Formwork system capable of being automatically adjusted and walking and operation method thereof

A technology of automatic adjustment and formwork, which is applied in the fields of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and preparation of building components on site, which can solve the problems of large manpower input, low comprehensive work efficiency, High labor intensity and other problems, to achieve the effect of good integrity, good waterproof performance, and good structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

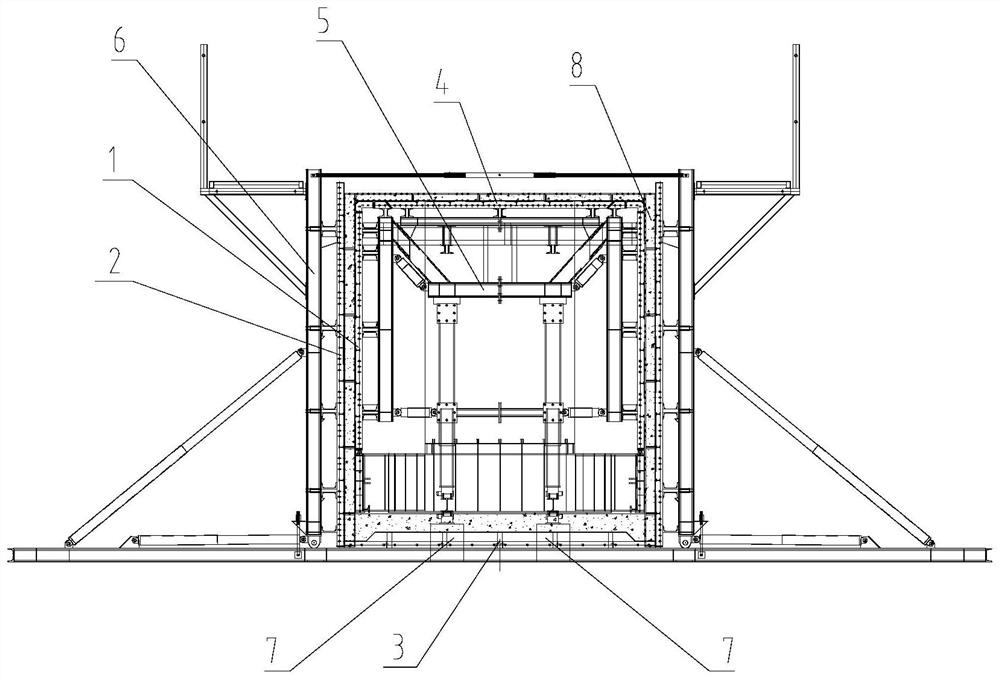

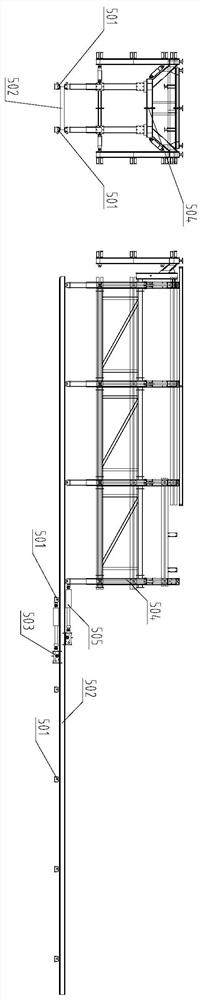

[0101] A self-adjusting and walking internal formwork system includes a formwork system, a steel frame system, a hydraulic system and an electrical system. The formwork system includes an interior wall formwork 1, an exterior wall formwork 2, a bottom formwork 3 and an interior wall roof formwork 4; the steel frame system includes an interior wall steel frame system 5 and an exterior wall steel frame system 6, The interior wall formwork 1, interior wall roof formwork 4 and interior wall steel frame system 5 form an interior wall formwork; the exterior wall formwork 2 and exterior wall steel frame system 6 form an exterior wall formwork, and the A pouring cavity is formed between the inner wall formwork and the outer wall formwork, and the electrical system controls the demoulding and walking of the inner wall formwork.

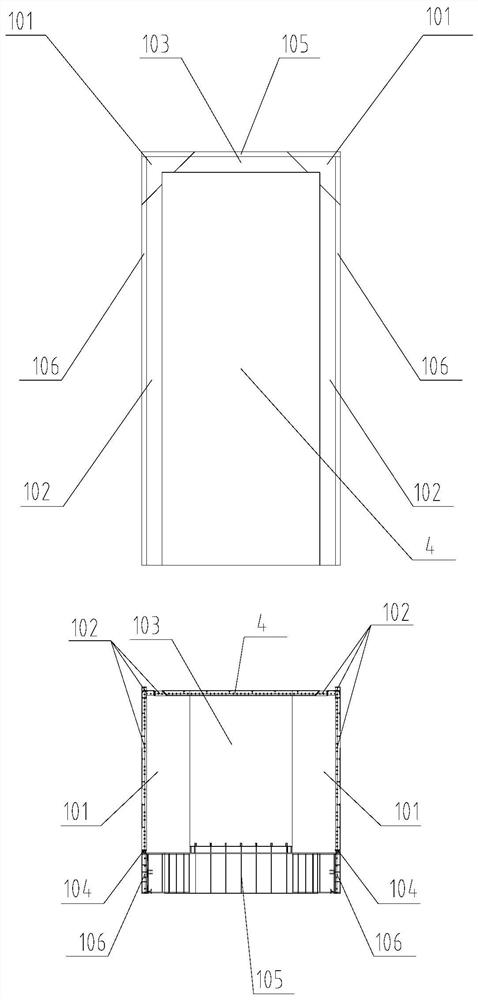

[0102] The upper part of the interior wall formwork 1 is an interior wall corner formwork 101, an interior wall formwork 102, an interior wall intermediate fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com