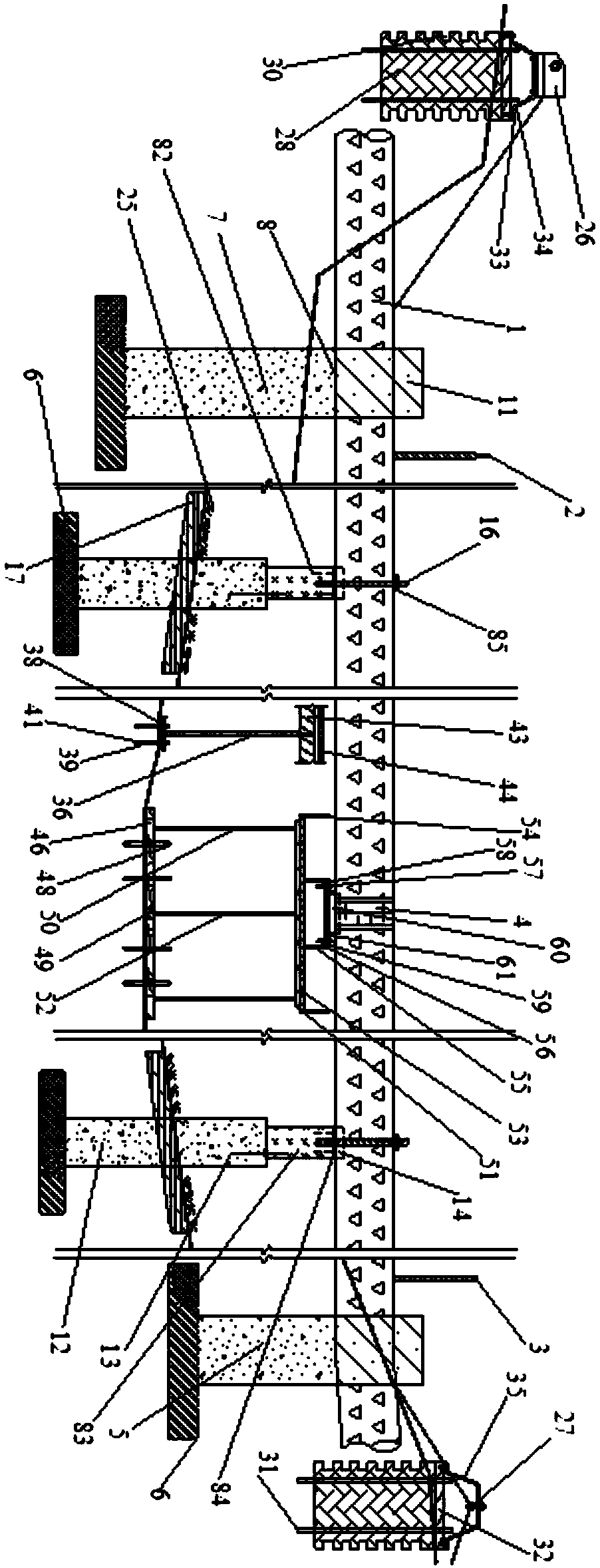

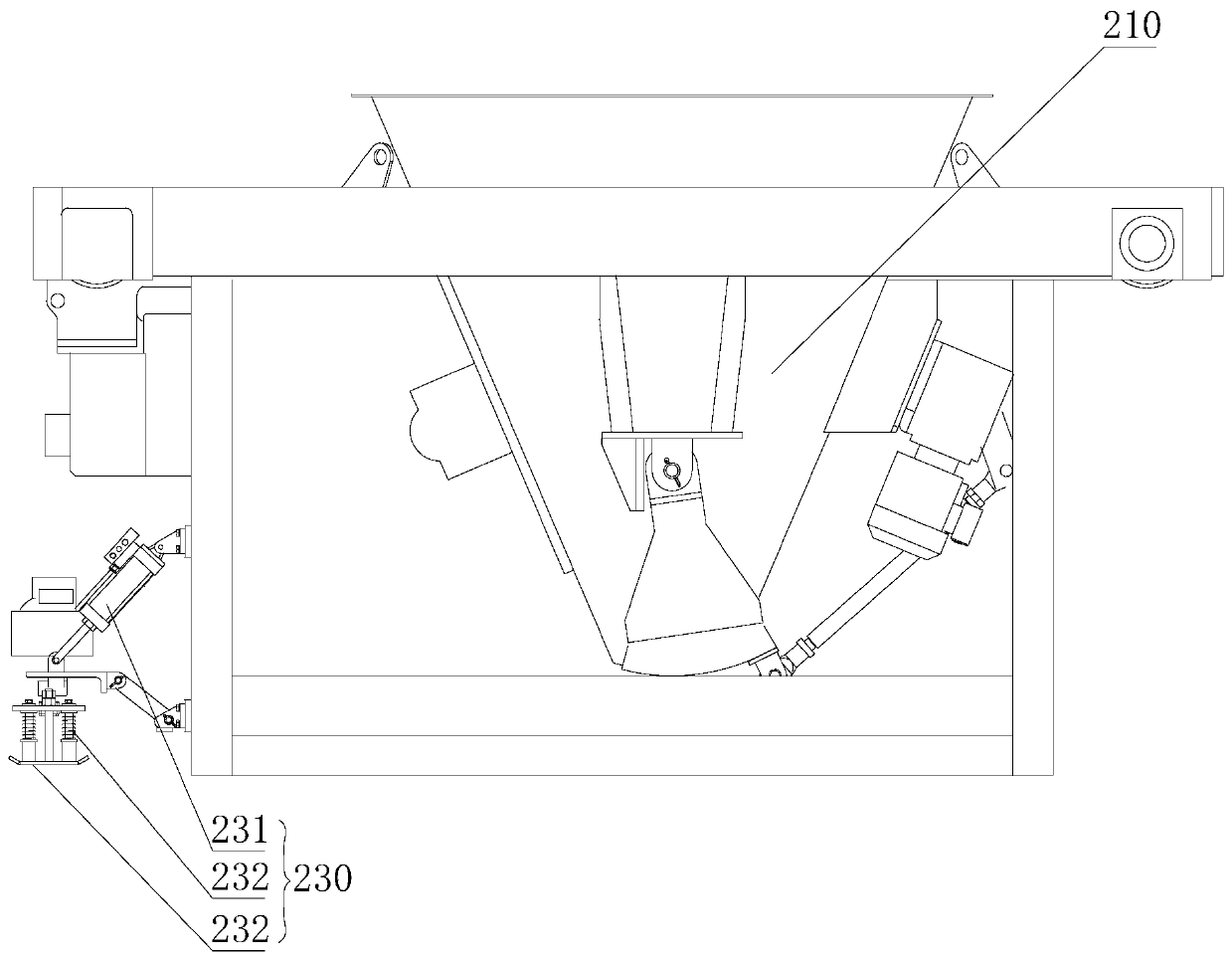

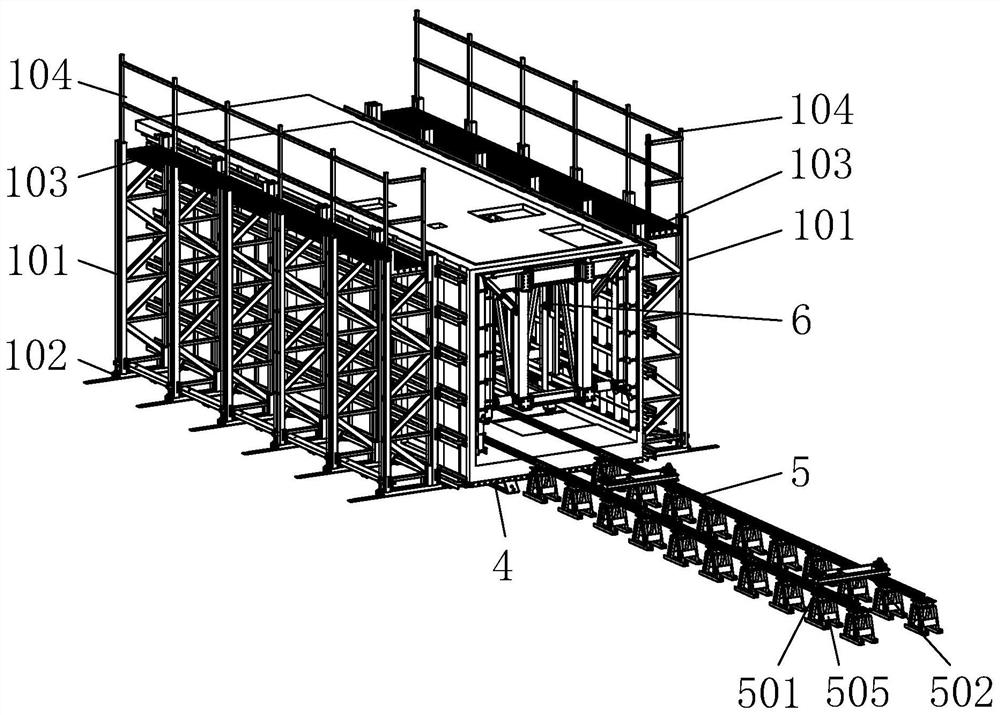

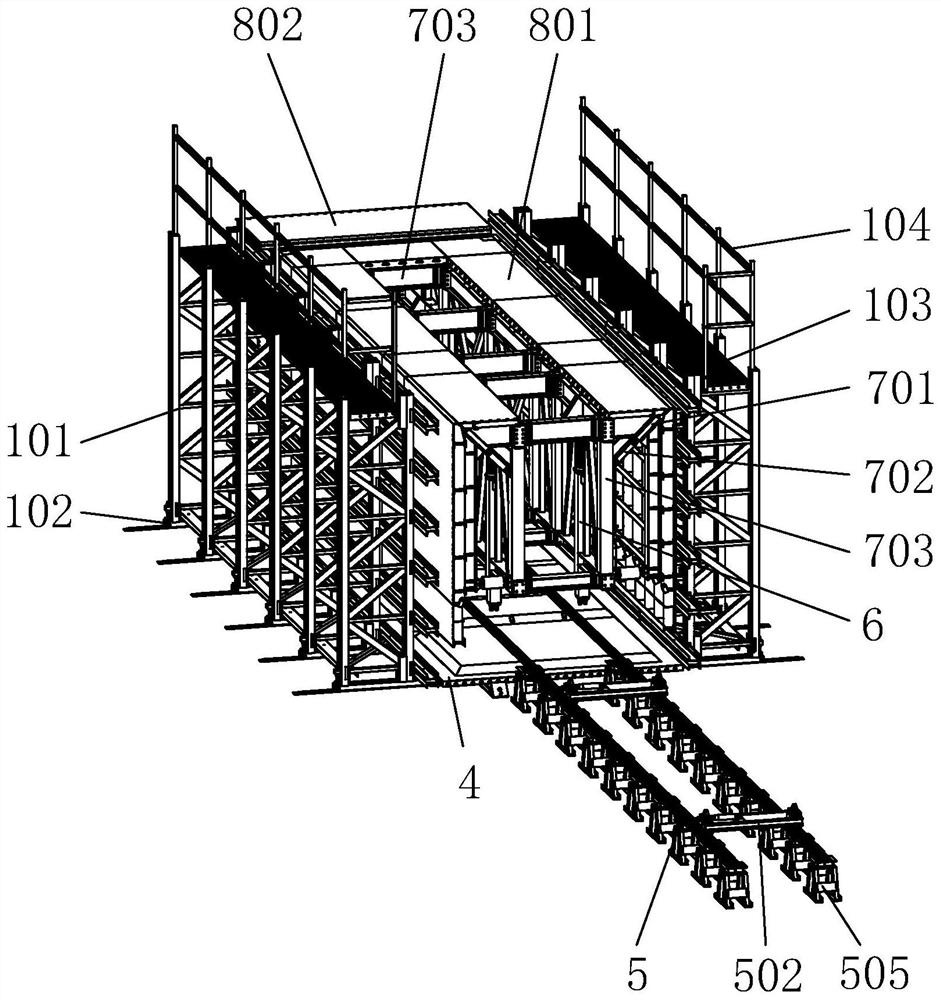

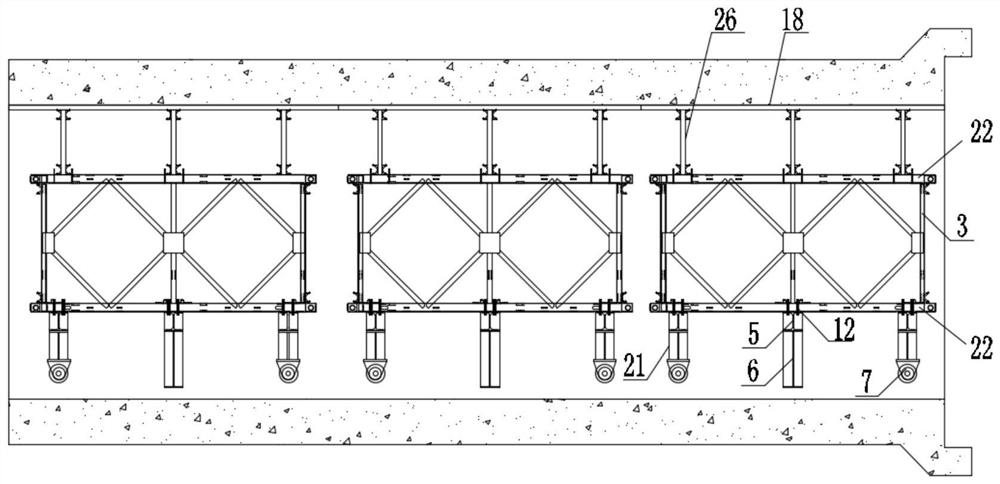

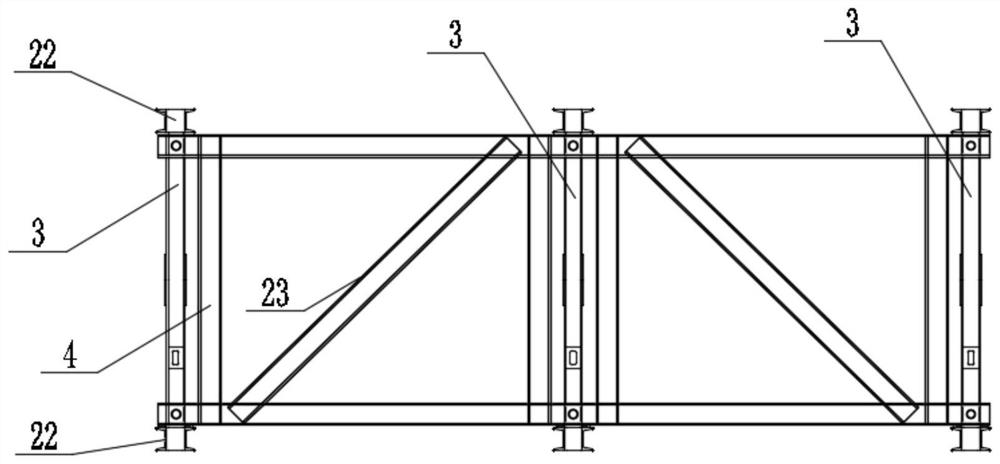

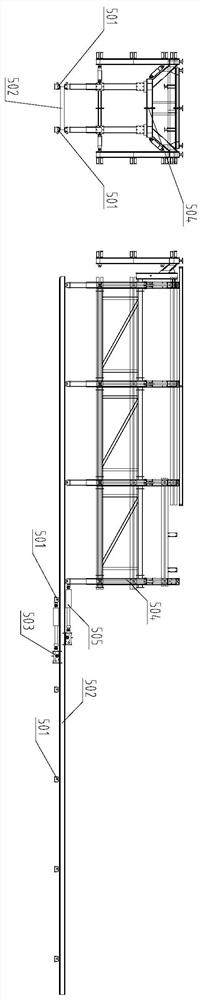

Walking type pipe gallery formwork supporting device

PendingCN112664235AFast assemblyImprove work efficiencyUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention relates to a walking type pipe gallery formwork supporting device. The walking type pipe gallery formwork supporting device comprises a vehicle body, an upper truss, an inner formwork assembly, a cross beam lengthening joint and a length-adjustable inclined strut, wherein the upper truss is connected with the top of the vehicle body; a short section formwork is fixedly connected to the upper portion of the cross beam lengthening joint; a chamfering formwork is arranged at the upper end of an inner side formwork; an upper cross beam of the upper truss is fixedly connected with a top formwork; the two ends of the upper cross beam of the upper truss are connected with the chamfering formwork of the inner side formwork through the cross beam lengthening joint; and one end of the length-adjustable inclined strut is connected with the cross beam lengthening joint. According to the walking type pipe gallery formwork supporting device, the inner side formwork can be adjusted to be fixed to the design position through the length-adjustable inclined strut, and side formworks can be adjusted at multiple angles and in multiple directions; the formwork splicing speed is high, side walls and a top plate can be poured at the same time, the operation efficiency can be greatly improved, the construction period is shortened, and economical efficiency is good; the vehicle body is of a bailey frame structure, the dead load is low, and walking is convenient; and machining and combination can be conducted in a segmented manner in the longitudinal direction, and the walking type pipe gallery formwork supporting device is very flexible to use in an operation section with large longitudinal slope changes.

Owner:CHINA CONSTR FOURTH ENG DIV

Construction method of equipment foundation reserved square hole

ActiveCN102493482AFlexible supportFlexible demolitionForms/shuttering/falseworksFoundation engineeringEngineeringPlastic film

The invention belongs to a construction method of an equipment foundation reserved square hole. The construction method of the equipment foundation reserved square hole is characterized by comprising the following steps: first step, assembling a die; second step, erecting the die: adjusting the dimensions of an upper opening of the reusable die of the equipment foundation reserved square hole, unscrewing a fourth positioning nut, moving a second sliding adjustment seat downwards to reach the rectangular dimensions of a corner die plate upper opening, unscrewing a second positioning nut, moving a first sliding adjustment seat downwards to reach the rectangular dimensions of an corner die plate lower opening, then screwing a third positioning nut and a first positioning nut, and taking a plastic film or a binding tape as a protective layer of the die plate to wrap up on the outside walls of the corner die plate and a middle die plate; third step, pouring concrete; fourth step, removing the die plates, extracting the corner die plate and leaving a square hole opening; and fifth step, cleaning the hole opening to obtain the equipment foundation reserved square hole. The method is simple to operate and is fast in die removal, and the die can be reused.

Owner:CHINA FIRST METALLURGICAL GROUP

Lightweight plaster wall and integral pouring procedure thereof

InactiveCN101041980BStrong impact resistanceImprove flexural strengthWallsThermal insulationEngineering

The invention relates to a light gesso wall and relative integral irrigation method. The wall is disposed with a light steel keel support whose two sides are arranged with strengthen mesh cloth. The space between two strengthen mesh cloths is fixed with flexible thermal insulator. The gesso mixture is filled in the light keel support to cover the flexible thermal insulator and the strengthen meshcloths. The invention has high shaping speed, high mould detaching speed, and maintenance free. And the wall has high strength, non crack, thermal insulation and sound adsorption, with smooth and flat surface.

Owner:刘辉

Formwork system capable of being automatically adjusted and walking and operation method thereof

PendingCN113047607AImprove appearance qualityUse lessForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringSteel frame

The invention provides a formwork system capable of being automatically adjusted and walking and an operation method thereof. The formwork system comprises a formwork system, a steel frame system, a hydraulic system and an electrical system; the formwork system comprises an inner wall body formwork, an outer wall body formwork, a bottom formwork and an inner wall top plate formwork; the steel frame system comprises an inner wall steel frame system and an outer wall steel frame system; an inner wall formwork is composed of the inner wall body formwork, the inner wall top plate formwork and the inner wall steel frame system; an outer wall formwork is composed of the outer wall body formwork and the outer wall steel frame system; a pouring cavity is formed between the inner wall formwork and the outer wall formwork; the electrical system controls the inner wall formwork to be demolded and walk. The integrity is good. According to the formwork system capable of being automatically adjusted and walking and the operation method thereof, one construction joint can be reduced through one-time pouring of concrete, the structural integrity is better, and the appearance quality of the concrete is better; and the wall-penetrating opposite-pulling process is omitted, a structural wall body is not provided with a wall-penetrating hole, and the structural appearance and the waterproof performance are improved.

Owner:JIANGXI GETO NEW MATERIALS CORP LTD

Method for preparing straw insulation board

InactiveCN102060495BWide variety of sourcesLow priceConstruction materialSolid waste managementPolymer scienceMicro bubble

The invention discloses a method for preparing a straw insulation board. The straw insulation board is prepared by the steps of string and mixing calcination desulfurization gypsum, calcium carbonate heavy, ordinary Portland cement, latex powder, surfactant, crop straw powder, vitrified micro bubbles, water and the like which are used as raw materials, pouring, molding, curing and the like. The straw insulation board prepared by the method has the advantages of low preparation cost, contribution to production, high mechanical property, fire resistance and durability, and high crack resistanceand thermal property, and the like, and provides building wall materials with high performance for vast rural areas.

Owner:CHONGQING UNIV

Pouring formwork and pouring method for large biogas tank body

InactiveCN102635230BHigh strengthRapid modelingForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksCircular cavityMaterials science

The invention discloses a pouring template for a large methane pool body. A pouring circle is enclosed by pouring templates which are connected mutually, each pouring template consists of an internal template and an external template which are connected by bolts, a forming cavity is formed between the internal template and the external template, the internal template and the external template are both doorframe-shaped metal skeletons consisting of angular steel, the bending surface of the angular steel faces outward, steel plates are welded on the inner side surface of the metal skeleton, locking holes are arranged at the left sides and right sides of the internal template and the external template, and a plurality of large methane pool body pouring templates are horizontally and sequentially connected by bolts through the locking holes correspondingly to form a methane pool body pouring circle with a circular cavity. By utilizing the structure, the pouring templates welded by the metal skeleton consisting of the angular steel and the steel plates, and the methane pool body pouring circle horizontally and sequentially assembled by the pouring templates is utilized to realize fast and convenient template installation and dismounting and quicken the construction speed, the dismounted internal template and external template can be repeatedly utilized, thus saving the production cost.

Owner:FUJIAN PUTIAN HONGDA ANIMAL HUSBANDRY

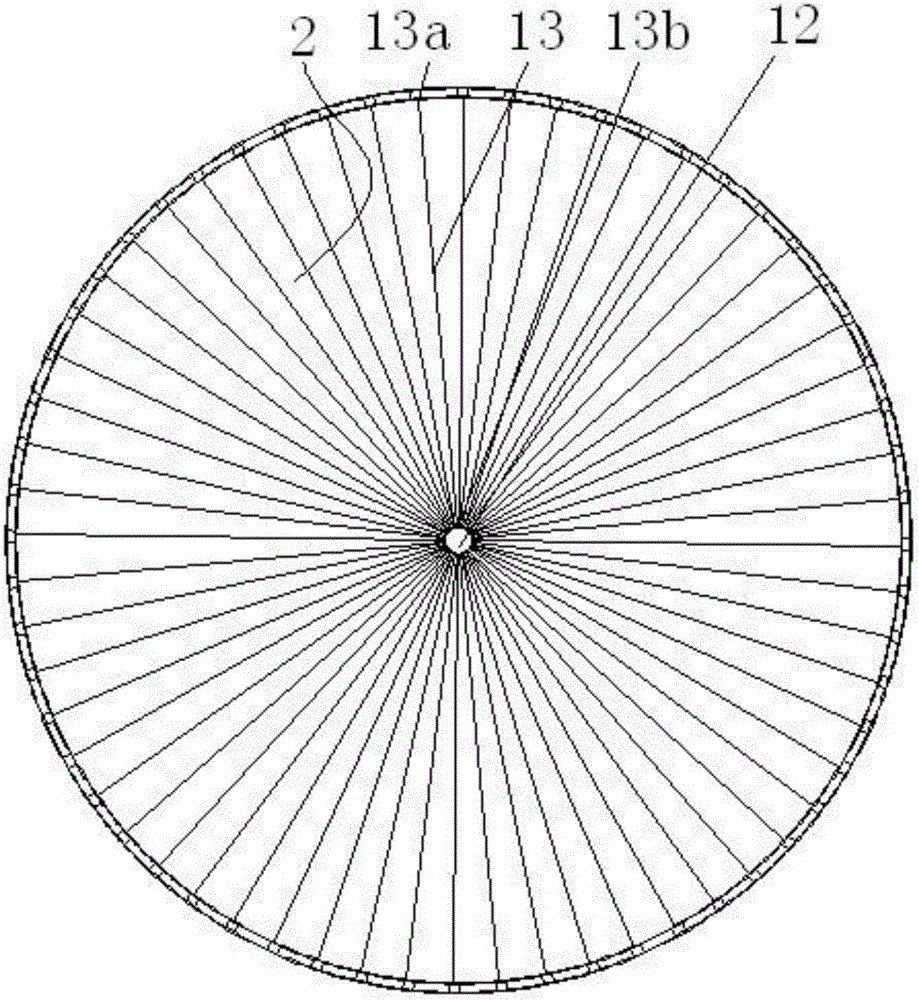

Equipment base pre-reservation round anchor bolt hole die

ActiveCN102433989BFlexible demolitionQuick dismantlingForms/shuttering/falseworksEngineeringScrew thread

The invention relates to a round hole die of an equipment base pre-reservation anchor bolt hole, in particular to an equipment base pre-reservation round anchor bolt hole die, which is characterized in that the equipment base pre-reservation round anchor bolt hole die comprises a center shaft, a first bracing and shrinking device, a second bracing and shrinking device, four templates and four joint sealing plates, wherein the four templates are all in an arc shape and uniformly distributed along a circumference, each joint sealing plate is inserted between two adjacent templates, the four templates and the four joint sealing plates enclose to form a cylindrical space, first template supports on the four templates are all articulated to the first bracing and shrinking device, second template supports on the four templates are all articulated to the second bracing and shrinking device, the lower part of the center shaft, the first bracing and shrinking device and the second bracing and shrinking device are all arranged in the cylindrical space enclosed by the four templates and the four joint sealing plates, the upper part of the center shaft is arranged above the cylindrical space and is provided with outside threads, and a handle is arranged at the upper end of the center shaft. The die is simple to operate and rapid to disassemble and can be used repeatedly.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com