Semiconductor integrated circuit wafer processing production line and production and processing method thereof

A technology of integrated circuits and semiconductors, which is applied in the semiconductor integrated circuit wafer processing line and its production and processing fields. It can solve the problems of complicated operation, inaccurate manual control of silicon crystal ingot slicing processing, and the inability to guarantee uniform wafer specifications, so as to achieve uniform specifications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

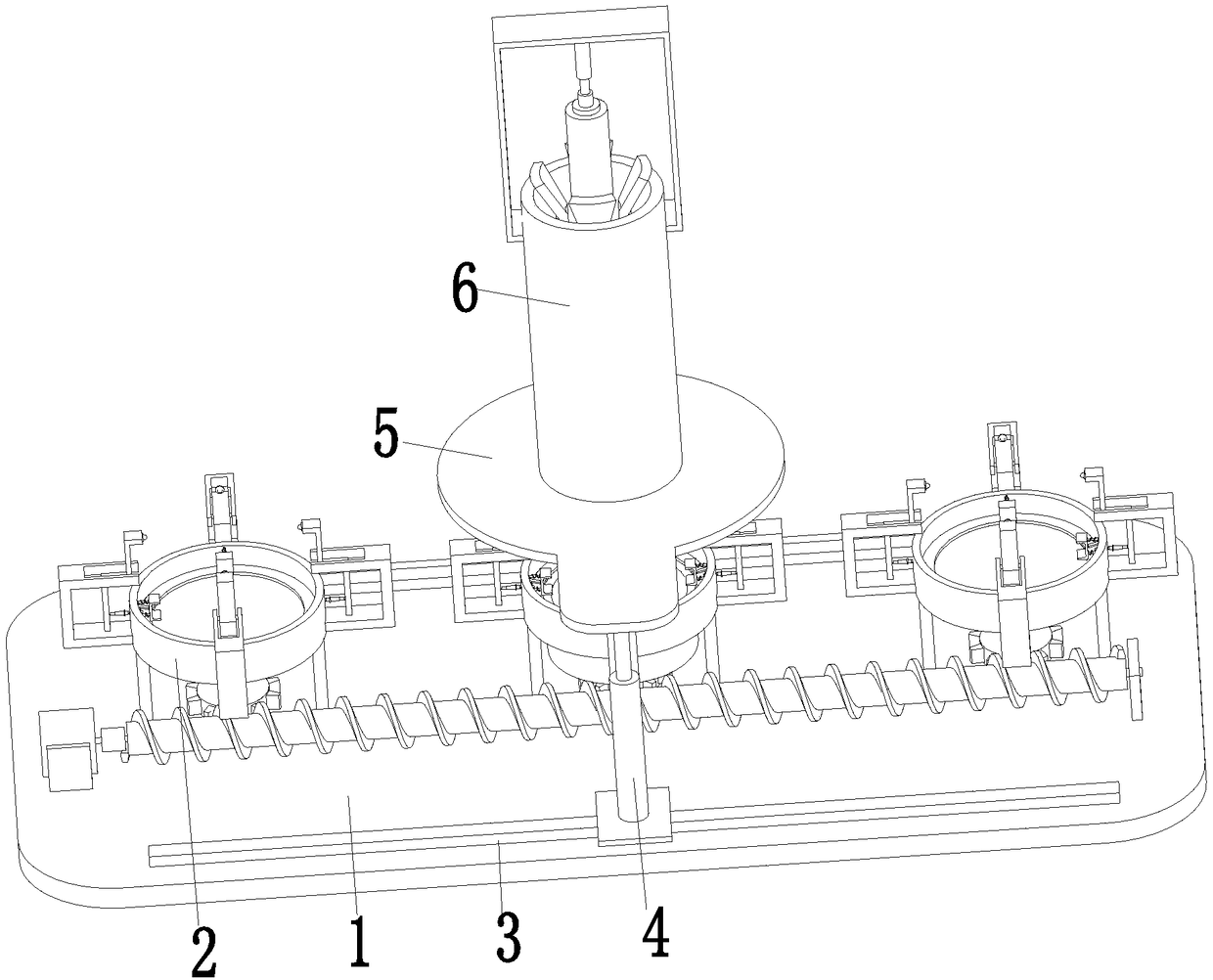

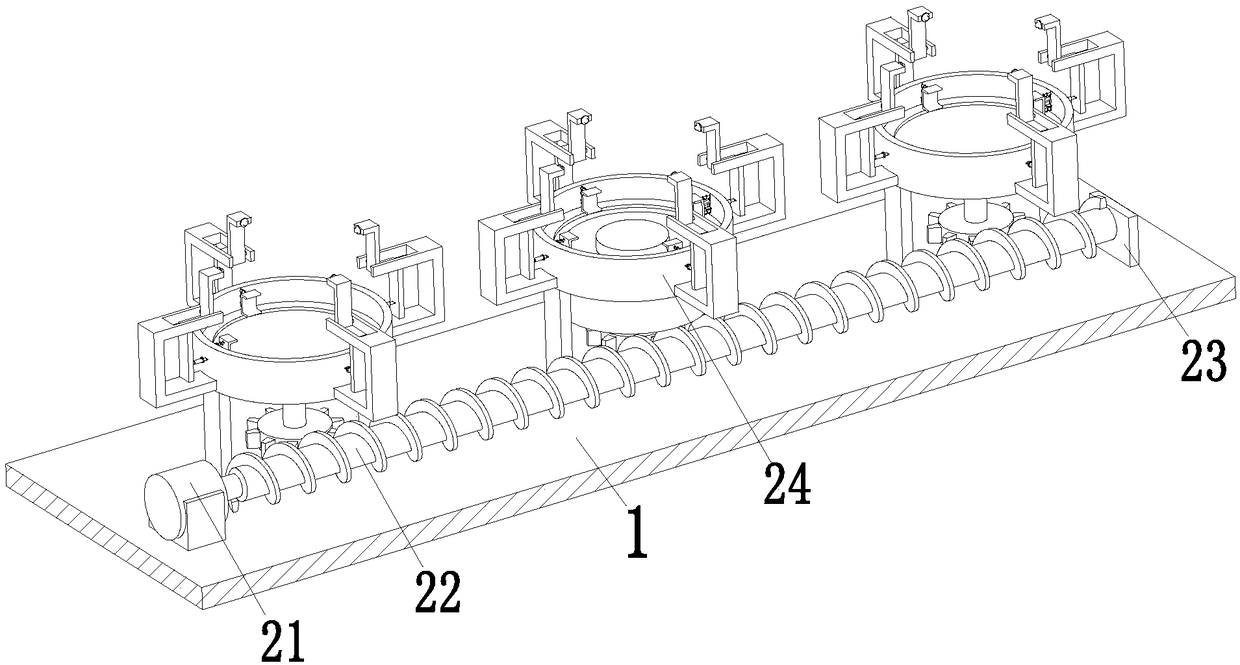

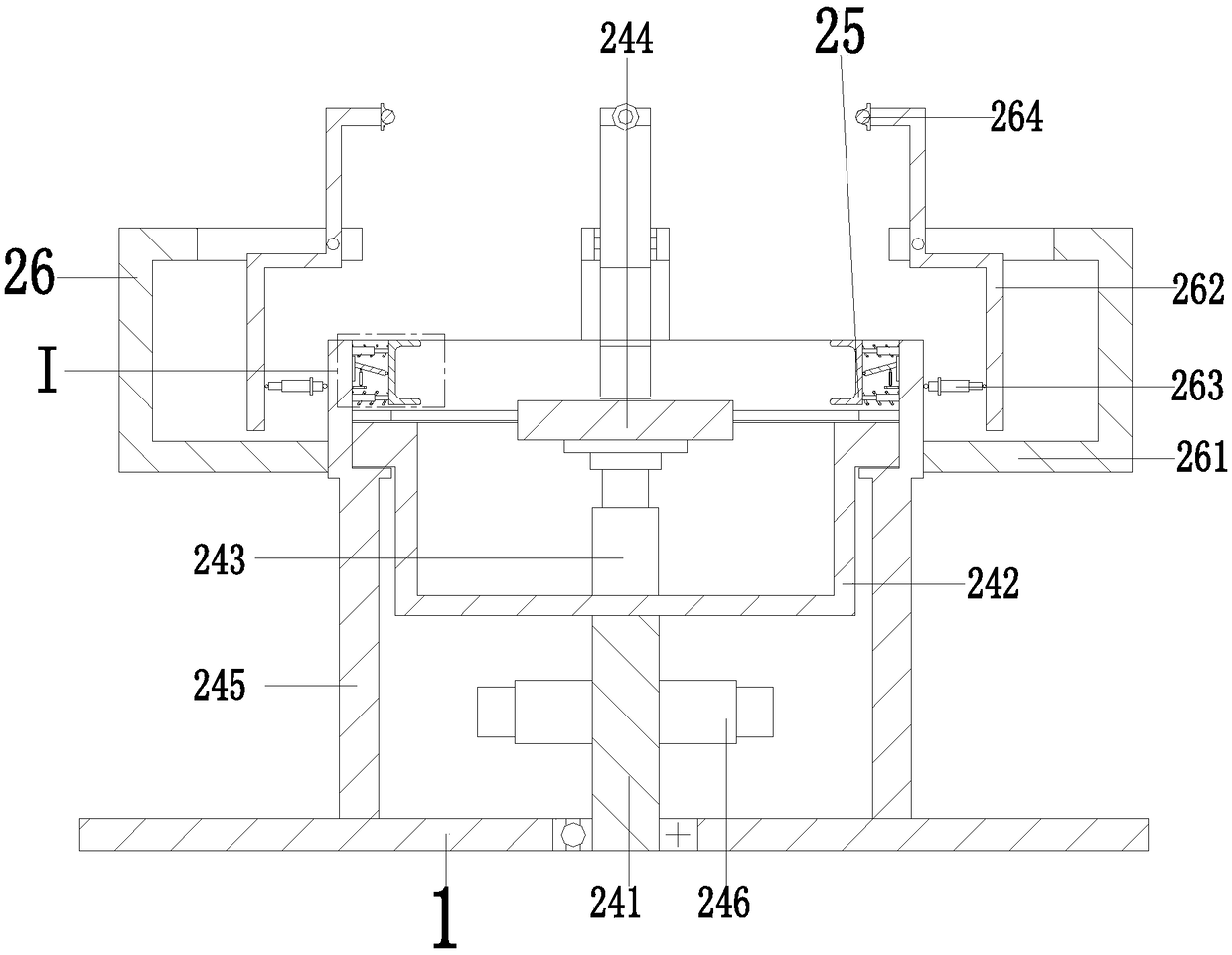

[0025] Such as Figure 1 to Figure 6As shown, a semiconductor integrated circuit wafer processing production line includes a base plate 1, an edge grinding device 2 is installed in the middle of the upper end of the base plate 1, and mobile electric sliders 3 are installed symmetrically on the front and rear sides of the base plate 1. The lifting adjustment cylinder 4 is installed, and the top of the lifting adjustment cylinder 4 is installed on the lifting driven plate 5 through the flange. The device 6 corresponds to the installation groove, and the slicing device 6 is located directly above the edging device 2. The mutual cooperation between the moving electric slider 3 and the lifting adjustment cylinder 4 can control the slicing device 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com