Lightweight plaster wall and integral pouring procedure thereof

A gypsum and wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of inability to realize mechanized production, primitive construction technology, poor sound insulation effect, etc., and achieve obvious sound insulation effect, excellent construction method, and fast wall forming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

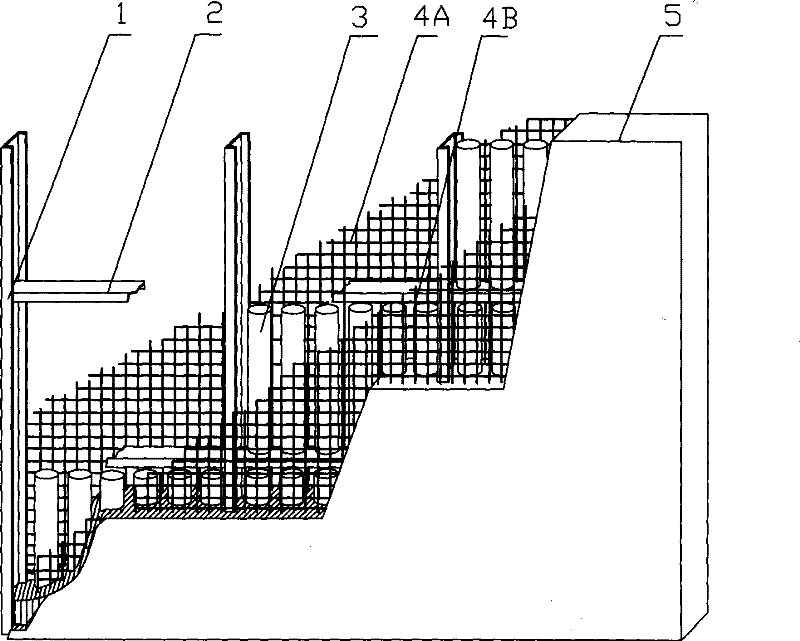

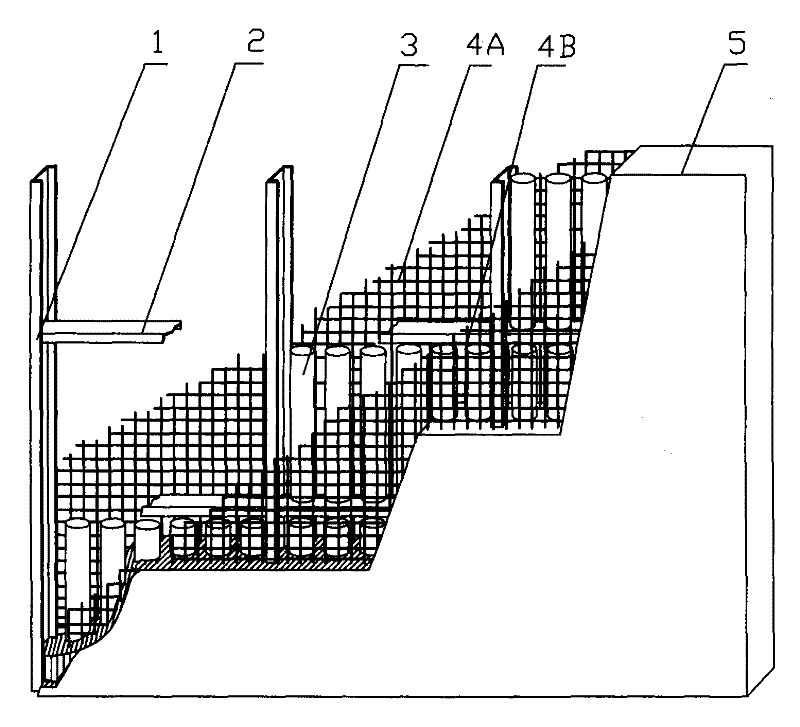

[0021] figure 1 The light-weight gypsum wall of the present invention shown is mainly composed of a light steel dragon frame, a reinforced grid cloth, a gypsum mixture, an elastic heat preservation body, and the like. Wherein the light steel keel frame includes several vertical keels 1 and horizontal keels 2 . The bottom end of vertical keel 1 is fixed on the ground by expansion bolts, and its top is fixed on the roof by expansion bolts (if it is used as a partition, its top is fixed to the top keel), and horizontal keel 2 is fixed in the gap between two adjacent vertical keels ( through the keel) to increase the strength of the entire skeleton.

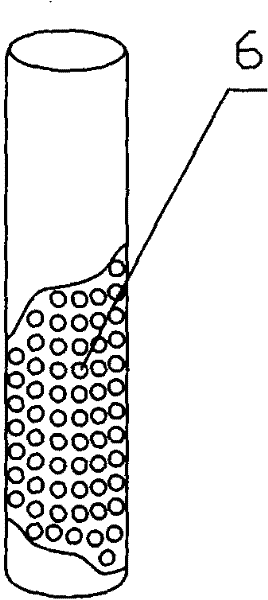

[0022] The reinforced grid cloth C is laid on both sides of the above-mentioned light steel dragon frame and fixed on the frame. In the space between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com