Biomass burner for flue-cured tobaccos

A biomass and burner technology, applied in the combustion method, combustion equipment, combustion of solid fuel, etc., can solve the problems of blockage, insufficient material combustion, and rising failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

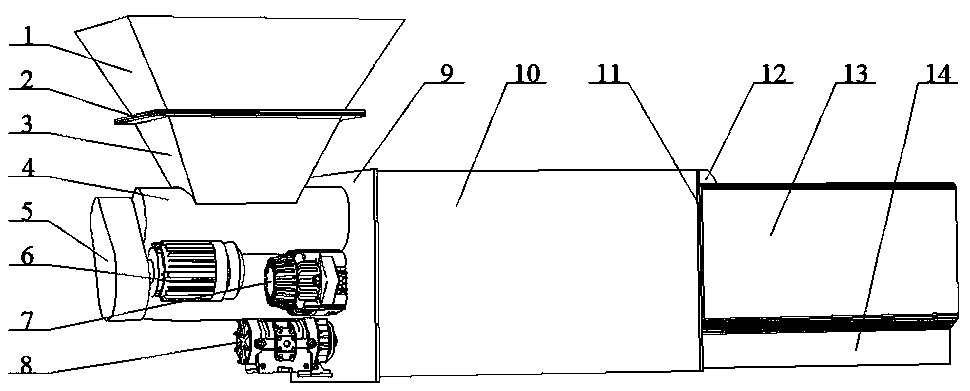

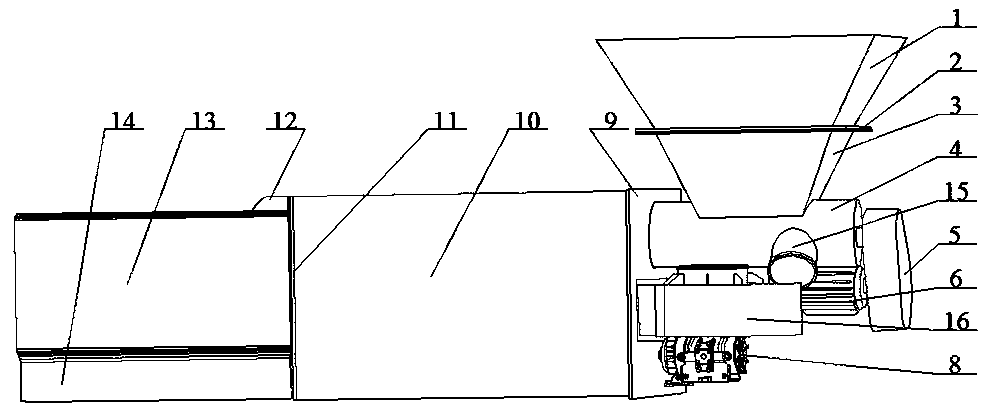

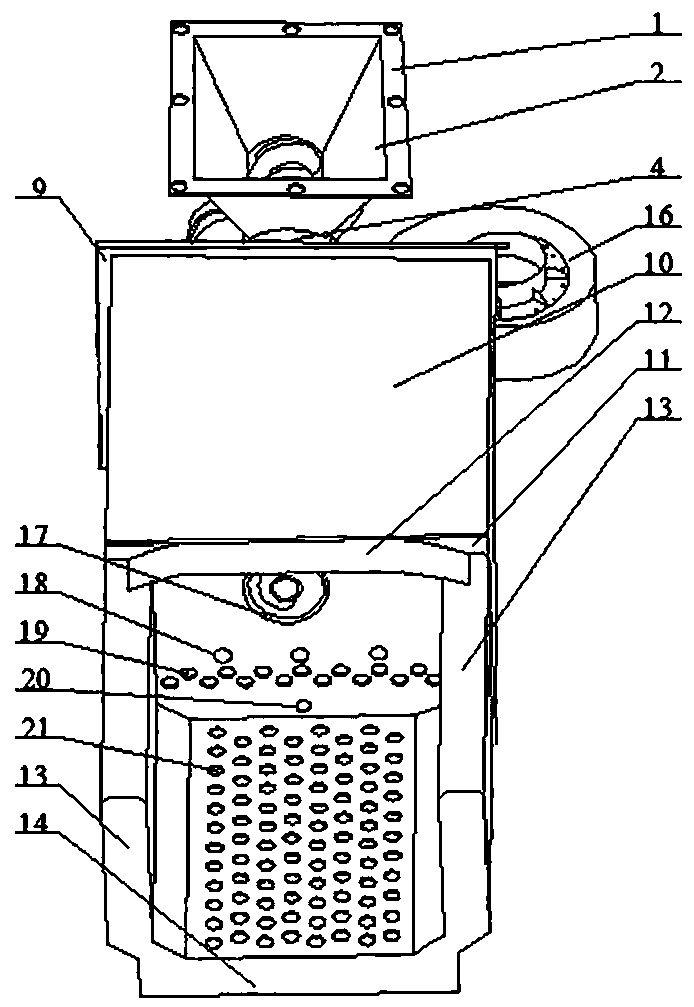

[0061] Embodiment 2. A biomass burner for flue-cured tobacco, comprising a ventilation chamber 10 in which an outer sealing baffle 9 is installed at the head port and an inner sealing baffle 11 is installed at the tail port to form a closed space, and a feeding material installed at the head of the ventilation chamber 10 device, the combustion furnace installed at the rear of the ventilation chamber 10 and the blower fan 16 installed on the blast air outlet opening 37 of the ventilation chamber 10, the front, rear, upper and lower sides of the ventilation chamber 10 and the sealed outer seals on the ports on both sides of the ventilation chamber The baffle plate 9 and the inner sealing baffle plate 11 form a closed ventilation chamber, and the mounting holes for each component are provided on the outer sealing baffle plate 9 and the inner sealing baffle plate 11 respectively.

[0062] The feeding device includes a fixed material box 3, a feeding channel 4, and a feeding power m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com