Movable die core of concrete core slab and box girder pouring die

A technology of movable mold core and hollow plate, applied in the direction of ceramic molding core, ceramic molding mandrel, etc., can solve the problems of large draft friction force, easily damaged surface, narrow core space, etc., and achieve low draft friction force , low labor intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

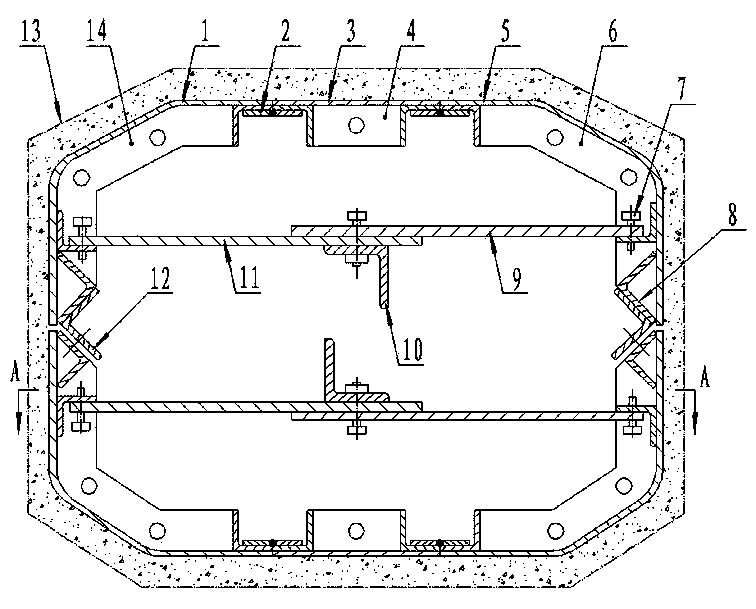

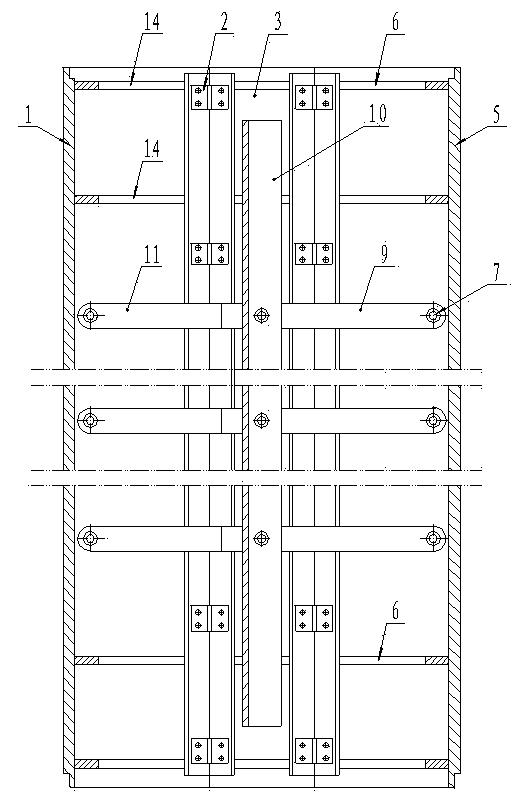

[0011] Such as Figure 1~2 As shown: the mold core is a square tube or a round tube structure formed by combining two concave or semicircular half molds, and each half mold is hinged to the middle plate by the middle plate 3 through the hinge 2 The left side plate 1 on the left side, the right side plate 5 hinged on the right side of the middle panel through another hinge 2, the plurality of left connecting rods 11 hinged on the inner surface of the left side plate 1 through the pin shaft 7 respectively, pass through respectively Other bearing pins 7 are hinged to a plurality of right connecting rods 9 on the inner surface of the right side plate 5, and the pull rods 10 hinged with corresponding left connecting rods 11 and right connecting rods 9 through other bearing pins 7 respectively.

[0012] In order to ensure that the two half-molds can be ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com