Inner heat-preservation noise-reduction air duct product production management system based on BIM

A production management system and sound-absorbing wind technology, applied in the direction of heat preservation, heat insulation protection of pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of prone to errors, great influence on the quality and technical level of finished products, large production site operating space, etc. problems, to achieve the effect of reducing project cost, improving production efficiency, and improving the competitive advantage of installation units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

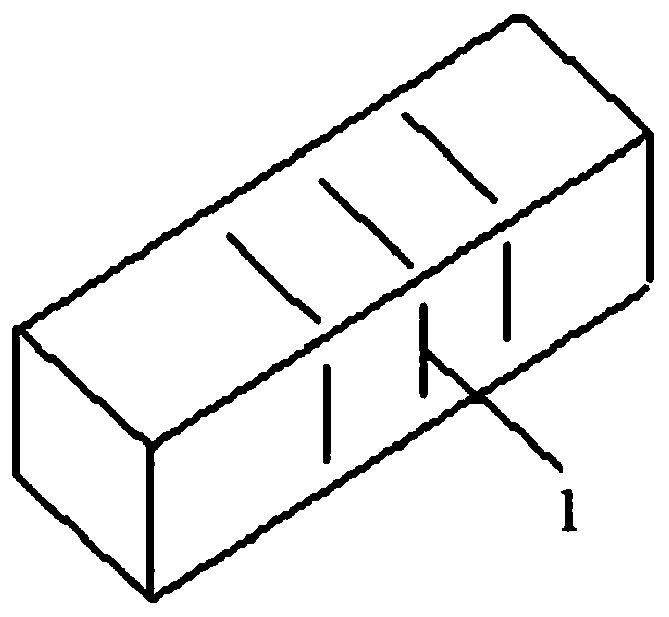

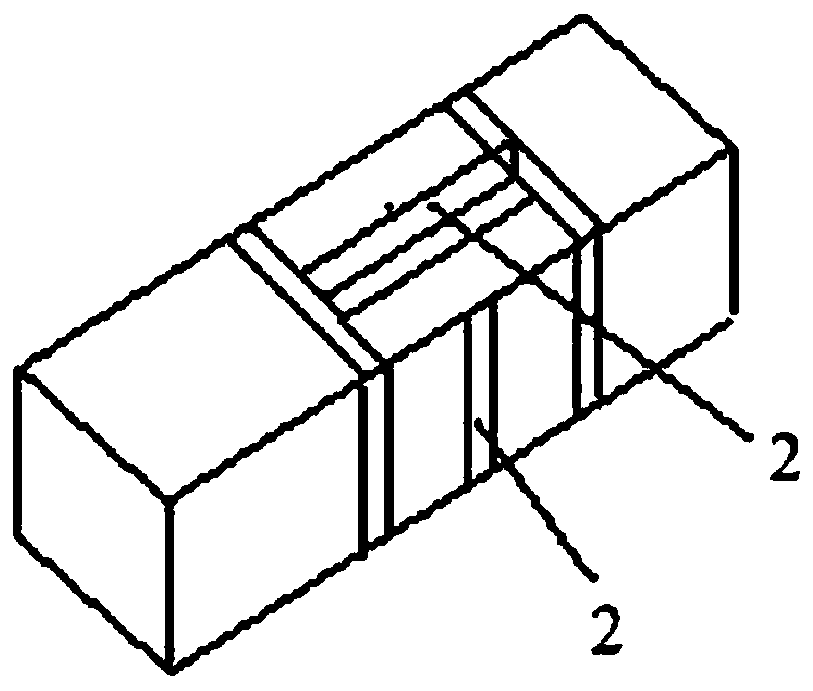

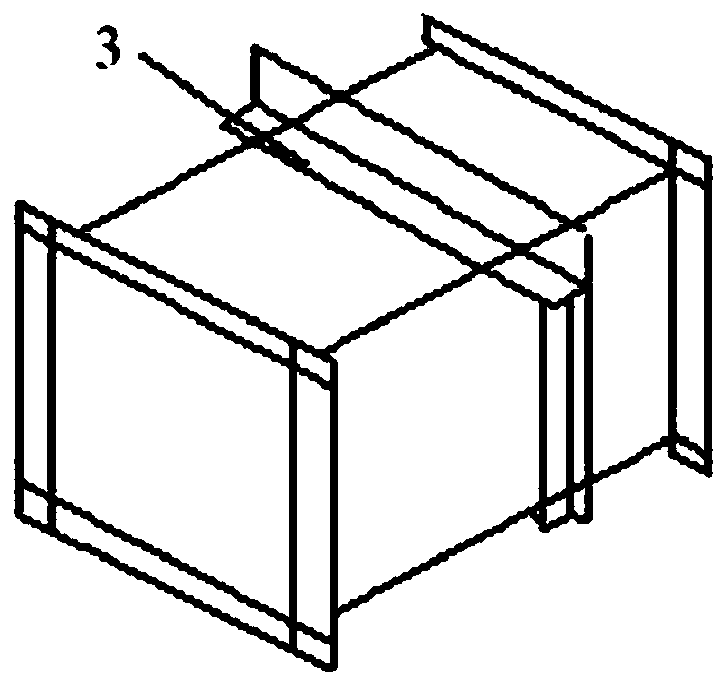

[0091] Internal insulation and silencer air ducts can be used in industrial plants, civil buildings, commercial buildings, and rail transit, and are mainly used in air-conditioning and ventilation systems for buildings that have certain requirements for air noise. The inner insulation and sound-absorbing air duct has good sound-absorbing performance, and the inner liner of glass fiber can eliminate aerodynamic noise. The BIM-based production management method for internal insulation and silencer air duct products, the specific preparation method is as follows:

[0092] Step 1 Construct the primary BIM model through Autodesk Revit according to the preparation requirements of the internal insulation and silencer air duct;

[0093] Step 2: Check and adjust the primary BIM model to confirm the secondary BIM model;

[0094] Step 3 Prepare the prefabricated product, perform secondary adjustment of the model according to the product formation, and determine the final BIM model;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com