Device for manufacturing safe fireworks fuse

A fuse and safety technology, applied in the field of production equipment for fireworks safety fuses, can solve problems such as unstable burning speed, inconsistent thickness and specifications of fuses, and flame failure of fuses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

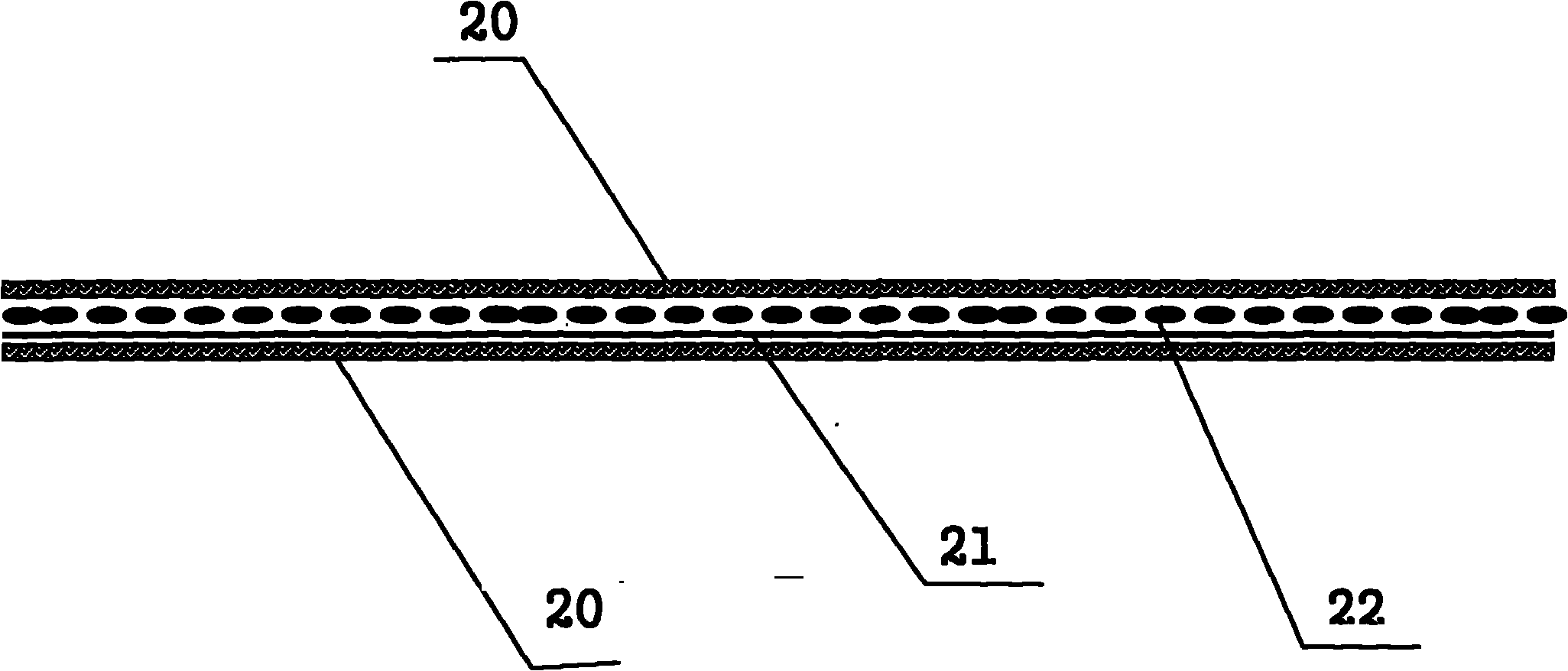

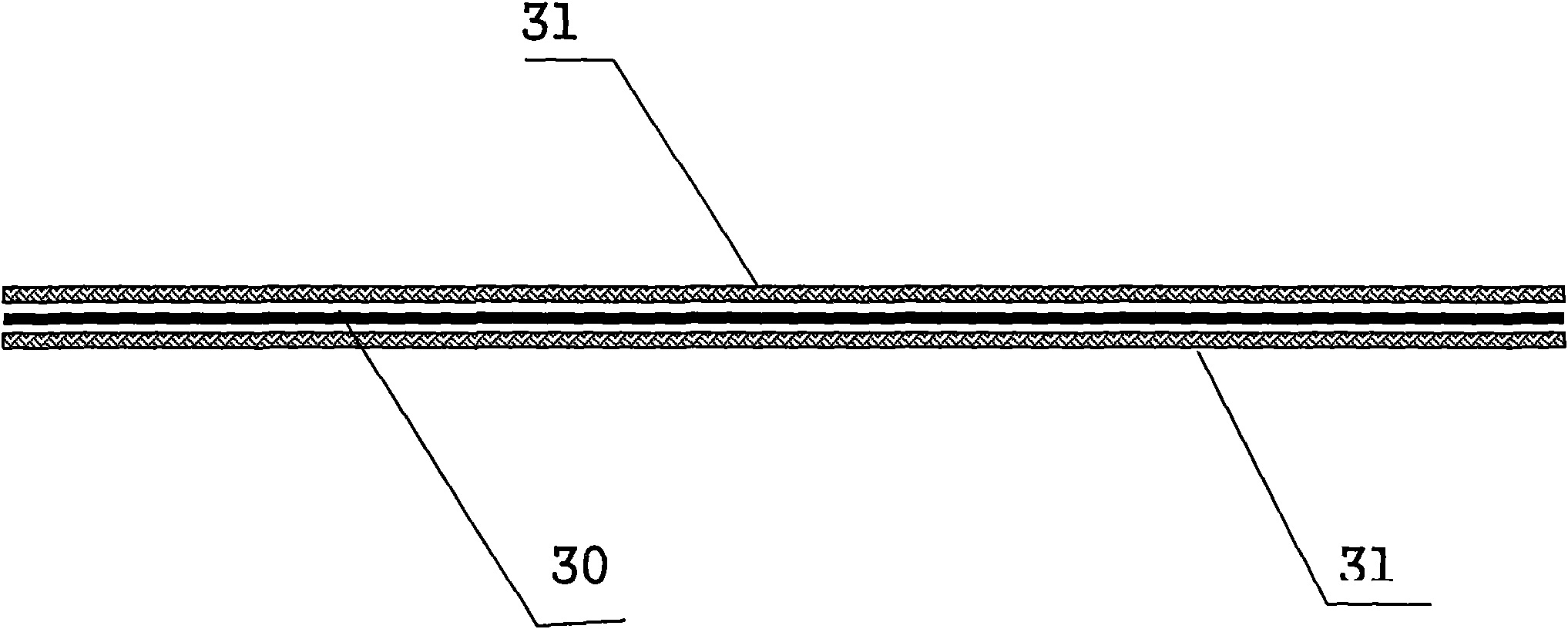

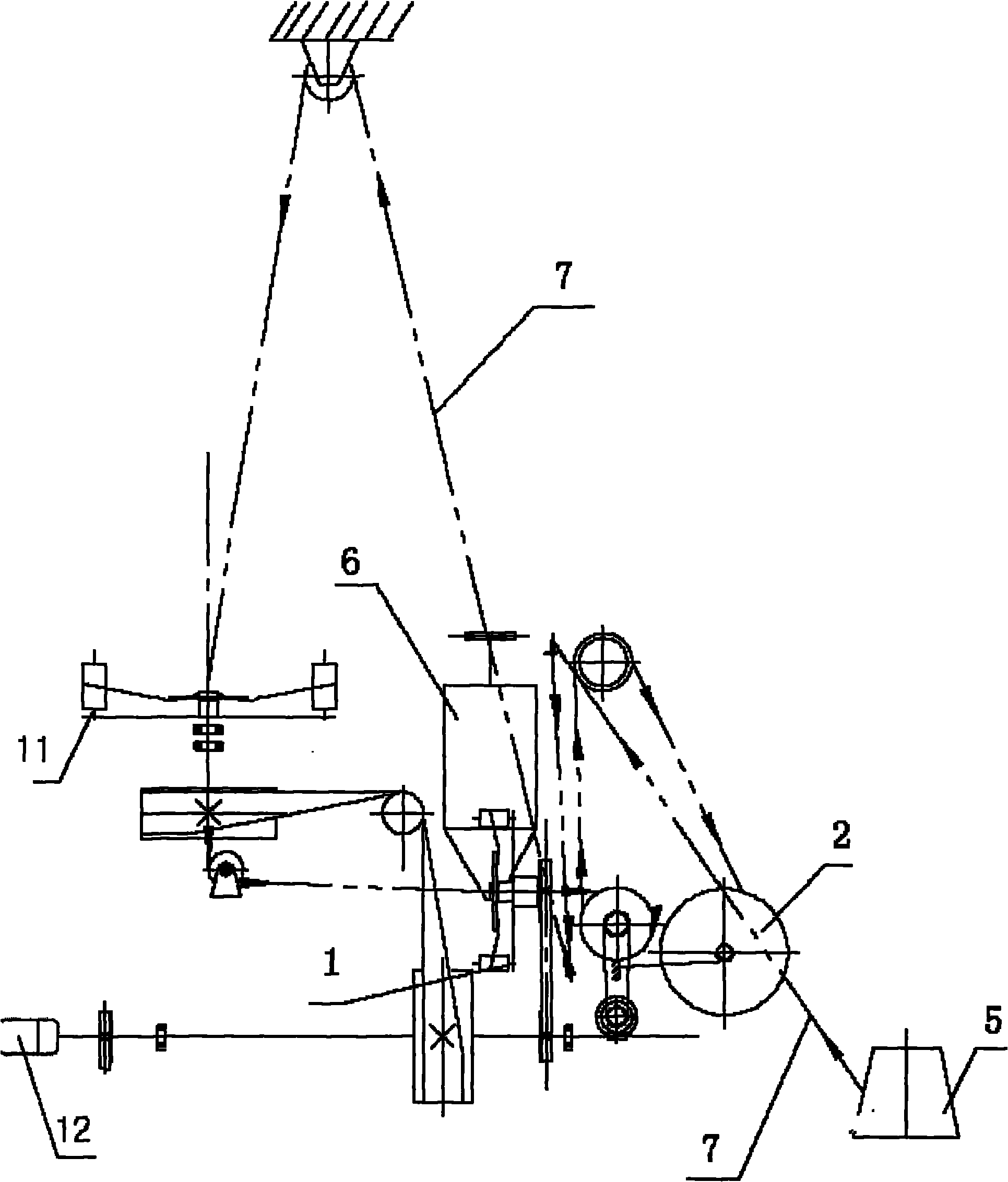

[0041] see Figure 7 , 8, 9, reflecting a kind of preferred structure of the present invention, the part names of each accompanying drawing label among the figure are as follows: frame--201; Power one shaft single V-belt pulley--202; Main shaft double V-belt pulley--203; Main shaft-- 204; vertical flexible line flat belt - 205 vertical flexible line assembly - 206 thread mound - 207 drug-introduced cotton yarn - 208; process pulley block - 209; medicine bucket mixing blade - 210; stirring shaft round belt Wheel——211; transmission round belt——212; double-groove reversing round belt pulley——213; forming lead wire second guide pulley——214; forming lead wire first guide pulley——215; stirring round belt main pulley— —216; Driven sprocket——217; Finished disc V-belt pulley——218; Finished lead wire flexing reel——219; Variable speed worm gear——220; Main sprocket——221; ; Seat-type flexible wire assembly V-belt pulley——223; Seat-type flexible wire assembly transmission main V-belt pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com