Patents

Literature

43results about How to "No labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

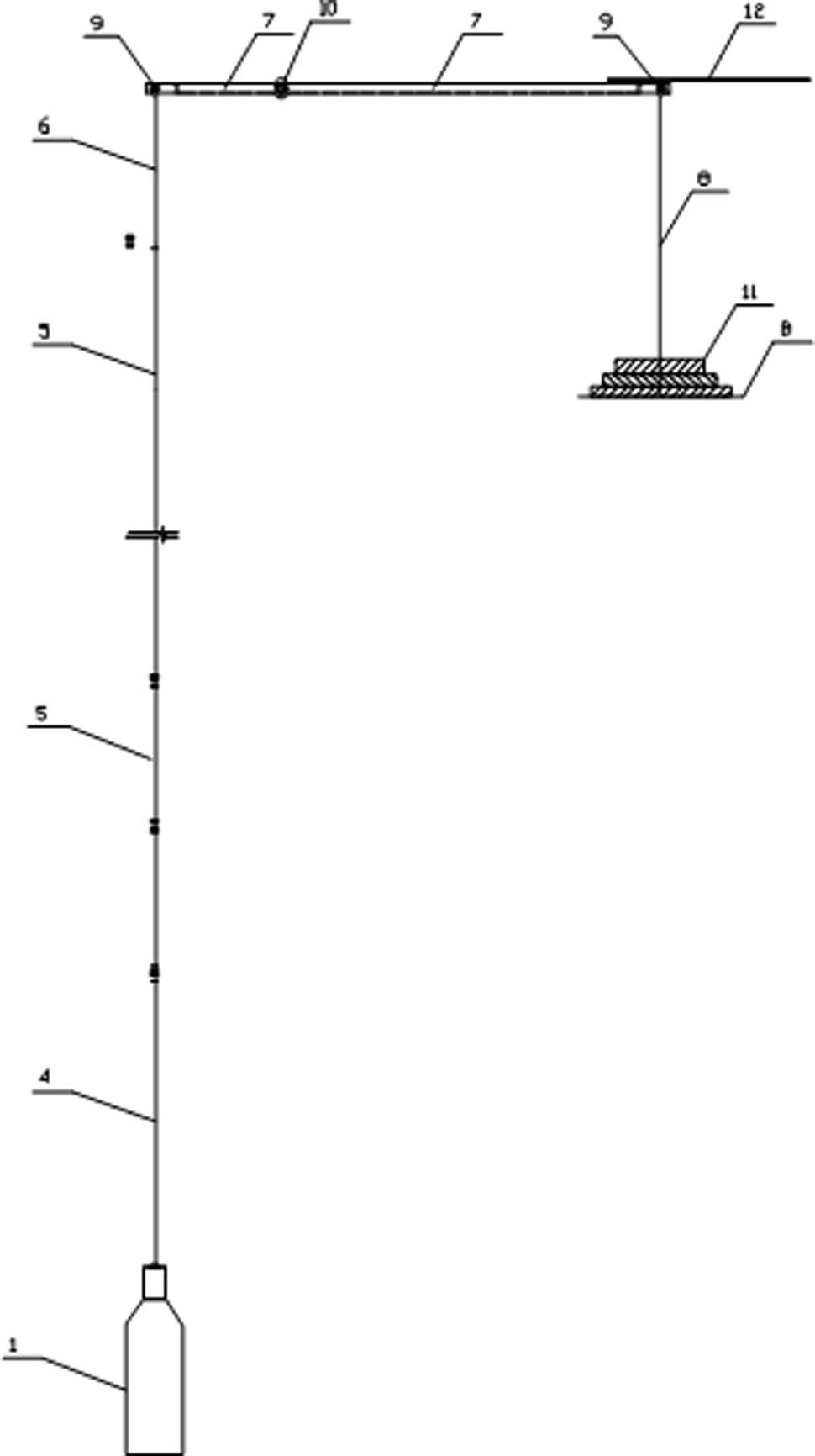

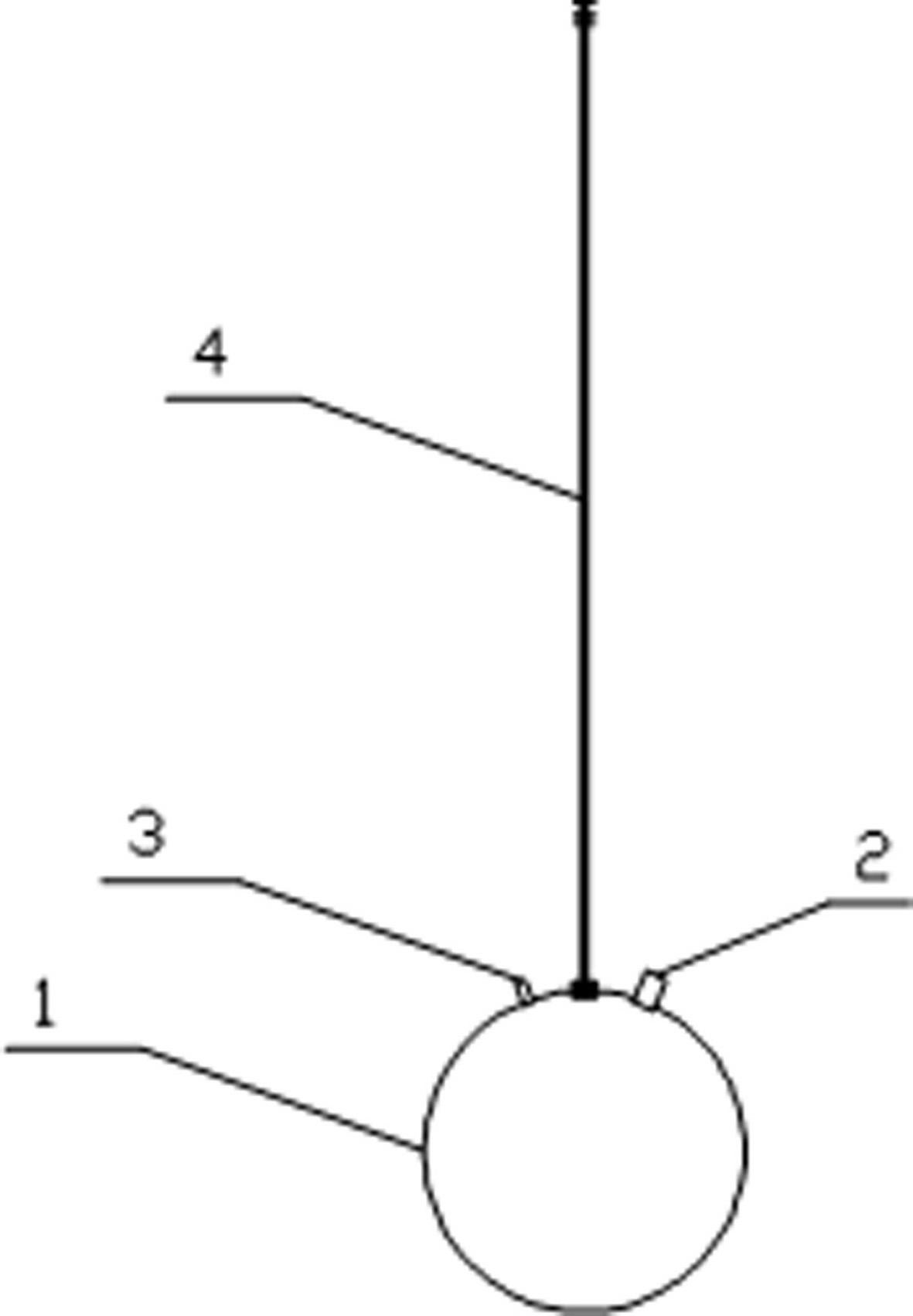

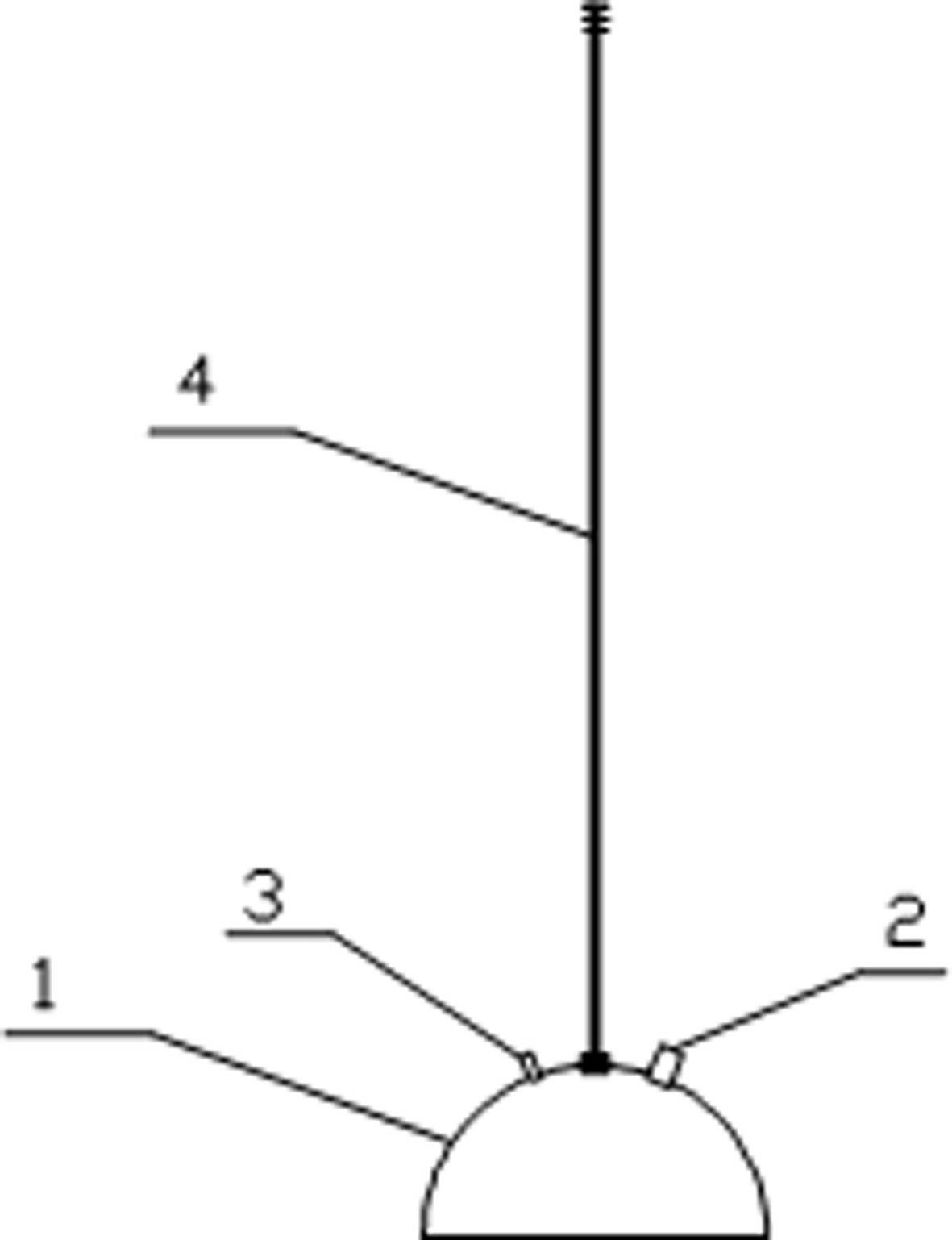

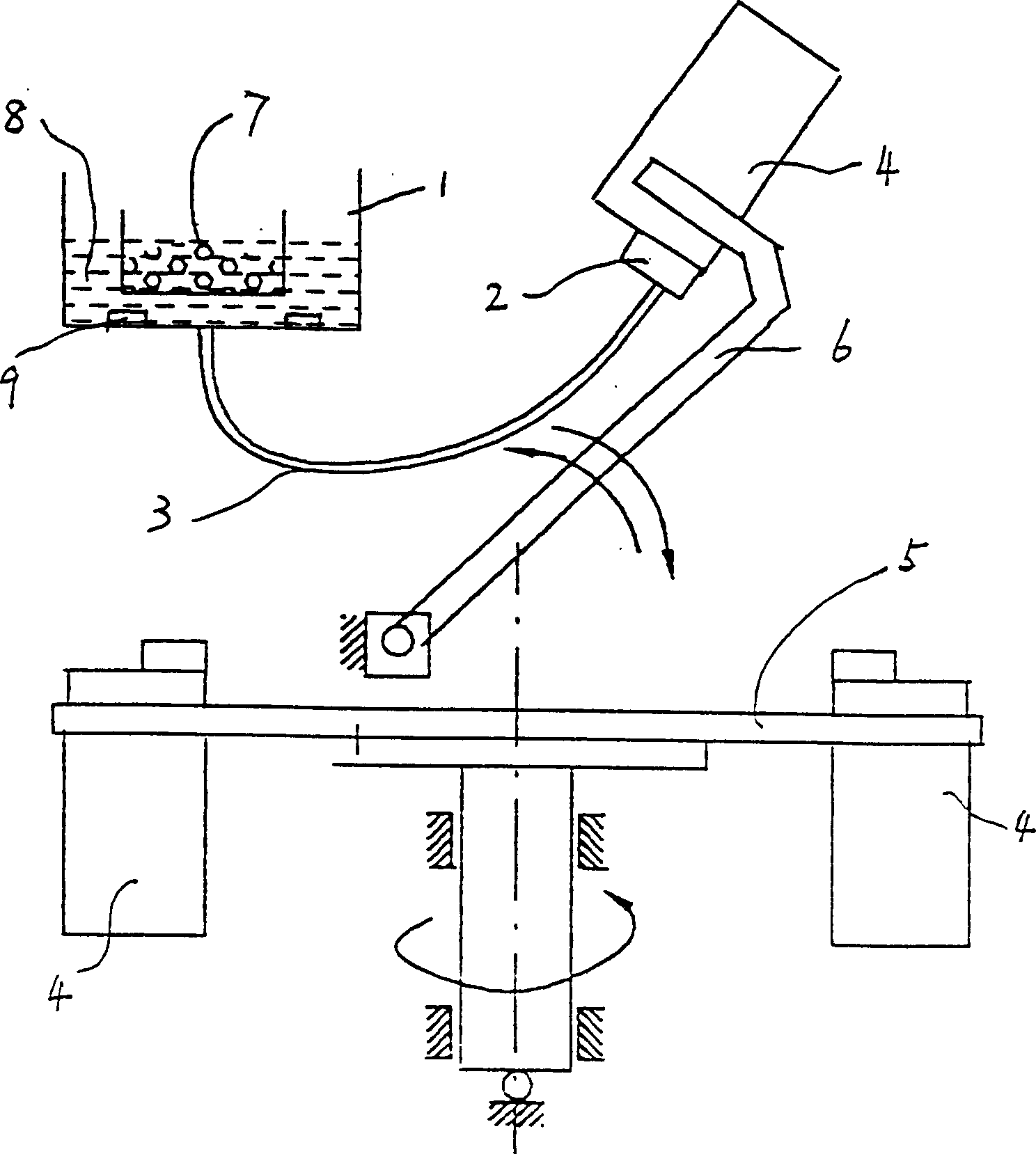

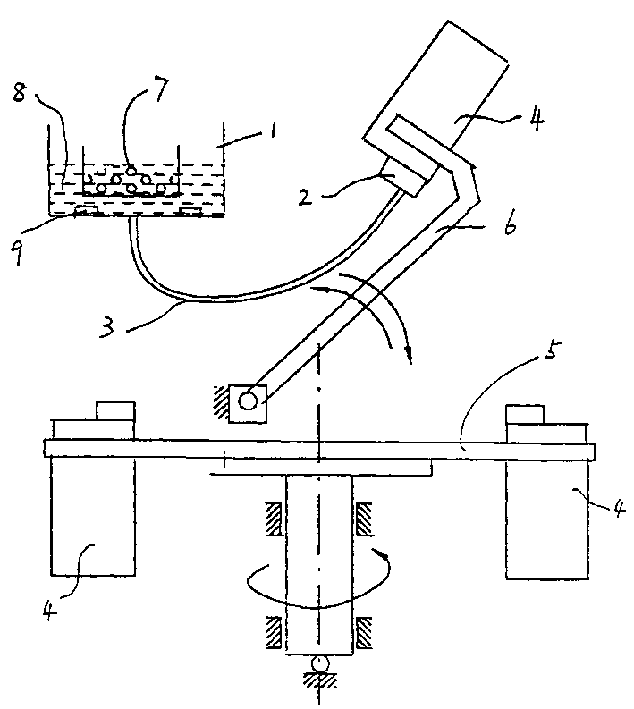

Underwater concrete pouring elevation control device and use method thereof

ActiveCN102359111ASave energyNot affected by adverse construction weatherFoundation engineeringConstruction managementUltimate tensile strength

The invention discloses an underwater concrete pouring elevation control device, which is characterized in that one end of a lever horizontal cross rod (7) is connected with a suspension appliance (1) by using an intermediate lengthening rod (5) and an upper regulating rod (6), and the other end of the lever horizontal cross rod (7) is connected with a counter weight. The underwater concrete pouring elevation control device has the advantages that wide suitable range, simple and convenient installation method and low labor intensity, can be used for completely eliminating a concrete under-pouring phenomenon and favorably controlling an excessive over-pouring phenomenon during concrete pouring, and is beneficial to not only project cost reduction but also to great promotion of construction management level and quality of concrete pouring construction products.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

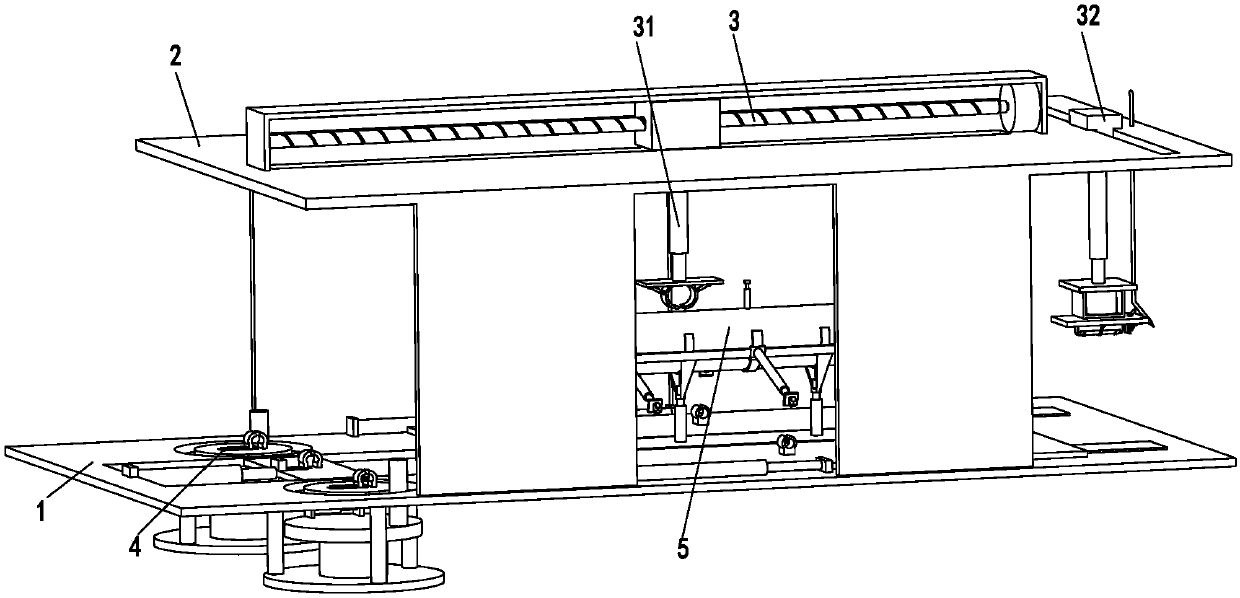

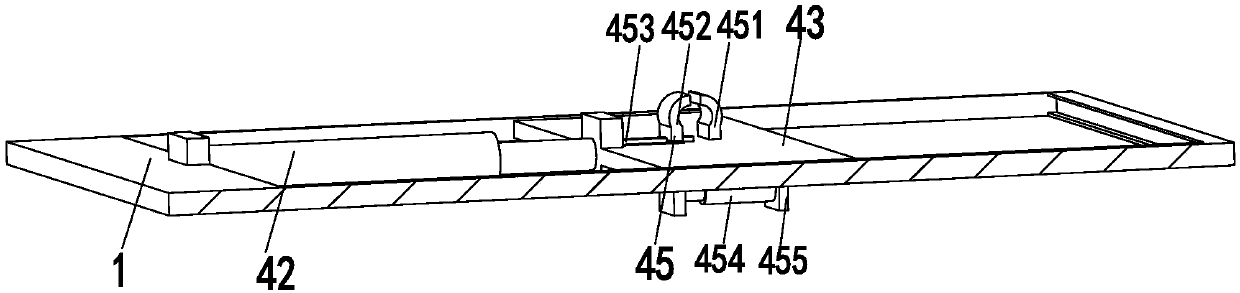

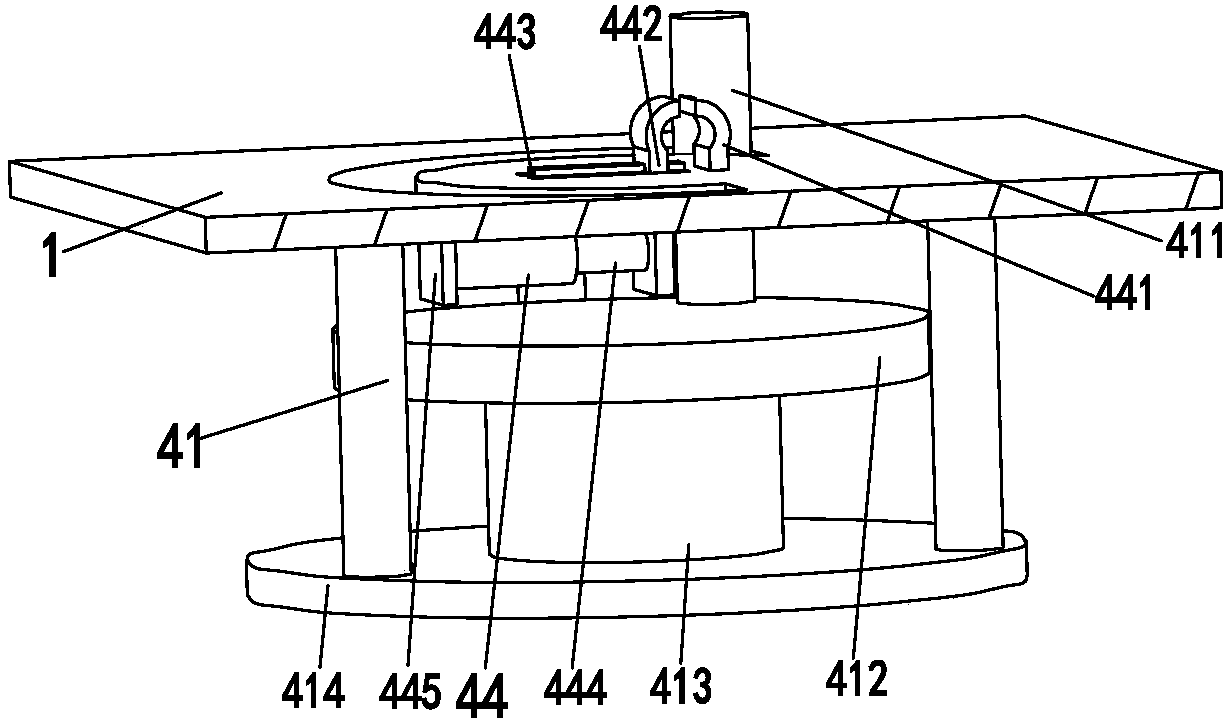

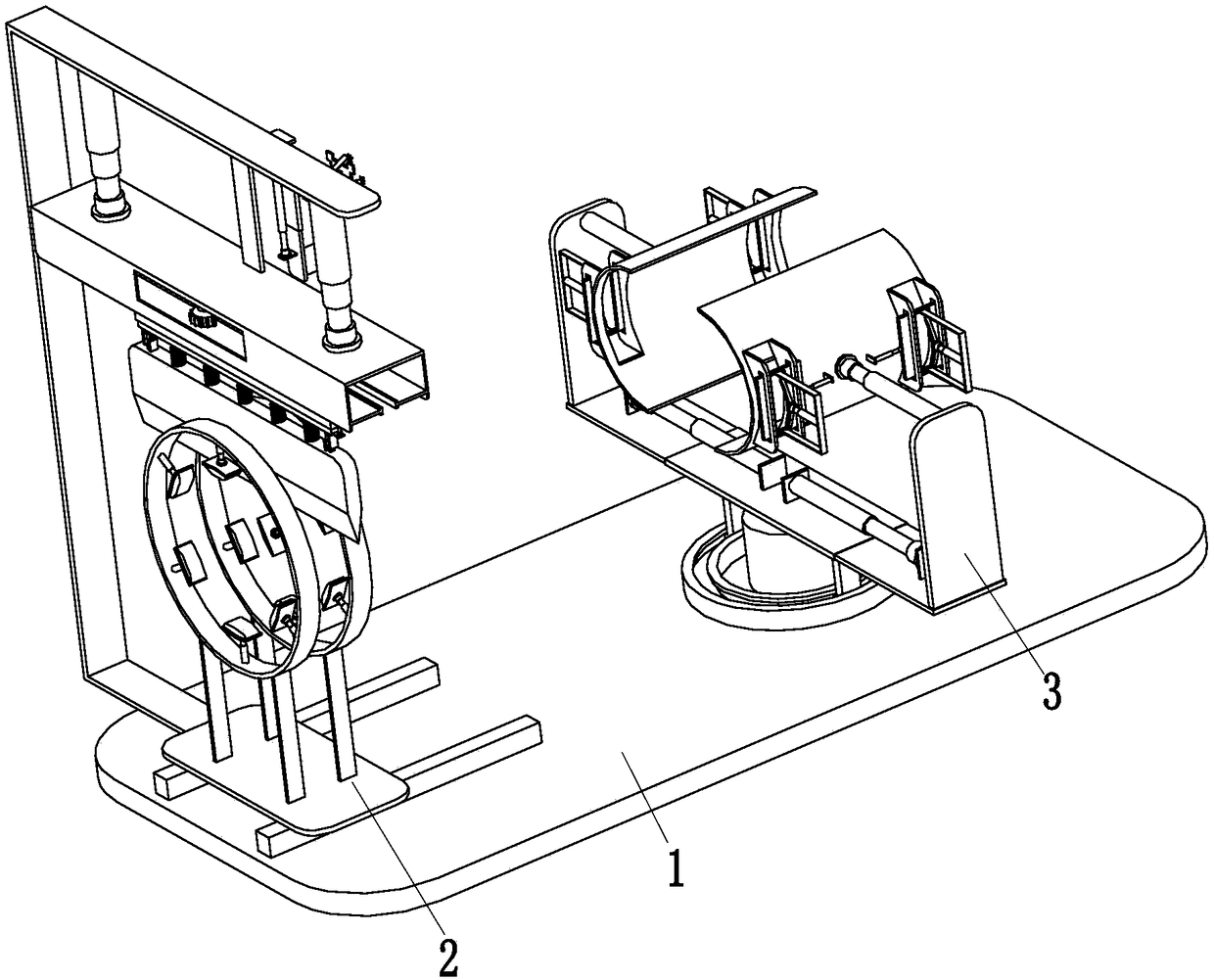

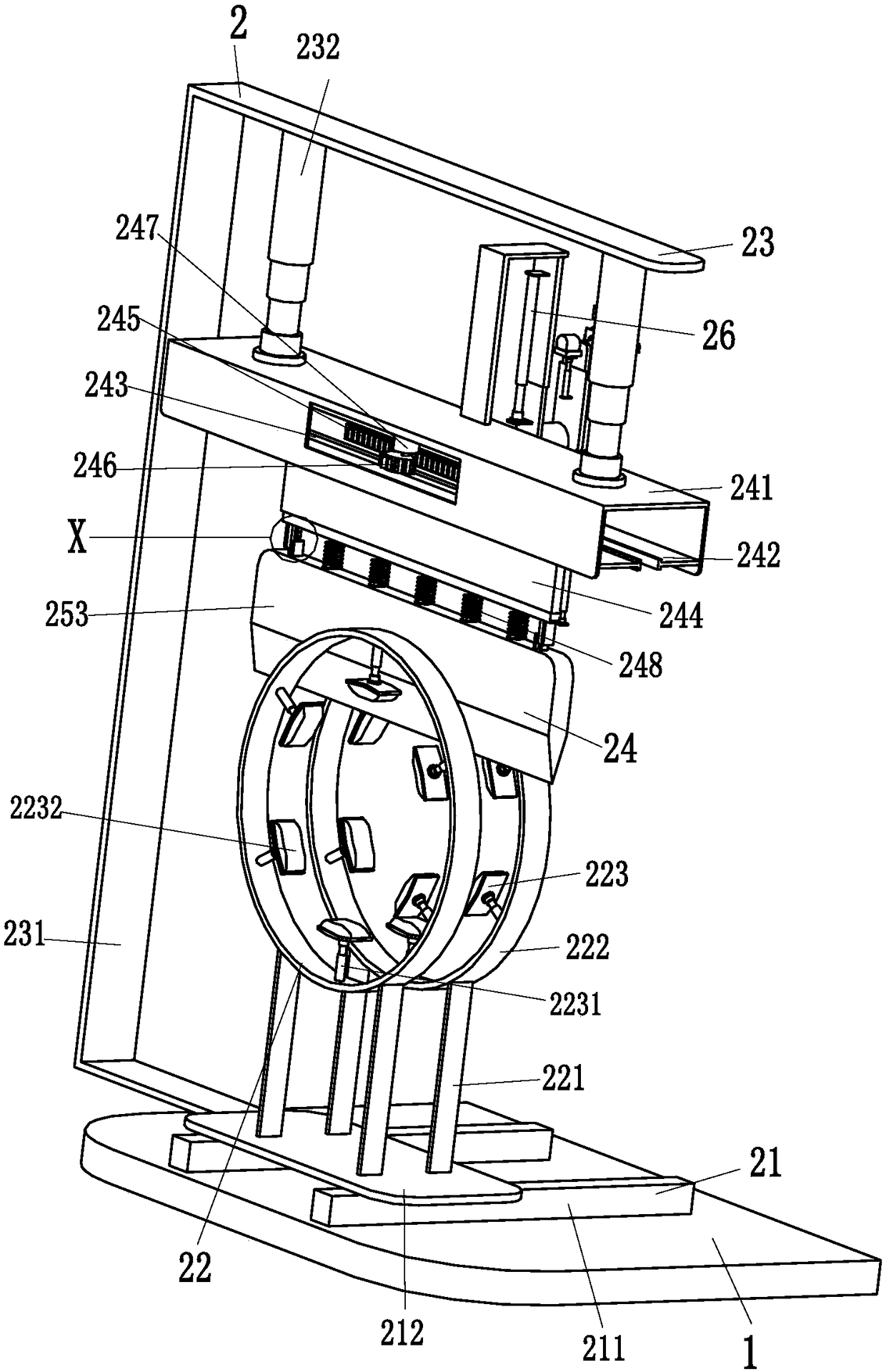

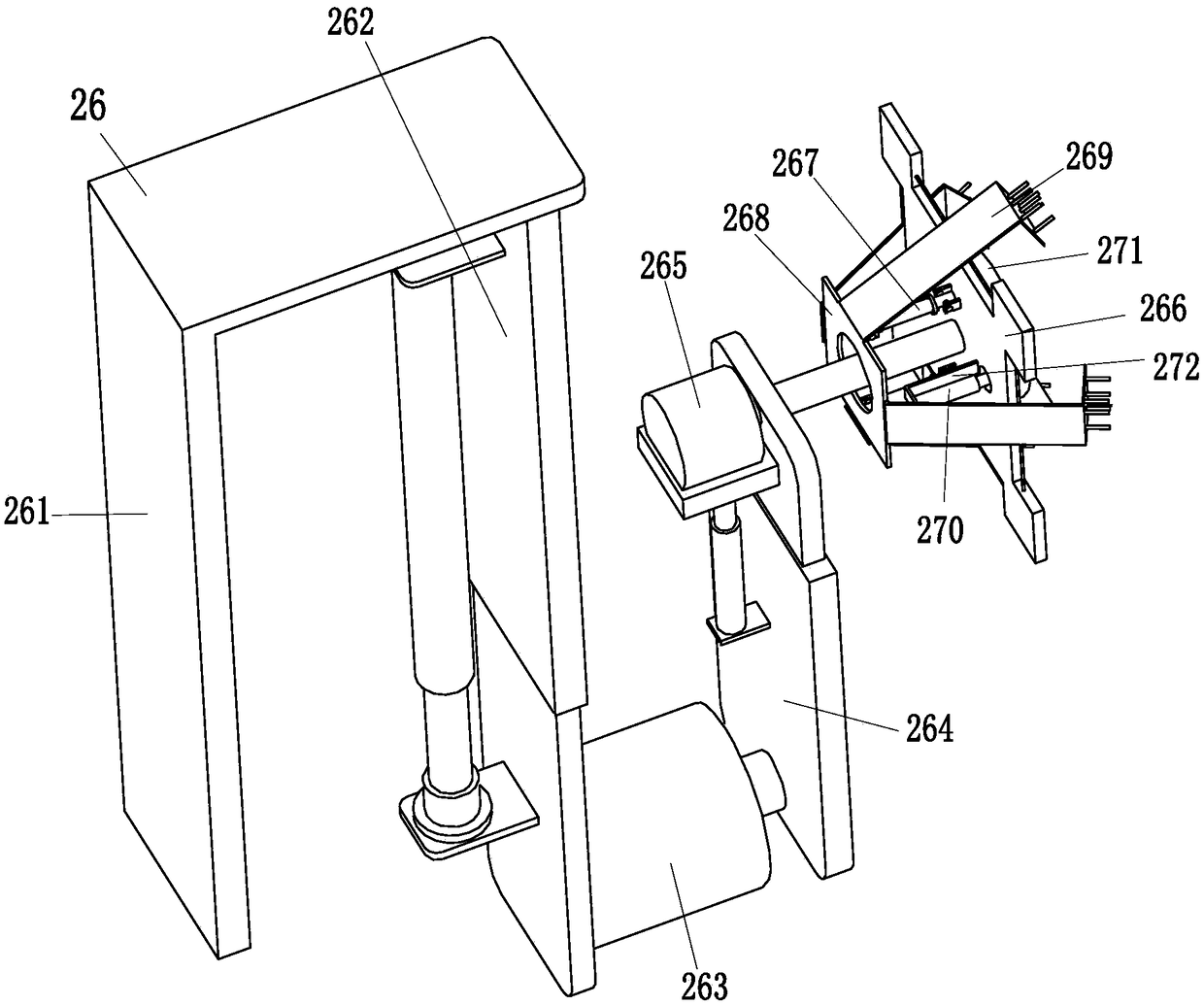

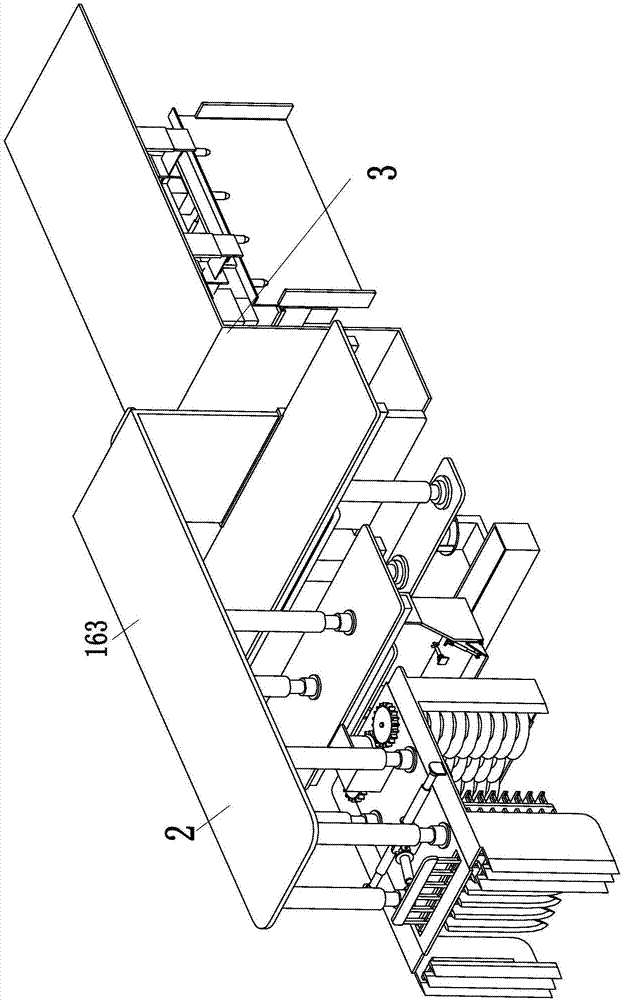

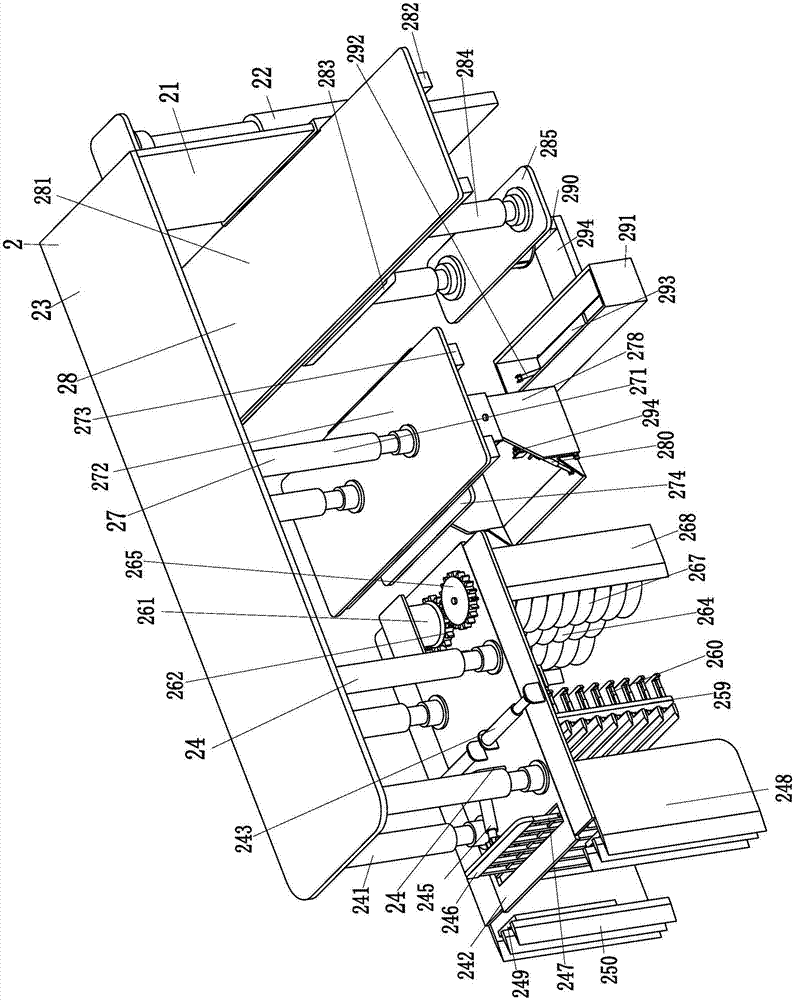

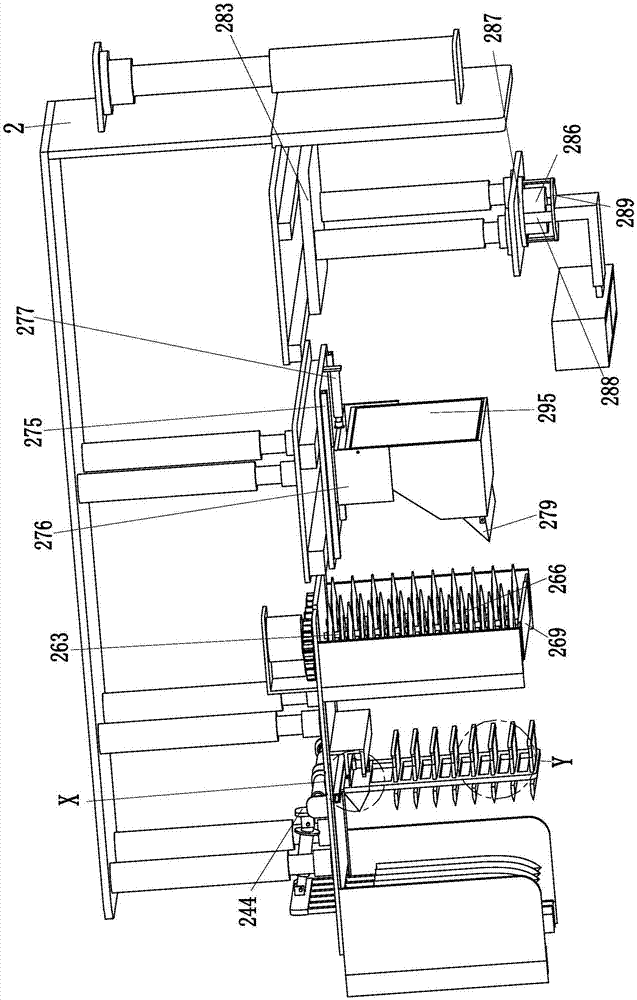

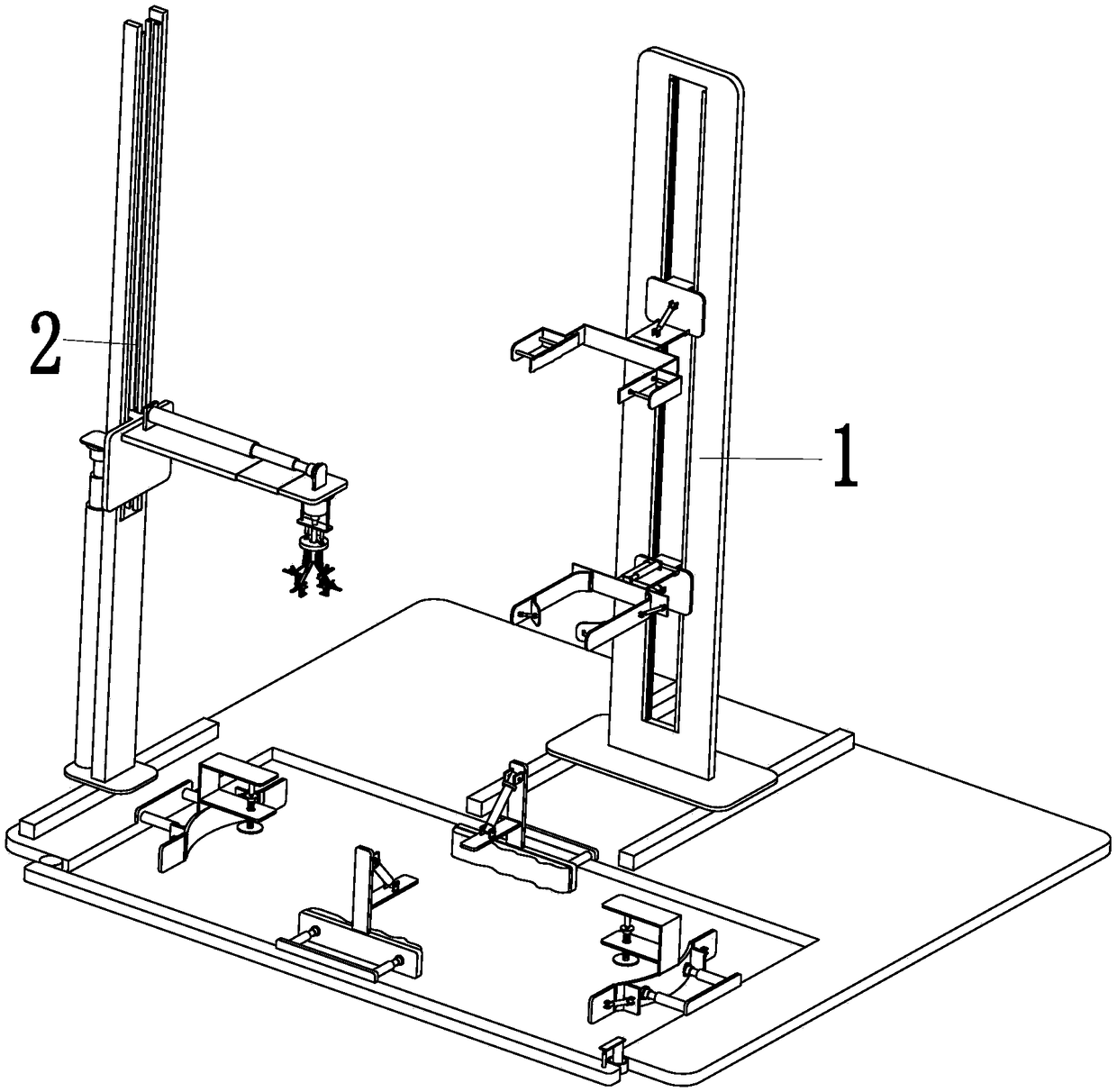

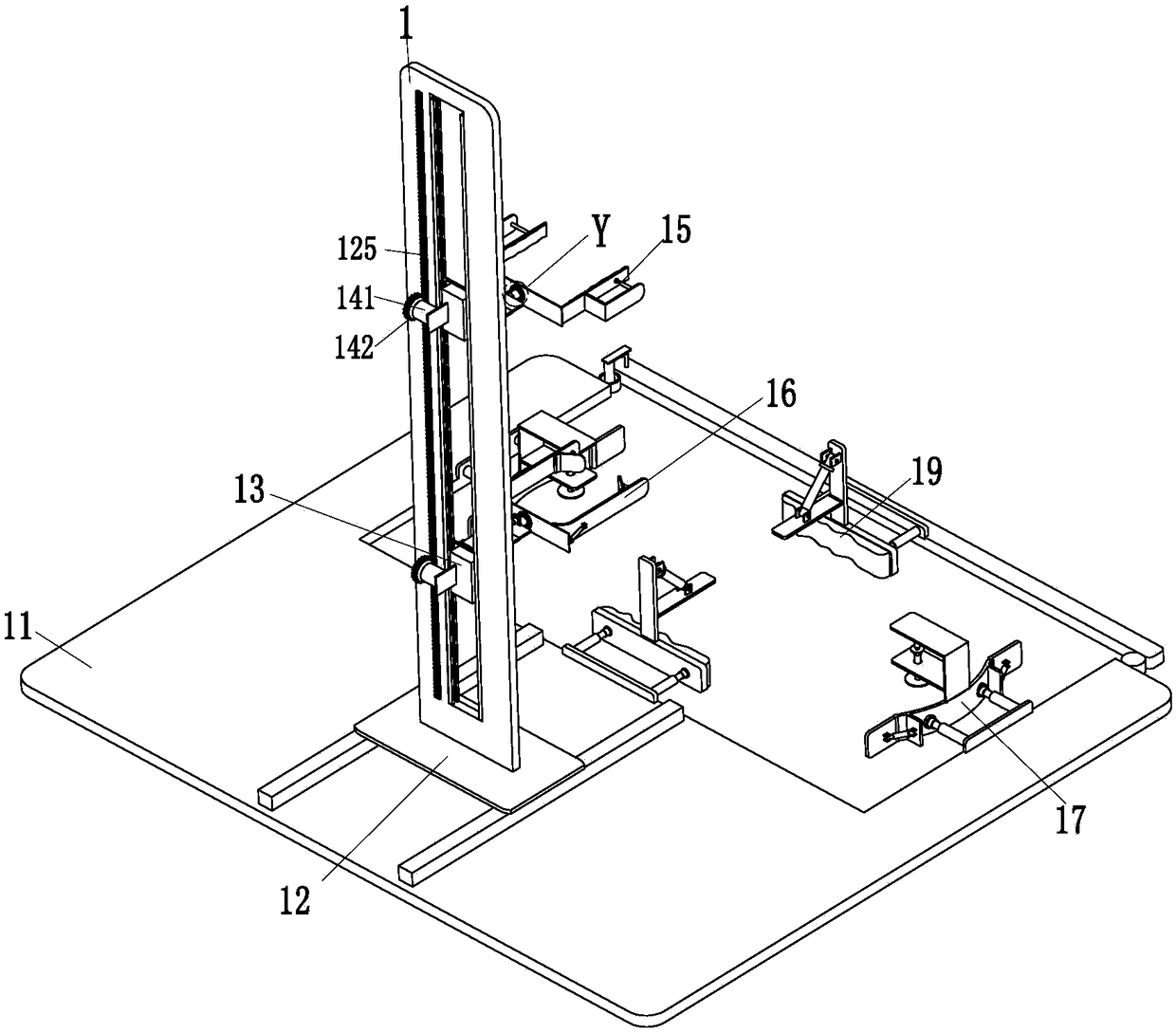

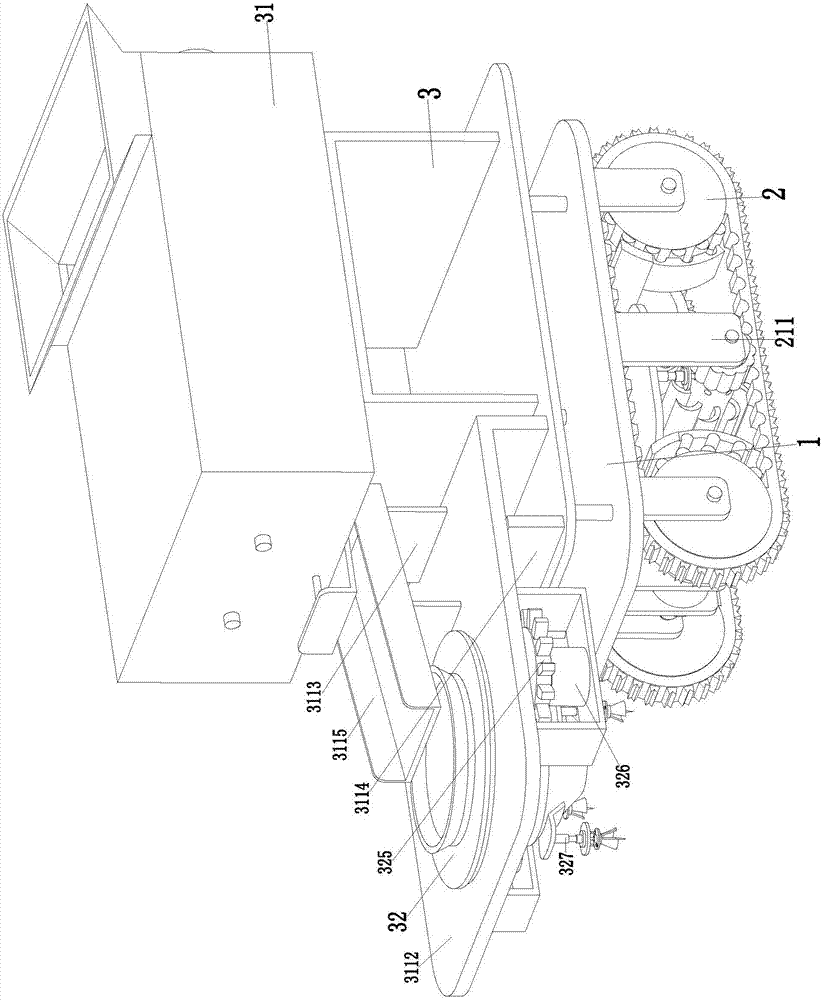

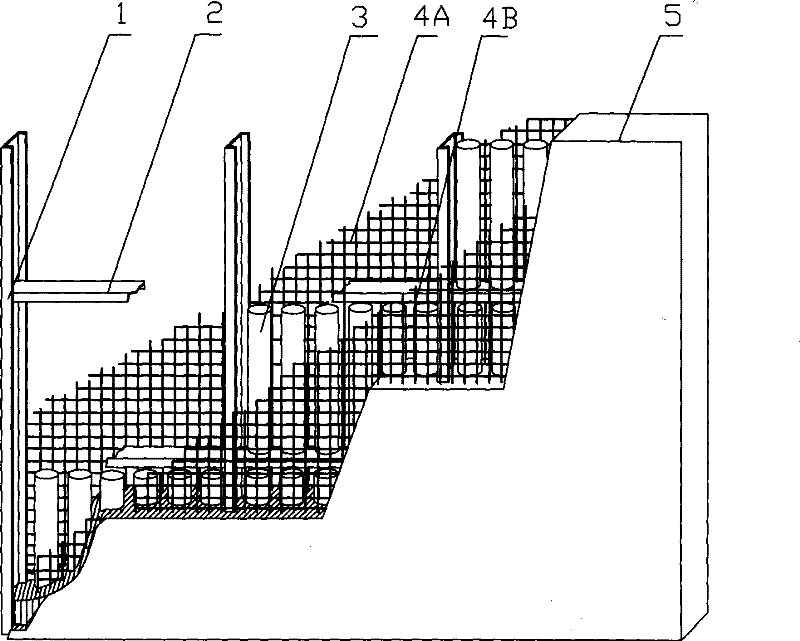

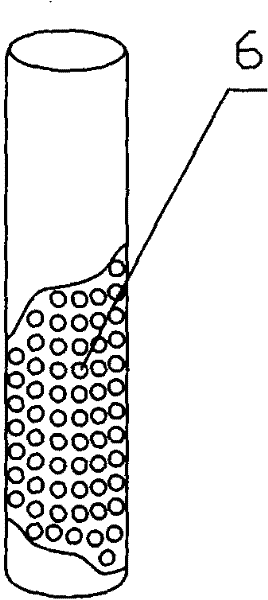

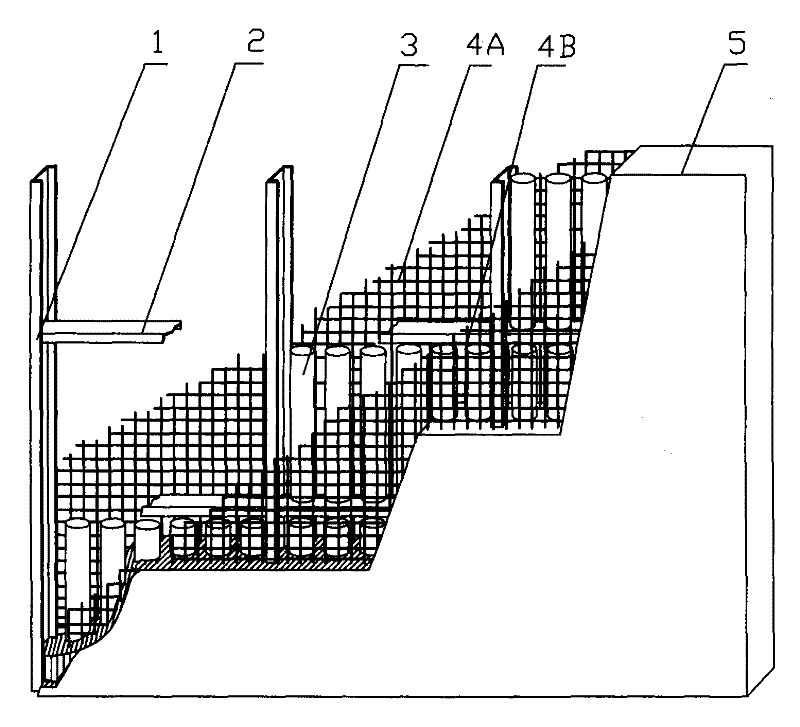

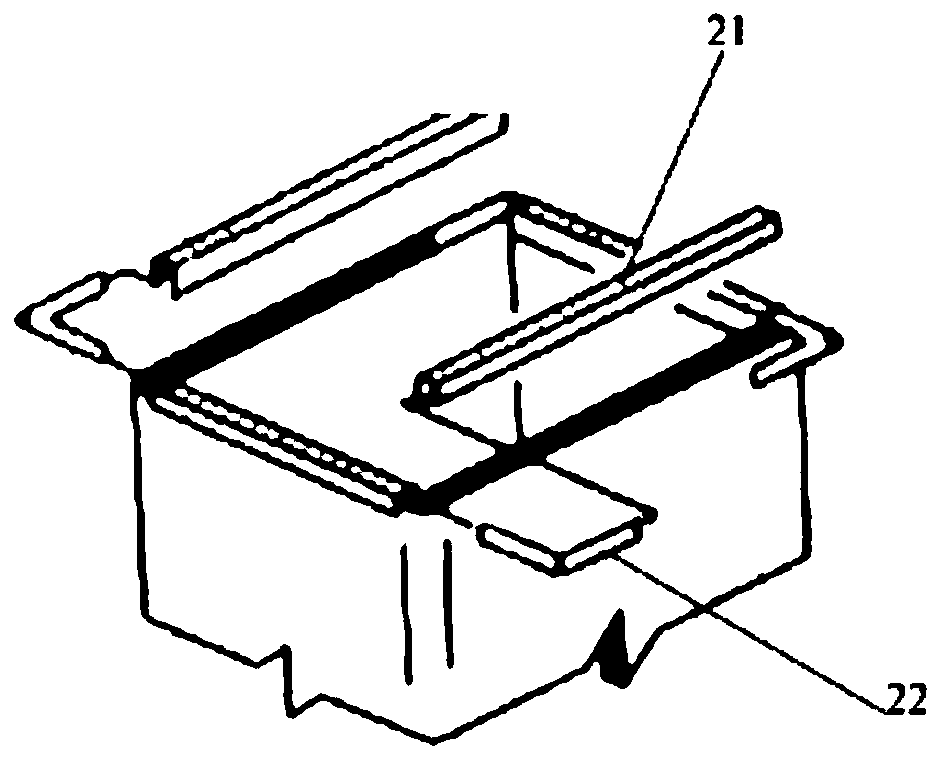

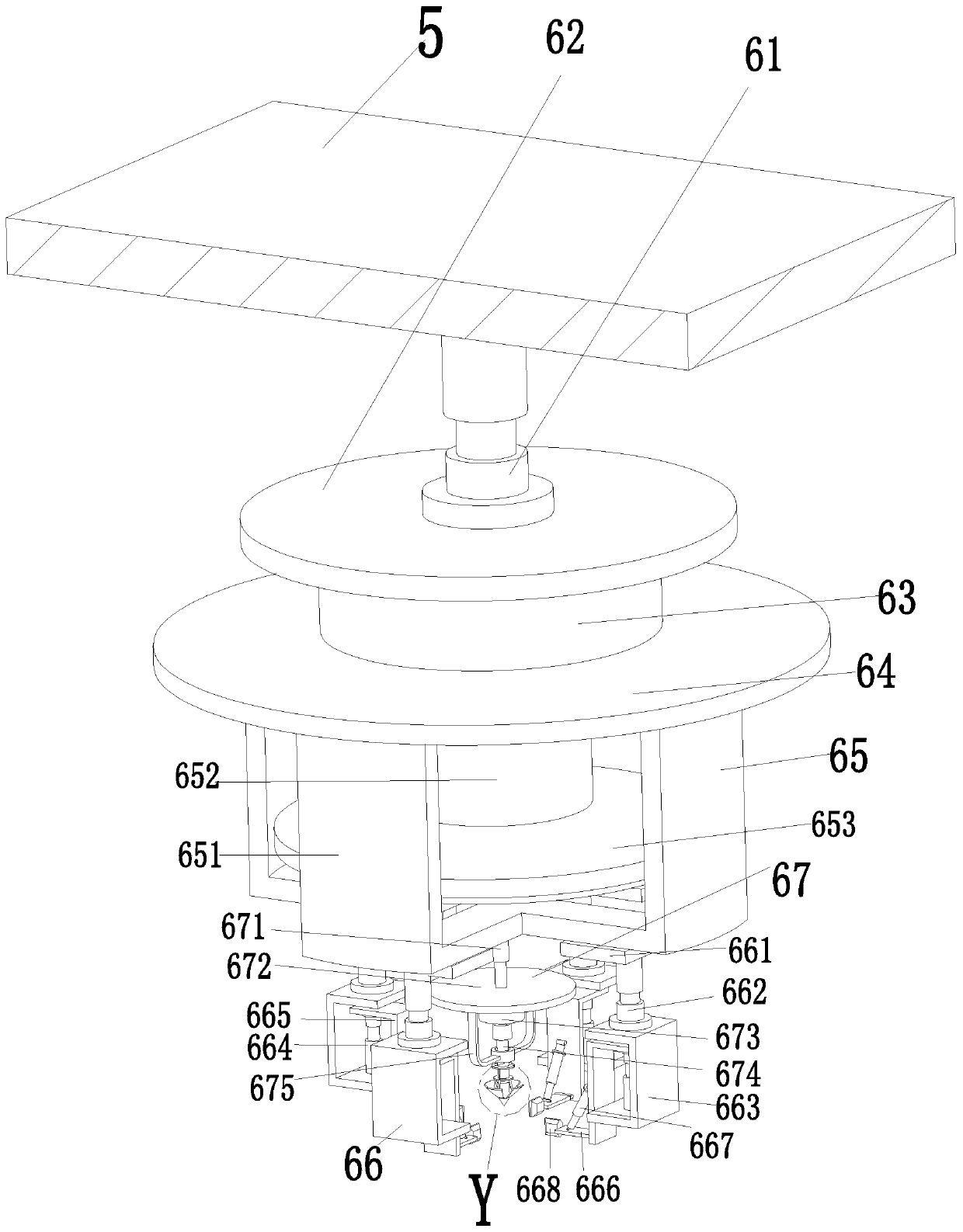

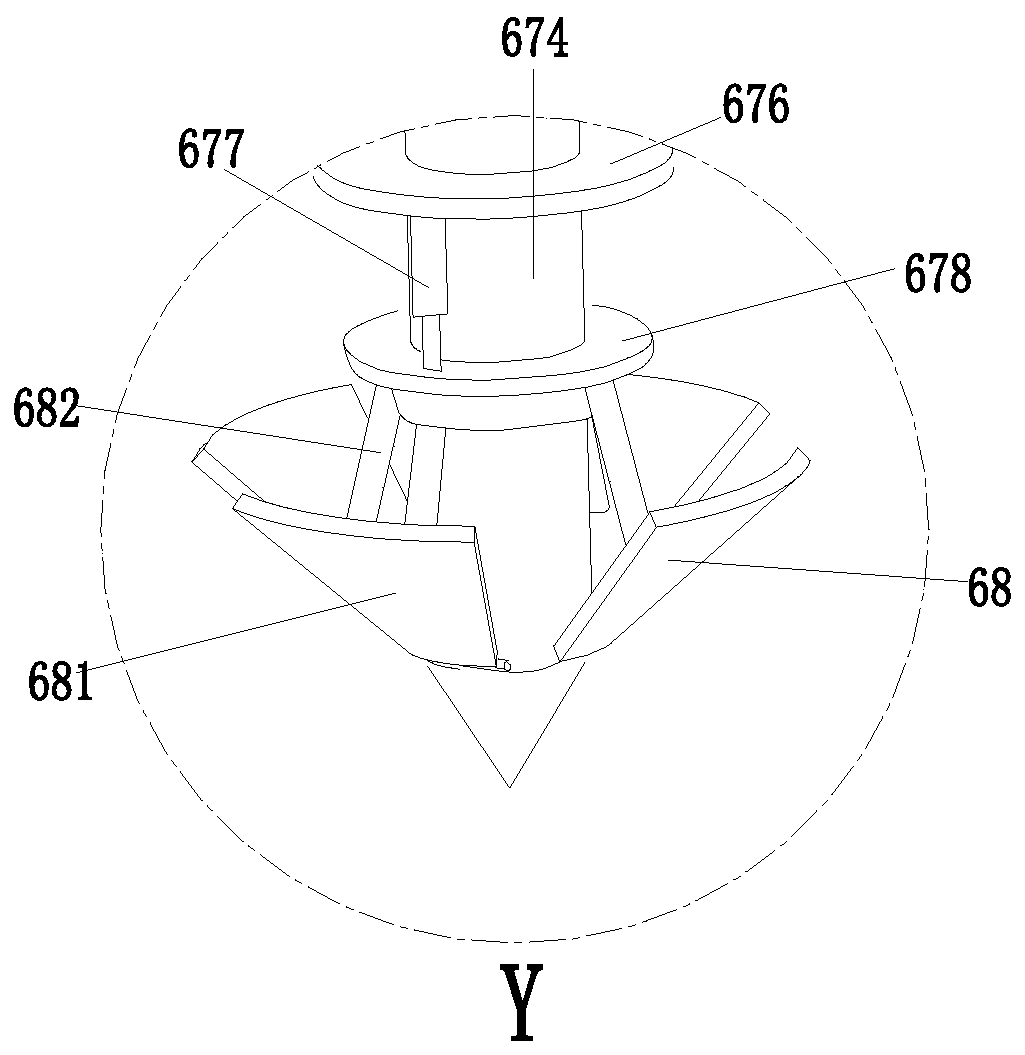

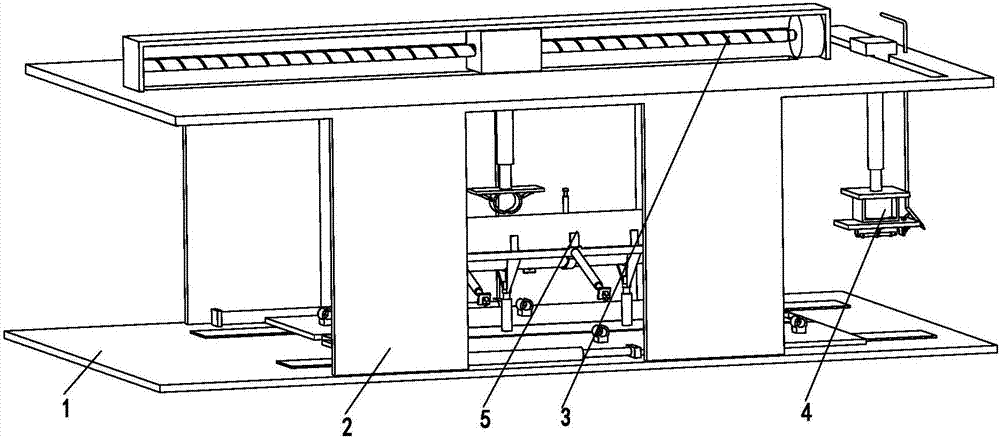

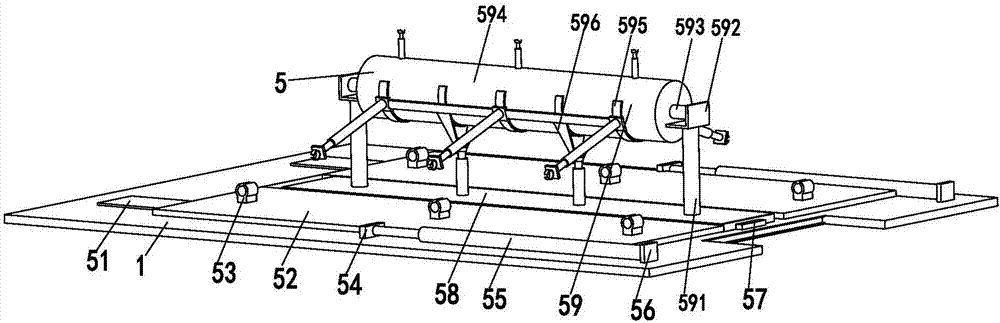

Building decoration machine capable of automatically building reinforced concrete triangle coping reinforcement cage

InactiveCN108031777AReduce labor intensityImprove work efficiencyWire networkBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a building decoration machine capable of automatically building a reinforced concrete triangle coping reinforcement cage. The building decoration machine comprises a base plate, an installing support, an auxiliary device, a bending device and a constructing device, the base plate is provided with the installing support, the installing support is provided with the auxiliarydevice, the lower end of the auxiliary device is provided with the bending device and the constructing device, the bending device and the constructing device are sequentially installed on the base plate from left to right, and the constructing device comprises a linear sliding rail, a base plate, a limiting groove, a connecting plate, a pushing air cylinder, a fixing plate, a linear guide rail, an electric sliding plate and a supporting mechanism. By means of the building decoration machine the problems that in the existing triangle coping reinforcement cage constructing process, potential safety hazards exist, the labor intensity is large, the labor cost is high, the working efficiency is low and the application condition is single are solved, the triangle coping reinforcement cage bending and constructing automation function can be achieved, and the beneficial effects of being free of potential safety hazards, low in labor intensity, low in labor cost, high in working efficiency, wide in using scope and the like are achieved.

Owner:胡红建

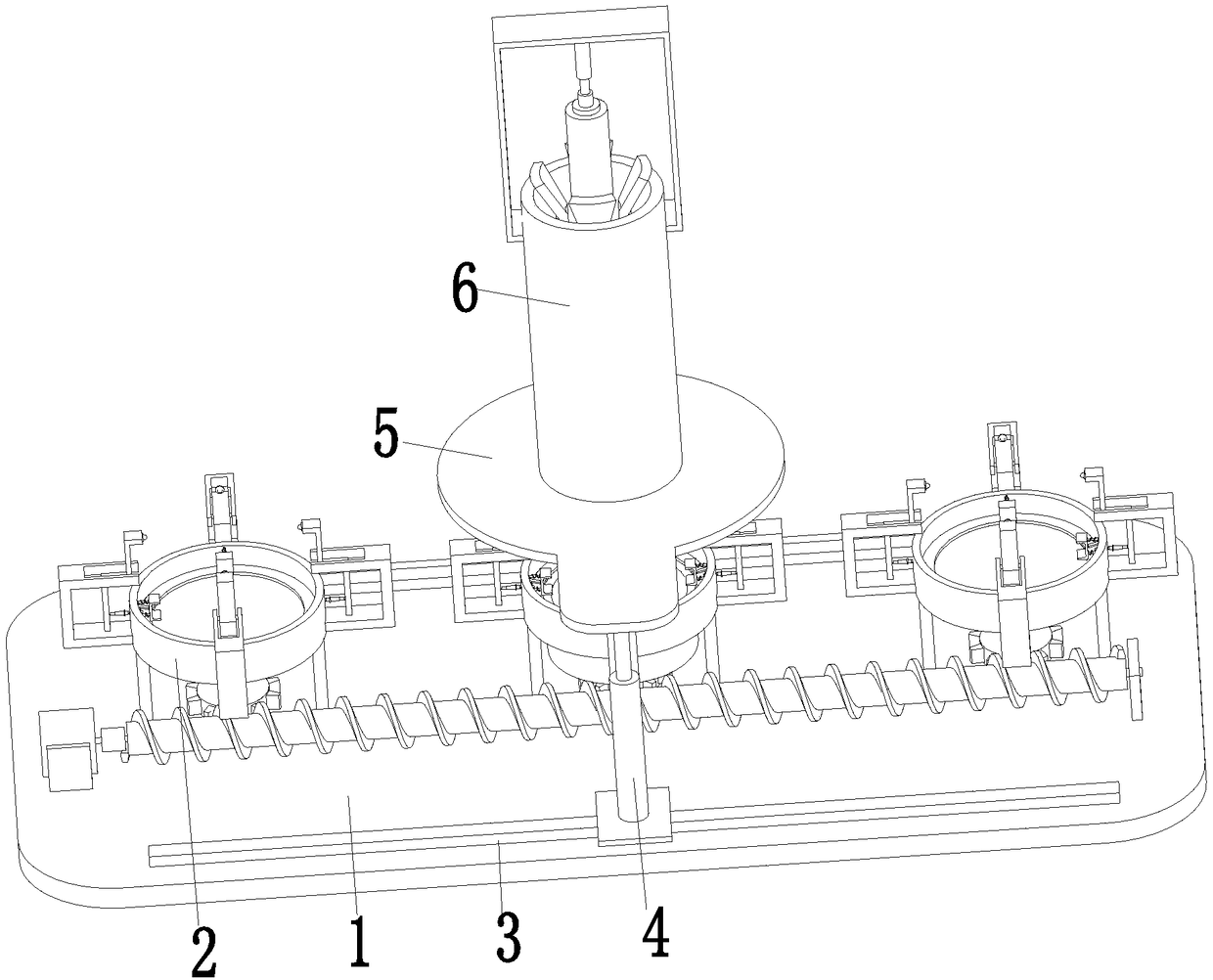

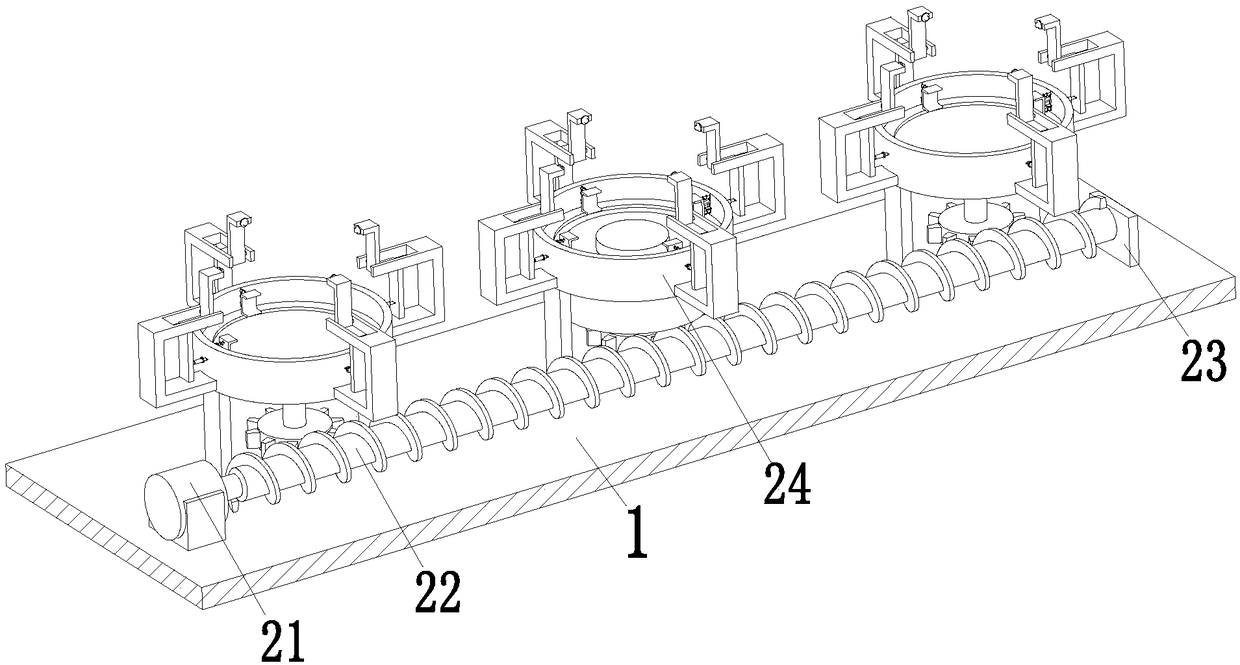

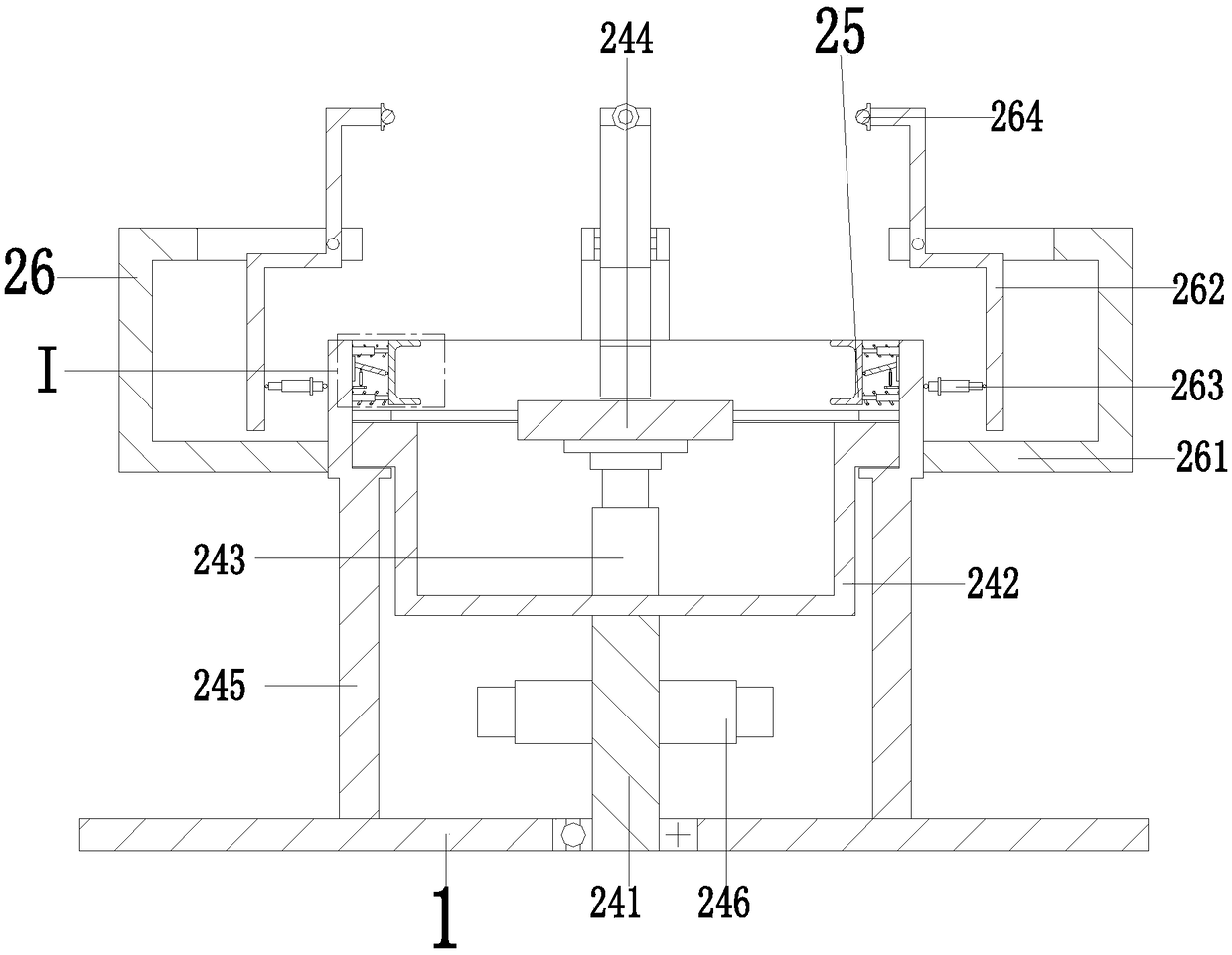

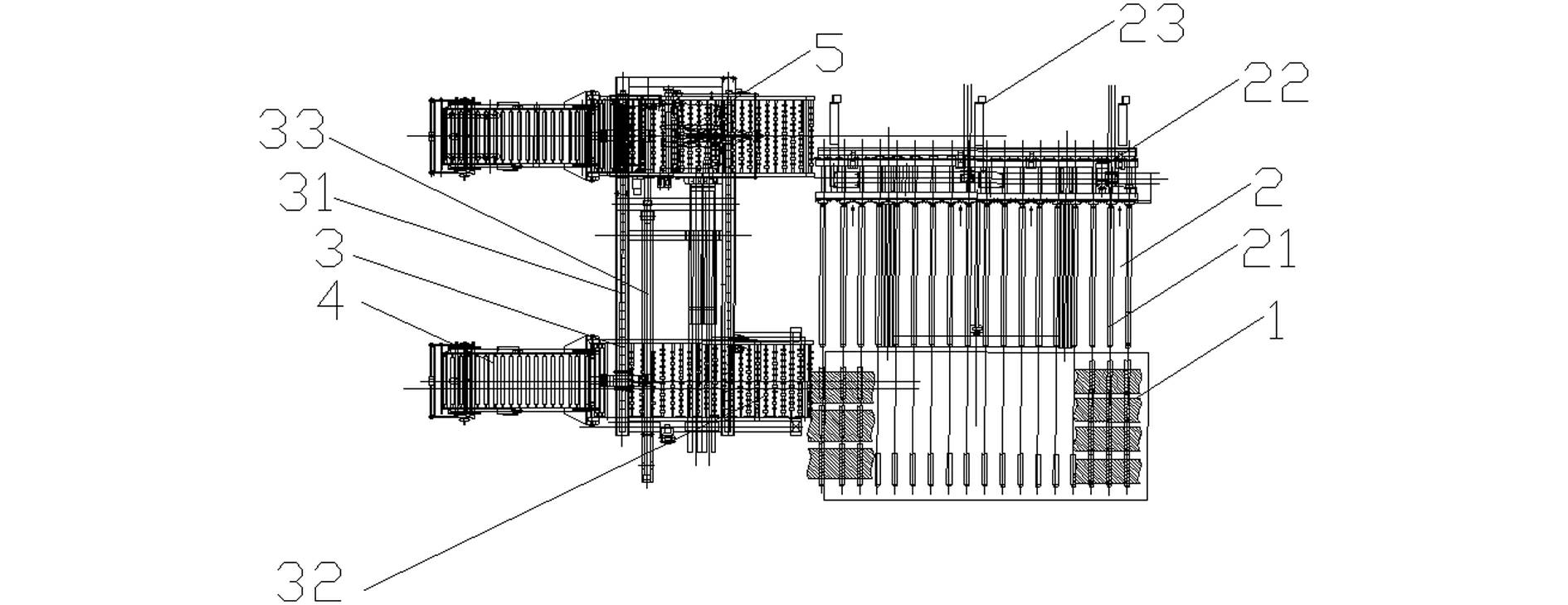

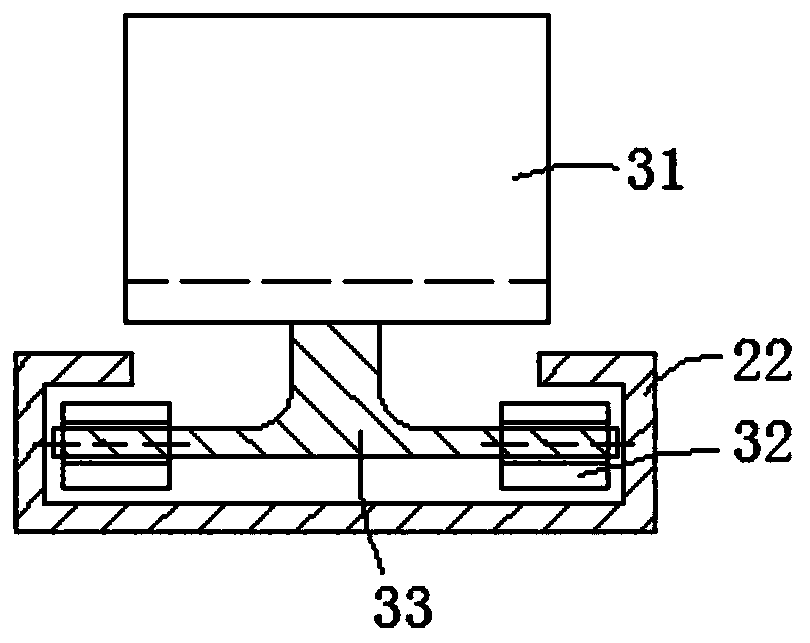

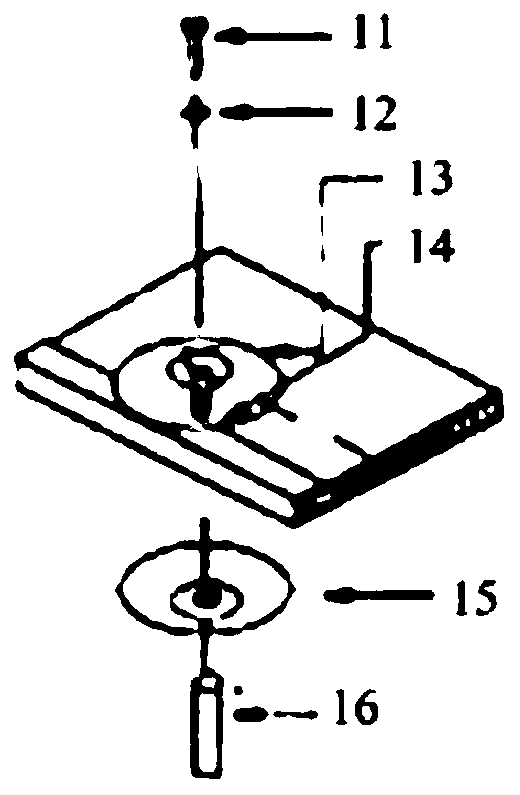

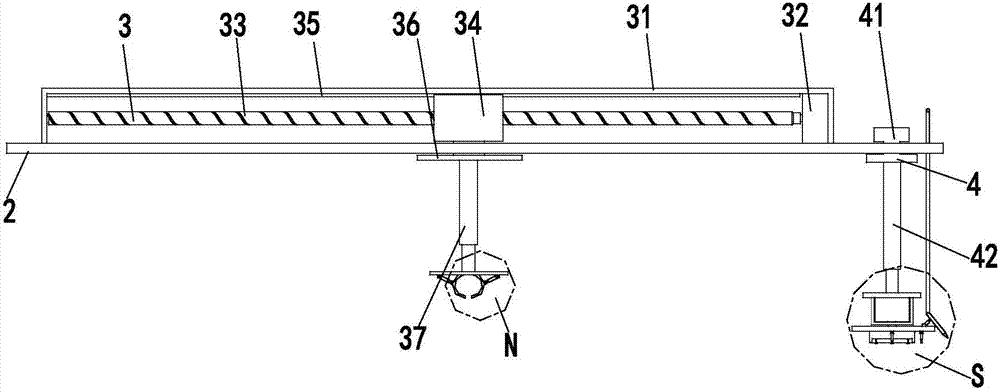

Semiconductor integrated circuit wafer processing production line and production and processing method thereof

ActiveCN108995060AUnified specificationsNo labor intensityEdge grinding machinesWorking accessoriesIntegrated circuitEngineering

The invention relates to a semiconductor integrated circuit wafer processing production line and a production and processing method thereof. The semiconductor integrated circuit wafer processing production line comprises a bottom plate, wherein edge grinding devices are installed at the middle part of the upper end of the bottom plate, movable electric sliders are symmetrically installed on the front and rear sides of the bottom plate, lifting adjusting cylinders are installed on the movable electric sliders, the top ends of the lifting adjusting cylinders are installed on a lifting driven plate through flanges, a slicing device is installed on the lifting driven plate, and the slicing device is positioned directly above the edge grinding devices. According to the semiconductor integratedcircuit wafer processing production line and the production and processing method thereof, the problems in the prior silicon crystal rod slicing and edging process that cut wafers need to be manuallytransported to a designated position for edging processing, the processing of the silicon crystal rod slicing is not accurately controlled manually, the wafers are prone to being injured by mistake inthe conveying process, the wafers cannot be normally used due to mutual collision during the wafers conveying process, the edging of the wafers takes a long time manually with the aid of the prior instrument and multiple wafers cannot be processed at the same time are solved.

Owner:WENZHOU YIWO MASCH TECH CO LTD

Cutting robot for processing communication cable

ActiveCN108406881ANo manual operationEasy to operateEdge grinding machinesMetal working apparatusMachining processProcess communication

The invention relates to a cutting robot for processing a communication cable. The cutting robot comprises a main board, a cutting and deburring device and a middle limiting device, wherein the frontend of the main board is provided with the cutting and deburring device, and the middle of the main board is provided with the middle limiting device. The cutting robot can solve the problems that inthe existing communication cable sleeve processing process, a communication cable sleeve needs to be limited by a worker and then be cut, the communication cable sleeves with different structures needto be grabbed in different ways by the worker when the communication cable sleeves are limited, and during cutting, pipe openings are not flat due to the fact the position is deviated easily during manual cutting, burrs are generated after the communication cable sleeve is cut, the consumed time of the process is long, the labor intensity is large and the efficiency is low. The cutting robot hasthe advantages that the communication cable sleeves can be limited and cut stably, the communication cable sleeves with different structures are limited targetedly, automatic cutting can be realized,the pipe openings are cut flatly, the burrs are automatically removed, manual operation is not needed, the consumed time is short, the operation is simple, the labor intensity is low, and the workingefficiency is high.

Owner:徐州海德力工业机械有限公司

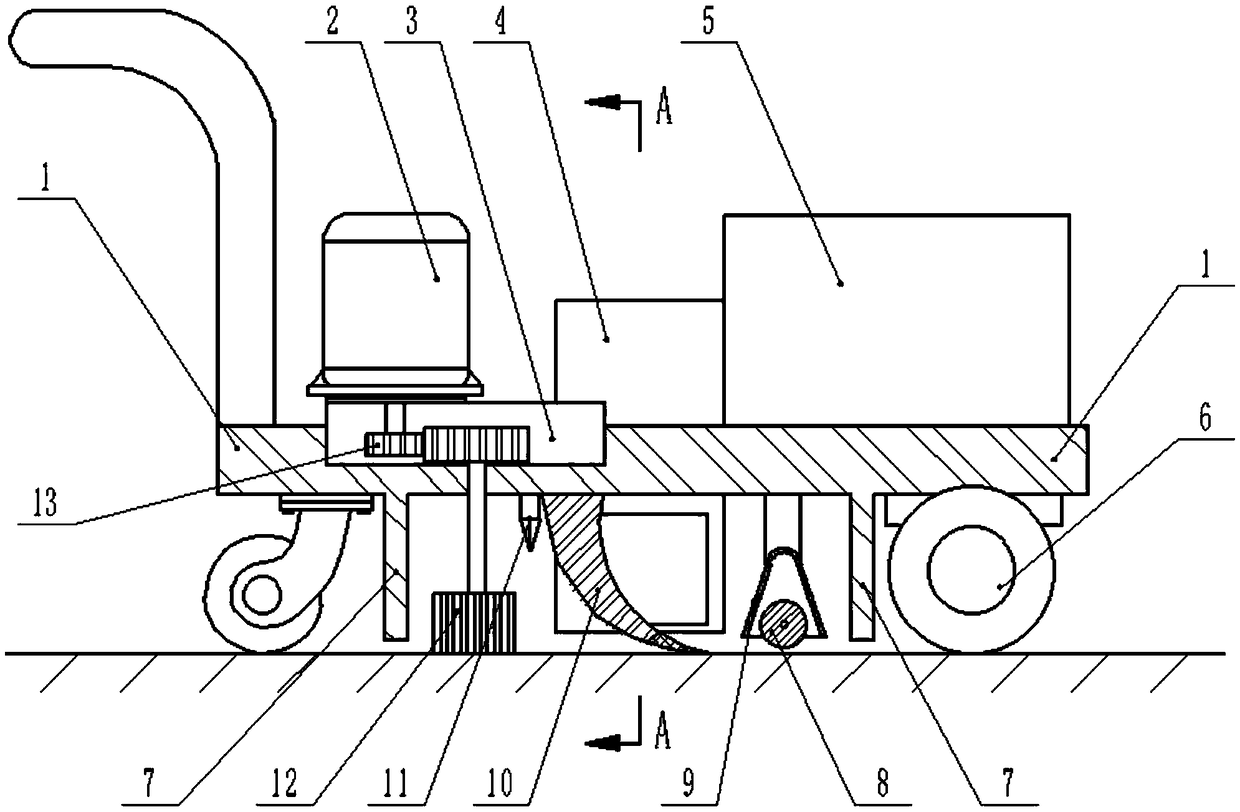

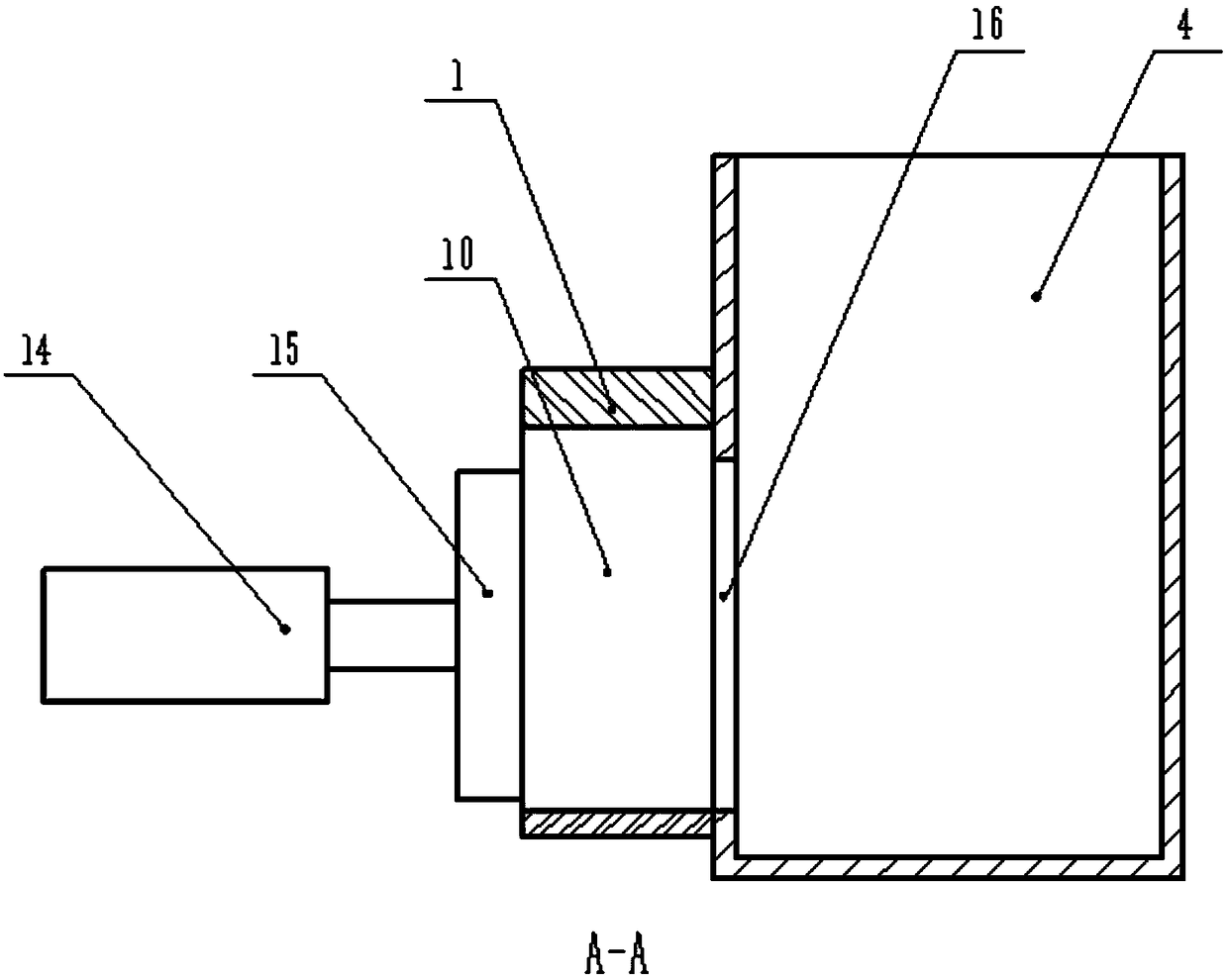

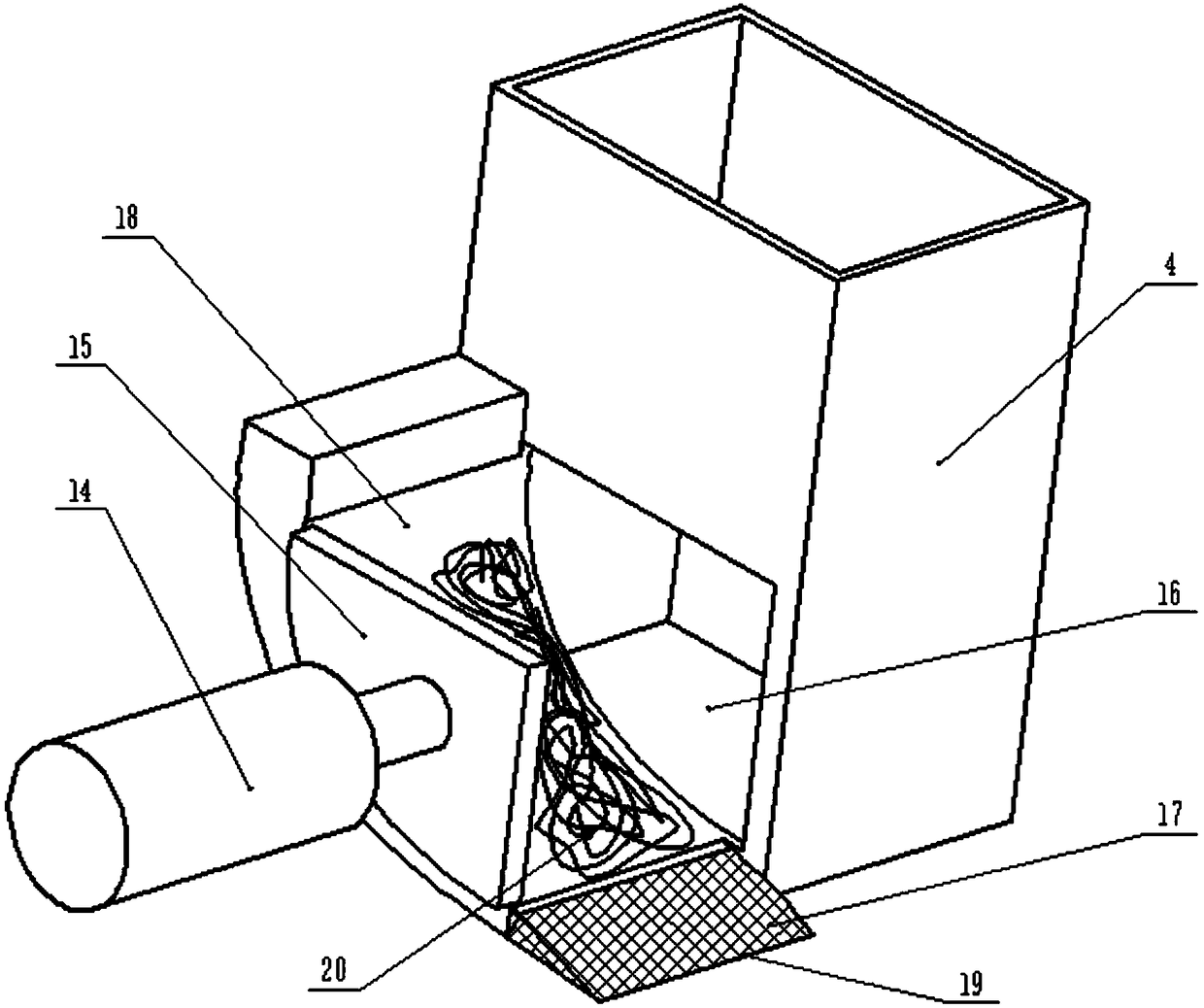

Road marking line remover

The technical scheme of the invention relates to a road marking line remover, and belongs to the technical field of road construction. The remover includes the body, a baking device, a blade, a battery, a waste line collection device and a backup cleaning device, A battery is mounted on the upper part of the vehicle body, the above-mentioned bake device, blades, scrap line collectors and spare cleaning devices are installed under the body. the device overcomes the noise and dust generated in the working process of the traditional road marking removing device, The damage to the pavement is alsoreduced to a very low degree, and the vibration generated by the device is very small when the operator uses the device to clear the road marking, thereby reducing the nuisance to the operator due tothe vibration and reducing the labor intensity.

Owner:刘一帆

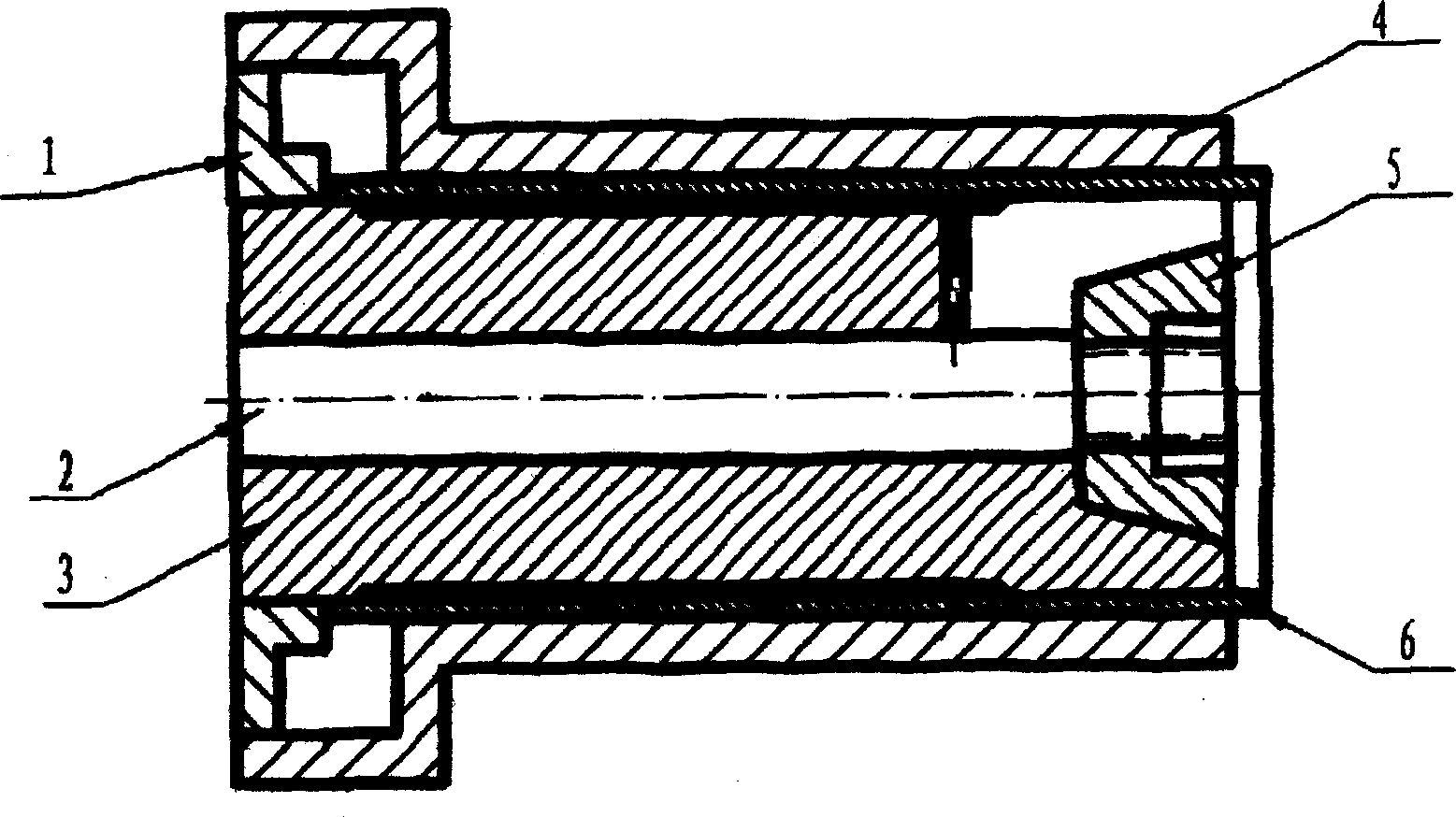

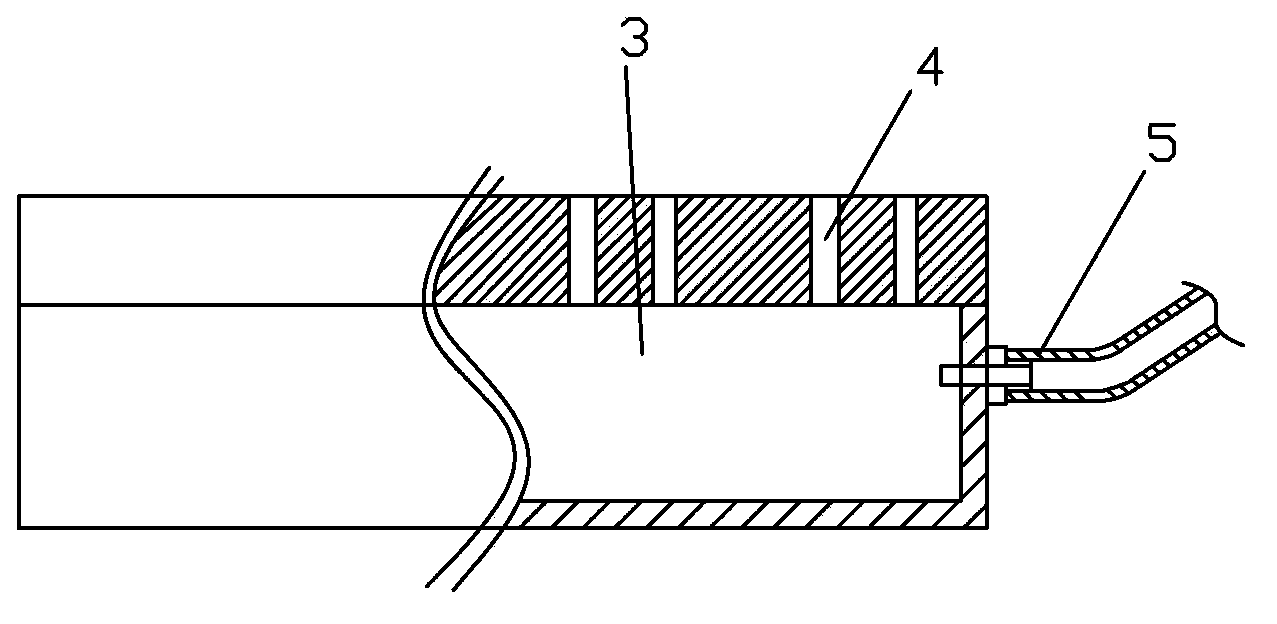

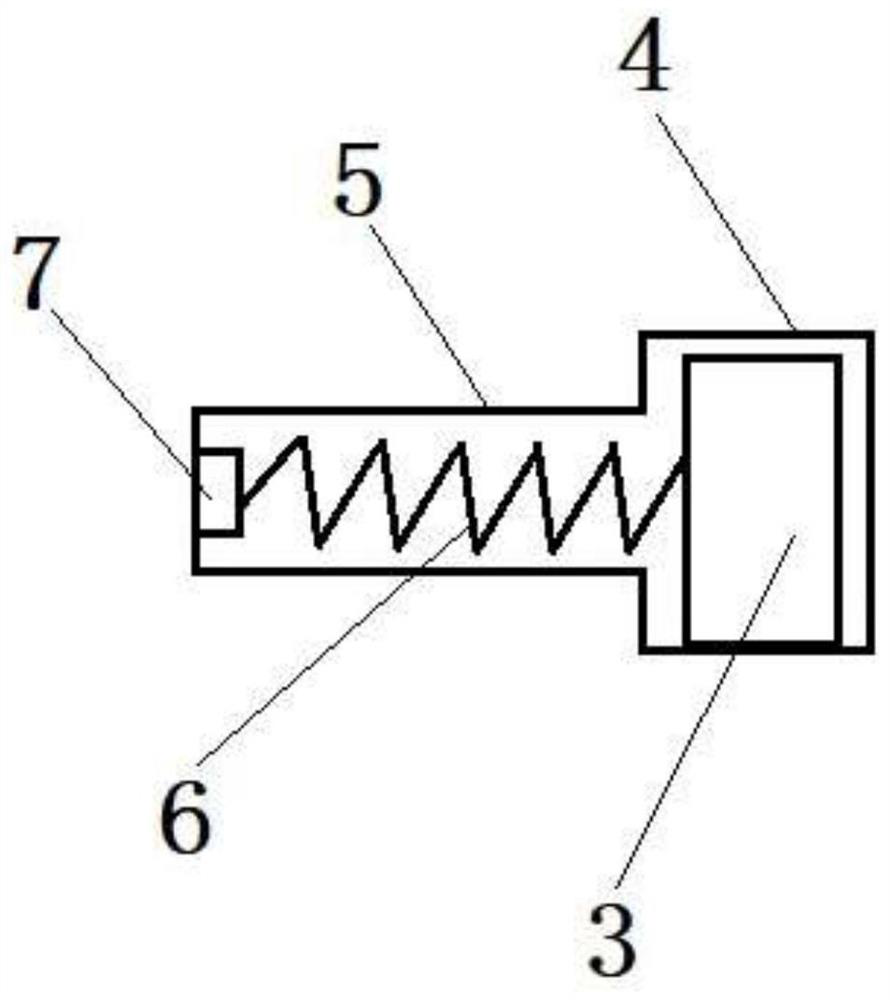

Cylinder liner spinning and flanging processing method and special fixture thereof

InactiveCN1544176AEasy to processReduce labor intensityCylinder headsCylindersEngineeringMechanical engineering

The invention discloses a cylinder case rotary pressing-curling processing method and its special clamp, and the method: installing and griping the cylinder case in the clamp and rotating the clamp, adopting a rotary pressing wheel to expand and press the mouth of the cylinder case to form a 120-150 degree bellmouthing, adopting an extrusion wheel to planish the big platform, loosening the cylinder case griped by the clamp and then ejecting the cylinder case and completing the processing, where the special clamp is a clamp: there is a space between the inner and outer bodies, the diameter of one side of the outer body is greater than that of the other side, there is a push-remove case between the inner and outer bodies on one end of the clamp and there is a conical stopper on the other end of the clamp, there is a pull rod set in the center of the inner body, and the pull rod is connected with the conical stopper. It has the characters of simple processing procedures, accurate assembly and positioning, high processing precision, high working efficiency and low labor strength.

Owner:烟台万斯特有限公司

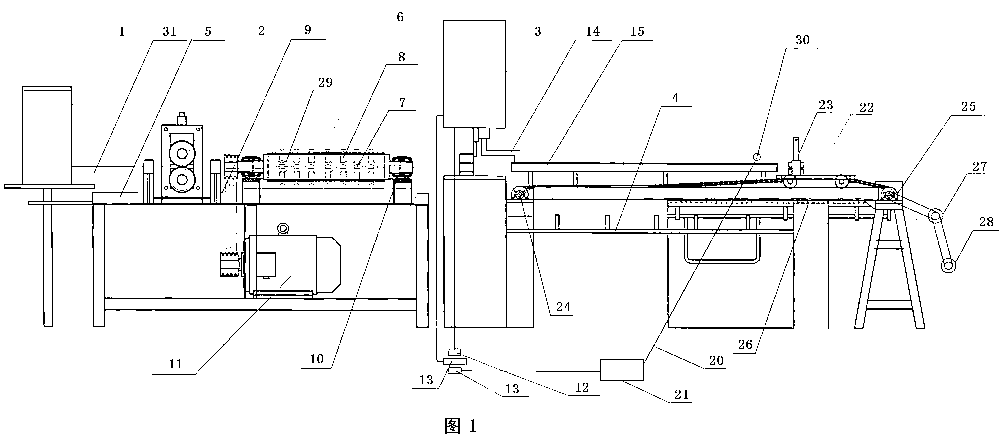

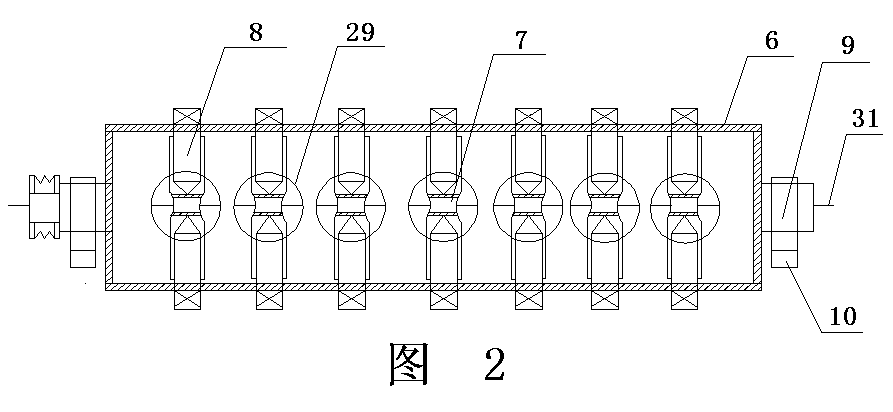

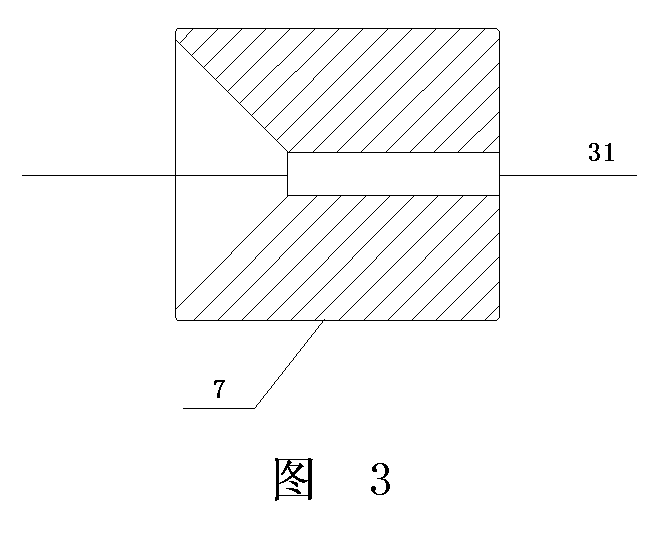

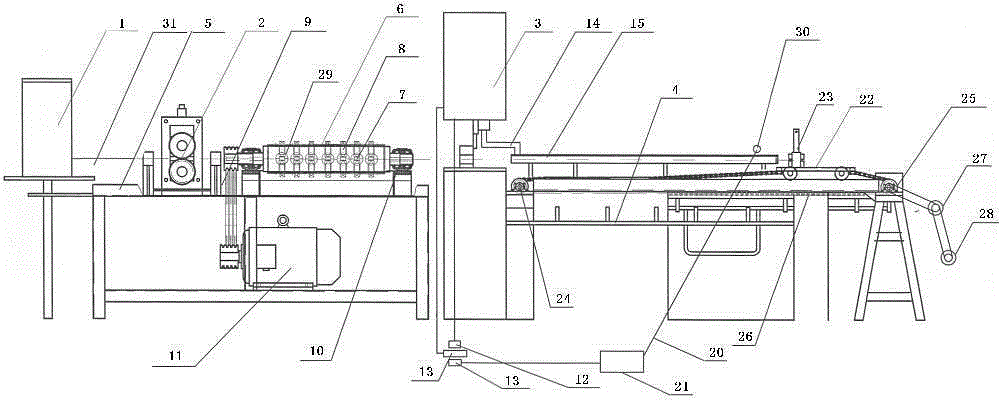

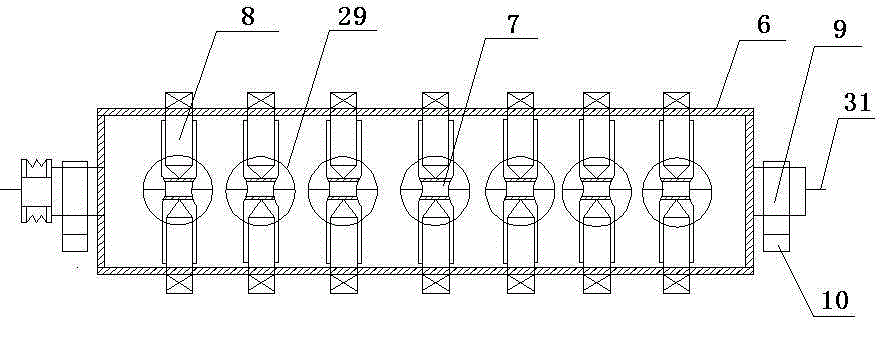

Valve steel plate element straightener

The invention discloses a valve steel plate element straightener which comprises a pay-off reel, a pinch roll, a straightening mechanism and a cut-off mechanism, wherein the straightening mechanism comprises a straightening barrel which is horizontally arranged, at least one straightening model is arranged in the straightening barrel, the straightening model is horizontally fixed in the straightening barrel by two adjustable jacking bolts symmetrical to each other vertically and has a cylinder structure, the outer sides of two ends of the straightening barrel are provided with rotating shafts with through holes at the center, the rotating shafts are arranged on a support frame, the support frame is fixed on a main frame table, and any of the rotating shafts is connected with the shaft of the motor by a transmission mechanism. The valve steel plate element straightener has the advantages of simple structure, low cost, easy operation, convenient overhauling, no scratch on the surface of wire, high straightening precision, automatic sizing, cutting-off and blanking, high sizing precision, low labor intensity, high efficiency, no balance of straightening steel wires, and high yield.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

Method for cultivating eucalyptus tissue culture seedling by adopting light media container

InactiveCN103477989AIncreased yield and quality of bottle seedlingsGood air permeabilityClimate change adaptationAfforestationRoot systemPesticide

A method for cultivating a eucalyptus tissue culture seedling by adopting a light media container is characterized by adopting plant tissue culture and rapid propagation, optimizing ratio and treating processes of light media raw materials, improving a rooting bottle seedling hardening method and selecting a small atomized insecticide spraying machine to replace a method for manually spraying insecticide. The light media container has good water permeability and air permeability and is light, so that the labor intensity is reduced; root systems are developed, nursery stocks are strong, and the seedling recovering period is short after afforestation, thus, costs for seedling culture and afforestation are reduced; and moreover, rooting bottle seedling yield is higher than 98%, transplanting survival rate of bottle seedlings is higher than 95%, seedling morbidity is lower than 2%, the seedling culture period is relatively shortened to 45-60 days, then, the outplanting can be performed, the outplanting rate of large seedlings is higher than 90%, and the survival rate of afforestation is increased by 15%.

Owner:沈云

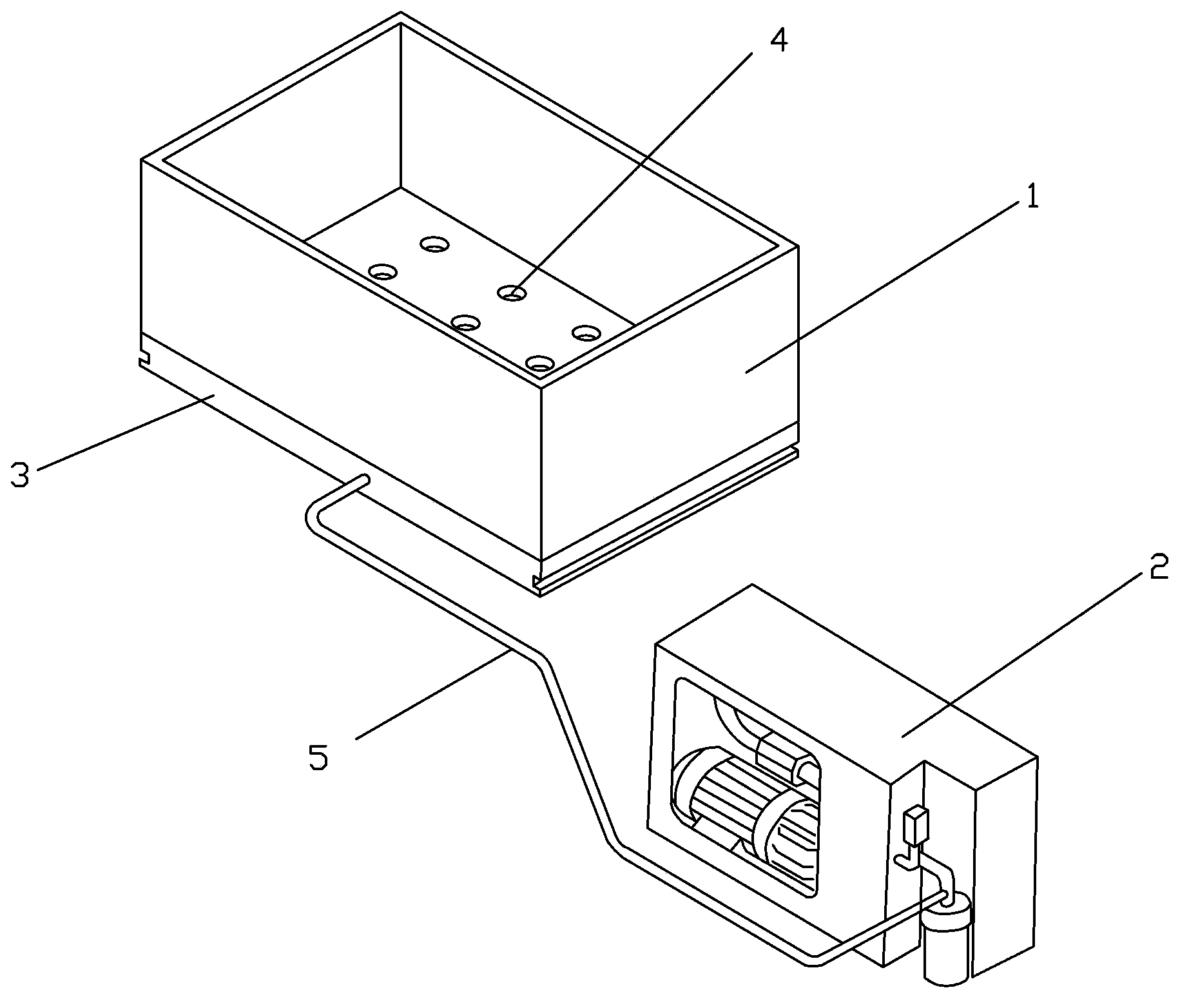

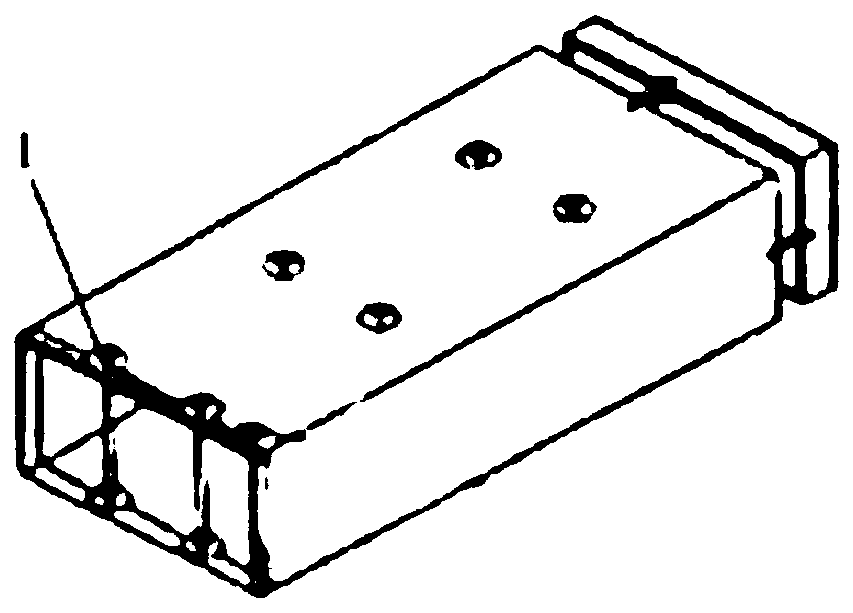

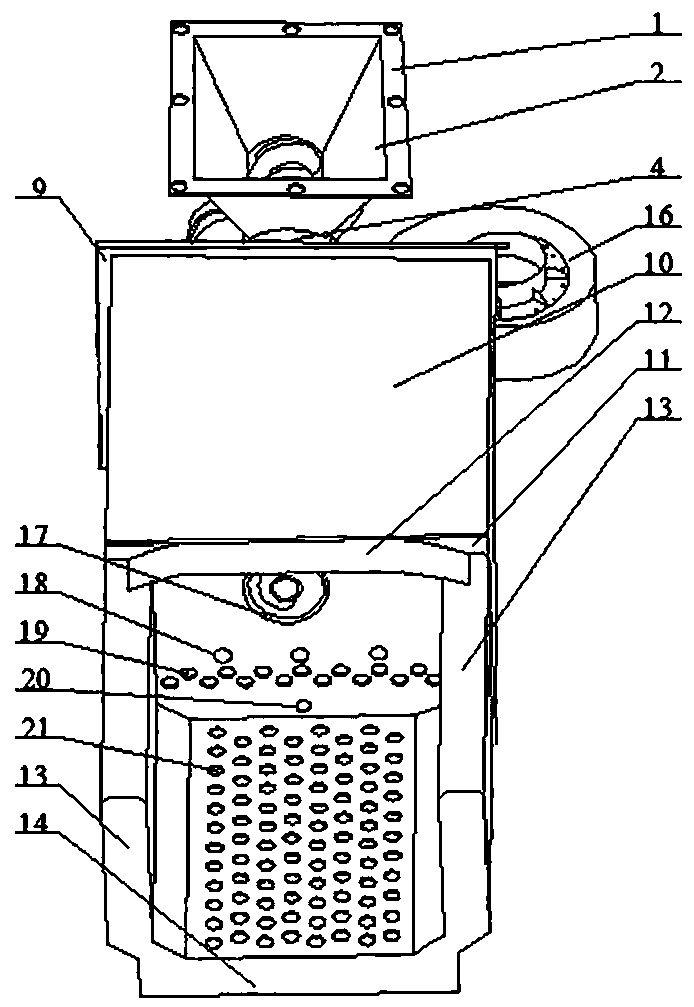

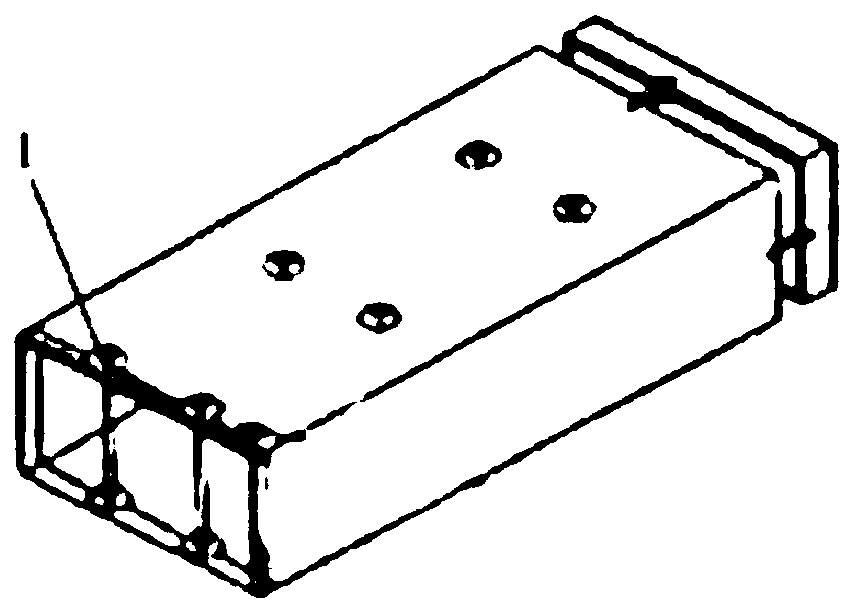

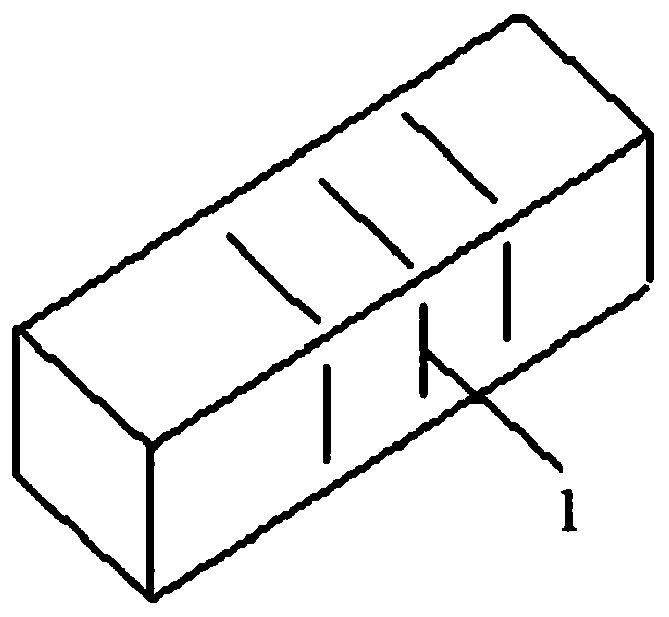

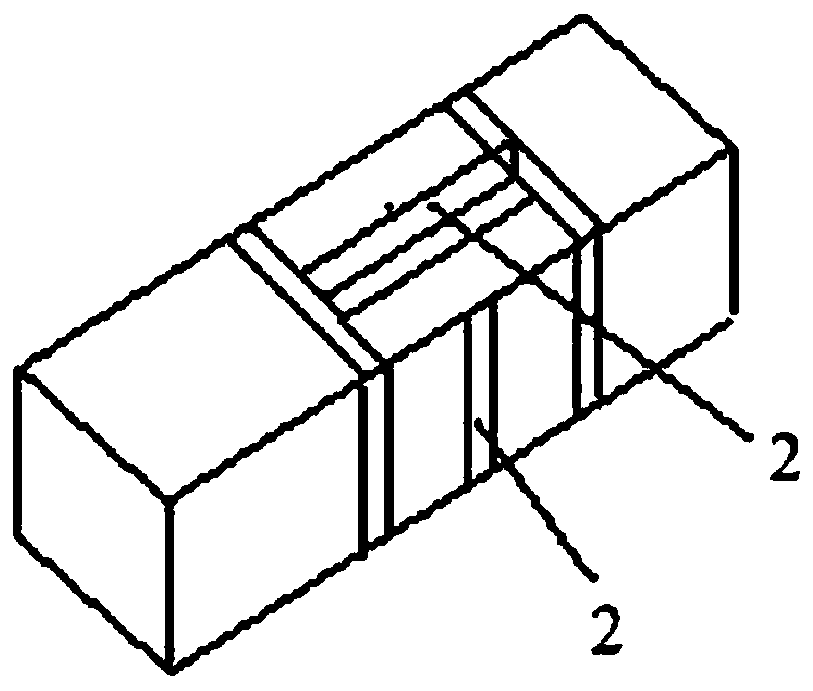

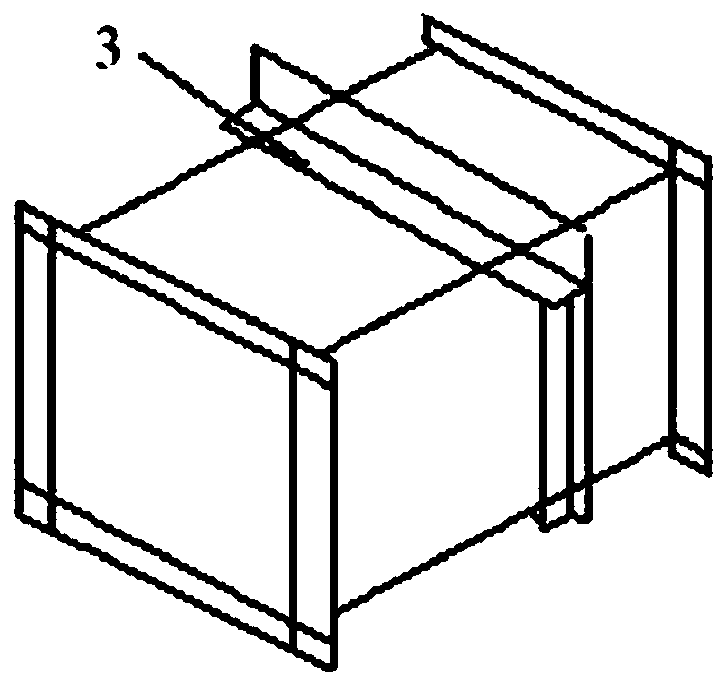

Polymerized plate vacuum adsorption device and polymerized plate manufacturing technology

InactiveCN103657949ANo pollution in the processNo damagePretreated surfacesCoatingsManufacturing technologyEngineering

The invention relates to the technical field of heat-preservation fireproof material manufacturing, and particularly relates to a polymerized plate vacuum adsorption device and a polymerized plate manufacturing technology. The vacuum adsorption device comprises a box body for containing plates and a vacuum pump, wherein a vacuum groove is formed in the bottom of the box body; the vacuum groove is communicated with a cavity of the box body through liquid flowing holes and also communicated with the vacuum pump through a vacuum pipe. A polymerized plate is manufactured by means of re-polymerizing an extruded plate with various fireproof environment-friendly and heat-preservation materials through new technology treatment, so that not only are the original various physical indexes of the extruded plate kept, but also the problems such as inflammability, toxic smoke release and melt-dripping of the extruded plate are solved. The polymerized plate is an incombustible material meeting grade-A fireproof requirements and the fire endurance of the polymerized plate surpasses that of inorganic materials such as rock wool, glass wool and foamed glass. The polymerized plate is high in production efficiency, low in cost, convenient to construct, free of environment pollution, free of breakage in transportation, safe to load and unload, and low in labor intensity.

Owner:天津市裕华玻璃钢有限公司

Direct-buried type communication cable laying equipment with capacity of realizing intelligent excavation and laying

InactiveCN107989093AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringSoil treatmentDirect-buried cable

The invention relates to direct-buried type communication cable laying equipment with capacity of realizing intelligent excavation and laying. The equipment comprises a lifting plate, an excavation device and a grouting device, wherein the excavation device is mounted at the front end of the lifting plate; the grouting device is mounted on the lifting plate. With the adoption of the equipment, theproblems that a worker is required to perform ditching and manual grouting and laying in conventional direct-buried cable mounting process and potential safety hazards are produced because of back injury caused by the fact that the worker needs to dig a ditch by a tool during ditching and bends down to work for a long time are solved, and furthermore, the problems that soil treatment is tedious after manual ditching, the bottom of the ditch is required to be subjected to grouting rolling manually during laying, the manual rolling is uneven as well as gaps are easily produced between cement slabs, the cement slabs are mounted unstably, time consumption of the laying process is high, labor intensity is high, efficiency is low and the like due to the fact that the cement slabs are required to be subjected to grouting solidification outside by the worker during grouting on the side surface and then transported to designated positions for mounting are solved, so that the equipment can realize functions of intelligent excavation and laying of communication cables.

Owner:刘静

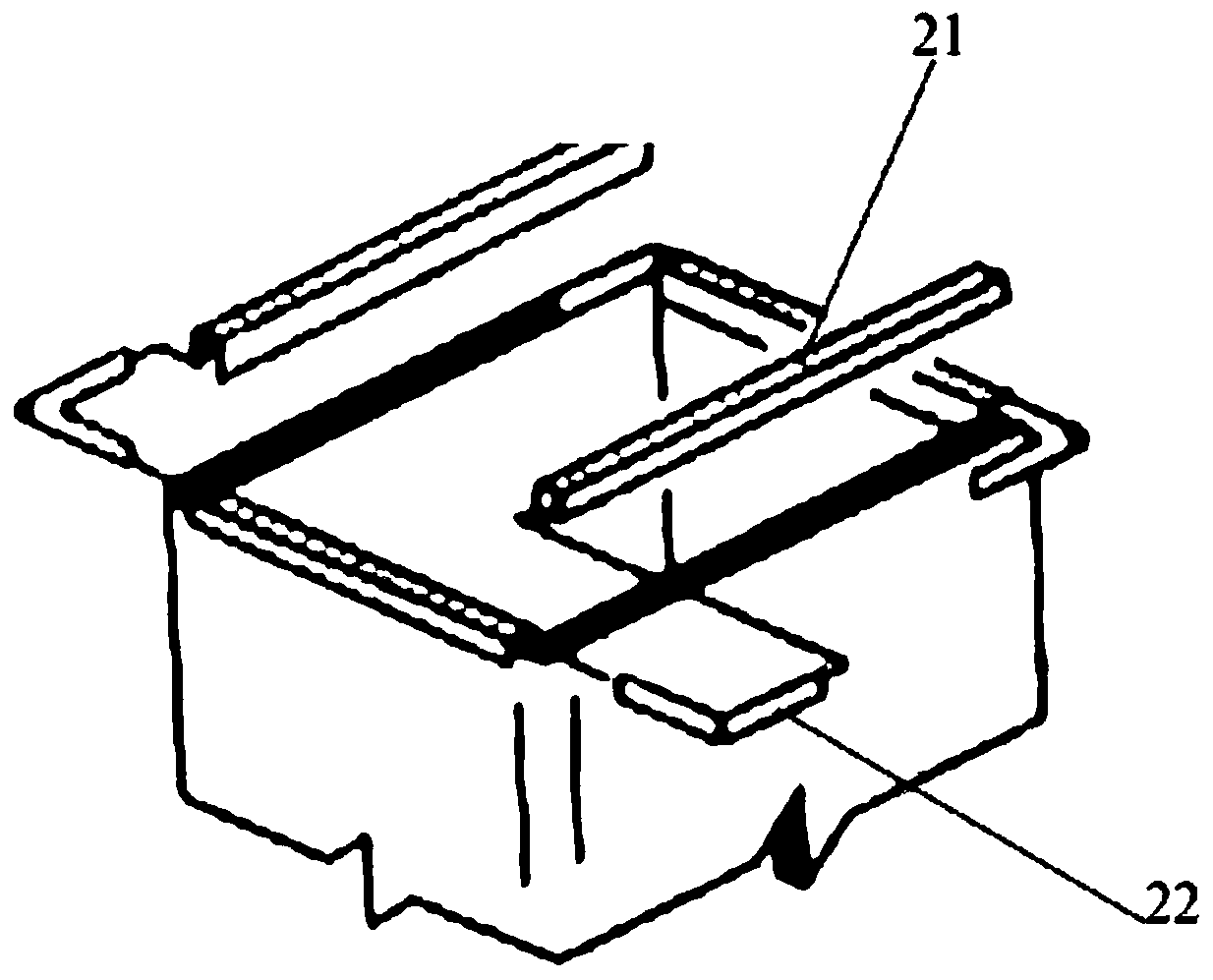

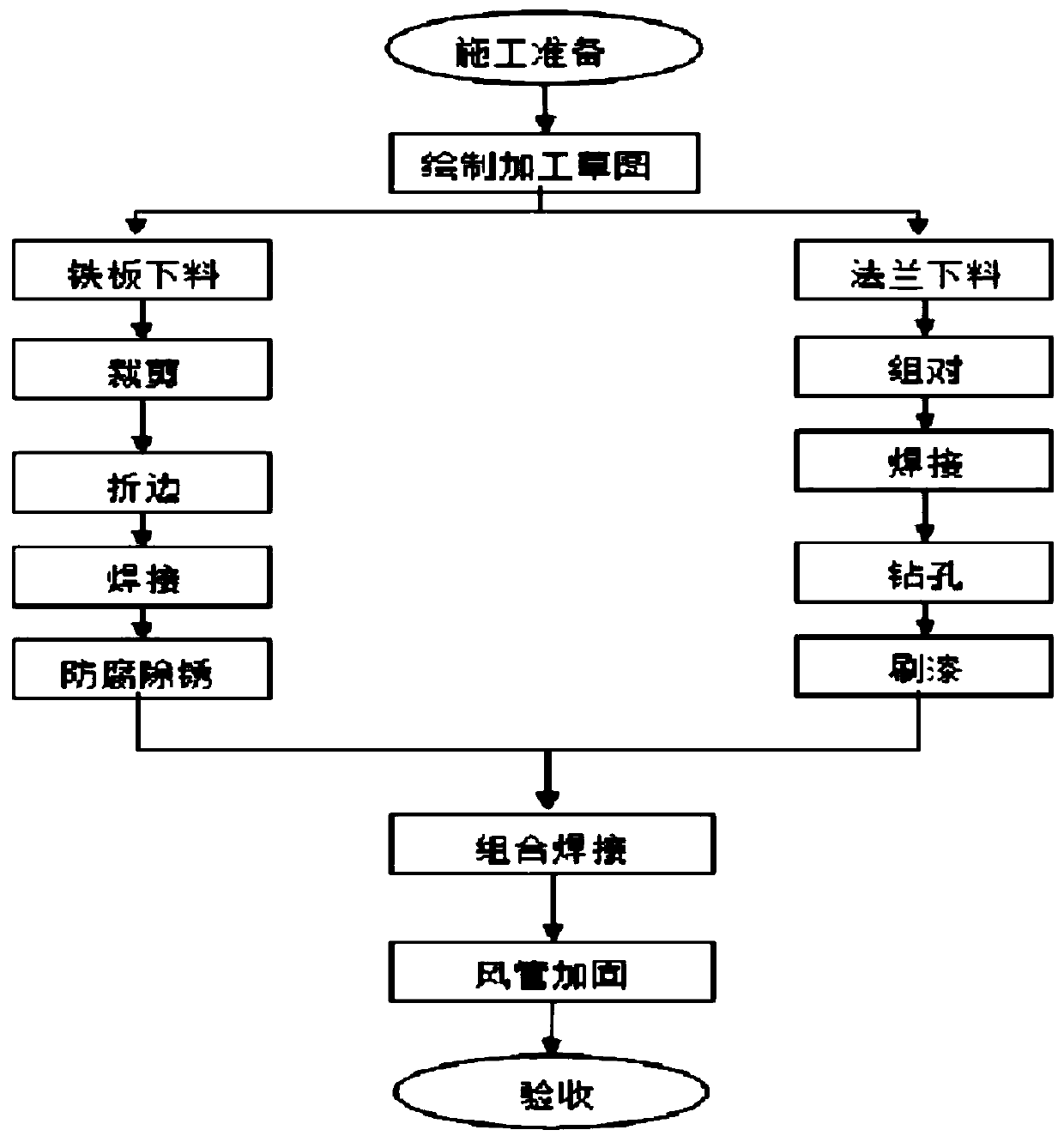

BIM-based composite air duct product production management system

InactiveCN111382471ARealize precise blankingSimple preparation processGeometric CADRigid pipesData controlThermal insulation

The invention relates to a BIM-based composite air duct product production management system. A composite air duct is of an air duct structure formed by taking a composite thermal insulation materialas a main material through cutting, bonding and splicing assembly. A production method of the composite air duct comprises the following steps of: drawing an air duct sketch through Autodesk Revit; manufacturing a single straight pipe air duct and a single special-shaped air duct on the basis of the sketch; importing prefabricated manufacturing information into an Autodesk Fabrication control system; and controlling the production process of the composite air duct through adopting the Autodesk Fabrication. The BIM-based composite air duct product production management system has the beneficialeffects that the air duct production process is automatic and intelligent; firstly, the sketch meeting the requirement is drawn according to the field requirement, then sketch data are imported intoa BIM system, and the manufacturing process of precise blanking, bending and fixing of the air duct is achieved through data control over production line machinery; in addition, the manufacturing process of the air duct can be simulated in advance, the manufacturing process is optimized to the maximum extent, and the possibility of misoperation is reduced.

Owner:天津奥特浦斯机电设备有限公司

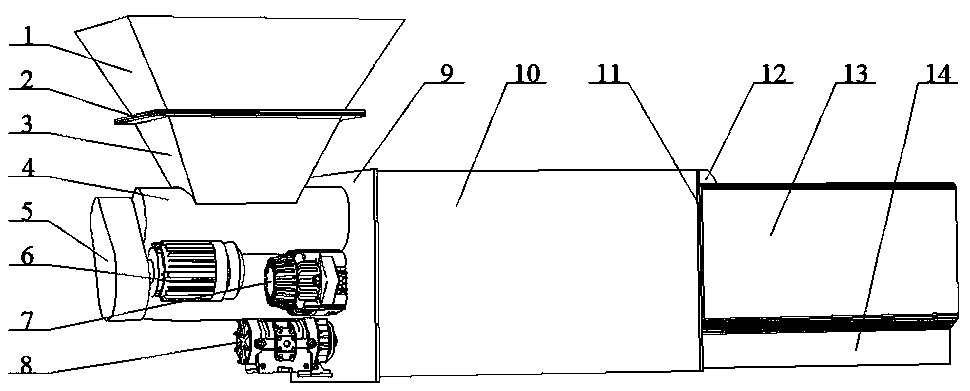

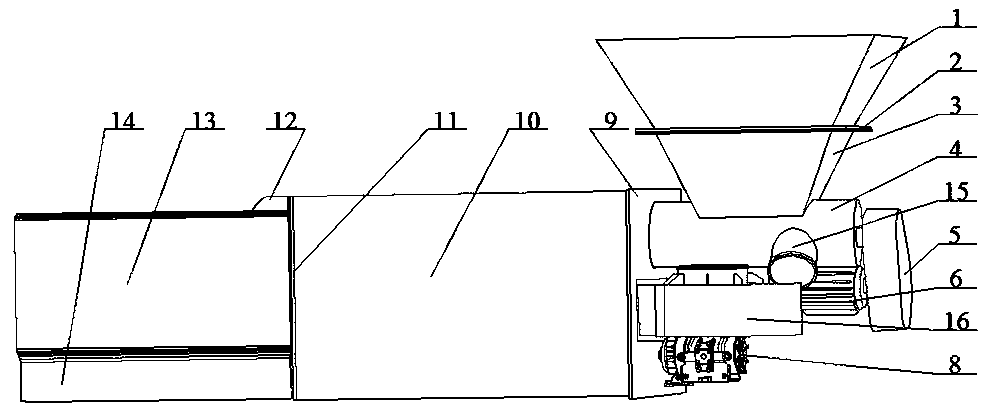

Biomass burner for flue-cured tobaccos

ActiveCN110410774AReduce volumeGuaranteed normal operationTobacco preparationSolid fuel combustionElectric machineHeater Rod

The invention discloses a biomass burner for flue-cured tobaccos. The biomass burner for flue-cured tobaccos comprises a ventilation chamber, a feeding device and a burning hearth, wherein the feedingdevice is installed on the head part of the ventilation chamber, and the burning hearth is installed at the tail part of the ventilation chamber. The feeding device comprises a fixed material box, afeeding channel and a feeding power motor. A comprehensive fixed plate is arranged in the ventilation chamber. A poker sleeve is welded to the top of the fixed plate. A poker is placed into the pokersleeve. The front side of a poker fixing plate is welded to the head part of the poker. The tail part of the poker extends into the burning hearth. A poking spiral transmission rod is welded to the middle of the reverse side of the poker fixing plate. A heating rod is arranged in the middle of the bottom of the fixed plate. An ignition spiral transmission rod is hinged to the head part of the heating rod. The tail part of the ignition spiral transmission rod is connected with a power output shaft of an ignition telescopic power motor. The tail part of the heating rod extends into the burning hearth. The burning hearth comprises a hearth outer wall and a hearth base. The biomass burner for flue-cured tobaccos has the advantages of being easy and convenient to operate, sufficient in burning,low in cost, free of pollution and high in efficiency.

Owner:HENAN AGRICULTURAL UNIVERSITY +2

Intelligent lampshade mounting device for indoor reading lamp

The invention relates to an intelligent lampshade mounting device for an indoor reading lamp, which comprises a limit device and a fixing ring adjusting device, wherein the fixing ring adjusting device is mounted at the left side of the front end of the limit device. The intelligent lampshade mounting device can solve the following current problems: in the process of replacing a lampshade, a person is required to take off a fixing ring, mount a lampshade, and then screw down the fixing ring again; when a reading lamp needs to be fixed, the person needs to limit the bedroom reading lamp with one hand and replace a lampshade with the other hand, and manually fixing the reading lamp can cause the damage to the external surface of the reading lamp due to excessive force; when the fixing ring needs to be taken off, because the size of the fixing ring is small, the fixing ring cannot be easily taken off manually, and the fixing ring can be lost due to improper placement after being taken off; when the fixing ring needs to be screwed down, the person needs to put the fixing ring onto a lamp holder from the top of the lampshade and screw down the fixing ring, the fixing ring can drop due to overlarge hands in the process of screwing, and the fixing ring cannot be easily screwed down manually. The intelligent lampshade mounting device can carry out the function of automatically fixing an indoor reading lamp and taking off and screwing down a fixing ring again.

Owner:江雪萍

BIM based production management system for galvanized sheet angle iron flange air duct product

InactiveCN110850816ARealize precise blankingSimple preparation processTotal factory controlProgramme total factory controlManufacturing technologyControl system

The invention relates to a BIM based production management system for a galvanized sheet angle iron flange air duct product. Angle iron flanges in the two edges are connected with each other in the galvanized sheet angle iron flange air duct. According to the production method of the galvanized sheet angle iron flange air duct, an air duct sketch is drawn through Autodesk Revit, a single straightpipe air duct and a single special-shaped air duct are both manufactured on the basis of the sketch, prefabricated manufacturing information is imported into an Autodesk Fabrication control system, and the production process of the galvanized sheet angle iron flange air duct is controlled through the Autodesk Fabrication. The air duct production process is automatic and intelligent; the sketch satisfying requirements is drawn according to onsite requirements, sketch data is introduced into a BIM system to realize accurate blanking, bending and fixing of the air duct by digitally controlling machinery of the production line; and the air duct manufacturing process is simulated in advance, the manufacturing technology is optimized to the largest extent, and the possibility of misoperation isreduced.

Owner:天津奥特浦斯机电设备有限公司

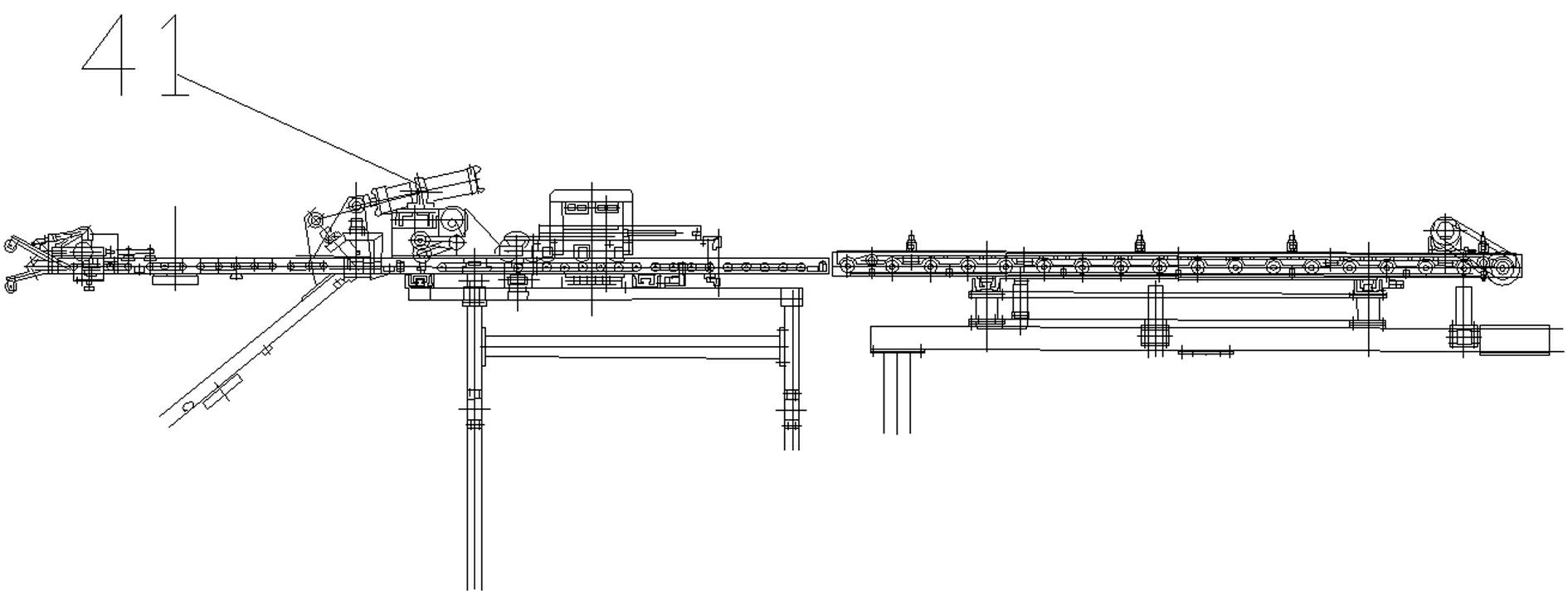

All-steel radial tire building machine feeding rack for automatically and laterally moving upper tread

InactiveCN102161445AHigh degree of automationManual labor intensity noFeed tablesAutomatic controlRadial tire

The present invention relates to an all-steel radial tire building machine feeding rack for automatically and laterally moving an upper tread. The feeding rack comprises a hydraulic elevator, an automatic drum-type fetching device, a lateral movement device, a front feeding device and a tread automatic deviation rectifying device. The hydraulic elevator and the automatic drum-type fetching device are adjacently arranged on the back of the lateral movement device, the tread automatic deviation rectifying device is fixedly installed above the lateral movement device, one end of which is provided with the front feeding device. During the process of being rolled out and moved, the tread is subjected to uniform force and is free from deformation, thereby guaranteeing the tread quality. Moreover, the feeding rack is automatically controlled and operated at a high efficiency, the tread quality is stable, all executive components are pneumatic components which are suitable for reciprocating and repeated movement, and have rapid, stable and reliable movement.

Owner:赵志东

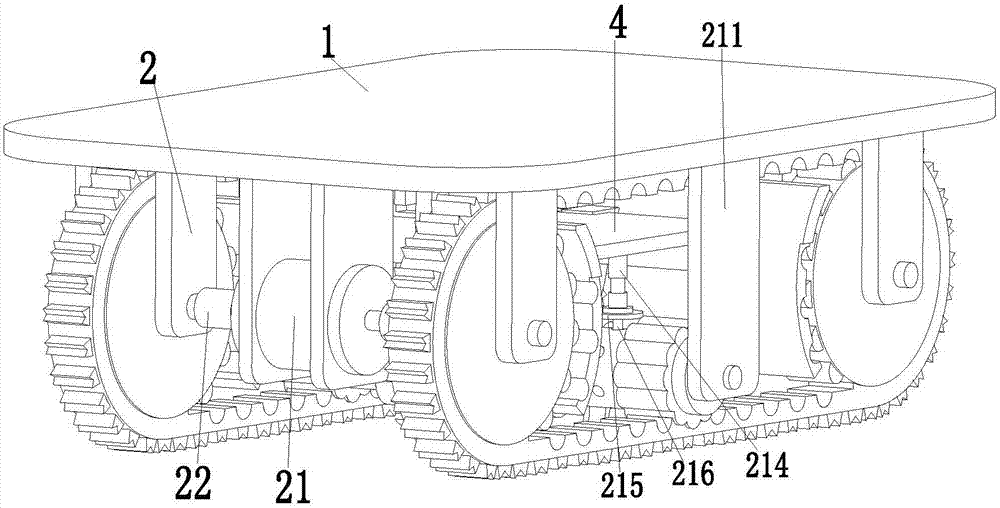

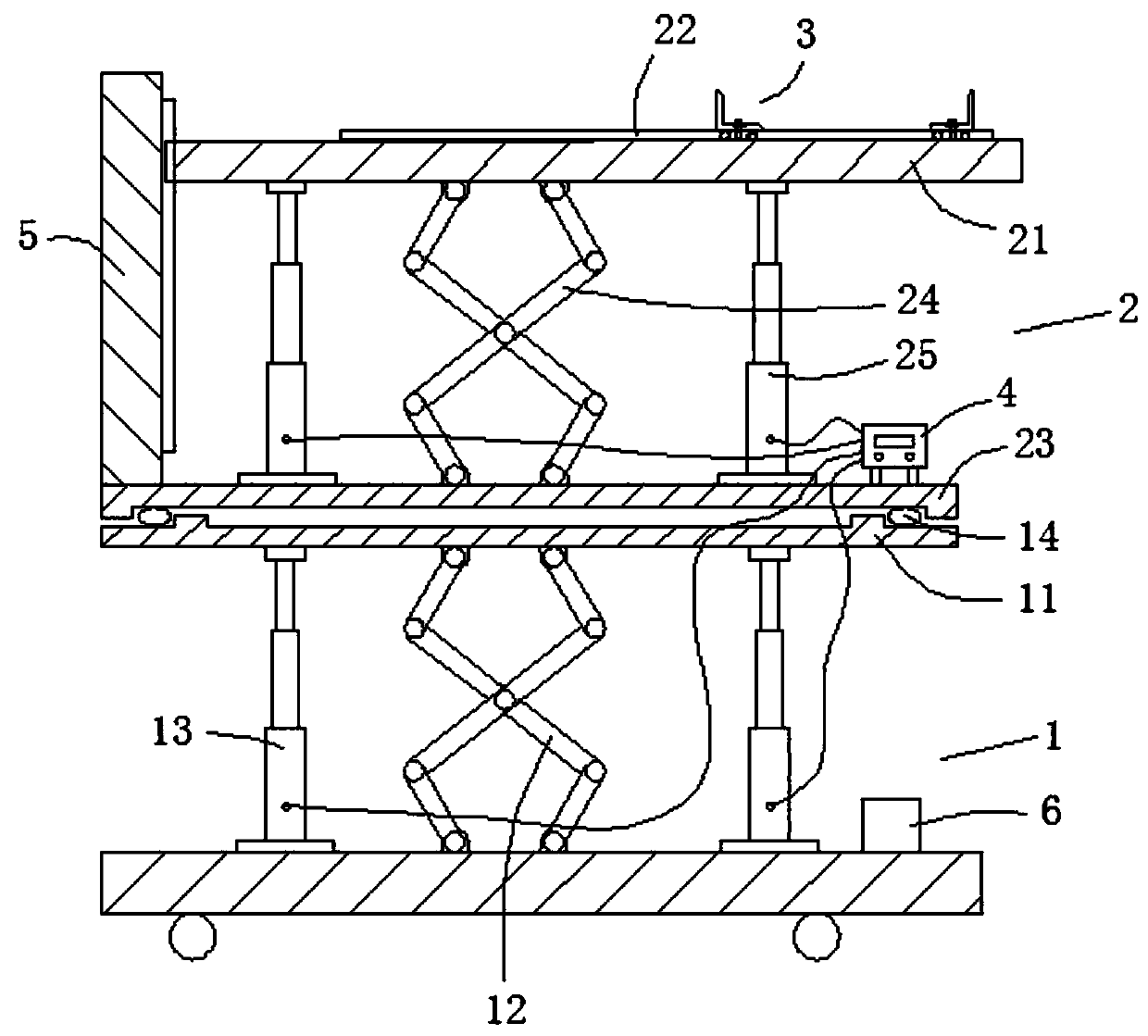

Automatic concrete pouring equipment for constructing bridge pile foundation

InactiveCN107514000ARealize the function of automatic perfusionThere is no security riskFoundation engineeringCement mixing apparatusStructural engineeringRoad surface

The invention relates to an automatic concrete pouring equipment for bridge pile foundation construction, which comprises a base plate, a moving device is installed at the lower end of the base plate, and a pouring device is installed at the upper end of the base plate. The present invention can solve the problems existing in the pile foundation construction process of existing construction projects that concrete needs to be transported by means of the existing concrete mixer truck, the existing pile foundation pouring tools need to be manually fixed, the road surface for pile foundation construction is complicated, and there is much rain. season, the ground is muddy, and the existing concrete mixer trucks have no corresponding protective measures on the muddy road surface, and are easy to sink into the muddy road surface, and the use of existing concrete mixer trucks to transport concrete pouring pile foundations consumes a lot of resources, and artificial Heavy mobile equipment moves the pouring tool to the working position, and the operation is complex. Manual control of the pouring tool is prone to accidents and poses a threat to the safety of workers. It can realize the function of automatic pouring of pile foundation concrete.

Owner:王辉

Production management system for carbon steel welding air duct product based on BIM (Building Information Modeling)

InactiveCN110802309AOptimize the production processReduce the possibility of mishandlingWelding accessoriesControl systemIndustrial engineering

The invention relates to a production management system for a carbon steel welding air duct product based on BIM (Building Information Modeling). Based on standard for manufacturing of galvanized sheet steel, connection or enhancement is carried out by means of welding; and due to the enhancement way, the air duct is good in welding formation quality, less in deformation and good in perception. Aproduction method of the carbon steel welding air duct comprises the following steps: making an air duct sketch through Autodesk Revit; making a single straight-pipe air duct and a single abnormal airduct based on the sketch; importing prefabricated making information into an Autodesk Fabrication control system; and controlling a production process of the carbon steel welding air duct through Autodesk Fabrication. The production management system for the carbon steel welding air duct product based on BIM disclosed by the invention has the beneficial effects that the production process of theair duct is automatic and intelligent; a sketch which meet a composite demand can be formulated according to scene demands, and data of the sketch are imported into a BIM system, and through data control of a production line machine, manufacturing processes of accurate blanking, bending and fixing of the air duct can be realized; and in addition, a manufacturing process of the air duct can be simulated in advance, so that the manufacturing process is optimized to the maximum limit, and the possibility of error operations is reduced.

Owner:天津奥特浦斯机电设备有限公司

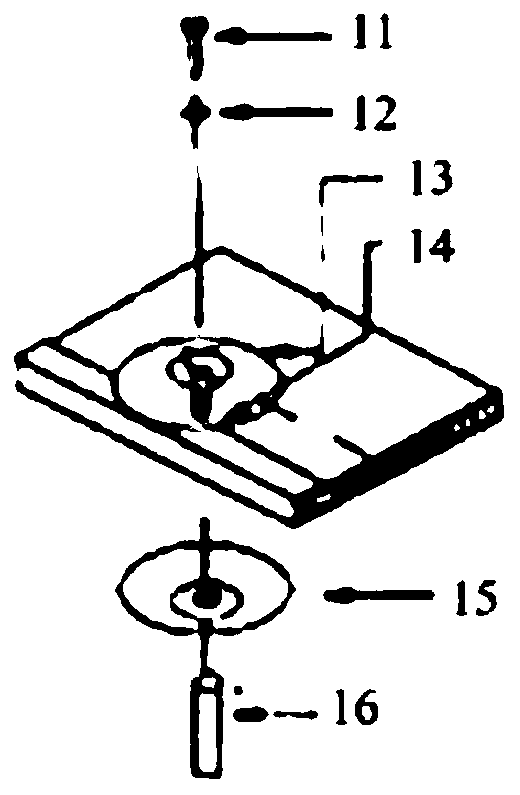

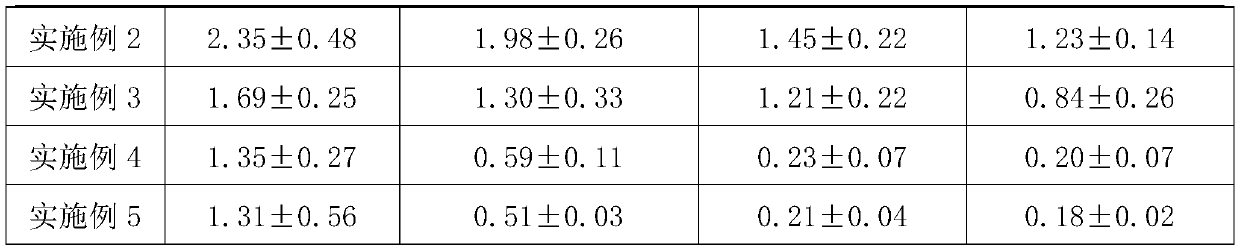

Cell dehydrator and its dehydration method

InactiveCN1116600CReduce processingReduce labor intensityPreparing sample for investigationBiomass after-treatmentUltrasonic sensorAlcohol

The present invention relates to a cell dehydrater and its dehydration method. It is characterized by that the biological tissue required for treatment is soaked in the treatment solutions of alcohol, acetone, dimethyl benzene and liquid paraffin, and is placed in the reverberation field produced by ultrasonic transducer, several liquid-storage tanks are placed on the rotating disk of the dehydrater, and are connected with closed container by means of flexible pipe and sealing joint. Said invention utilizes the rotating disk, conveying arm and changer-over sealing joint to implement the replacement of liquid-storage tank. It can automatically and quickly replace water content in cell by liquid paraffin, and can effectively shorten the treatment process of biological tissue of cell, and can raise its working reliability.

Owner:SHANGHAI JIAO TONG UNIV

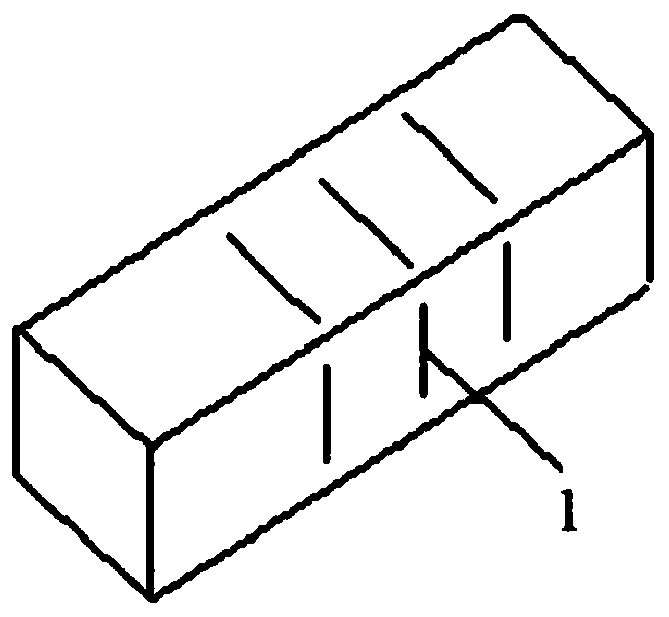

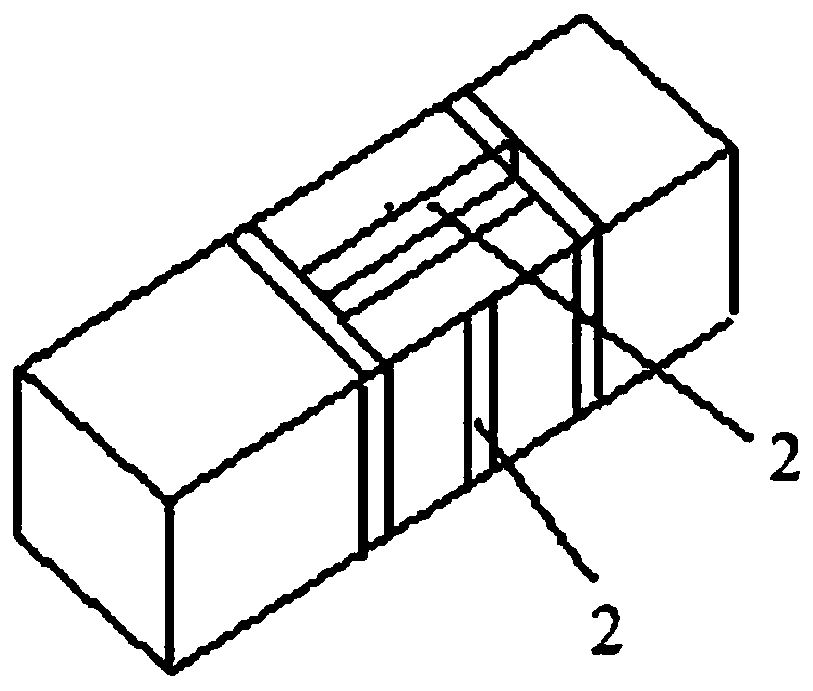

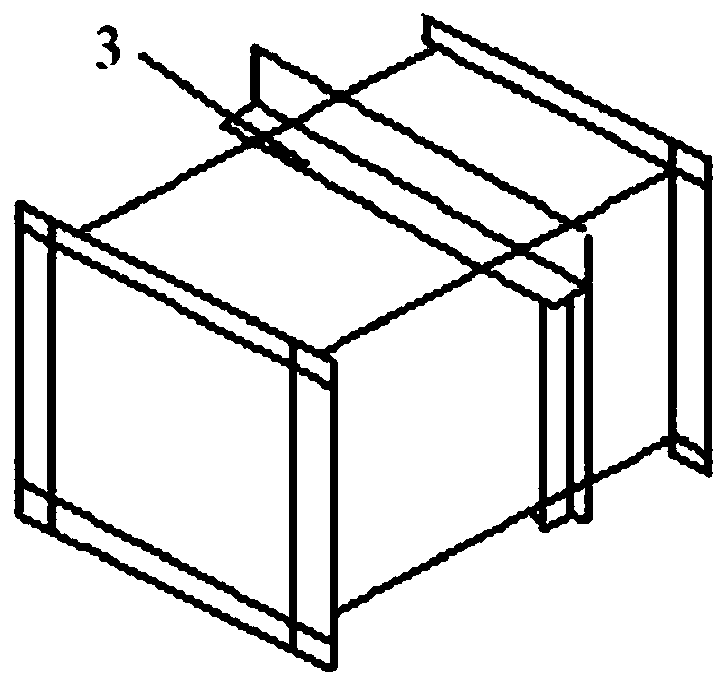

Lightweight plaster wall and integral pouring procedure thereof

InactiveCN101041980BStrong impact resistanceImprove flexural strengthWallsThermal insulationEngineering

The invention relates to a light gesso wall and relative integral irrigation method. The wall is disposed with a light steel keel support whose two sides are arranged with strengthen mesh cloth. The space between two strengthen mesh cloths is fixed with flexible thermal insulator. The gesso mixture is filled in the light keel support to cover the flexible thermal insulator and the strengthen meshcloths. The invention has high shaping speed, high mould detaching speed, and maintenance free. And the wall has high strength, non crack, thermal insulation and sound adsorption, with smooth and flat surface.

Owner:刘辉

High temperature resistant inorganic molding agent and preparation method thereof

InactiveCN111069525AHigh viscosityImprove high temperature resistanceFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention provides a high temperature resistant inorganic molding agent with high adhesive strength and capable of directly replacing coal powder and a bonding material and a preparation method ofthe high temperature resistant inorganic molding agent. The high temperature resistant inorganic molding agent is prepared from the following components in percentage by weight: 0-10% of soda ash, 0-10% of talcum powder, 0-10% of attapulgite, 0.5-40% of a high temperature resistant mixture, 0.5-30% of alumina, 0-5% of aluminium dihydrogen phosphate, 0-30% of sepiolite powder, 20-95% of bentoniteand the like.

Owner:陈仁清

A hanging pumping method for well completion of beam pumping unit operation

ActiveCN105863574BProduct stabilityNo labor intensityDrilling rodsFluid removalUnit operationSucker rod

Owner:CHINA PETROLEUM & CHEM CORP +1

Valve steel plate element straightener

ActiveCN102921835BAchieve straightening effectImprove straightening accuracyRotational axisEngineering

The invention discloses a valve steel plate element straightener which comprises a pay-off reel, a pinch roll, a straightening mechanism and a cut-off mechanism, wherein the straightening mechanism comprises a straightening barrel which is horizontally arranged, at least one straightening model is arranged in the straightening barrel, the straightening model is horizontally fixed in the straightening barrel by two adjustable jacking bolts symmetrical to each other vertically and has a cylinder structure, the outer sides of two ends of the straightening barrel are provided with rotating shafts with through holes at the center, the rotating shafts are arranged on a support frame, the support frame is fixed on a main frame table, and any of the rotating shafts is connected with the shaft of the motor by a transmission mechanism. The valve steel plate element straightener has the advantages of simple structure, low cost, easy operation, convenient overhauling, no scratch on the surface of wire, high straightening precision, automatic sizing, cutting-off and blanking, high sizing precision, low labor intensity, high efficiency, no balance of straightening steel wires, and high yield.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

A kind of high temperature resistant inorganic plasticizer and preparation method thereof

InactiveCN111069525BHigh compressive strengthHigh refractorinessFoundry mouldsFoundry coresPhosphatePlasticizer

The invention provides a high temperature resistant inorganic molding agent with high adhesive strength and capable of directly replacing coal powder and a bonding material and a preparation method ofthe high temperature resistant inorganic molding agent. The high temperature resistant inorganic molding agent is prepared from the following components in percentage by weight: 0-10% of soda ash, 0-10% of talcum powder, 0-10% of attapulgite, 0.5-40% of a high temperature resistant mixture, 0.5-30% of alumina, 0-5% of aluminium dihydrogen phosphate, 0-30% of sepiolite powder, 20-95% of bentoniteand the like.

Owner:陈仁清

Tomato planting method

ActiveCN113545258AImprove fruit setting rateImproves armyworm effectAgriculturePlant genotype modificationFruit setAgricultural engineering

The invention discloses a tomato planting method belongs to the field of planting, and particularly relates to tomato planting. The most troublesome problem of the tomato planting is low fruit setting rate. In order to improve the tomato fruit setting rate, the tomato planting method is provided, and comprises the following steps that in a tomato flowering phase, a permanent magnet is fixed to a tomato stem, an electromagnet is arranged at the same horizontal position as the permanent magnet, the electromagnet is powered by pulse current, and the electromagnet is used for applying acting force to the permanent magnet so that the permanent magnet can push tomato plants to shake. According to the tomato planting method, the tomato fruit setting rate can be increased, the pest sticking effect of a pest sticking plate can be improved, so that the yield is increased, the labor intensity is reduced, no pollution is caused, and organic planting is facilitated.

Owner:宁夏禹尧农产品科技有限公司

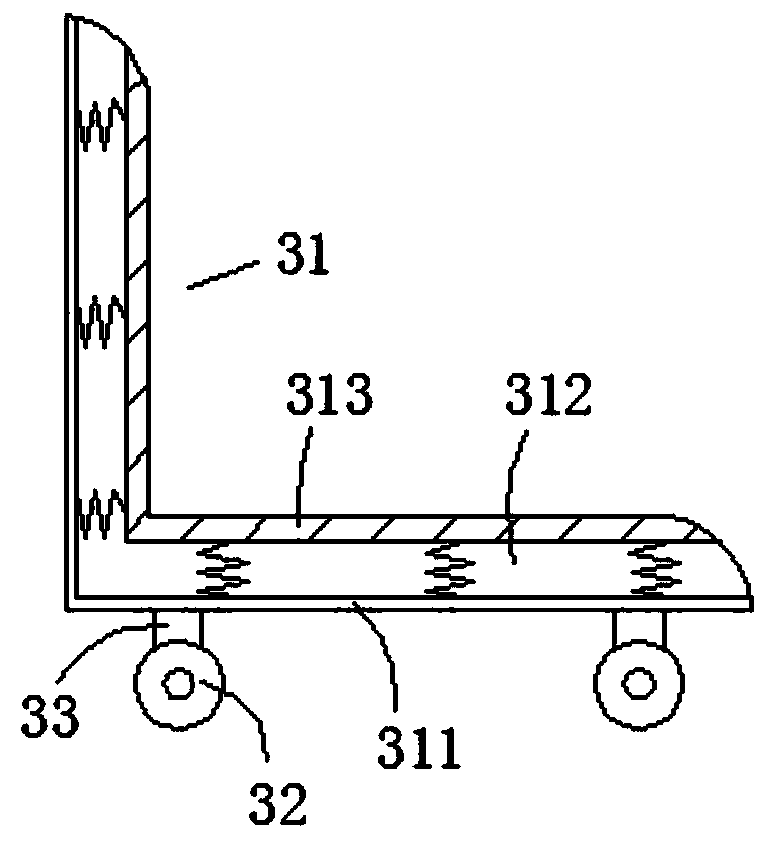

Assembling and disassembling assisted device of supporting roller spherical pad as well as assembling and disassembling method

PendingCN110815113AGuaranteed stabilityAdjustable spacingMetal-working hand toolsStructural engineeringMechanical engineering

The invention provides an assembling and disassembling assisted device of a supporting roller spherical pad as well as an assembling and disassembling method, and belongs to the technical field of maintenance of steel rolling equipment. The assembling and disassembling device comprises a trolley, a lifting mechanism and a supporting mechanism; a first platform with adjustable height is arranged onthe trolley; the lower end face of the lifting mechanism is rotatably connected with the upper end face of the first platform; a second platform with adjustable height is arranged on the lifting mechanism; the supporting mechanism is arranged on the second platform in a sliding way and is provided with two supporting plates for supporting the spherical pad; the distance between the two supportingplates is adjustable; and the height of the supporting mechanism is adjusted by virtue of the first platform and / or the second platform. The assembling and disassembling method comprise the followingsteps: moving the device to below the spherical pad, mounting the spherical pad on a bearing pedestal by a tool, or disassembling the spherical pad by a tool and falling on the supporting mechanism.According to the assembling and disassembling assisted device of the supporting roller spherical pad as well as the assembling and disassembling method, the positions of the supporting plates are adjustable, the spherical pad is supported, the assembling and disassembling labor intensity of the spherical pad is low, the potential safety hazard is small and assembling and disassembling are simple.

Owner:HEBEI IRON AND STEEL

BIM-based air duct product production management system

InactiveCN111382492ARealize precise blankingSimple preparation processDesign optimisation/simulationData controlControl system

The invention relates to a BIM-based air duct product production management system. An air pipe production method comprises the following steps of: drawing an air duct sketch through Autodesk Revit; manufacturing a single straight pipe air duct and a single special-shaped air duct on the basis of the sketch; importing prefabricated manufacturing information into an Autodesk Fabrication control system; and controlling the production process of the composite air duct through adopting the Autodesk Fabrication. The BIM-based composite air duct product production management system has the beneficial effects that the air duct production process is automatic and intelligent; firstly, the sketch meeting the requirement is drawn according to the field requirement, then sketch data are imported intoa BIM system, and the manufacturing process of precise blanking, bending and fixing of the air duct is achieved through data control over production line machinery; in addition, the manufacturing process of the air duct can be simulated in advance, the manufacturing process is optimized to the maximum extent, and the possibility of misoperation is reduced.

Owner:天津奥特浦斯机电设备有限公司

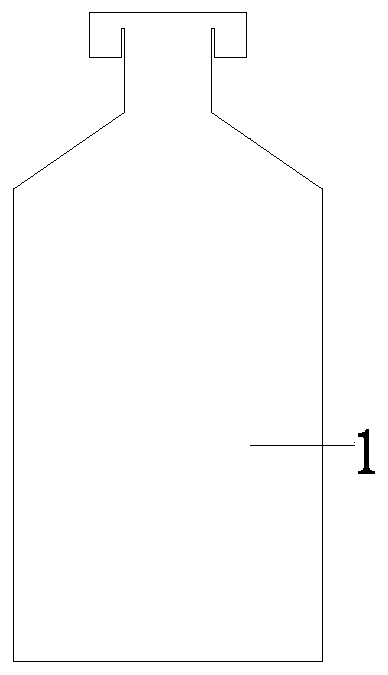

A medical instrument for processing a medical saline bottle

InactiveCN108862156BNo manual operationThere is no security riskHand-operated cutting devicesPower-operated cutting toolsElectric machineApparatus instruments

Owner:孟宪凤 +1

Coking crude ammonia water purification method

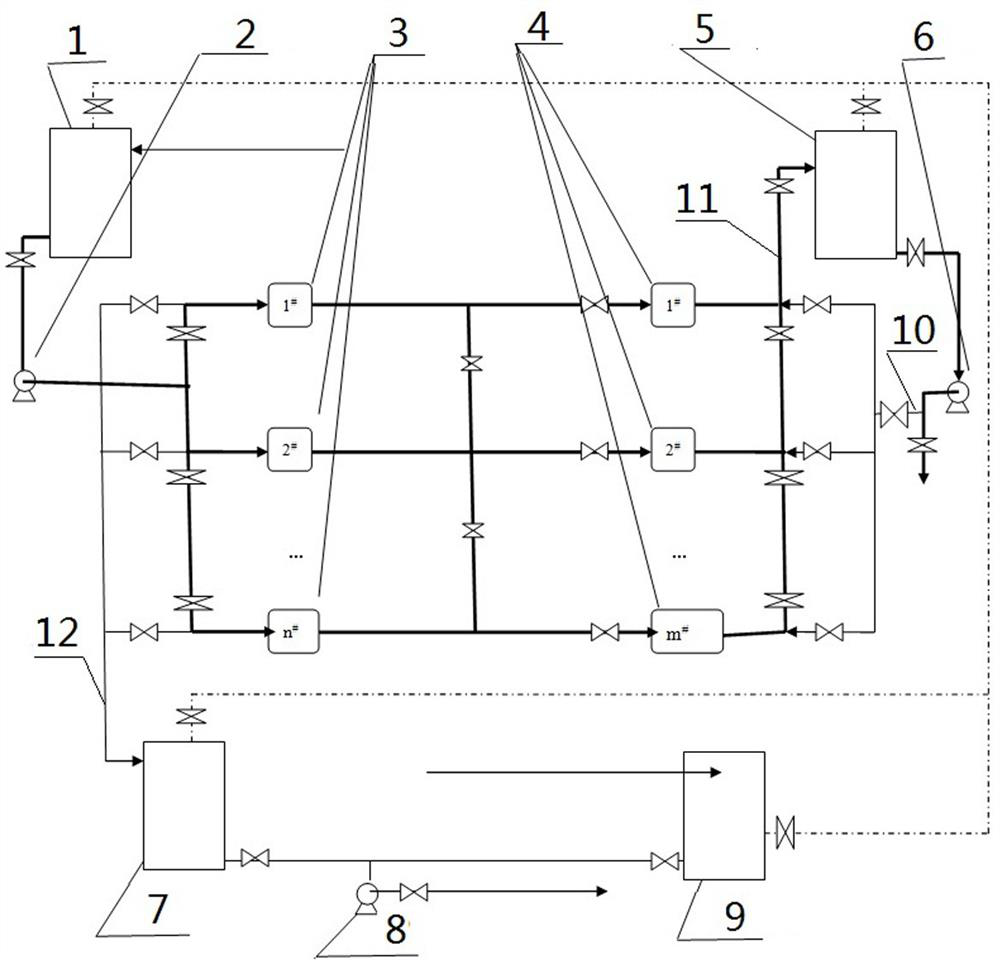

ActiveCN113750622AEliminate disadvantagesNo cumulative effectFiltration separationPurification methodsFiltration

The invention discloses a coking crude ammonia water purification method. The method comprises the following steps: purifying crude ammonia water by using a coking crude ammonia water purification device; the coking crude ammonia water purification device comprises a crude ammonia water tank which is provided with a product crude ammonia water outlet connected with the front end of the Fossam method production device, the crude ammonia water tank is connected with a filter through an ammonia water conveying pump, a purified ammonia water outlet pipe of the filter is connected with a purified ammonia water tank, and the purified ammonia water tank is connected with a user interface through a purified ammonia water pump; and the purification method comprises the following steps: continuously conveying crude ammonia water produced by a phosam process to the crude ammonia water tank by residual pressure of a production system, continuously conveying the crude ammonia water to pass through the filter by the crude ammonia water conveying pump, feeding purified ammonia water subjected to filtration and purification into the purified ammonia water tank, and finally continuously conveying the purified ammonia water to a user by the purified ammonia water pump. According to the method, the quality of the crude ammonia water produced by the rectification-free Frixamer process can be effectively improved, and secondary pollution is avoided.

Owner:LIUZHOU IRON & STEEL

Inner heat-preservation noise-reduction air duct product production management system based on BIM

InactiveCN110848477AOptimize the production processReduce the possibility of mishandlingGeometric CADFlanged jointsPhysicsProcess engineering

The invention relates to an inner heat-preservation noise-reduction air duct product production management system based on a BIM. After air duct seams are manufactured and flanges are formed, heat preservation cotton is pasted to the inner walls of air ducts. According to a production method for the inner heat-preservation noise-reduction air ducts, an air duct sketch is manufactured through Autodesk Revit, one or more single straight-tube air ducts and one or more single special-shaped air ducts are manufactured on the basis of the sketch, preset manufacture information is imported into an Autodesk Fabrication control system, and the production process for the inner heat-preservation noise-reduction air ducts is controlled through Autodesk Fabrication. The inner heat-preservation noise-reduction air duct product production management system based on the BIM has the advantages that the air duct production process is automated and intelligentized; the sketch meeting the demand is made according to the site demand first, then sketch data is imported into a BIM system, through datamation control over production line machinery, and the manufacture process of precise blanking, bending and fixing for the air ducts is achieved; and in addition, the air duct manufacture process can be simulated in advance, the manufacture technology is optimized to the greatest degree, and the possibility of error operation is lowered.

Owner:天津奥特浦斯机电设备有限公司

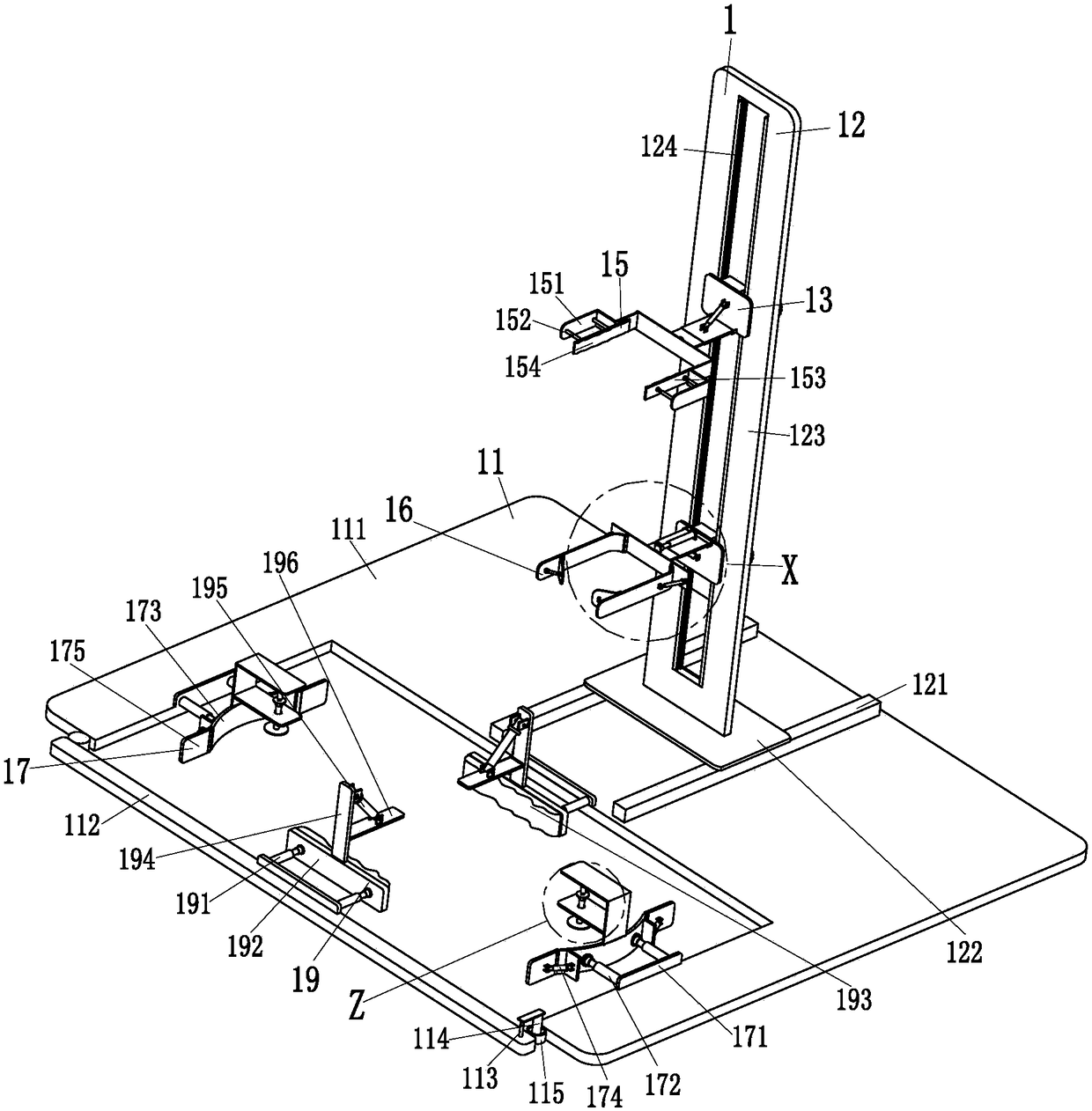

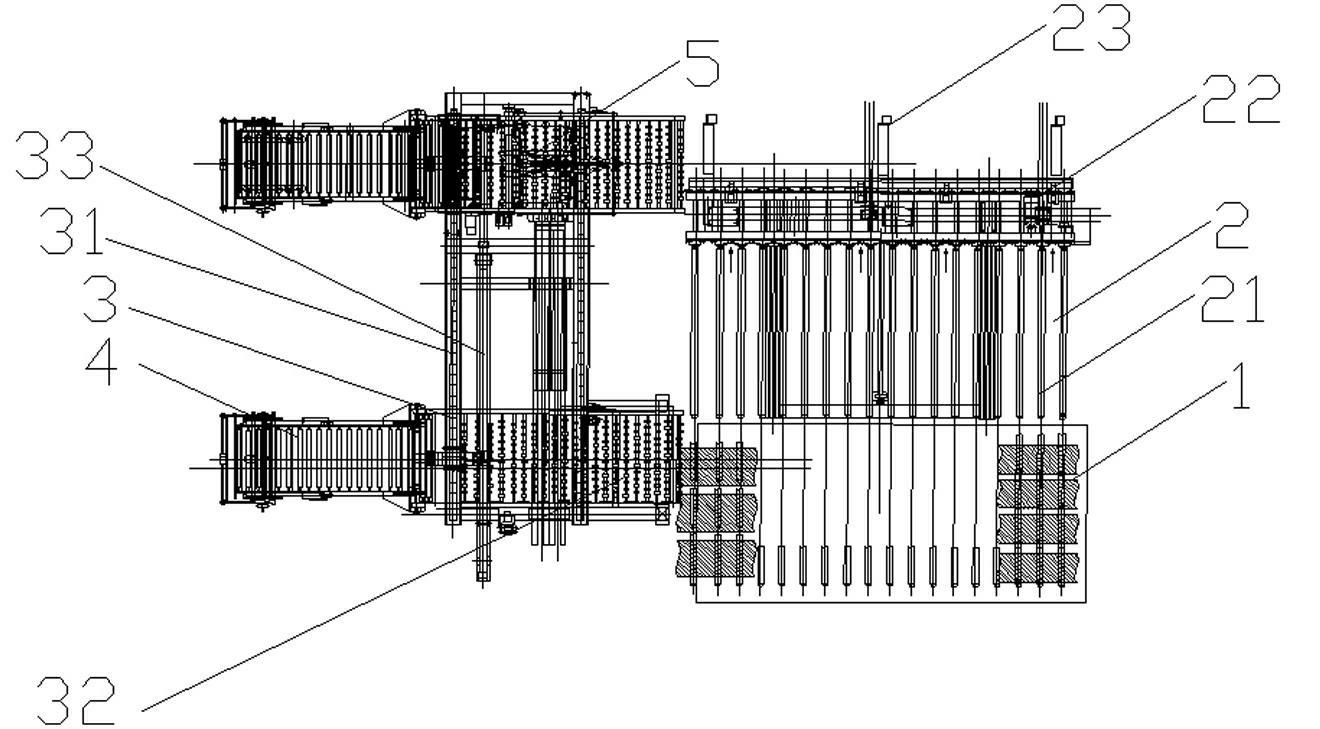

Building reinforced concrete preparation equipment with capacity of automatically constructing triangular reinforcement cage

InactiveCN107989379AIncrease labor costReduce labor costsBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to building reinforced concrete preparation equipment with capacity of automatically constructing a triangular reinforcement cage. The equipment comprises a bottom plate, a mounting rack, a grabbing device, a connecting device and a constructing device, wherein the mounting rack is mounted on the bottom plate; the grabbing device and the connecting device are mounted on the mounting rack from left to right in sequence; the constructing device is arranged at the lower end of the grabbing device and mounted on the bottom plate and comprises linear sliding rails, a substrate, limit grooves, a connecting plate, a pushing cylinder, a fixing plate, a liner guide rail, an electric sliding plate and a supporting mechanism. According to the equipment, the problems of large potential safety hazard, high labor intensity, high labor cost, low work efficiency and single application condition of an existing triangular reinforcement cage construction process can be solved, automatic construction of the triangular reinforcement cage can be realized, and the equipment has the advantages of being free of potential safety hazard, low in labor intensity, low in labor cost, high in work efficiency, wide in use range and the like.

Owner:黄远明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com