BIM-based composite air duct product production management system

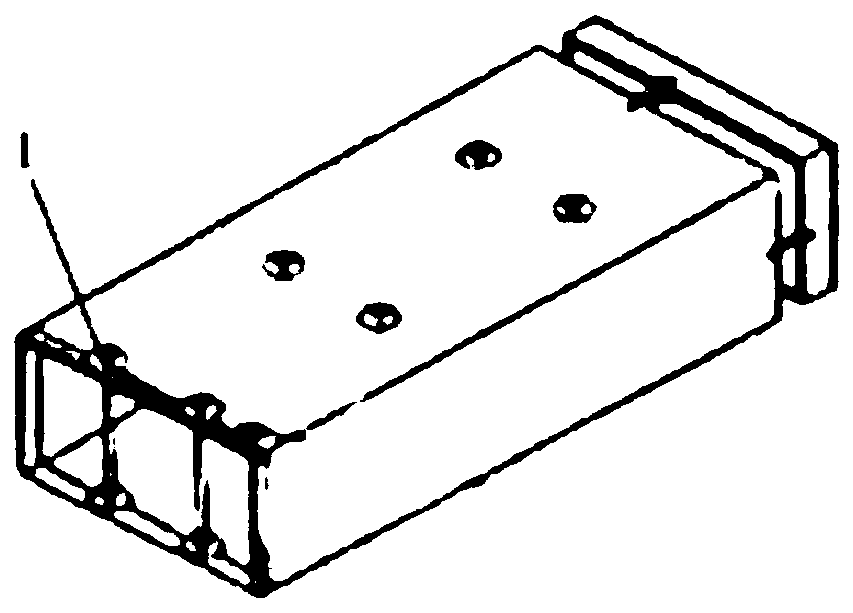

A production management system, a technology for composite air ducts, applied in the direction of pipes/pipe joints/pipes, pipes, rigid pipes, etc., which can solve problems such as errors prone to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] The production management method of composite air duct products based on BIM, the specific preparation method is as follows:

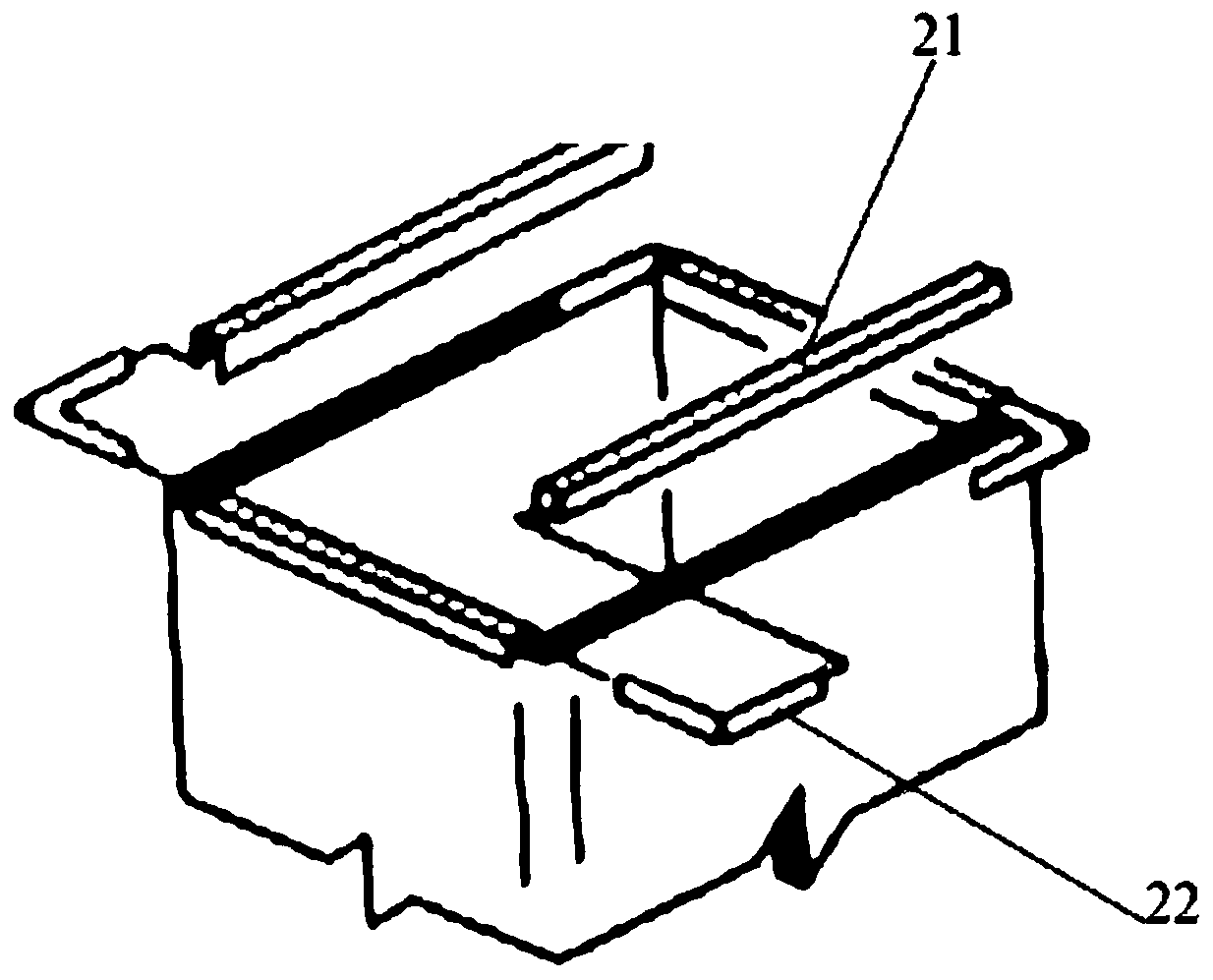

[0078] Step 1: Construct the primary BIM model through Autodesk Revit according to the preparation requirements of the composite air duct;

[0079] Step 2: Check and adjust the primary BIM model to confirm the secondary BIM model;

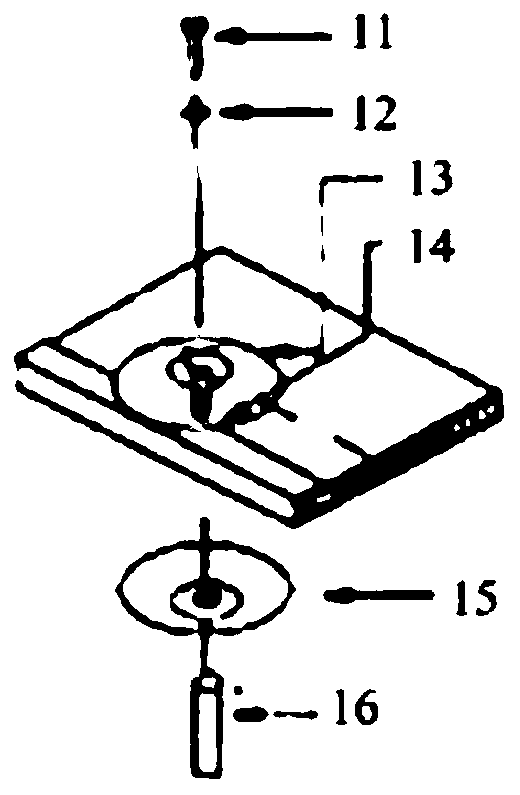

[0080] Step 3 Prepare the prefabricated product, perform secondary adjustment of the model according to the product formation, and determine the final BIM model;

[0081] Step 4 import the product information standard into the Autodesk Fabrication control system, and generate the prefabricated product library in the BIM model through the product information standard of the interactive module;

[0082] Step 5 Generate prefabricated products according to the final BIM model information, code the produced prefabricated products, and the coded information is in one-to-one correspondence with the formed pipe fittings;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com