A kind of high temperature resistant inorganic plasticizer and preparation method thereof

A technology of high temperature resistance and plasticizing agent, applied in the field of high temperature resistant inorganic plasticizing agent and its preparation, can solve the problems of poor high temperature resistance, easy to cause pollution, shortage of resources, etc., to improve viscosity, reduce usage, moisture low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

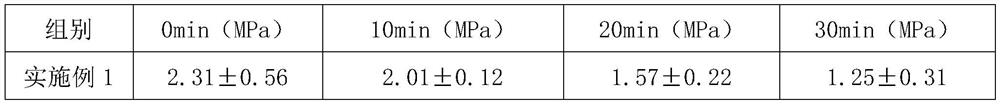

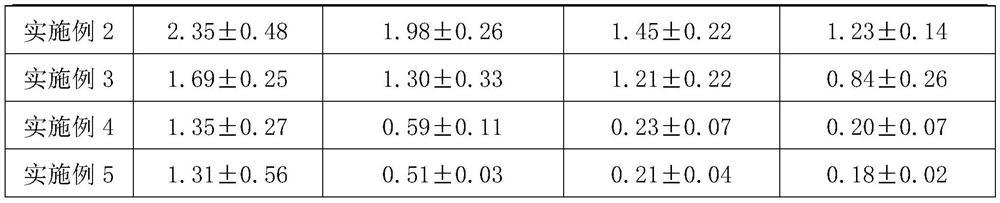

Examples

Embodiment 1

[0072] A high-temperature-resistant inorganic plasticizer, which is composed of the following ingredients in weight percentage, soda ash: 1%; talcum powder: 4%; attapulgite: 5%; high-temperature-resistant mixture: 10%; aluminum oxide: 3%; Aluminum: 2%; sepiolite powder: 10%; bentonite: 60%, tricalcium phosphate 2%, calcium pyrophosphate 3%. The respective proportions of the high temperature-resistant mixture in the mixture (kaolin 5%; bauxite 5%; corundum powder 10%; quartz powder 5%; iron oxide powder 10%; magnesia powder 5%; zircon powder 5% %; diatomite 10%; chromite powder 5%; mullite powder 5%; silicon carbide powder 5%; silica powder 5%; spinel powder 7%; kyanite powder 8%; forsterite powder 10%) .

[0073] The preparation method of the high temperature resistant inorganic plastic agent in the above-mentioned embodiment: comprises:

[0074] (1) First crush bentonite powder, talc powder, sepiolite powder, attapulgite powder, tricalcium phosphate, calcium pyrophosphate a...

Embodiment 2

[0078] A high-temperature-resistant inorganic plasticizer, which is composed of the following ingredients in weight percentage, soda ash: 1%; talcum powder: 4%; attapulgite: 5%; high-temperature-resistant mixture: 10%; aluminum oxide: 3%; Aluminum: 2%; sepiolite powder: 10%; bentonite: 60%, tricalcium phosphate 2%, calcium pyrophosphate 3%. The respective proportions of the high temperature-resistant mixture in the mixture (kaolin 5%; bauxite 5%; corundum powder 10%; quartz powder 5%; iron oxide powder 10%; magnesia powder 5%; zircon powder 5% %; diatomite 10%; chromite powder 5%; mullite powder 5%; silicon carbide powder 5%; silica powder 5%; spinel powder 7%; kyanite powder 8%; forsterite powder 10%) .

[0079] The preparation method of the high temperature resistant inorganic plastic agent in the above-mentioned embodiment: comprises:

[0080] (1) First crush bentonite powder, talc powder, sepiolite powder, attapulgite powder, tricalcium phosphate, calcium pyrophosphate a...

Embodiment 3

[0083] Embodiment three (only containing tricalcium phosphate):

[0084] A high-temperature-resistant inorganic plasticizer, which is composed of the following ingredients in weight percentage, soda ash: 1%; talcum powder: 4%; attapulgite: 5%; high-temperature-resistant mixture: 10%; aluminum oxide: 3%; Aluminum: 2%; Sepiolite Powder: 10%; Bentonite: 63%, Tricalcium Phosphate 2%. The respective proportions of the high temperature-resistant mixture in the mixture (kaolin 5%; bauxite 5%; corundum powder 10%; quartz powder 5%; iron oxide powder 10%; magnesia powder 5%; zircon powder 5% %; diatomite 10%; chromite powder 5%; mullite powder 5%; silicon carbide powder 5%; silica powder 5%; spinel powder 7%; kyanite powder 8%; forsterite powder 10%) .

[0085] The preparation method of the high temperature resistant inorganic plastic agent in the above-mentioned embodiment: comprises:

[0086] (1) First mix bentonite powder, talcum powder, sepiolite powder, attapulgite powder, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com