Patents

Literature

40results about How to "Guaranteed mechanical performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel and production method thereof

InactiveCN105349911AGuaranteed Performance RequirementsGuaranteed production costHigh pressure waterHigh pressure

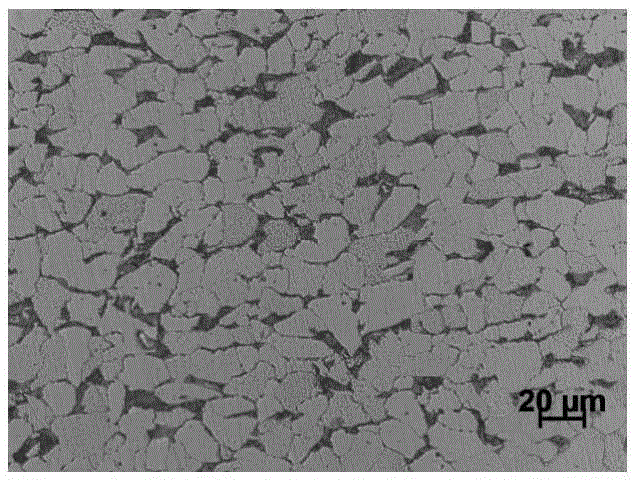

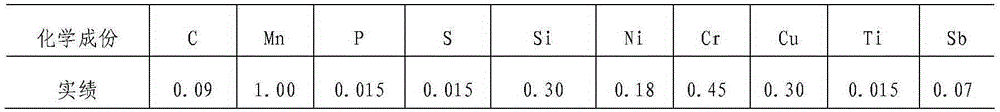

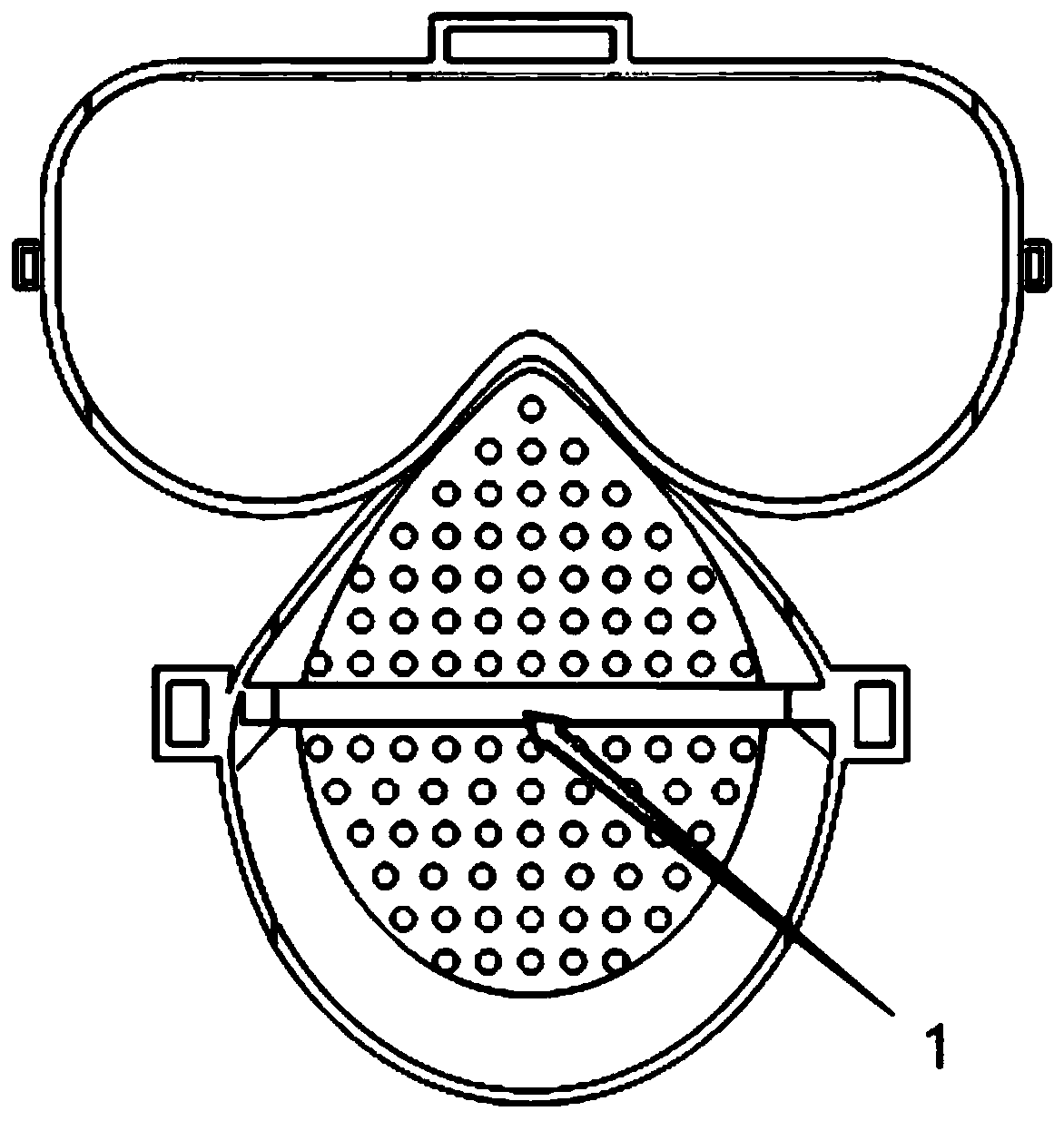

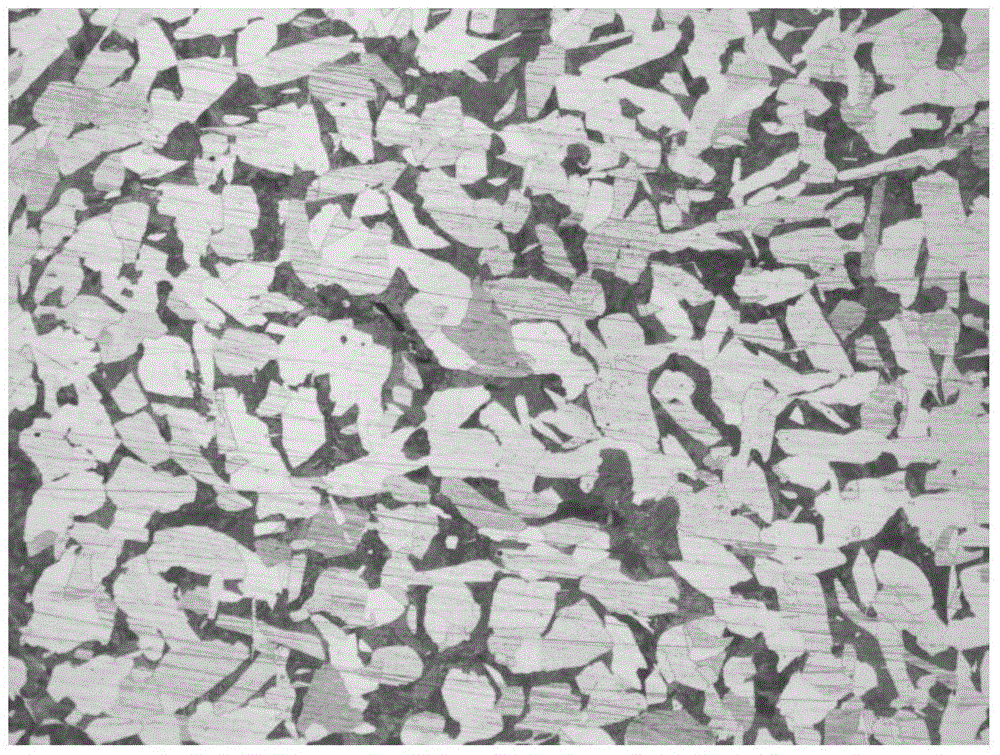

The invention provides low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel. The steel is characterized by comprising the following elements in percentage by mass: smaller than or equal to 0.12% of C, smaller than or equal to 0.55% of Si, 0.75% to 1.20% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.025% of S, 0.50% to 1.2% of Cr, 0.20% to 0.50% of Cu, smaller than or equal to 0.25% of Ni, 0.05% to 0.15% of Sb, smaller than or equal to 0.025% of Ti, smaller than or equal to 0.010% of V, 0.020% to 0.050% of Alt and 0.0005% to 0.0035% of Ca. The tissues of the steel disclosed by the invention are ferrite and pearlite; the heating temperature is increased; generation of relatively thick iron oxide scale is facilitated; transient temperature reduction of the surface iron oxide scale is increased during descaling of high-pressure water, so that shrinkage of the surface iron oxide scale is intensified, the iron oxide scale is easier to remove from a base body, the descaling efficiency is improved, and iron oxide scale residues are fundamentally reduced.

Owner:NANJING IRON & STEEL CO LTD

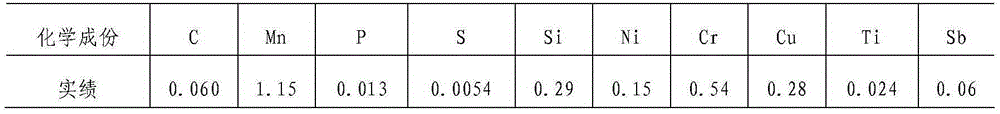

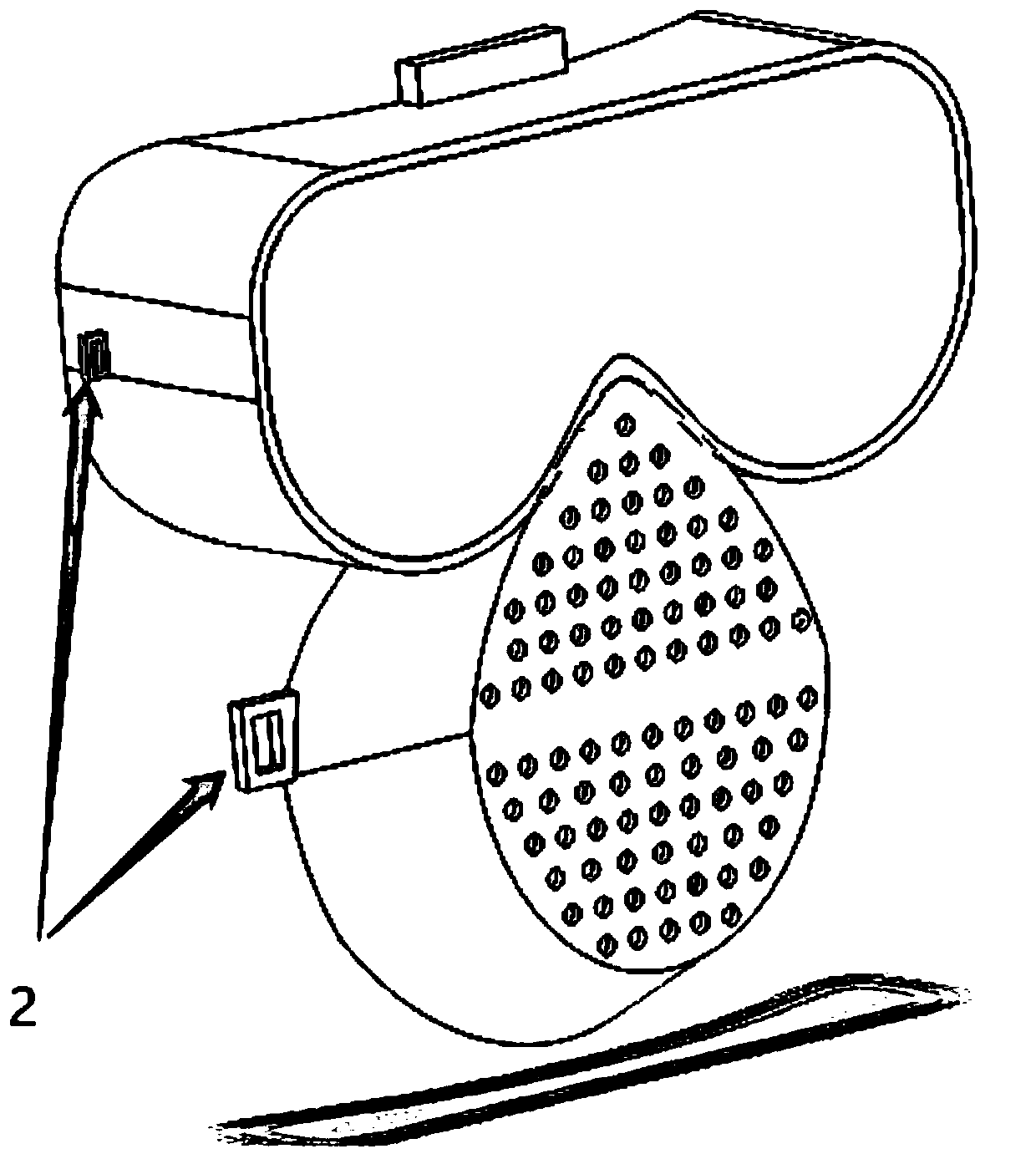

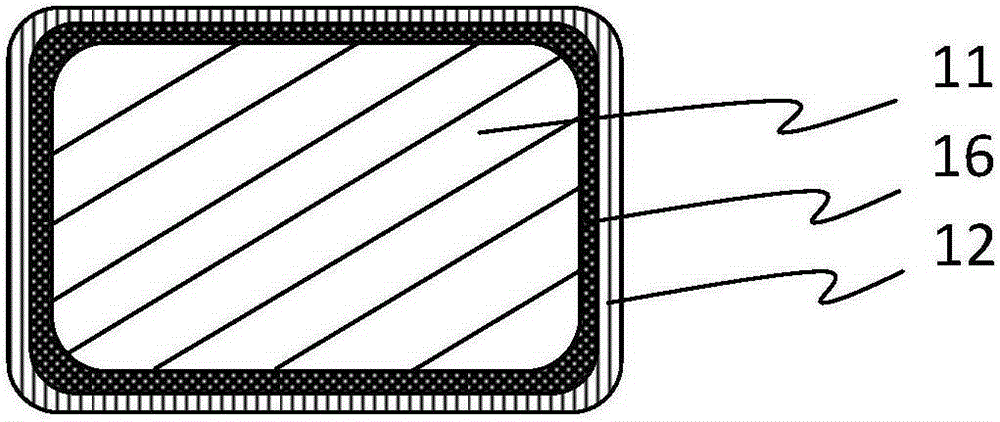

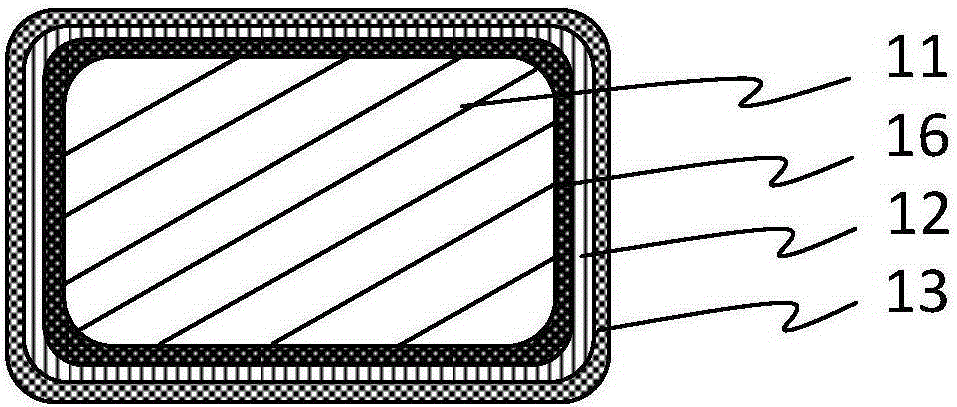

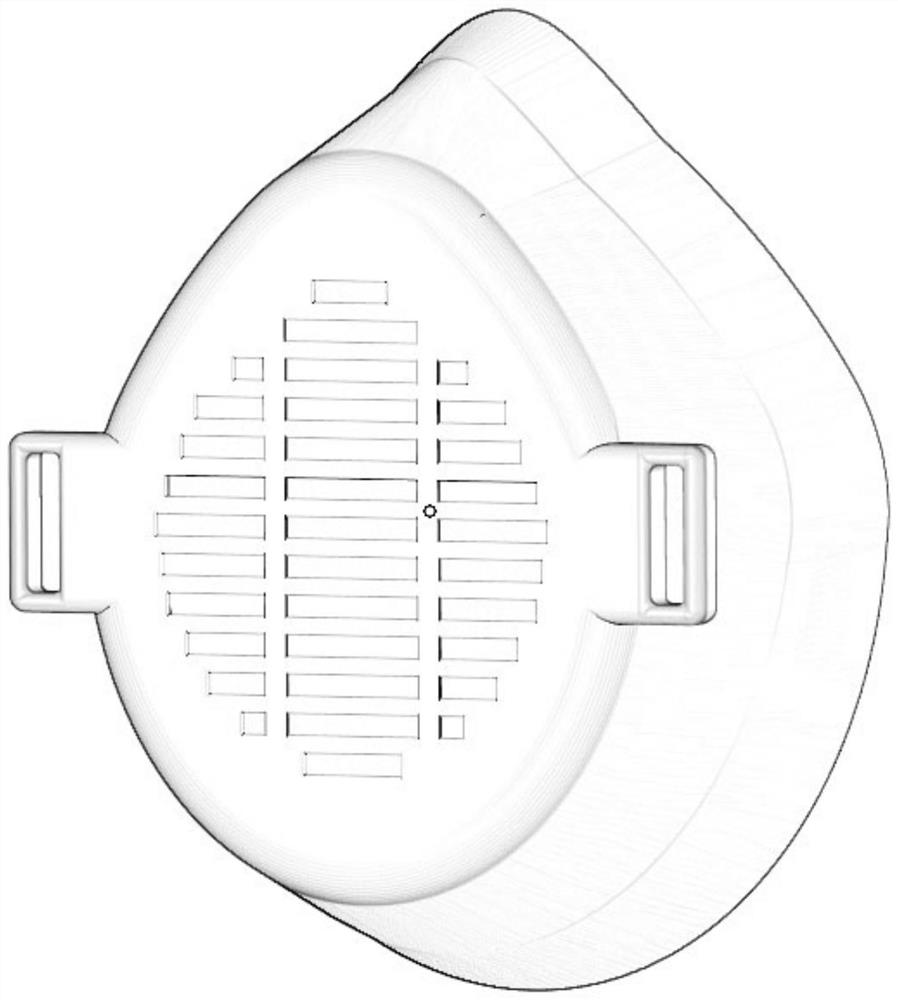

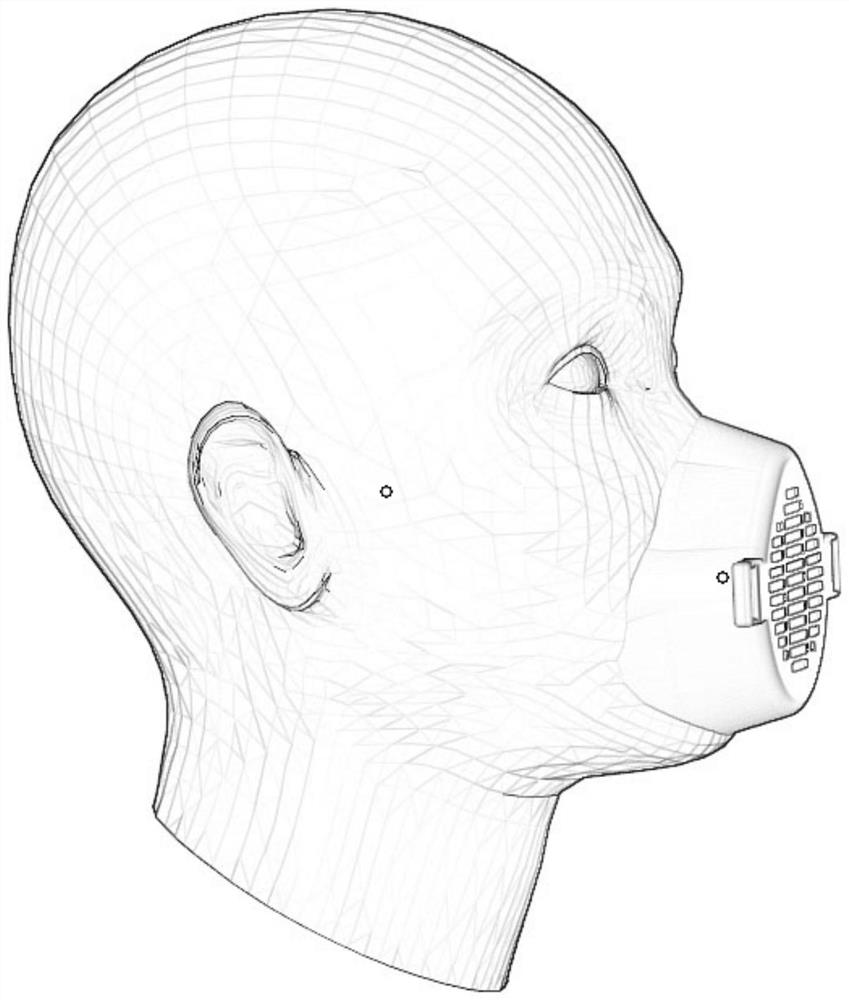

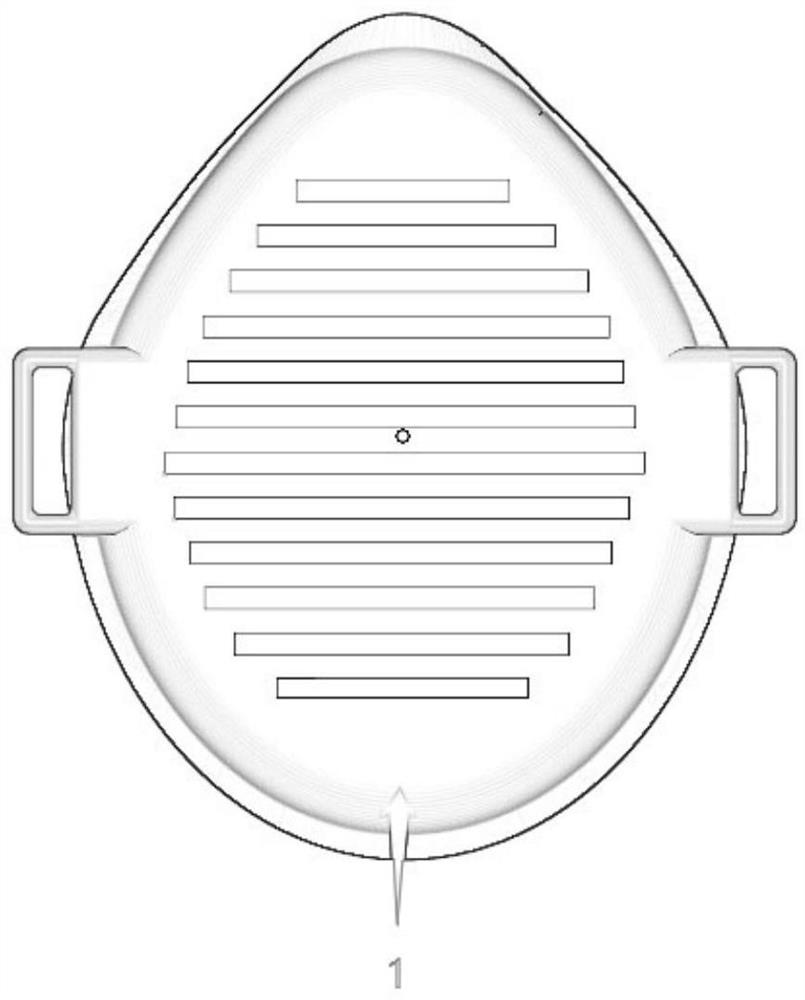

Manufacturing method of 3D printing intelligent integrated protective mask

InactiveCN111251607AEffective isolationEasy to wearAdditive manufacturing apparatus3D object support structures3d printMechanical engineering

The invention discloses a manufacturing method of a 3D printing intelligent integrated protective mask and belongs to the field of 3D printing technology and medical protective tools. The intelligentintegrated protective mask has the lens antifog function and the body temperature real-time monitoring function, enables air circulation in the single direction and separates the mouth from the nose.The manufacturing method comprises the following steps: adopting SolidWorks, Magics and other software for designing and optimizing the model of the protective mask main body, adopting finite elementsimulation to verify whether the combination property of the designed model reaches expectation, sectioning the finally optimized model, introducing the sectioned model in SLS or FDM 3D printing equipment, manufacturing the mask main body according to certain printing parameters, through carrying out a series of aftertreatment on the printed entity and combined assembling with an additional deviceon the printed entity, finally obtaining the intelligent integrated protective mask which is excellent in mechanical property, leakproofness, light and comfortable, has the lens antifog function andthe body temperature real-time monitoring function, enables air circulation in the single direction and separates the mouth from the nose.

Owner:BEIJING UNIV OF TECH

Absorbable iron-based alloy implantation medical appliance

ActiveCN106581784AAvoid corrosionReduce corrosionSurgeryPharmaceutical delivery mechanismPolymerInflammation

The invention relates to an absorbable iron-based alloy implantation medical appliance which includes an iron-based alloy base body, a degradable polymer formed on the surface of the iron-based alloy base body, and a corrosion inhibiting layer formed on the surface of the iron-based alloy base body. The corrosion inhibiting layer can delay corrosion on the iron-based alloy base body in early stage and ensures mechanical performances of the implanted medical appliance in early stage, and also can inhibit degradation of the polymer in the early stage of implantation of the medical appliance, thereby reducing usage amount of the degradable polymer and reducing risk of inflammation reaction.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

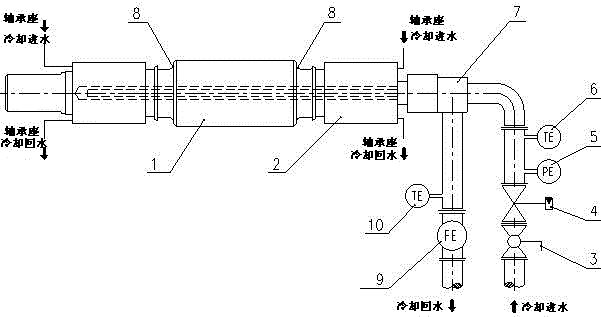

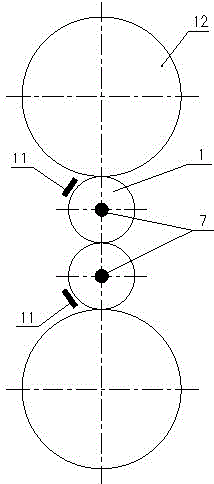

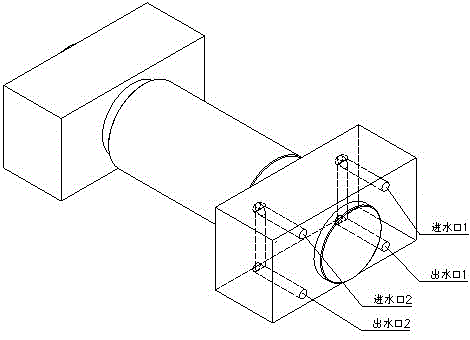

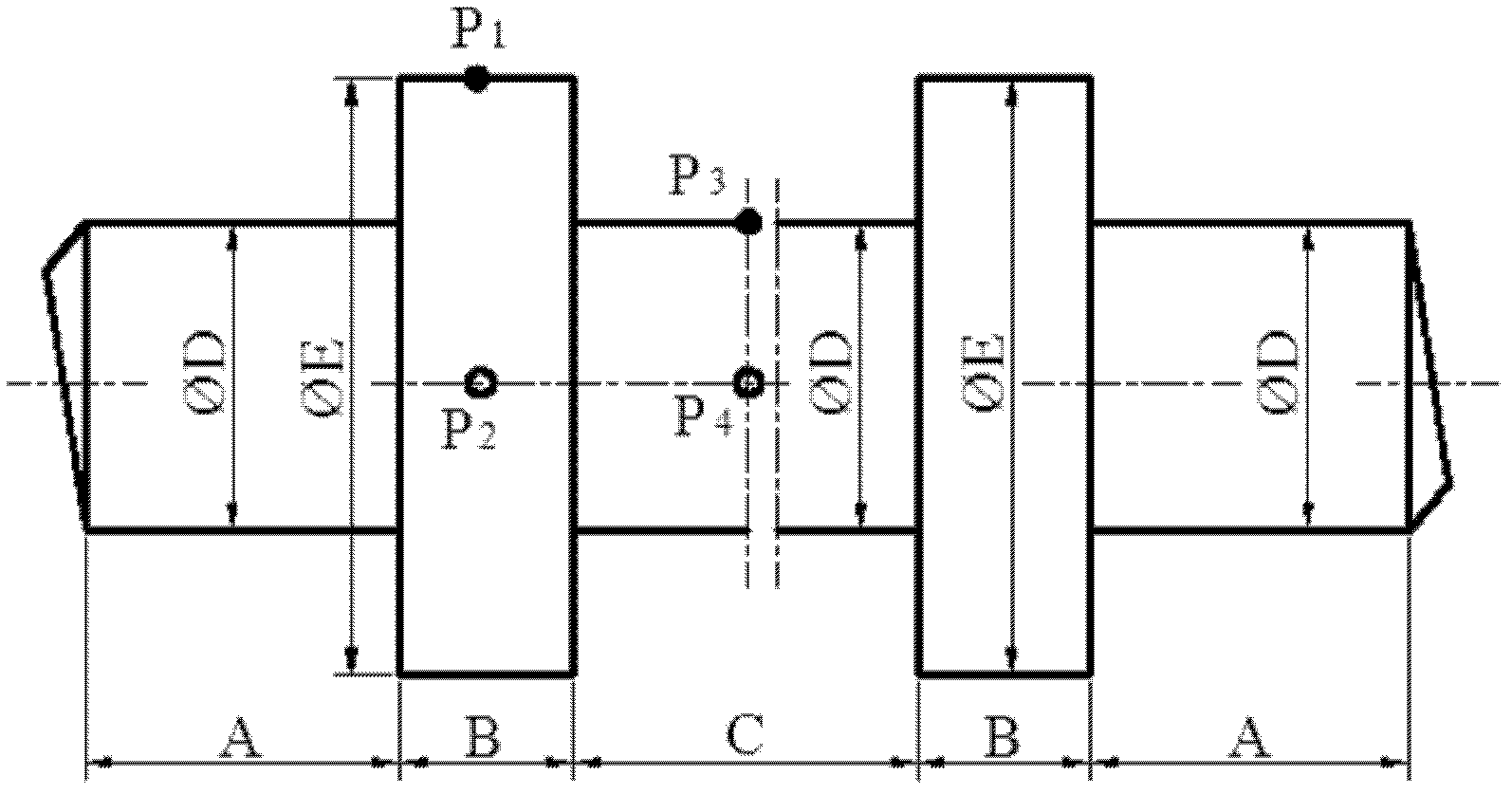

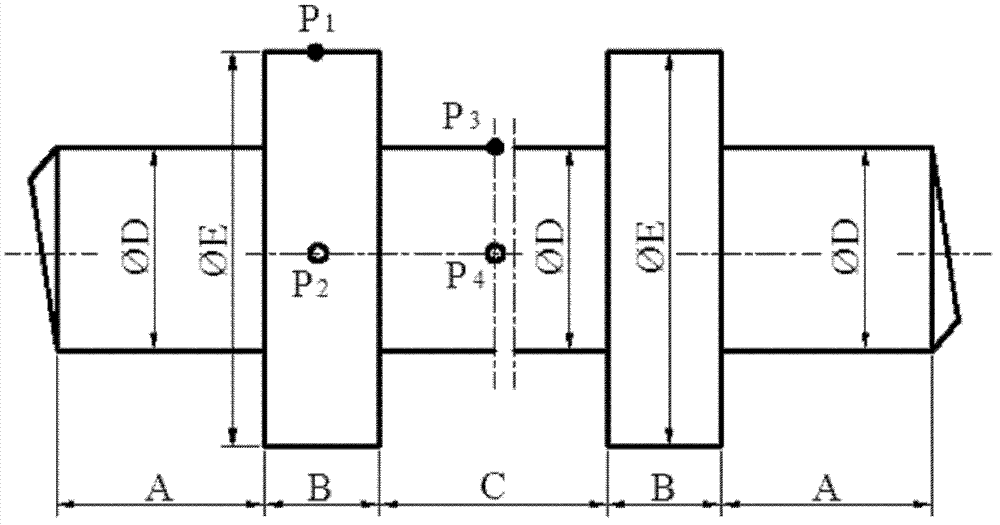

Warm-rolling working roll and control method of internal and external temperature field

ActiveCN105834218AStrong enoughRigid enoughTemperature control deviceRollsTemperature controlControl system

The invention relates to the technology of temperature-controlled rolling of the working roll. The warm-rolling working roll is characterized in that a long hole is formed in an operation side of the end part of a working roll (1), and a rotary joint (7) and a pipeline are installed. The control method of the internal and external temperature field comprises following steps: firstly, using a temperature signal of a temperature monitor (8) at the roller shoulder of the roll as a first target without affecting the temperature field of a roll surface of the roll such that temperature data of the roll shoulder of the roll monitored in a real-time mode can be sent to an intelligent processing unit and the intelligent processing unit is used for sending a calculation result to a PLC control system; secondly, using temperature measured by a return water temperature monitor (10) and a water inlet temperature monitor (6) as a second target such that water temperature data monitored in a real-time mode can be sent to the intelligent processing unit and the intelligent processing unit is used for calculating temperature differences and sending the result to the PLC control system and the a water inlet flow control valve (4) is used for regulating water inlet flow according to an instruction sent by the PLC control system such that reasonable in-roll temperature can be controlled.

Owner:BAOSHAN IRON & STEEL CO LTD

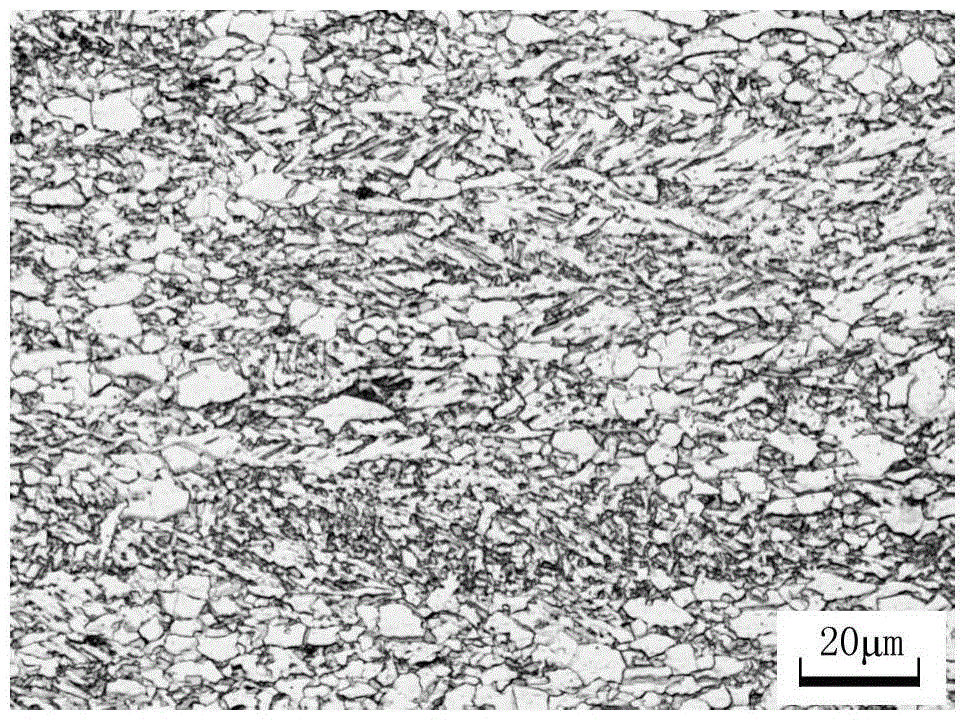

900Mpa heavy-gauge and high-toughness hot rolled steel strip and preparation method thereof

ActiveCN109097664AImprove mechanical propertiesGood low temperature toughnessTemperature control deviceSteel platesSheet steel

The invention provides a 900Mpa heavy-gauge and high-toughness hot rolled steel strip and a preparation method thereof, and belongs to the field of structural steel. The steel strip comprises chemicalcomponents in percentage by mass as follows: 0.06%-0.08% of C, 0.15-0.18% of Si, 1.4%-1.6% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.008% of S, 0.8%-1.2% of Cr, 0.005%-0.012% of B, 0.01%-0.03% of Ti and the balance of Fe and inevitable impurities. According to preparation of the steel strip, the product is obtained through smelting-casting, hot rough rolling, hot finish rolling, cooling and coiling. By means of reasonable component design and the controlled rolling and controlled cooling process, yield strength of the steel strip can reach 900 MPa, and the steelstrip is used for replacing a steel plate of the same level obtained with a TMCP and tempering process or a heat treatment process.

Owner:天铁热轧板有限公司

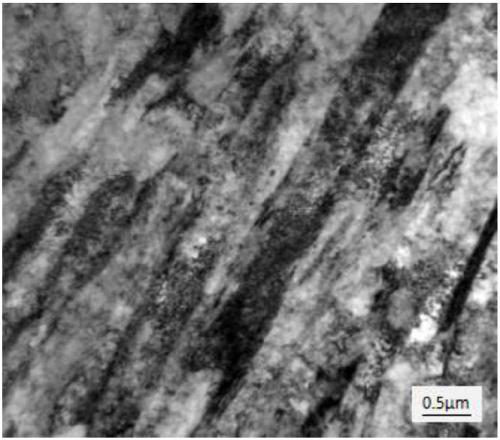

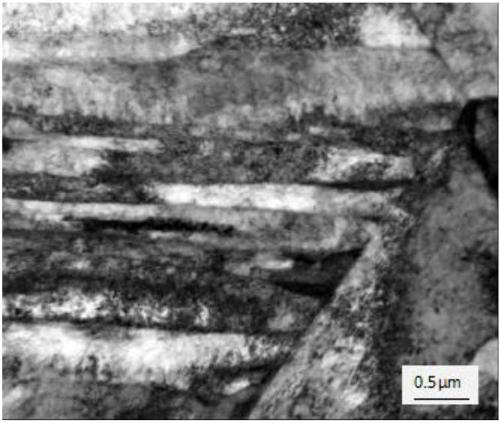

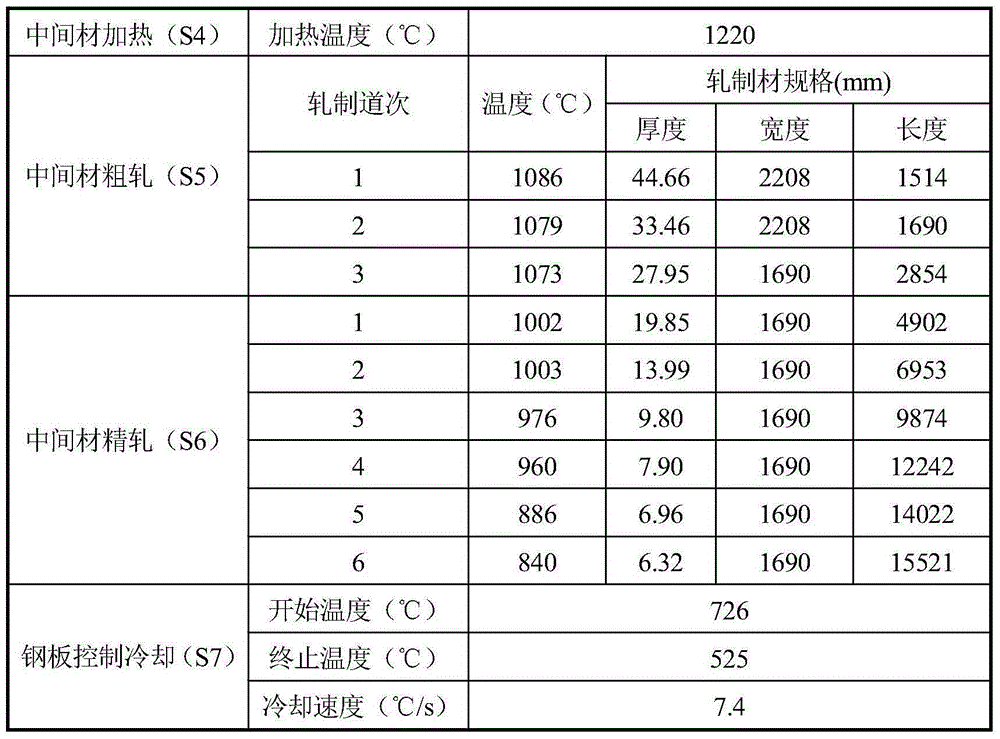

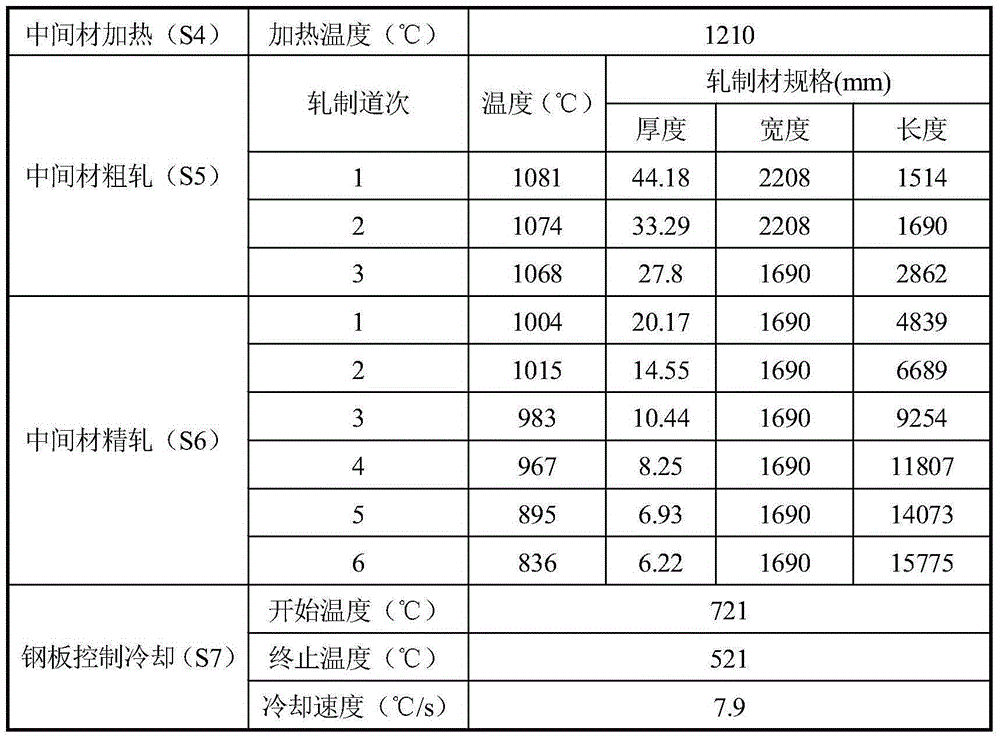

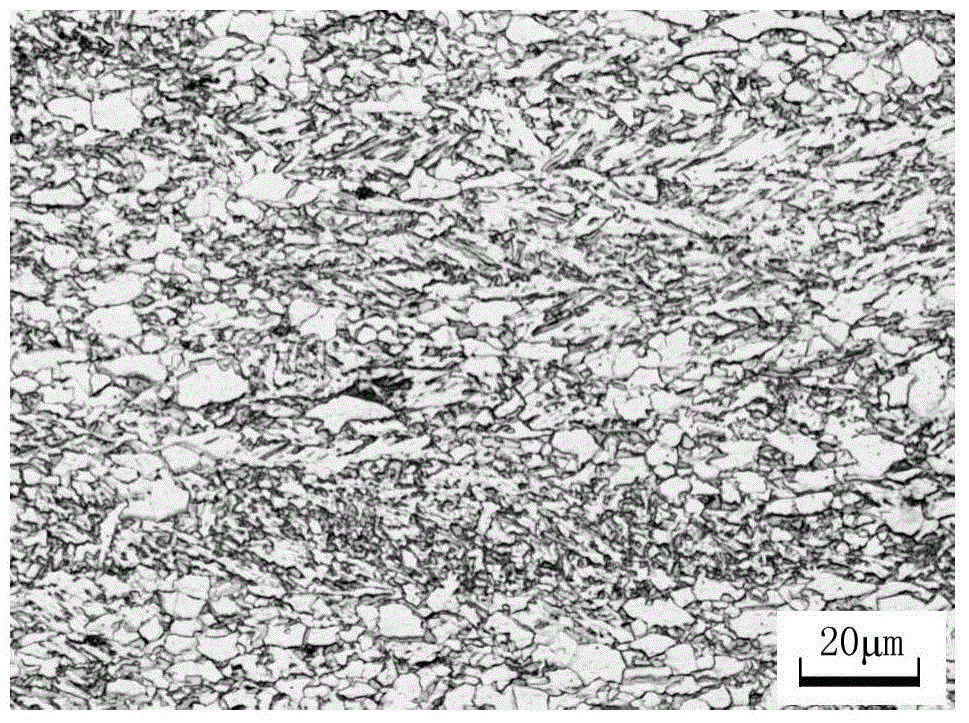

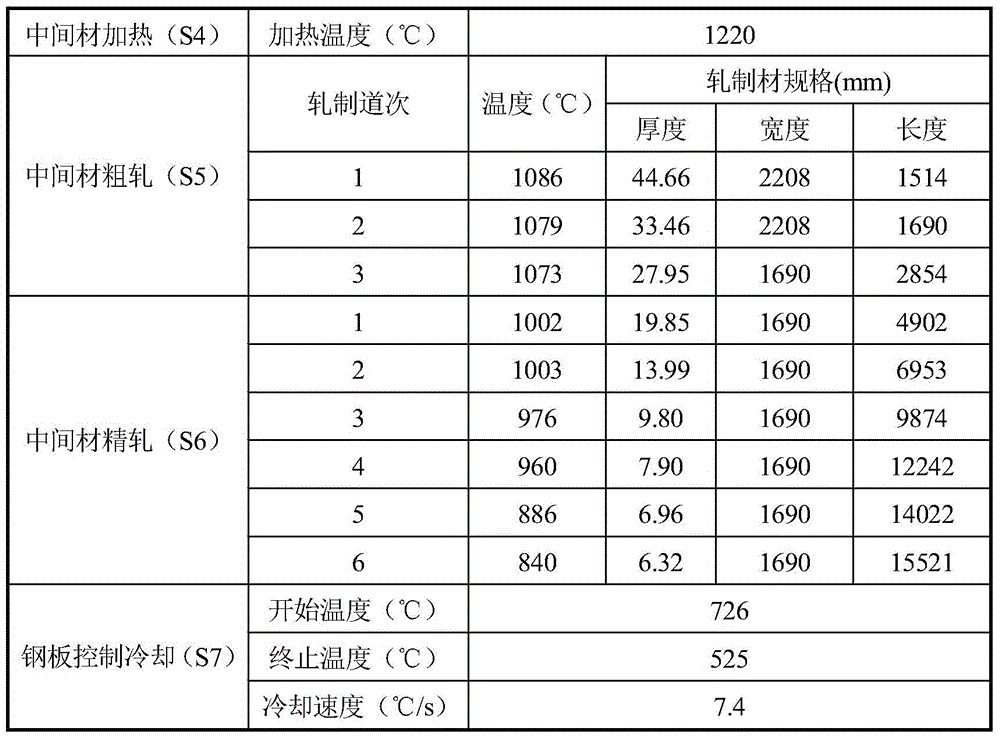

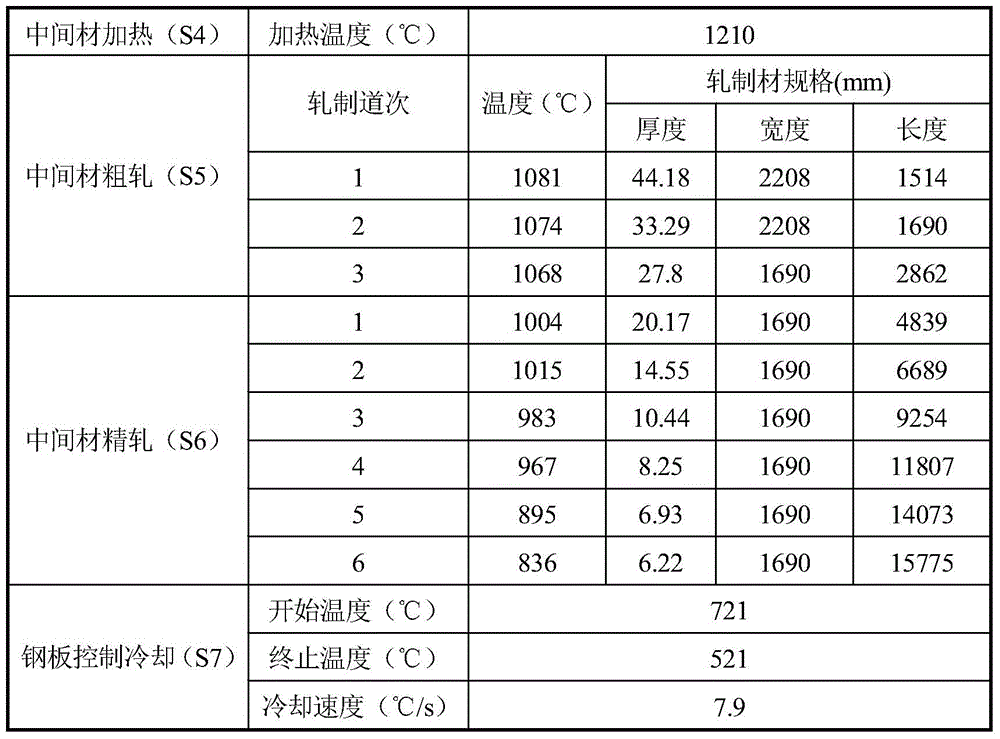

Ultra-low carbon bainite thin gauge steel plate rolled through heavy and medium plate mill and production method of ultra-low carbon bainite thin gauge steel plate

ActiveCN105063511AShorten the lengthGuaranteed temperature uniformityTemperature control deviceImpurityBainite

The invention discloses an ultra-low carbon bainite thin gauge steel plate rolled through a heavy and medium plate mill. The ultra-low carbon bainite thin gauge steel plate comprises, by weight, 0.02%-0.08% of C, 0.10%-0.40% of Si, 0.90%-2.00% of Mn, 0.018% of P or less, 0.005% of S or less, 0.40% of Cu or less, 0.0003% of B or less, 0.10%-0.55% of Ni, 0.10%-0.40% of Mo, 0.12%-0.60% of Cr, 0.030%-0.090% of V, 0.010%-0.035% of Nb, 0.005%-0.035% of Ti, 0.060% of Als or less and the balanced Fe and inevitable impurities. A production method comprises the steps of smelting, casting, heating, rolling, slitting, intermediate material heating, rough rolling, finish rolling and cooling control. The ultra-low carbon bainite thin gauge steel plate is reasonable in process, good in product performance and small in unevenness and can be widely applied to bridge U rib structures.

Owner:武汉钢铁有限公司 +1

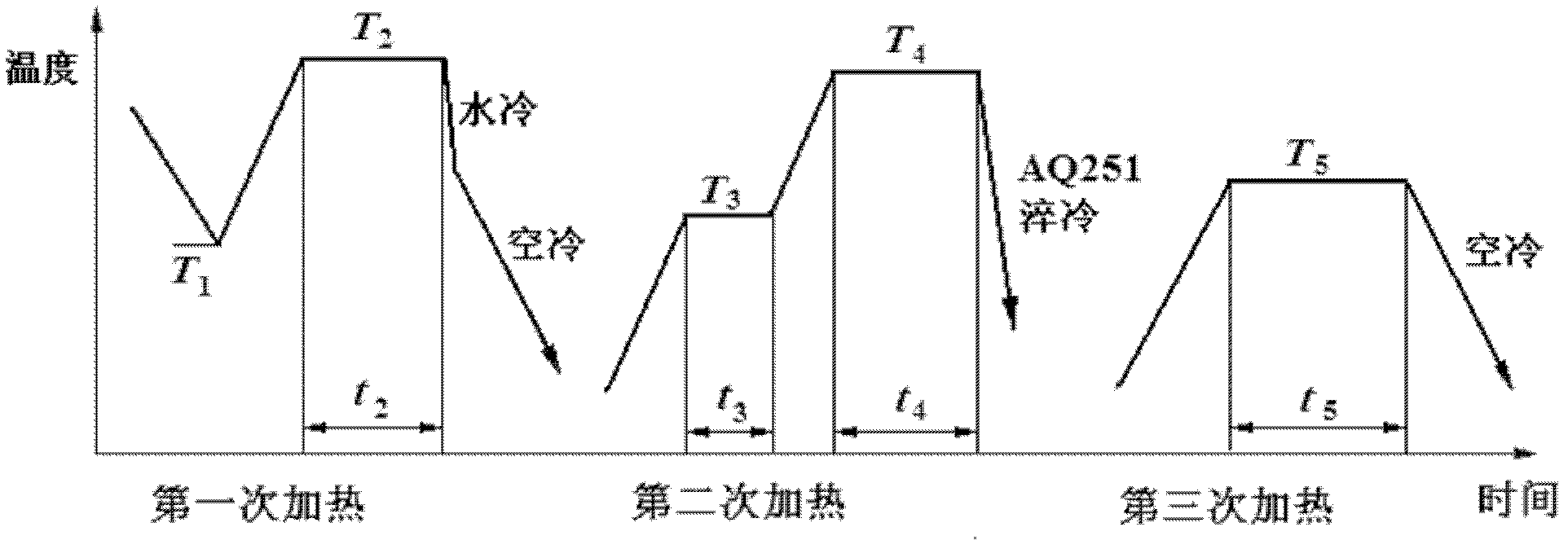

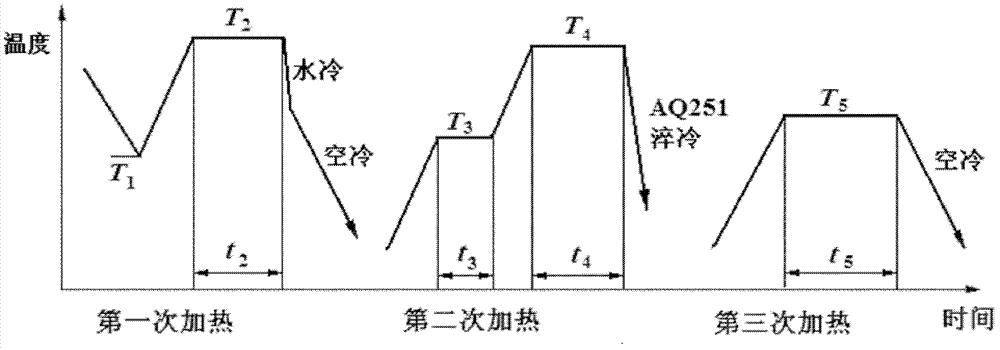

Heat treatment process for large 35CrMo steel axis forgings

InactiveCN102560043AGuaranteed mechanical propertiesGuaranteed mechanical performance requirementsHeating timeRoom temperature

The invention discloses a heat treatment process for large 35CrMo steel axis forgings. The heat treatment process comprises the following steps of: performing one-time forging on the forgings at the temperature of higher than 800DEG C, and performing air cooling until the surface temperature is 500-600DEG C; heating to the temperature of between 870 and 880DEG C, keeping the temperature for 3.8 to 4 hours, taking out of a furnace, vertically putting into water at a speed of 2-3 meters per second, pulling out at a speed of 3-5 meters per second after the forgings are completely put into the water, and performing air cooling to normal temperature; preliminarily cutting, heating to the temperature of between 600 and 620DEG C, and keeping the temperature for 0.4 to 0.6 hour, continuously heating to the temperature of between 830 and 850DEG C, keeping the temperature for 3.4 to 3.6 hours, taking out of the furnace, vertically putting into an AQ251 solution at a speed of 2-3 meters per second, and cooling to room temperature; and heating to the temperature of between 680 and 690DEG C, keeping the temperature for 5.5 to 6 hours, taking out of the furnace and performing air cooling. By the heat treatment process, the internal stress of the forgings can be effectively controlled in the heating process, plastic deformation and internal cracks are avoided, the heating time for the forgings is effectively shortened, and energy consumption is reduced.

Owner:广州造船厂有限公司

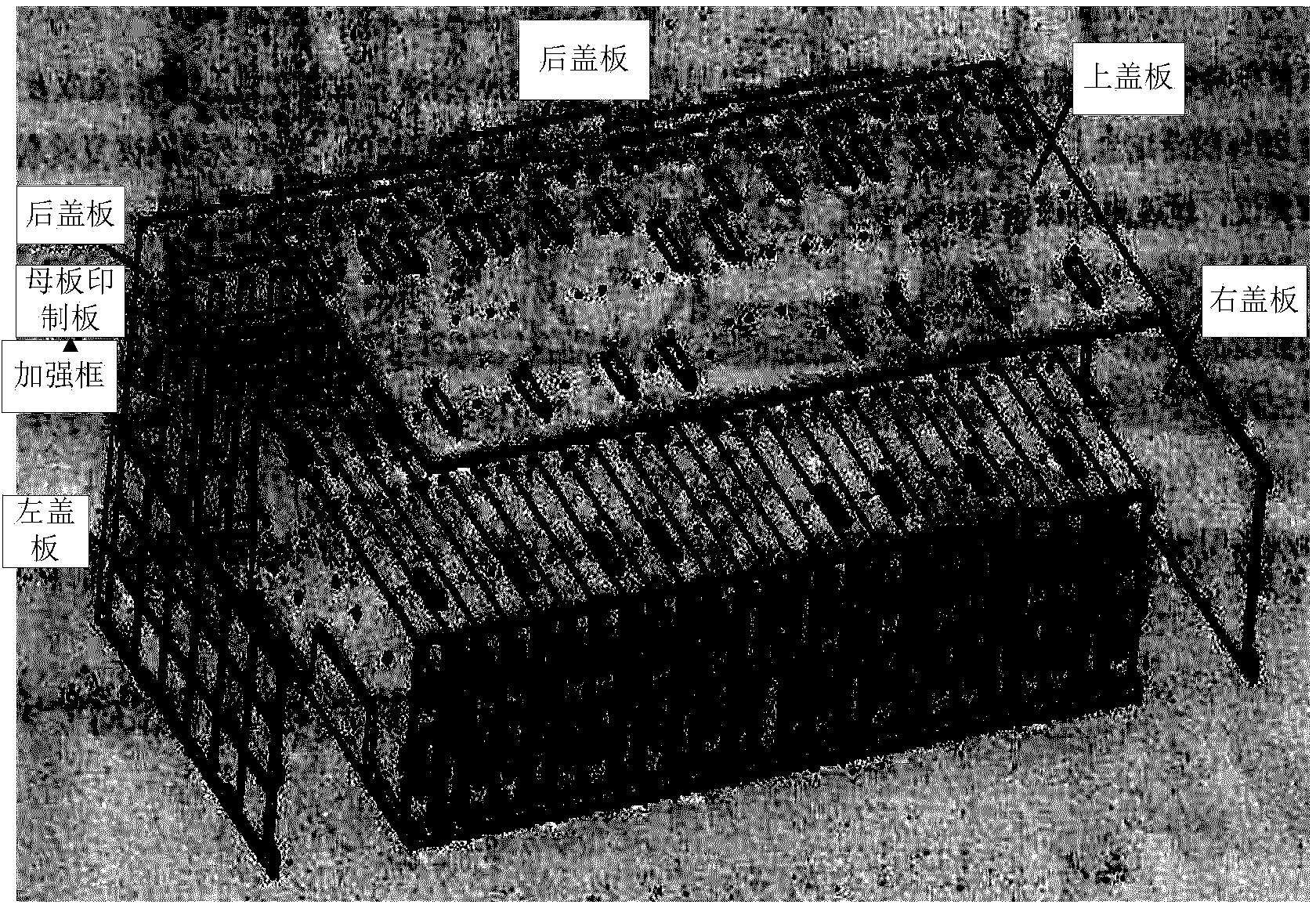

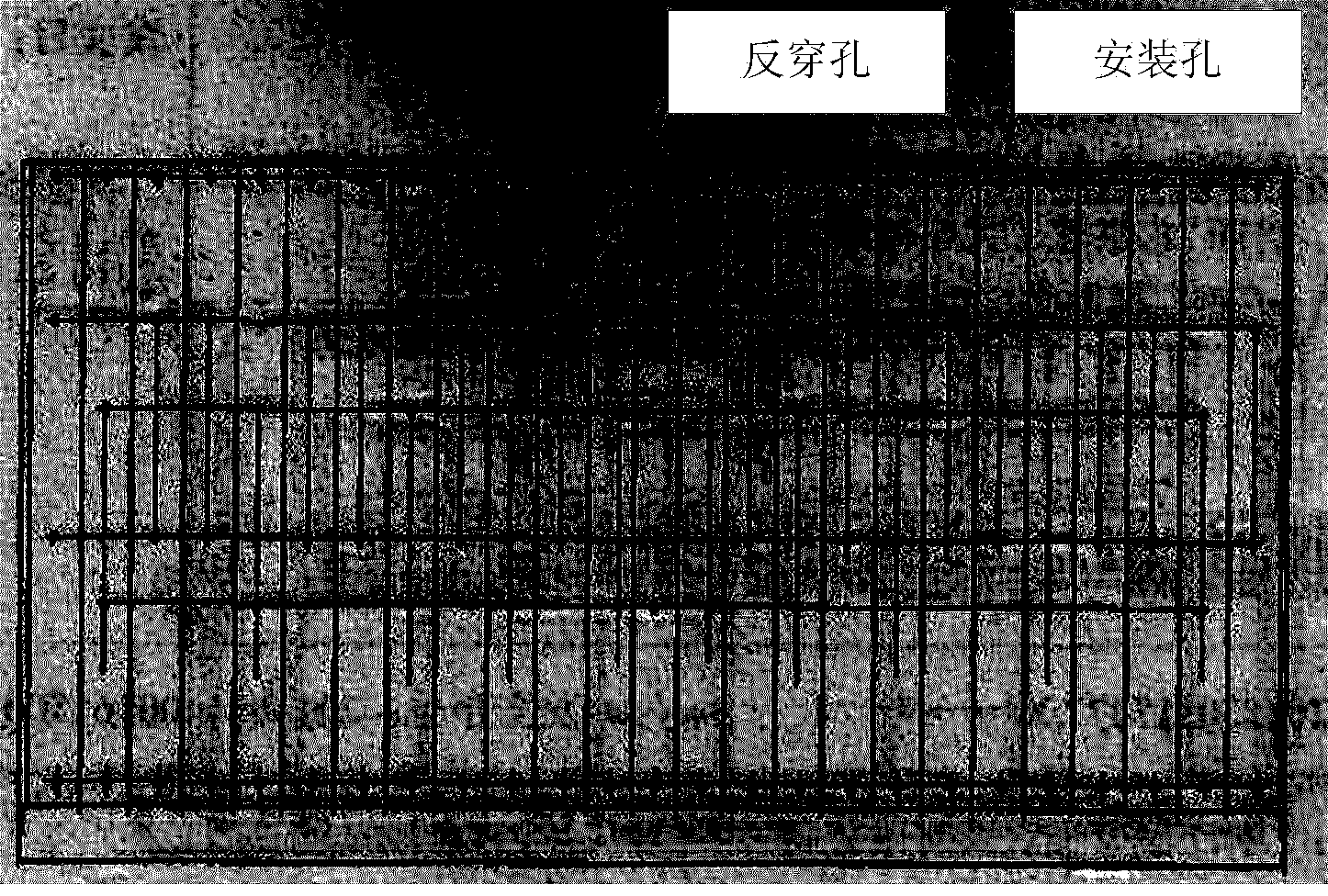

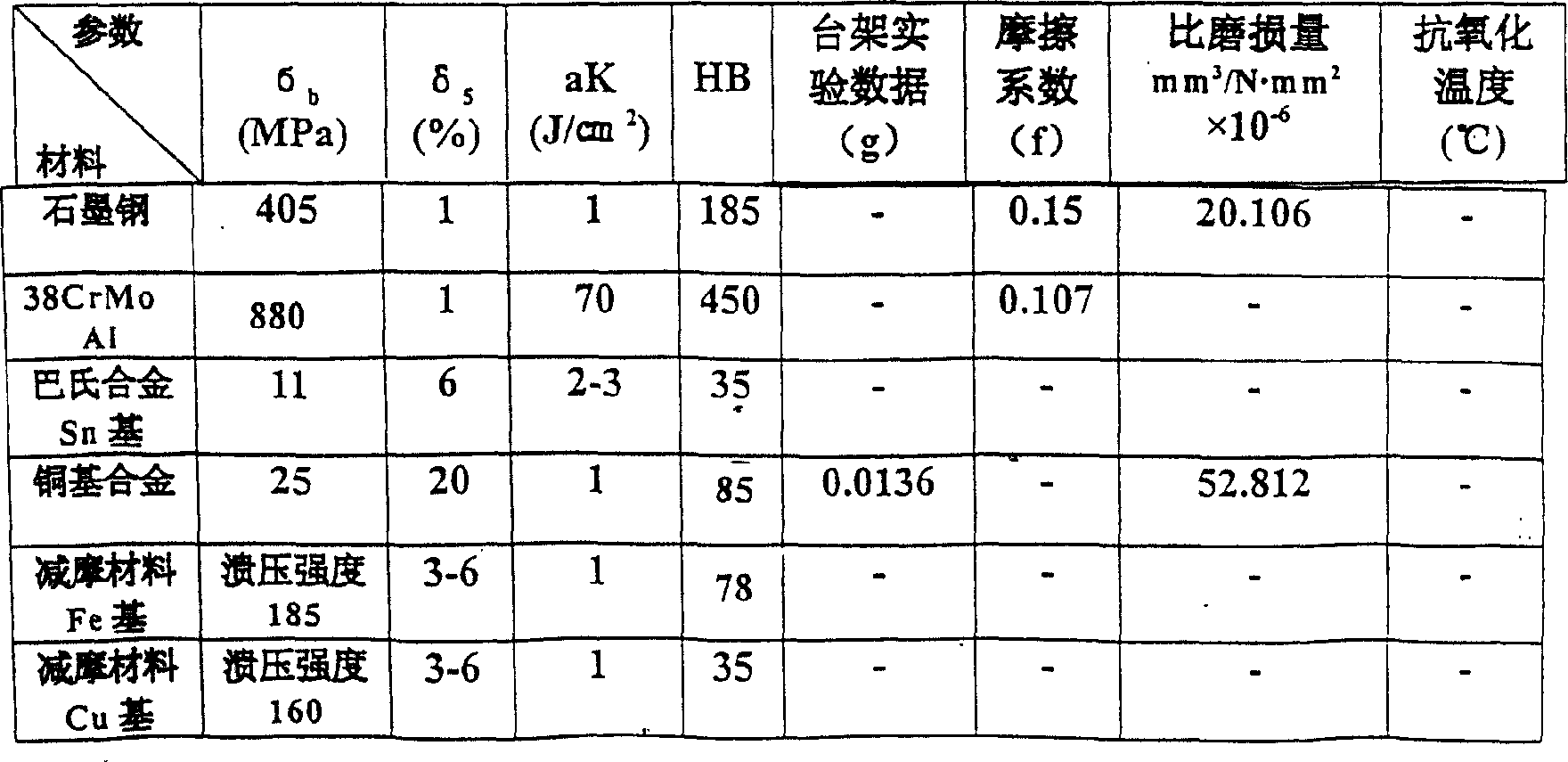

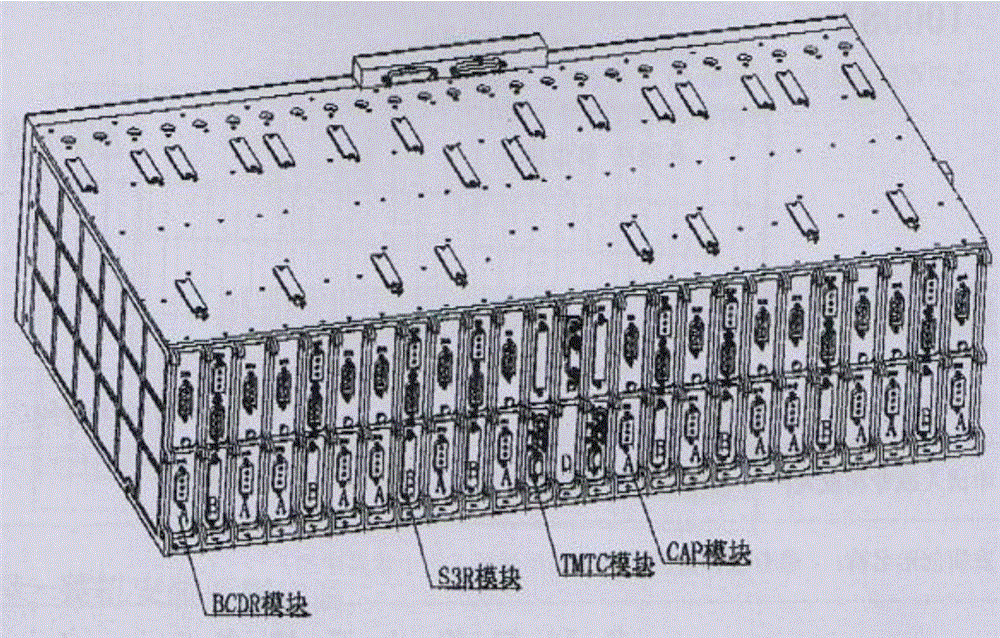

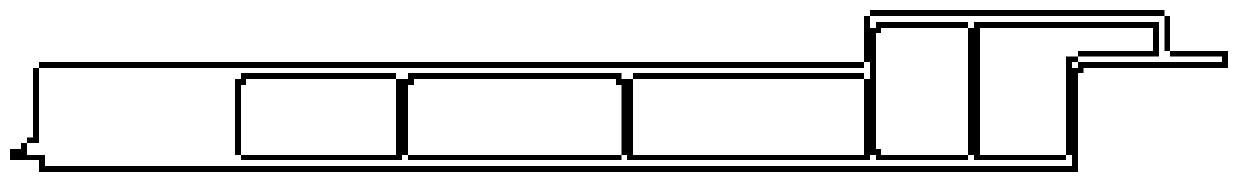

Extensible platform of power supply controller

ActiveCN104065250ARealize three-dimensional layoutUse of internal spacePower conversion systemsCapacitanceExtensibility

The invention provides an extensible platform of a power supply controller. The main structure of each structure module of the extensible platform of the power supply controller is a tetrahedral structure hollowed out as a whole and provided with a front panel, a rear panel, a top panel and a bottom panel, and hollowed-out grids are arranged in each module and include at least two layers of grids. Devices in each structure module are laid out three-dimensionally in the grids, so that internal space of the power supply controller is effectively utilized, and three-dimensional layout in the modules is achieved. A reinforcing frame not only provides an installation space but also connects all the modules as a main force bearing component of the whole controller, so that the strength of connection between the modules and the rigidity and the strength of the whole controller meet the requirements of a satellite mechanical environment. A capacitor (CAP) module is used for containing capacitors, the large number of capacitors are used in cooperation with the other modules to stabilize bus voltage, and thus good extensibility is achieved. Due to the use of installing holes and reverse-penetration holes, it is guaranteed that mechanical property requirements of device connecting pieces in the mechanical analysis and environment test process are met.

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

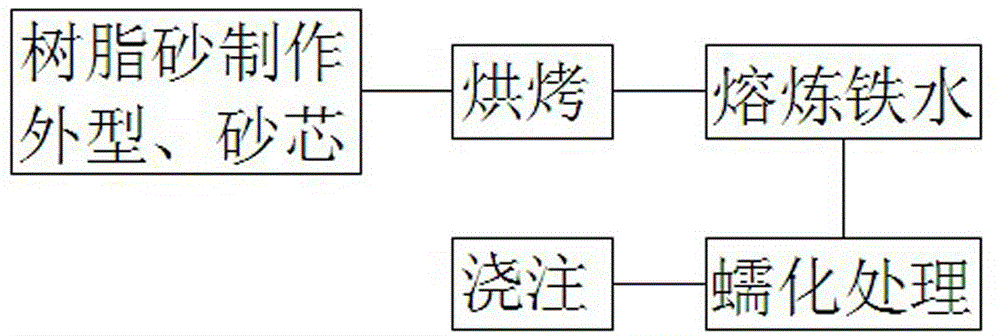

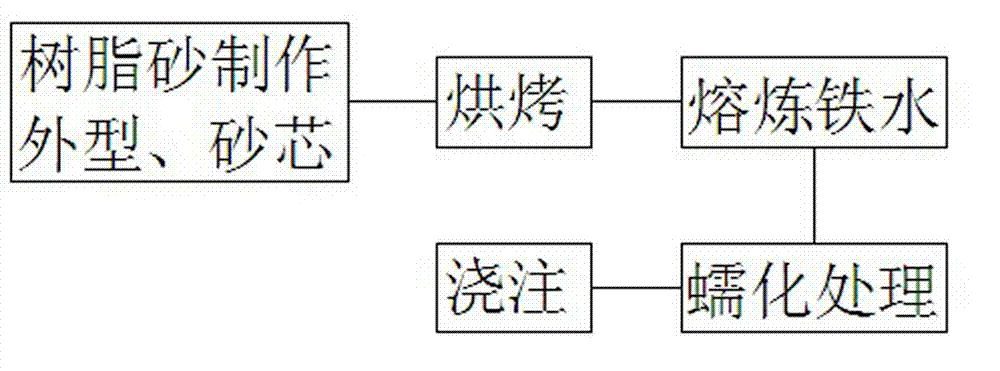

Manufacturing technology for natural aerodynamic cylinder

ActiveCN103600021AHigh dimensional accuracyHigh surface finishFoundry mouldsFoundry coresSurface finishManufacturing technology

The invention discloses a manufacturing technology for a natural aerodynamic cylinder and aims to solve the problems that a conventional cast natural aerodynamic cylinder is low in precision and intensity and has multiple casting defects. The manufacturing technology disclosed by the invention mainly comprises the working procedures of contour and sand core manufacturing, baking, molten iron smelting, vermicularizing treatment and pouring. The natural aerodynamic cylinder manufactured by the manufacturing technology has the characteristics of high contour size precision, high surface smoothness, high intensity and high mechanical property, and the manufacturing technology is particularly suitable for manufacturing of the natural aerodynamic cylinder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

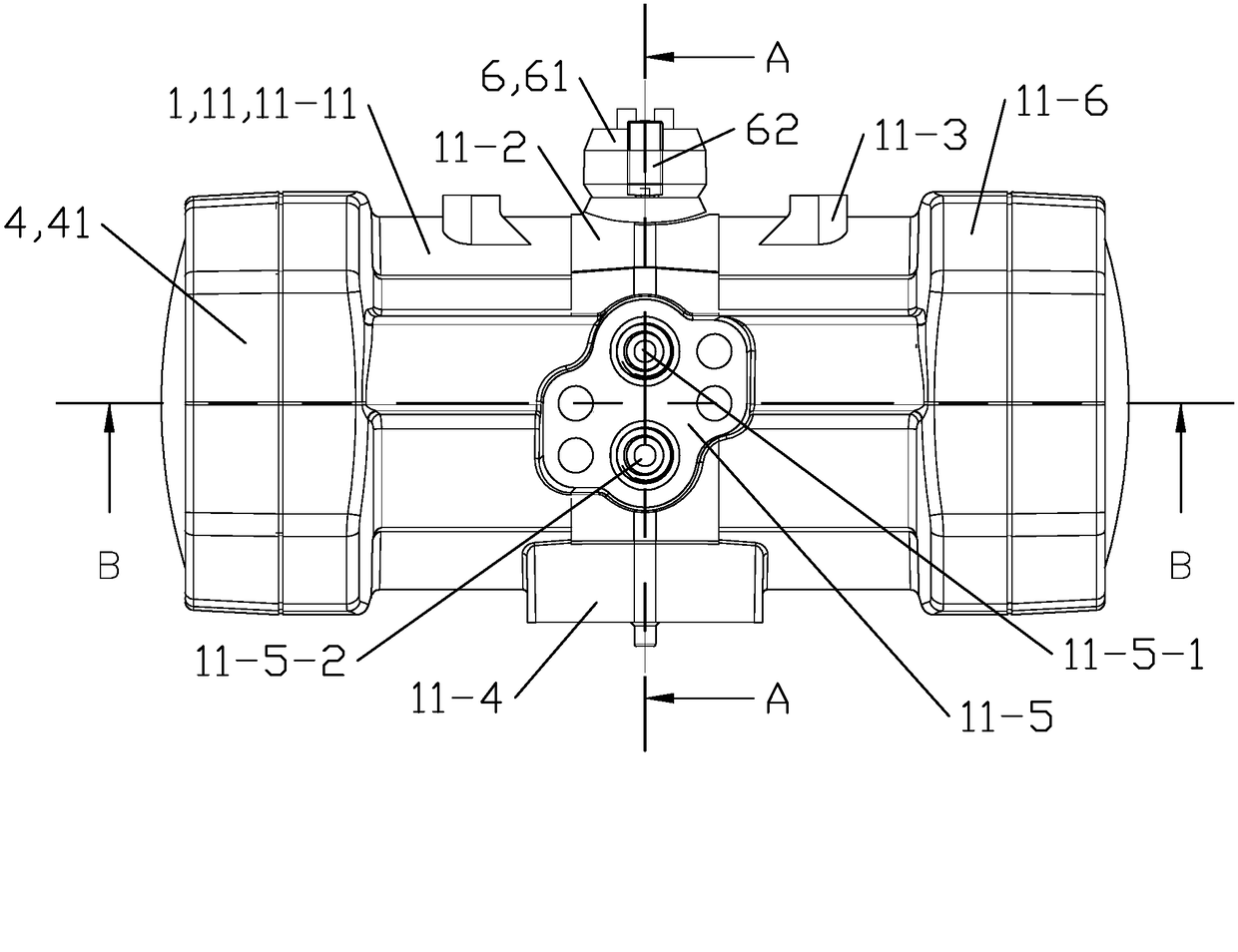

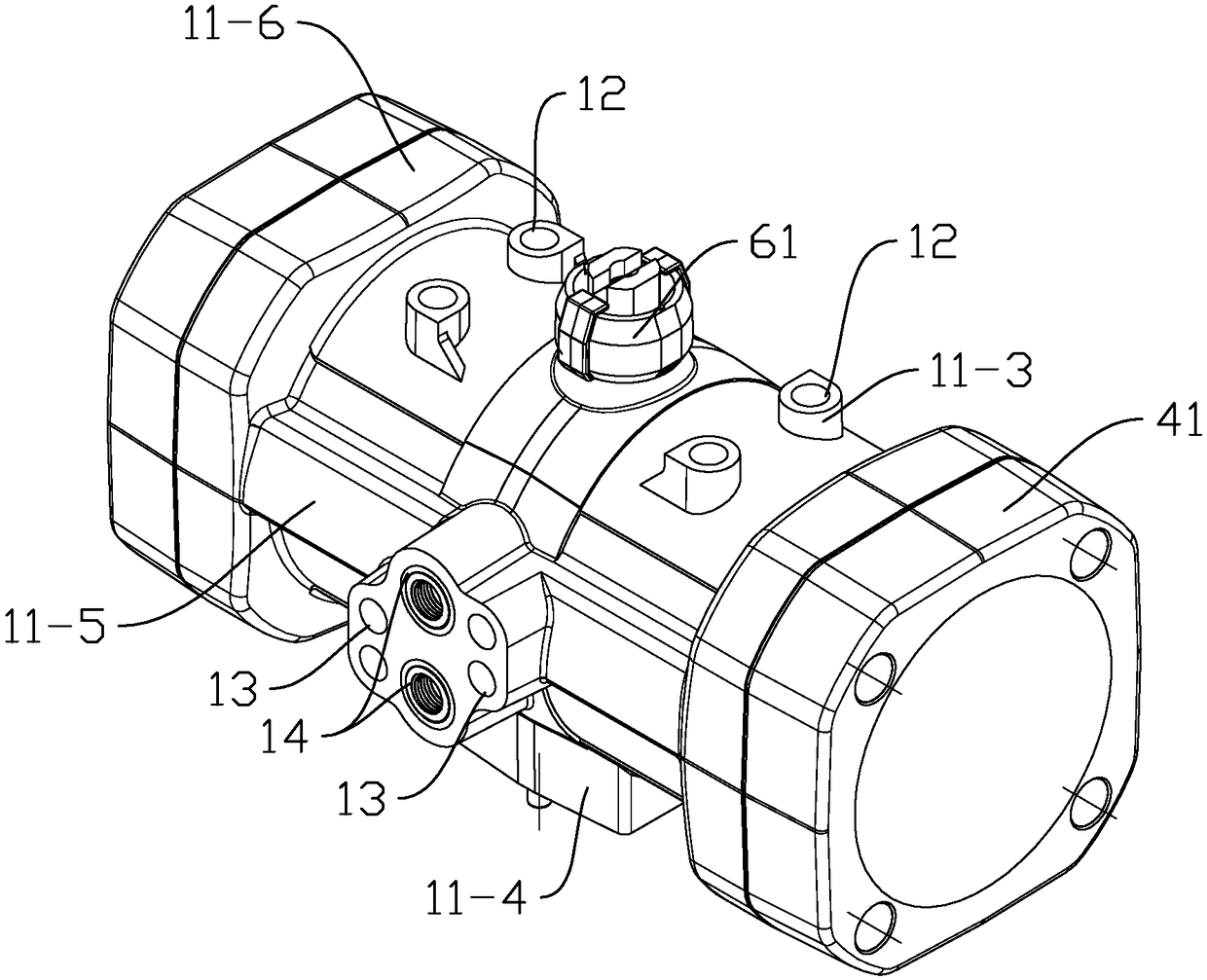

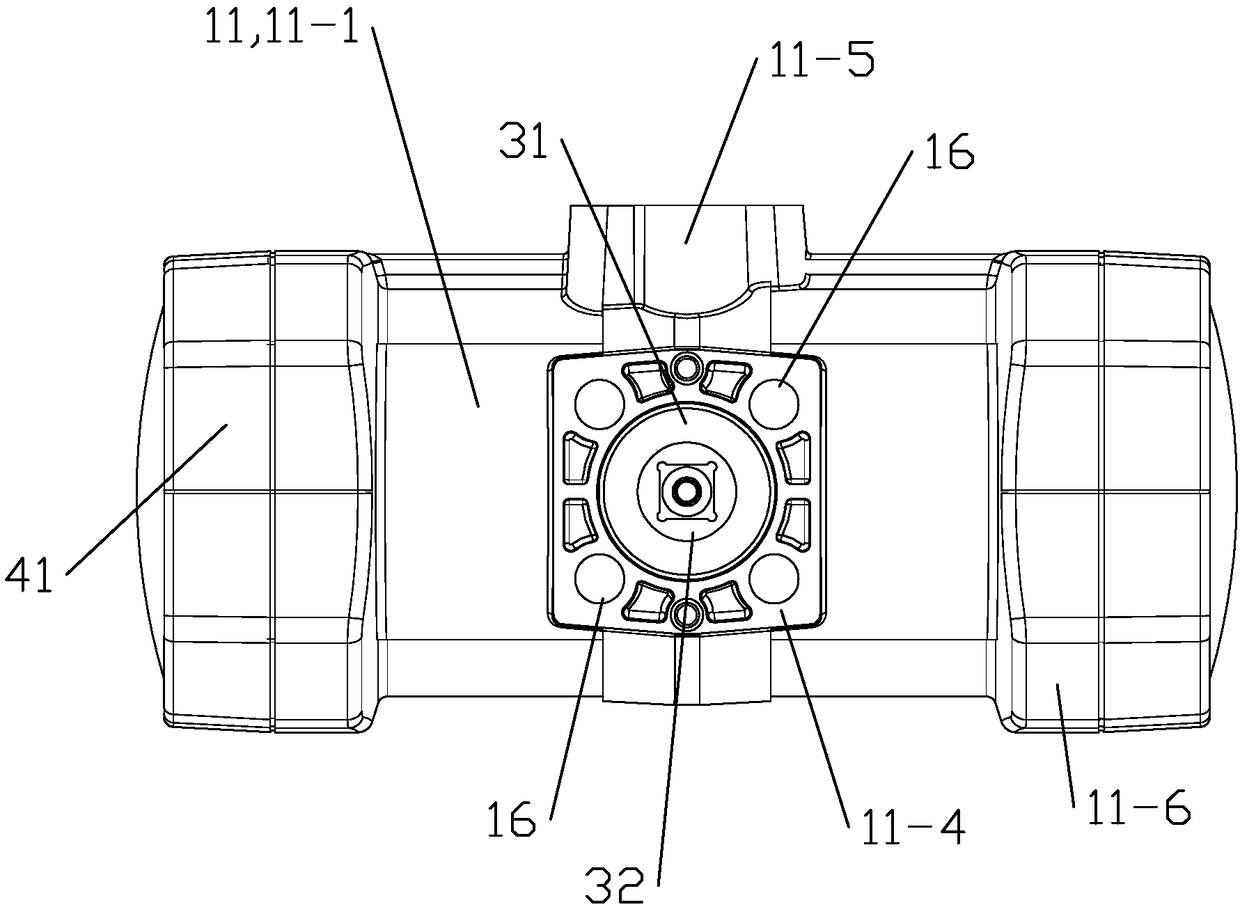

Pneumatic valve actuator

PendingCN108087610AImprove corrosion resistanceImprove rigidityOperating means/releasing devices for valvesRotational axisPneumatic valve

The invention relates to a pneumatic valve actuator. The pneumatic valve actuator comprises an air cylinder assembly, a piston assembly, a drive output assembly, an end cover assembly and a spring return assembly, wherein the air cylinder assembly comprises an air cylinder; the piston assembly comprises two pistons which are symmetrically arranged left and right; the two pistons are oppositely arranged in the horizontal direction; the two pistons are arranged in an inner cavity of a cylinder body main shaft of the air cylinder; the drive output assembly comprises a rotary shaft and an output insert; the output insert is arranged in a central through hole of the rotary shaft in a limiting mode, and rotates along with the rotary shaft; the drive output assembly is arranged in the air cylinder; a rack section part of the rotary shaft is in engaged and power connection with first racks of two pistons of the piston assembly; the end cover assembly comprises two end covers; the two end covers are separately mounted on the air cylinder from left and right ends; the spring return assembly comprises 2n springs; and the two groups of the springs are separately arranged between the end coverat one side inside the air cylinder and the corresponding piston to elastically support the corresponding piston. The actuator can operate for a long time under a high-corrosion special working condition.

Owner:JIANGSU HUASHENG PLASTIC

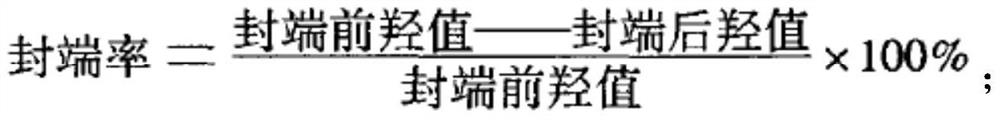

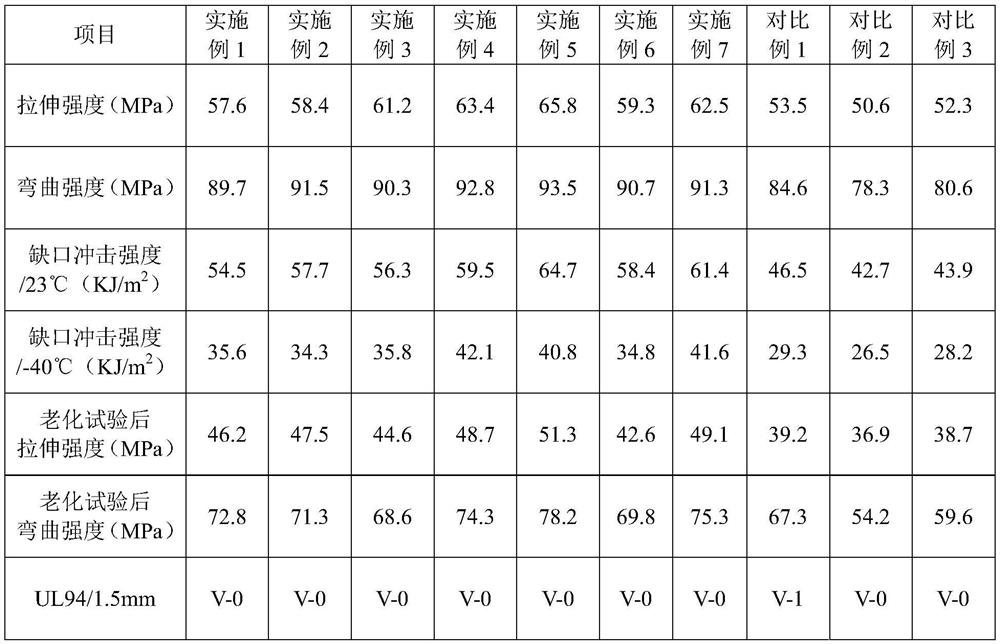

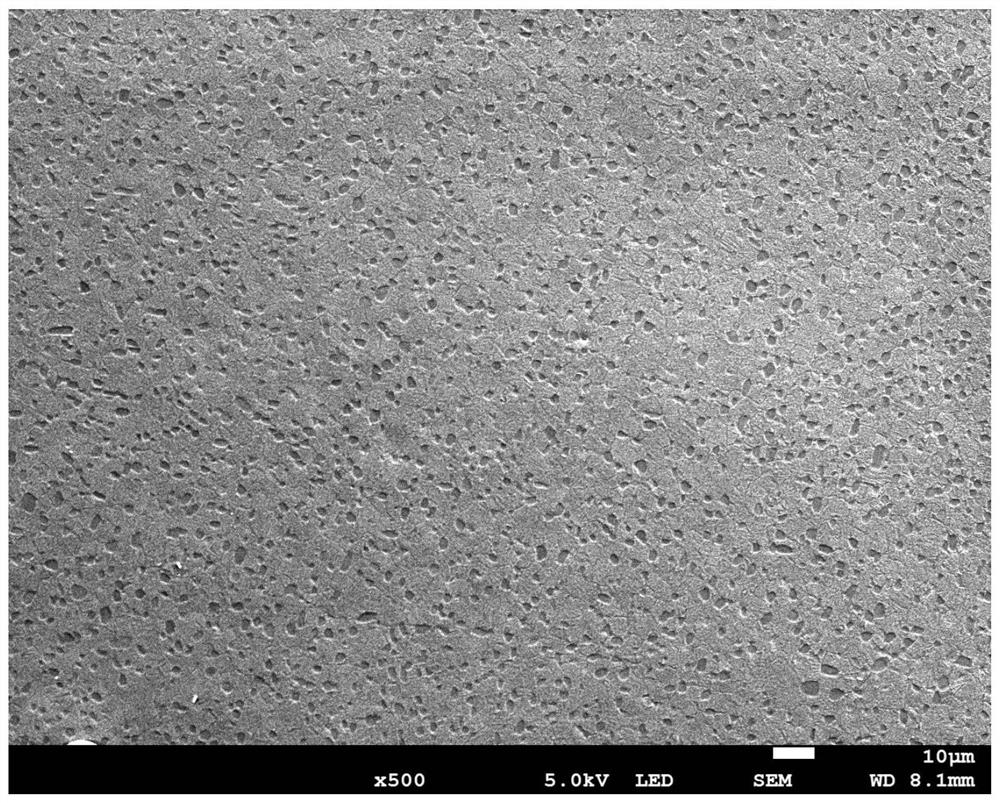

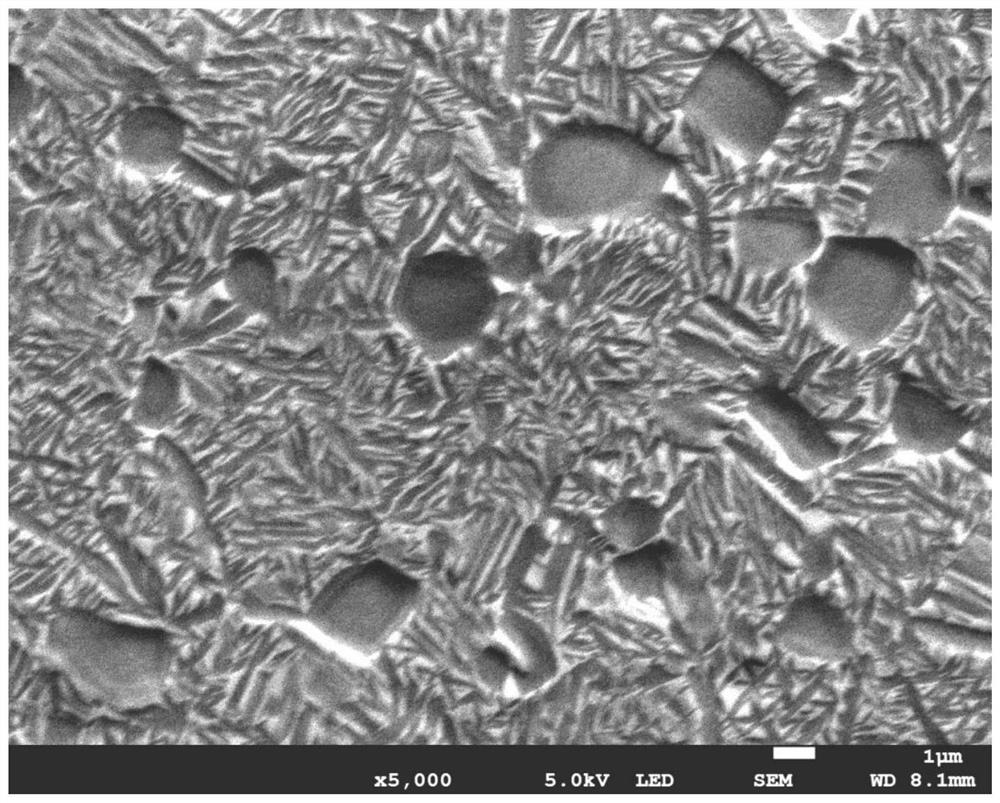

PC/ABS alloy material and application thereof

ActiveCN112724627AGuaranteed thermal stabilityGuaranteed processing effectWeather resistanceMetallurgy

The invention relates to the technical field of PC / ABS alloy materials, and discloses a PC / ABS alloy material and an application thereof. The alloy material is obtained by melting and mixing a PC / ABS alloy composition, and the PC / ABS alloy composition contains PC, ABS, a toughening agent, a flame retardant and modified graphene; based on the total weight of the composition, the composition comprises 65-80 wt% of PC, 10-30 wt% of ABS, 1-5 wt% of a flexibilizer, 5-12 wt% of a flame retardant and 0.5-1 wt% of modified graphene. The alloy material has the advantages of higher mechanical properties, environment friendliness, flame retardancy and excellent weather resistance.

Owner:CHINA PETROLEUM & CHEM CORP +2

Spraying-free material and manufacturing method of spraying-free ornament for automotive interiors

The invention discloses a spraying-free material. The spraying-free material comprises the following components in percentage by mass: 80-95% of matrix resin, 0.1-3% of effect toner, 0.1-3% of basic toner, 1-3% of auxiliary master batch and 0-20% of filler; and the spraying-free material has various different color effects and has good toughness. The invention further discloses a manufacturing method of a spraying-free ornament for automotive interiors. According to the manufacturing method, a double-color forming mold is adopted; a movable mold of the double-color forming mold is provided with a first color forming area and a second color forming area. The manufacturing method comprises the following steps that: S1, a material A and a material B are weighed correspondingly, the material Ais the spraying-free material, and the material B is an ornament framework injection molding material; S2, respectively putting the material A and the material B into corresponding gun barrels, closing the mold, and carrying out injection molding on the material A in the first color forming area to form an ornament surface layer; and S3, opening the mold, after rotating the mold to change the position of the mold, closing the mold again, carrying out injection molding on the material B on the second color forming area so as to form an ornament framework. The technological process is simple, and flow marks and weld line defects can be avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

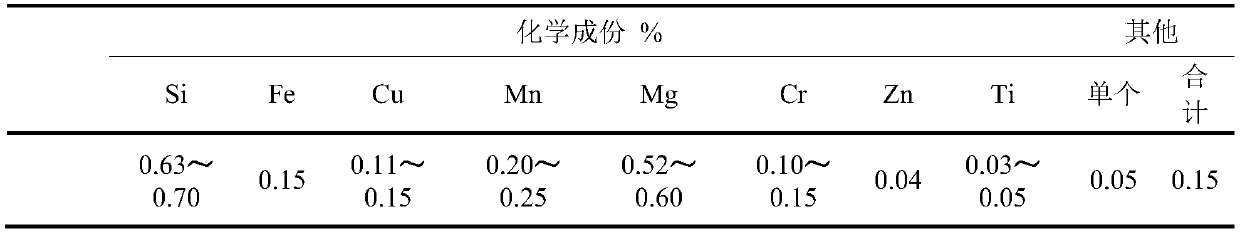

6101B aluminum alloy casting production process

InactiveCN112342414AOptimize the production processGuaranteed mechanical performance requirementsCorrosion resistantMechanical properties of carbon nanotubes

The invention relates to a 6101B aluminum alloy casting production process, and belongs to the field of aluminum alloy casting production. The 6101B aluminum alloy casting production process comprisesthe steps of burdening, furnace charging, smelting, stirring, refining, slagging-off, component adjusting, online refining, online degassing, filtering and casting. Through connection of all processsteps in the production process and control over all process parameters, the 6101B aluminum alloy casting production process is optimized, products meet the mechanical property requirement, the product yield is increased, and the corrosion resistance and oxidation resistance of the products are improved.

Owner:CHINA ZHONGWANG

Ti2AlNb-based alloy bar and preparation method and application thereof

ActiveCN114262852AImprove tissue uniformityHigh strengthFurnace typesHeat treatment furnacesIngotHeat conservation

The invention relates to the technical field of Ti2AlNb-based alloys, in particular to a Ti2AlNb-based alloy bar as well as a preparation method and application thereof. The preparation method comprises the following steps: (A) carrying out homogenizing heat treatment on a Ti2AlNb-based alloy cast ingot at 1160-1200 DEG C to obtain a cast ingot blank; (B) carrying out heat preservation treatment at 1130-1170 DEG C, and then extruding and drawing out to obtain a primary bar blank; (C) carrying out heat preservation treatment on the primary bar billet at 1020-1060 DEG C, then cooling the primary bar billet to 500 DEG C or below along with the furnace, and discharging the primary bar billet; (D) carrying out heat preservation treatment at 960-980 DEG C, and then extruding and drawing out to obtain a secondary bar blank; and (E) the secondary bar blank is subjected to solid solution heat treatment and aging heat treatment, and the Ti2AlNb-based alloy bar is obtained. According to the method, the tensile strength, the ductility and the structure uniformity of the Ti2AlNb-based alloy bar are improved.

Owner:BEIJING CISRI GAONA TECH

Coaxial cable for nuclear power station

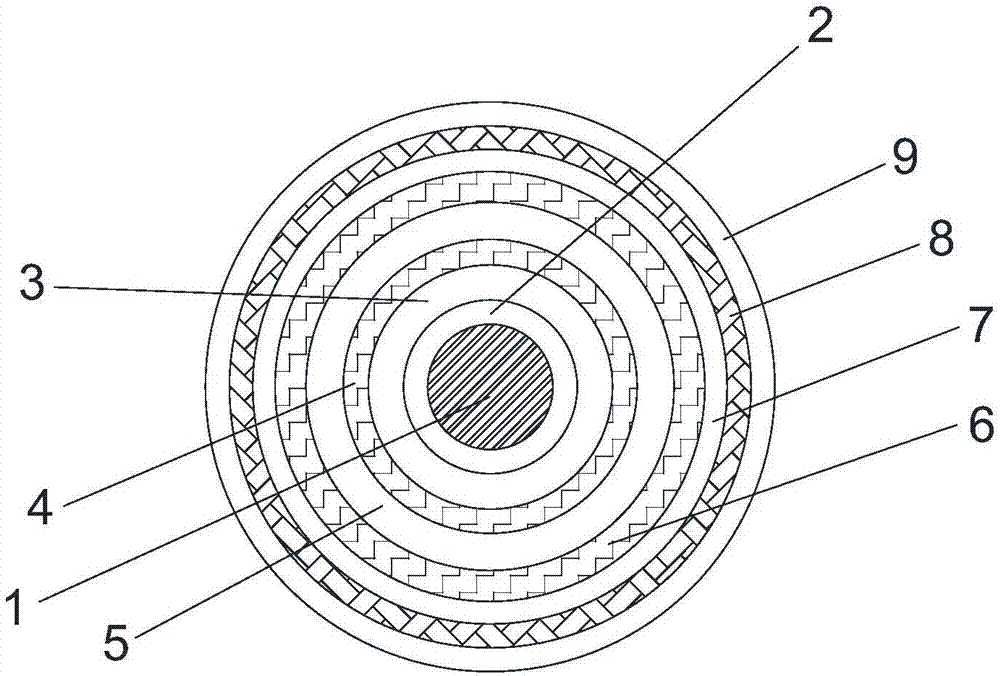

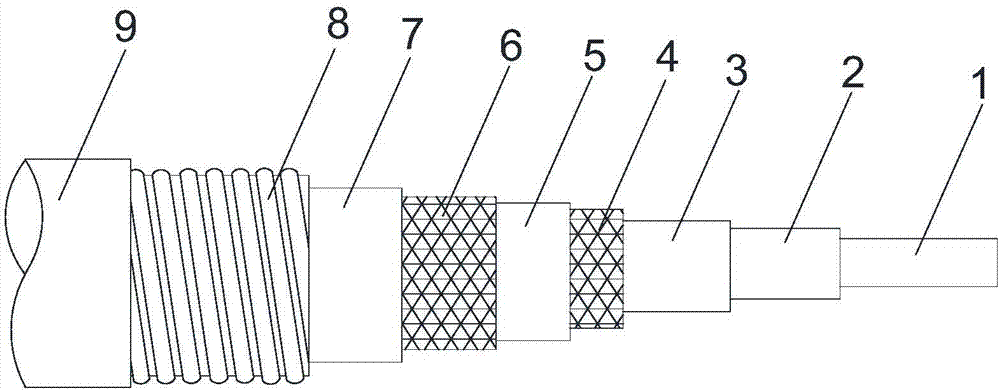

ActiveCN107204215AGuaranteed irradiationWarranty requirementsPlastic/resin/waxes insulatorsConcentric cablesPoly ether ether ketonePolyolefin

The invention relates to the field of a cable, and particularly to a coaxial cable for a nuclear power station. The cable comprises a conductor. A first insulating layer, a second insulating layer, a first woven shielding layer, a first inner sheath, a second woven shielding layer, a second inner sheath, a metal corrugated pipe and an outer sheath successively wrap the external surface of the conductor. The first insulating layer is made of a thin-wall extruded poly-ether-ether-ketone modified cable insulating material. The second insulating layer is made of radiating crosslinked polyolefin. The thickness ratio between the first insulating layer and the second insulating layer is 1:3-20. The coaxial cable satisfies a requirement for signal transmission among a reactor workshop neutron detector and a junction box and a through member and among an auxiliary workshop through member and a pre-amplifier and a signal processing cabinet in a Chinese third-generation nuclear power plant instrument system. Furthermore the coaxial cable satisfies a requirement for executing a safe function in a designed reference accident environment condition of the third-generation nuclear power plant.

Owner:CHANGZHOU BAYI CABLE

Structural conductive silicone rubber for electromagnetic shielding and preparation thereof

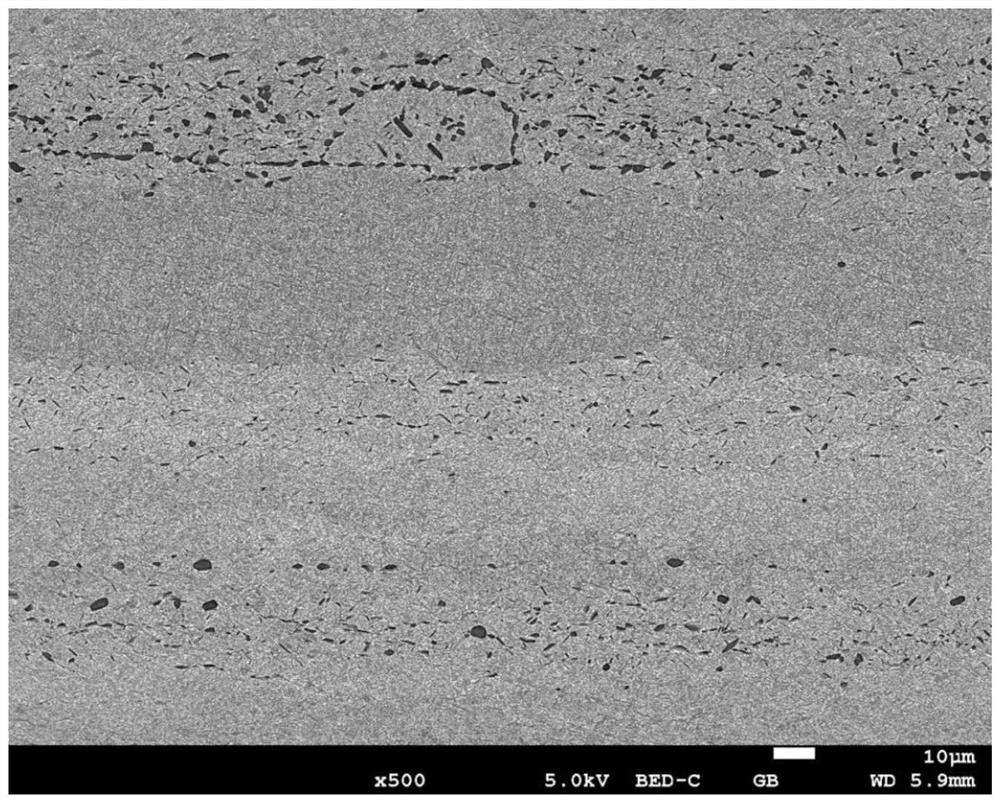

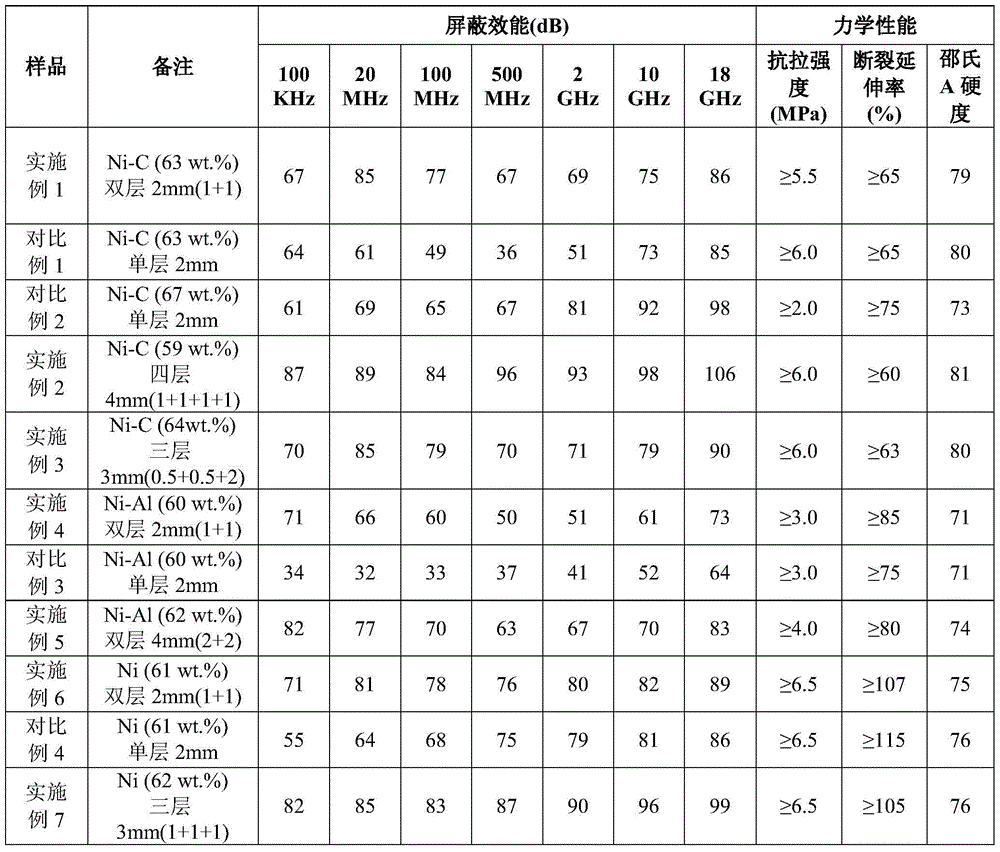

InactiveCN103496228BGuaranteed mechanical performance requirementsImprove shielding effectLaminationLamination apparatusPolymer scienceConductive polymer composite

A structural conductive silicone rubber for electromagnetic shielding and its preparation, belonging to the technical field of conductive polymer composite materials. Conductive silicone rubber composite material with double-layer or multi-layer structure, and a layer of base glue is coated between the layers as an insulating adhesive layer. Conductive silicone rubber composite material: conductive powder, silicone containing vinyl polydimethylsiloxane Rubber matrix, acetylenic alcohol inhibitor, platinum catalyst, crosslinking agent. The structural conductive silicone rubber prepared by the invention can effectively improve the shielding efficiency and performance stability in the 100KHz-18GHz wide frequency range while ensuring the general mechanical performance requirements.

Owner:BEIJING UNIV OF TECH

Pouring method of natural gas power cylinder body

The invention discloses a pouring method of a natural gas power cylinder body, which aims to solve the problems of poor feeding property and more casting defects of a casting piece produced by an existing pouring method. According to the pouring method, the pouring temperature ranges from 1330 DEG C to 1350 DEG C. The pouring method is beneficial to feeding of a casting piece and can reduce other casting defects.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

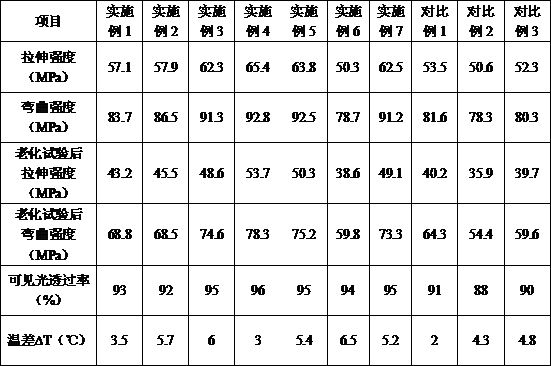

Weather-resistant heat-insulating PC/PMMA composite material and preparation method thereof

ActiveCN114316552AHigh light transmittanceImprove stabilityPolymethyl methacrylateUltraviolet lights

The invention provides a PC / PMMA (polycarbonate / polymethyl methacrylate) alloy material with weather resistance and heat insulation performance. The PC / PMMA alloy material comprises the following components: 60-80% of polycarbonate; 10% to 20% of polymethyl methacrylate; 1%-5% of a composite toughening agent; 0.5%-4% of a compound compatilizer; 0.1%-0.5% of a chain extender; 1%-6% of a coupling agent; 0.1%-0.3% of an antioxidant; 0.5%-12% of nano ATO (antimony tin oxide); 5%-20% of a heat-conducting filler; 0.05%-0.3% of a lubricant; and 0.2%-1% of an ultraviolet light absorber. According to the invention, PC, PMMA and a plurality of compound modification auxiliary agents are subjected to melt mixing through a high-volume and high-torque co-rotating twin-screw extruder to prepare the PC / PMMA alloy material suitable for high-end application fields of buildings, automobile industry, electronic and electrical appliances and the like. The material has good mechanical properties, weather resistance and heat insulation performance, has good light transmittance, and can realize green, safe, energy-saving and consumption-reducing functions in a plurality of application fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

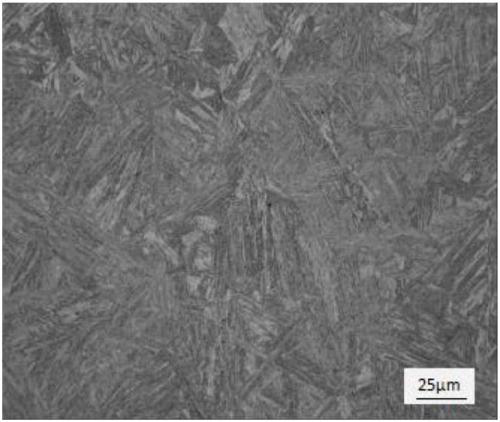

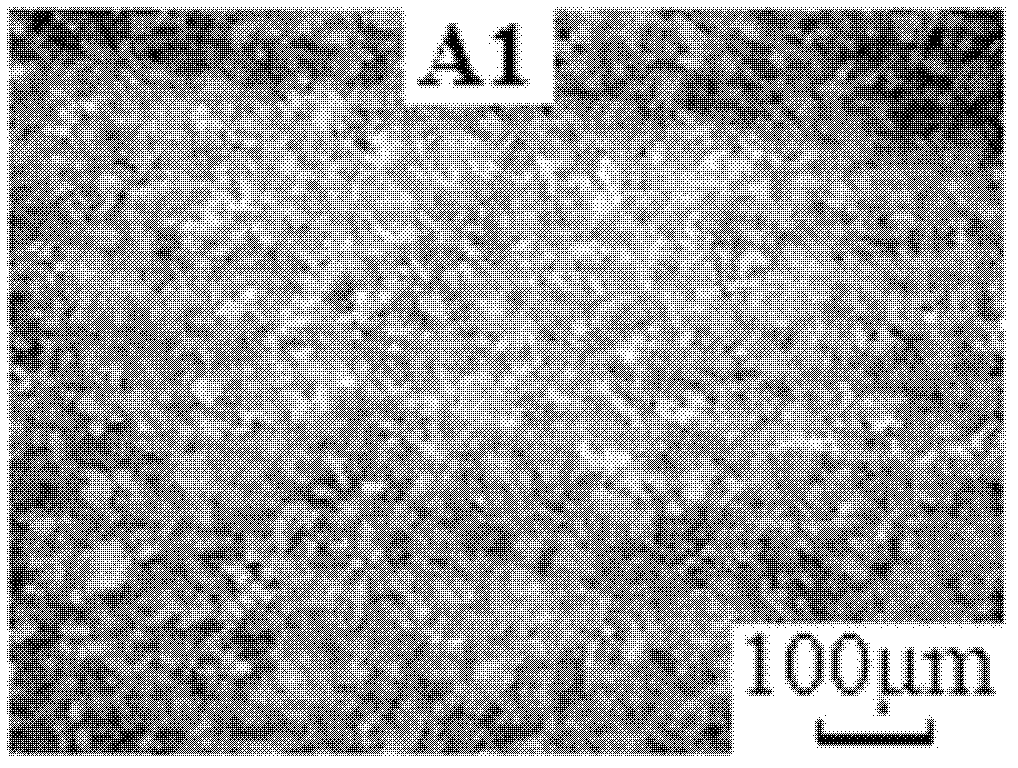

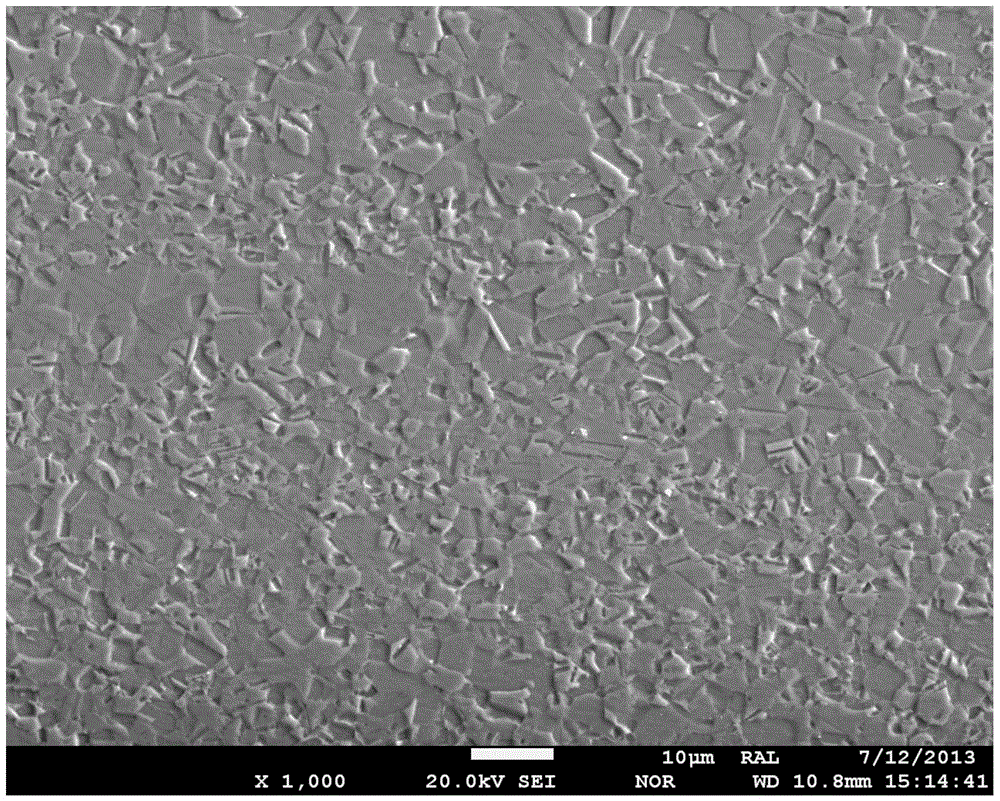

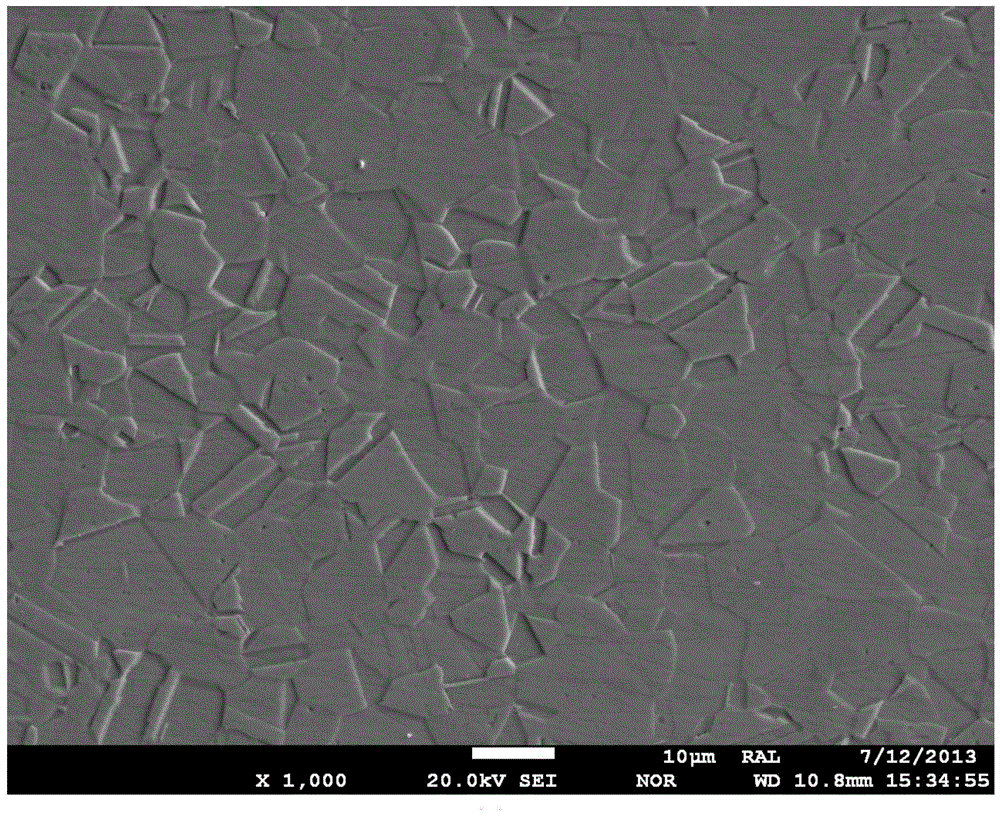

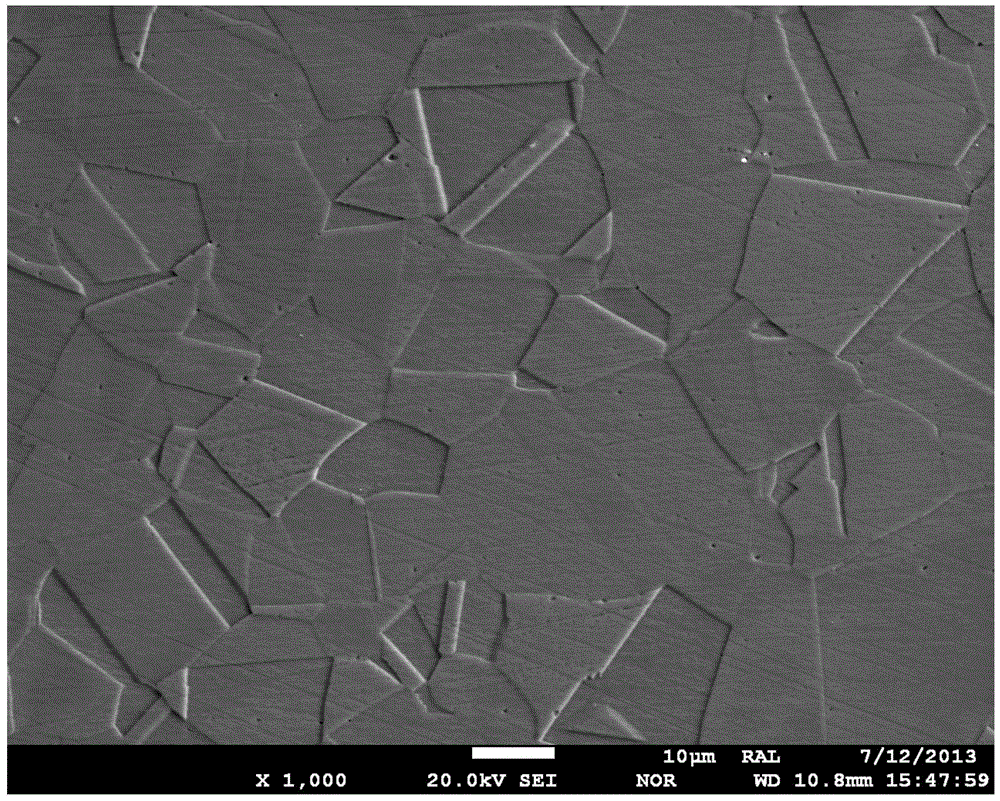

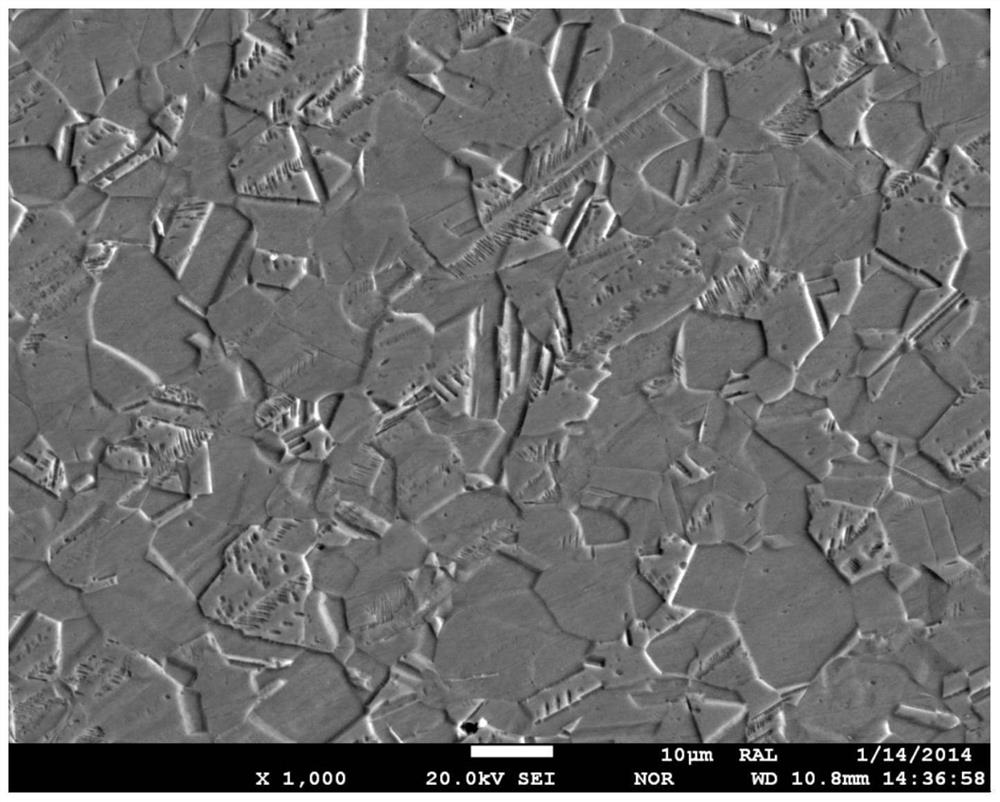

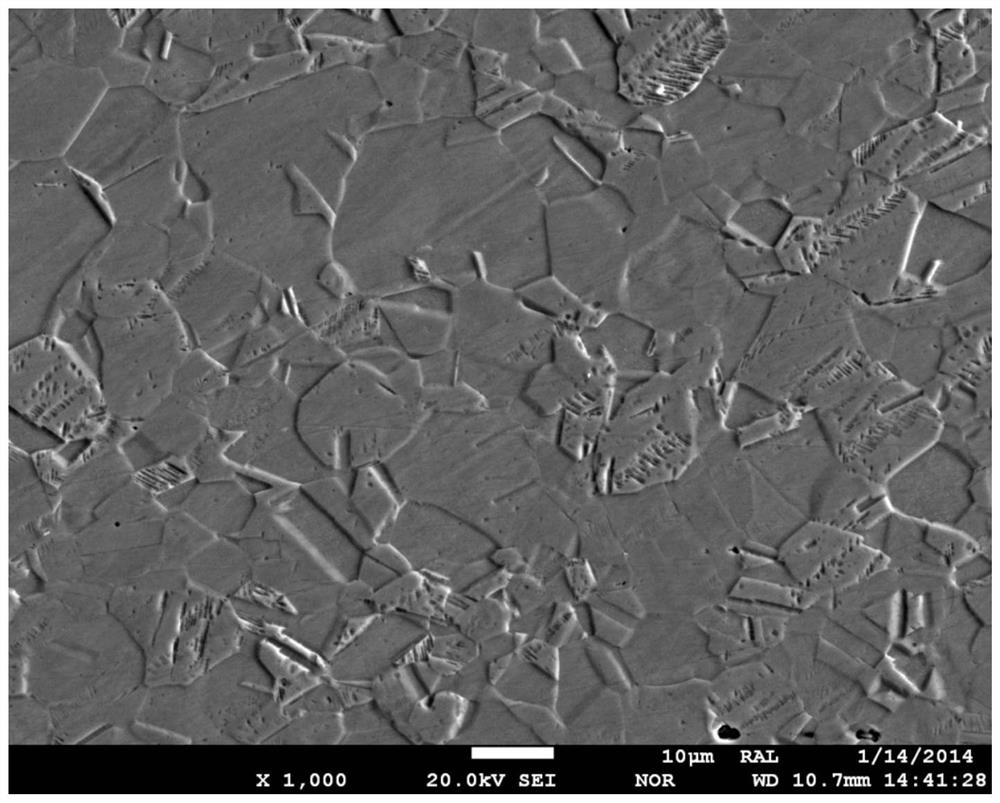

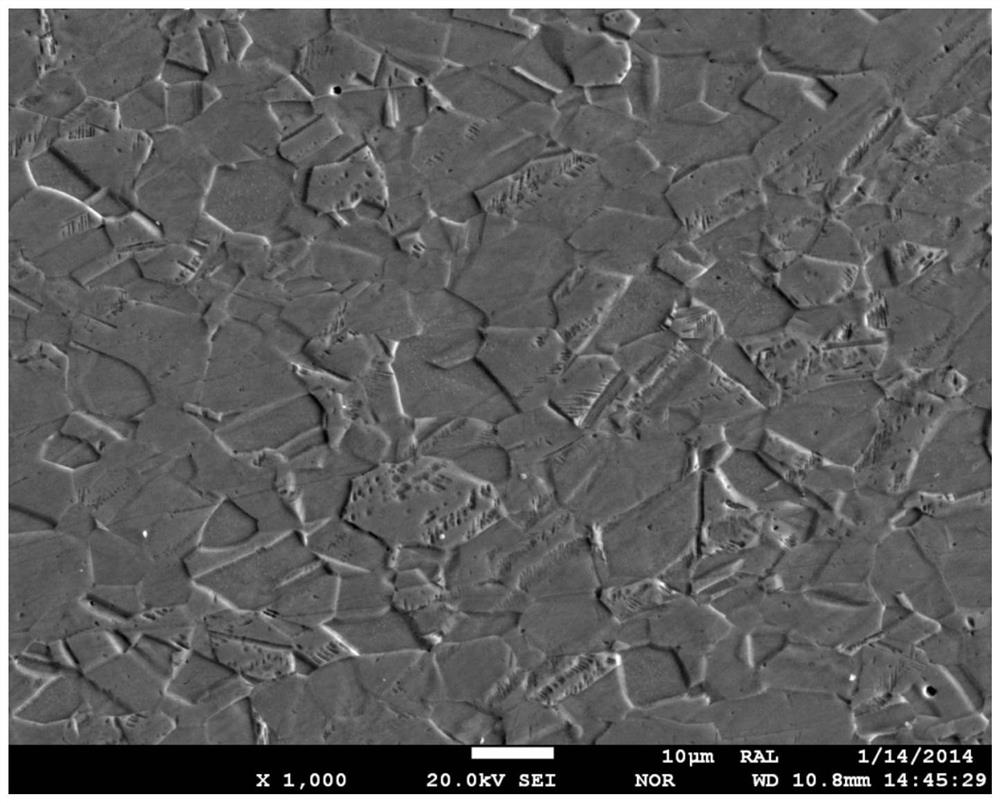

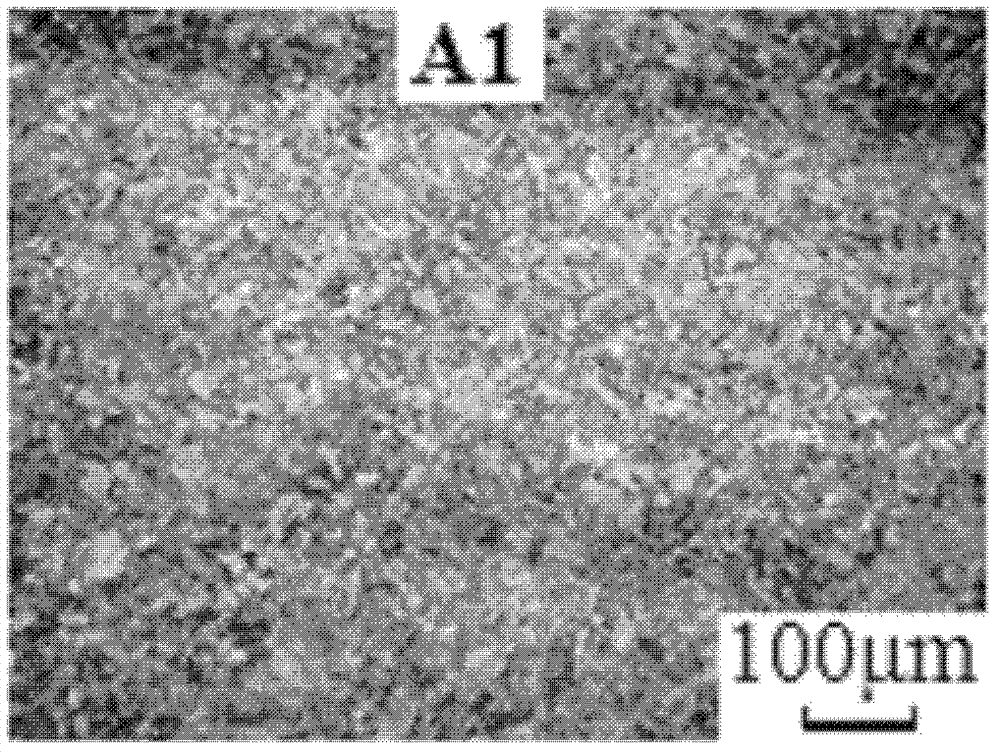

A kind of cr, n-type high manganese austenitic steel plate and preparation method thereof

ActiveCN105177439BOptimal Design Chemical CompositionMicroorganizedSolution treatmentChemical composition

The invention discloses a Cr / N-containing high-manganese austenitic steel plate and a preparation method thereof. The Cr / N-containing high-manganese austenitic steel plate comprises the following chemical components in percentage by weight: 0.28-0.32% of C, 24.8-25.2% of Mn, 2.8-3.2% of Cr, 2.8-3.2% of Al, 0.02-0.20% of N, at most 0.015% of P, at most 0.005% of S and the balance of Fe. The preparation method comprises the following steps: smelting molten steel according to set components, casting into an ingot, heating to 1200 DEG C, keeping the temperature for 2 hours, forging into a plate blank, carrying out hot rolling until the thickness is 6mm, carrying out homogenizing treatment, carrying out cold rolling to the thickness of 1mm or so, and finally, carrying out solution treatment, thereby obtaining favorable strength-plasticity compatibility and having certain oxidation resistance and corrosion resistance.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

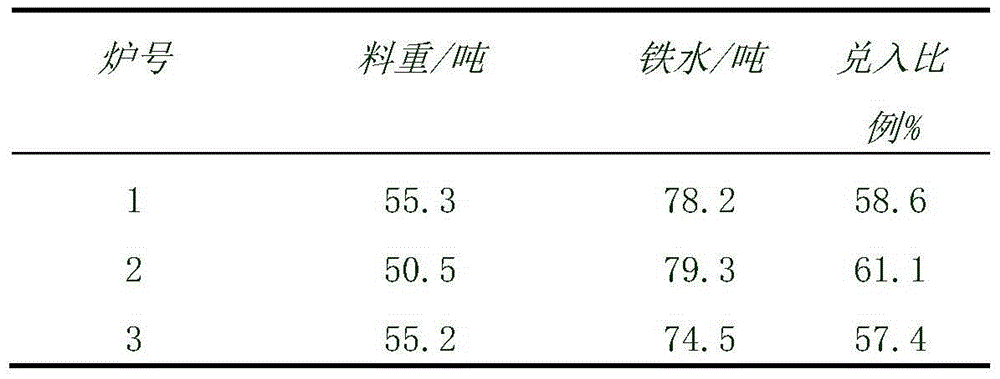

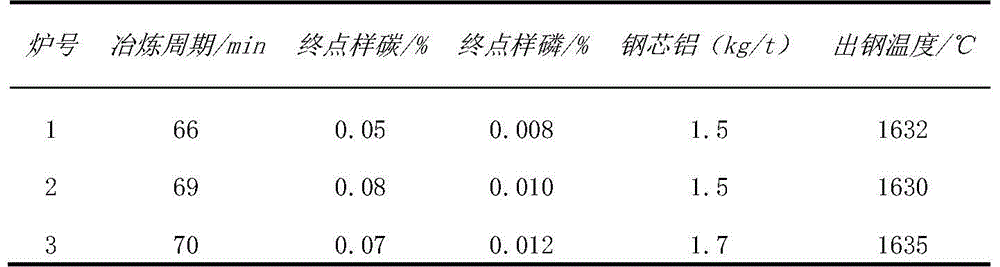

Steel for high-pressure pipeline valve and manufacturing method thereof

ActiveCN104480404BGuaranteed mechanical performance requirementsGuaranteed welding performance requirementsSlag (welding)Manganese

The invention discloses steel for a high-pressure pipeline valve and a manufacturing method of the steel. The steel for the high-pressure pipeline valve comprises components in percentage by weight as follows: 0.19%-0.23% of C, 0.15%-0.25% of Si, 0.95%-1.10% of Mn, smaller than or equal to 0.30% of Cr, smaller than or equal to 0.40% of Cu, smaller than or equal to 0.020% of S, smaller than or equal to 0.020% of P, smaller than or equal to 0.40% of Ni, smaller than or equal to 0.12% of Mo, 0.010%-0.040% of Ti, smaller than or equal to 0.03% of V, smaller than or equal to 0.02% of Nb, 0.015%-0.025% of Al, smaller than or equal to 15*10<-6> of O, smaller than or equal to 90*10<-6> of N and the balance of Fe and inevitable impurities. Through content control of carbon and manganese elements, the mechanical property requirements of steel are guaranteed, meanwhile, the content of residual elements is controlled, the material welding property requirement is guaranteed, the fatigue strength of steel is enhanced, and the valve stability is guaranteed. Through control of molten iron (or pig iron) mixing proportion, furnace slag refining amount, VD (vacuum degassing) furnace operation and reinforced water gap protection and casting effect, titanium is added for nitrogen fixation, and the nitrogen content can be controlled below 90 ppm.

Owner:SHANDONG IRON & STEEL CO LTD

Antitheft door made from novel composite material

InactiveCN104649696AGuaranteed AntioxidantHigh strengthBurglary protectionCeramic layered productsSelf-healingCarbon fibers

The invention discloses an antitheft door made from a novel composite material and especially disposed an antitheft door material suitable for home life. In the technical scheme, the novel composite material is a carbon fiber reinforced ceramic-based composite material and a silicon carbide fiber reinforced ceramic-based composite material, wherein an inner surface is prepared from boron nitride. The novel composite material is mainly prepared through composition of the silicon carbide fiber and ceramic. The novel composite material not only can ensure a requirement of mechanical performances but also has an interface layer having an anti-oxidizing capability and a self-healing capability. The novel composite material not only has many excellent performances of a ceramic material, such as high strength, high modulus, excellent chemical corrosion resistance, excellent high temperature resistance and excellent oxidization resistance, but also has a metal-like breaking behavior, is insensitive to cracks and is free of destructive damage. The novel composite material is low in cost, is easy to obtain and is a preferably selection of composite materials.

Owner:青岛唐鹏钢结构工程有限公司

A kind of corrosion-resistant high manganese austenitic steel plate and preparation method thereof

ActiveCN112342352BLow costGuaranteed mechanical performance requirementsFurnace typesHeat treatment furnacesManganeseIngot

The invention discloses a corrosion-resistant high-manganese austenitic steel plate. The high-manganese austenitic steel has an austenite structure, the non-proportional elongation strength of the high-manganese austenitic steel is Rp0.2≥424MPa, and the tensile strength is Rm ≥613MPa, elongation after fracture A≥48%, 8h salt spray corrosion weight gain ≤0.011mg / mm 2 . The purpose of the present invention is to provide a method for improving the corrosion resistance of high manganese austenitic steel based on grain boundary engineering, which solves the problem of poor corrosion resistance of high manganese austenitic steel in the prior art. The invention discloses a preparation method of a corrosion-resistant high manganese austenitic steel plate, which specifically includes: step 1, forging an ingot into a slab; step 2, preheating the slab, and then performing 4 passes of rolling In step 3, the hot-rolled plate obtained in step 2 is subjected to homogenization treatment, and then cold-rolled and annealed to obtain a high-manganese steel plate; in step 4, the annealed high-manganese steel plate is deformed to obtain a final sheet.

Owner:XI'AN POLYTECHNIC UNIVERSITY

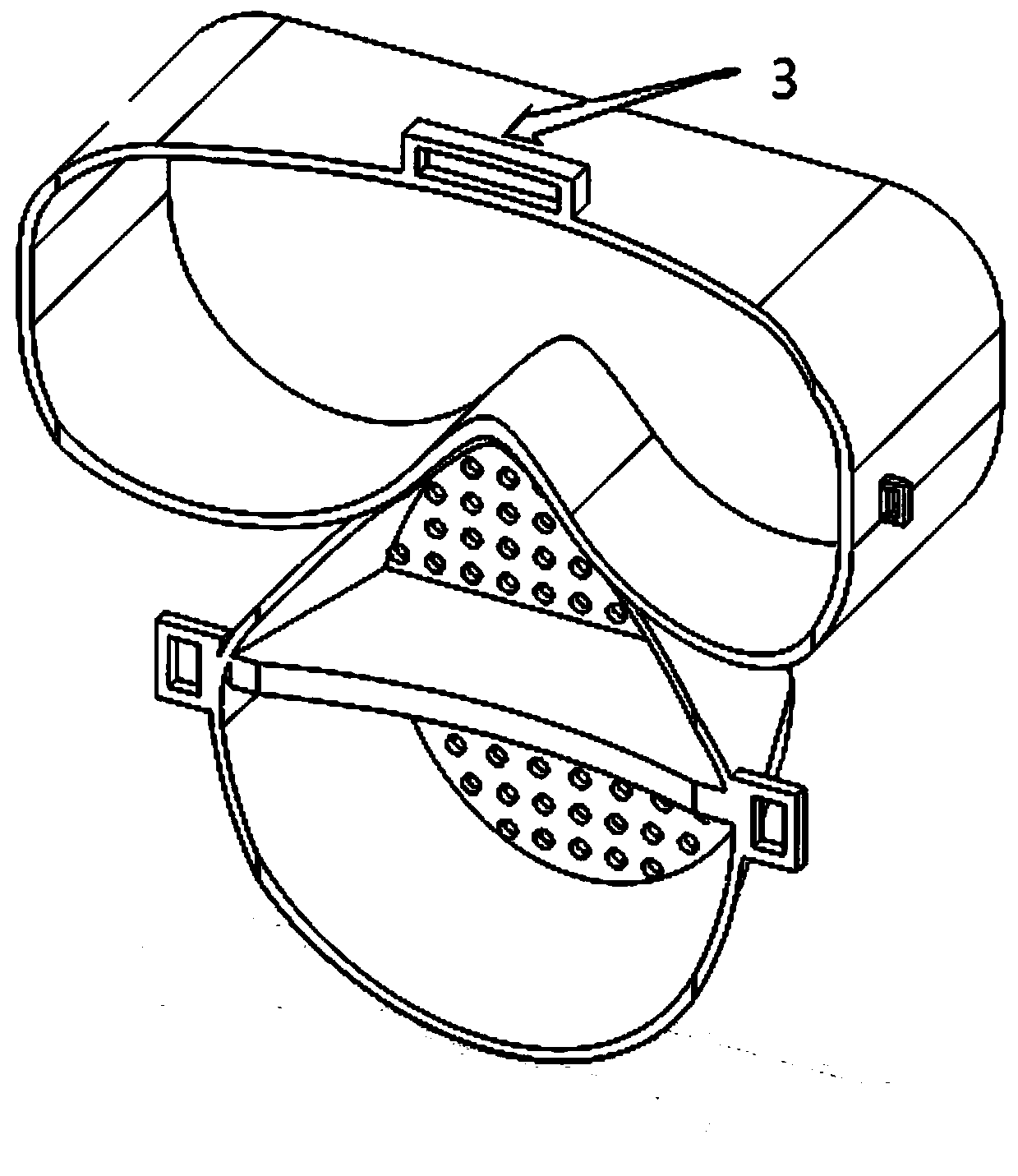

A method for making in-situ 3D printed custom masks based on facial feature extraction

ActiveCN112848273BInnovativeSynchronous fast and efficient productionAdditive manufacturing apparatusCharacter and pattern recognition3d printFeature extraction

Owner:BEIJING UNIV OF TECH

Heat treatment process for large 35CrMo steel axis forgings

InactiveCN102560043BGuaranteed mechanical propertiesGuaranteed mechanical performance requirementsHeating timeRoom temperature

Owner:广州造船厂有限公司

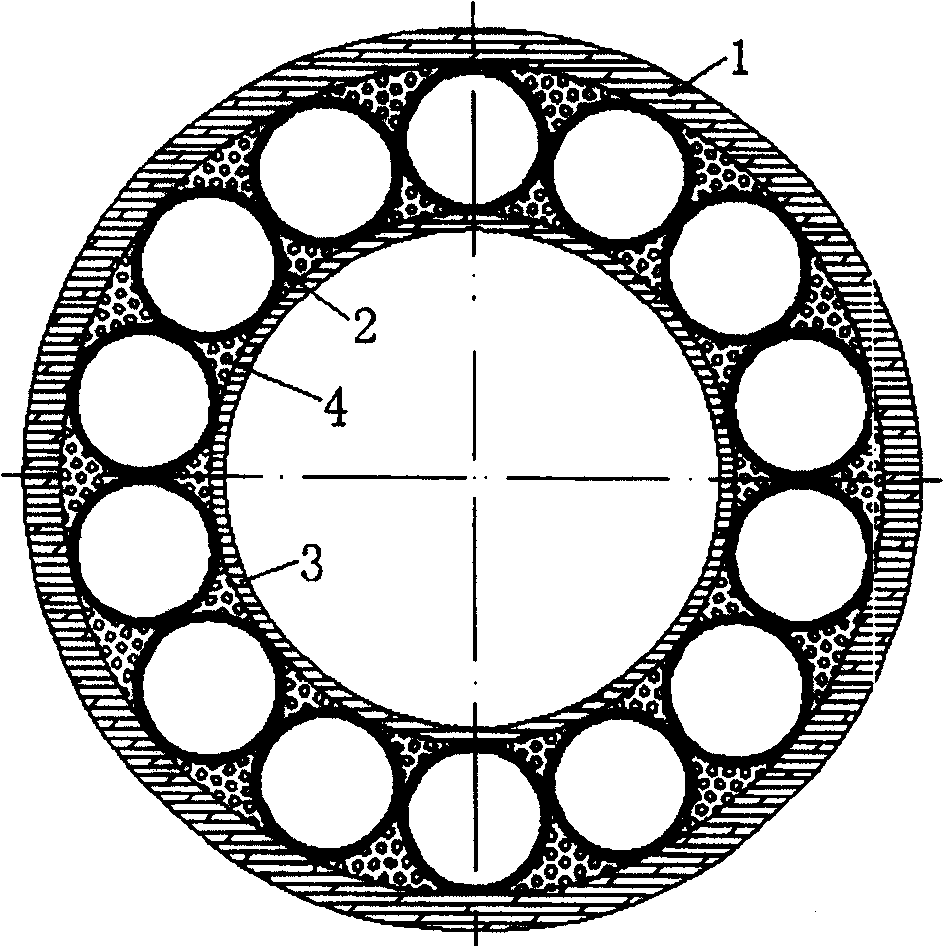

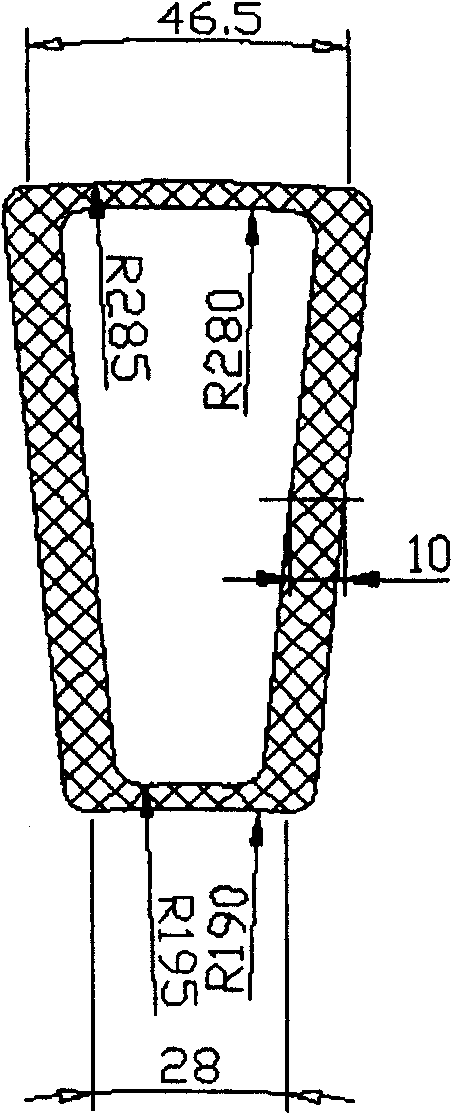

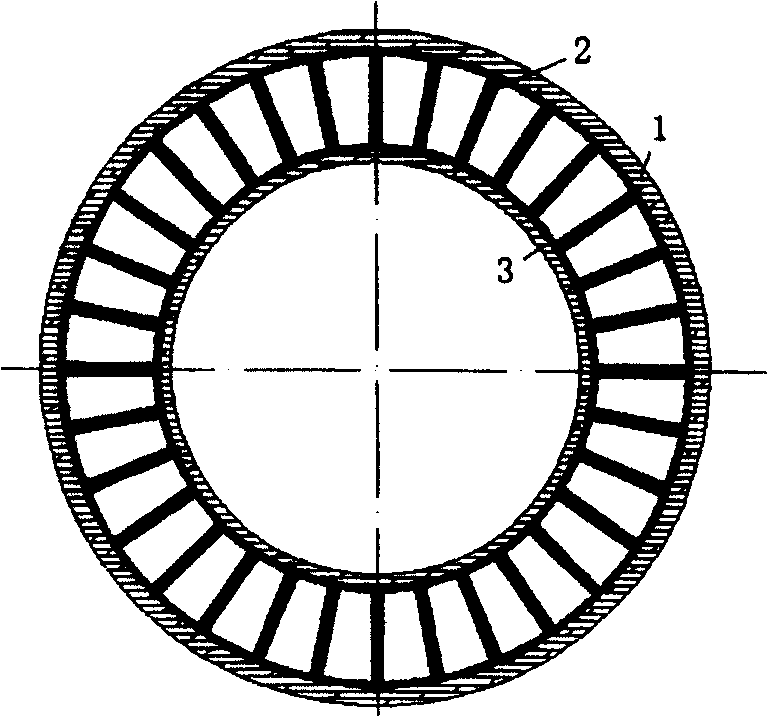

Composite hollow insulator core-rod and making method

InactiveCN100428371CHigh strengthImprove flashover performanceSuspension/strain insulatorsGlass fiberYarn

Core rod of compound hollow insulator is composed of composite tube 1, composite tube 3, and some shape bars 2 in composite material arranged in circumference between tube 1, and tube 3. Filler 4 in composite material is filled in interspaces among shape bars. Fillers 4 are made from rosin based composite material through pultrude combined circumferential wrapping, laying down or rolling techniques. Shape bars 2 are prepared through continuous fiber pultrude, or pull wrapping or hand pasting. Composite tube 1 and composite tube 3 are prepared through wrapping fiber yarn or rolling glass fiber cloth, or combining both manners. Features are: reasonable structure, excellent electric specification, reduced weight of core rod of compound hollow insulator, and ensuring requirement of mechanical properties so as to put materials to good use.

Owner:WUHAN UNIV OF TECH

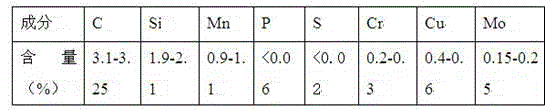

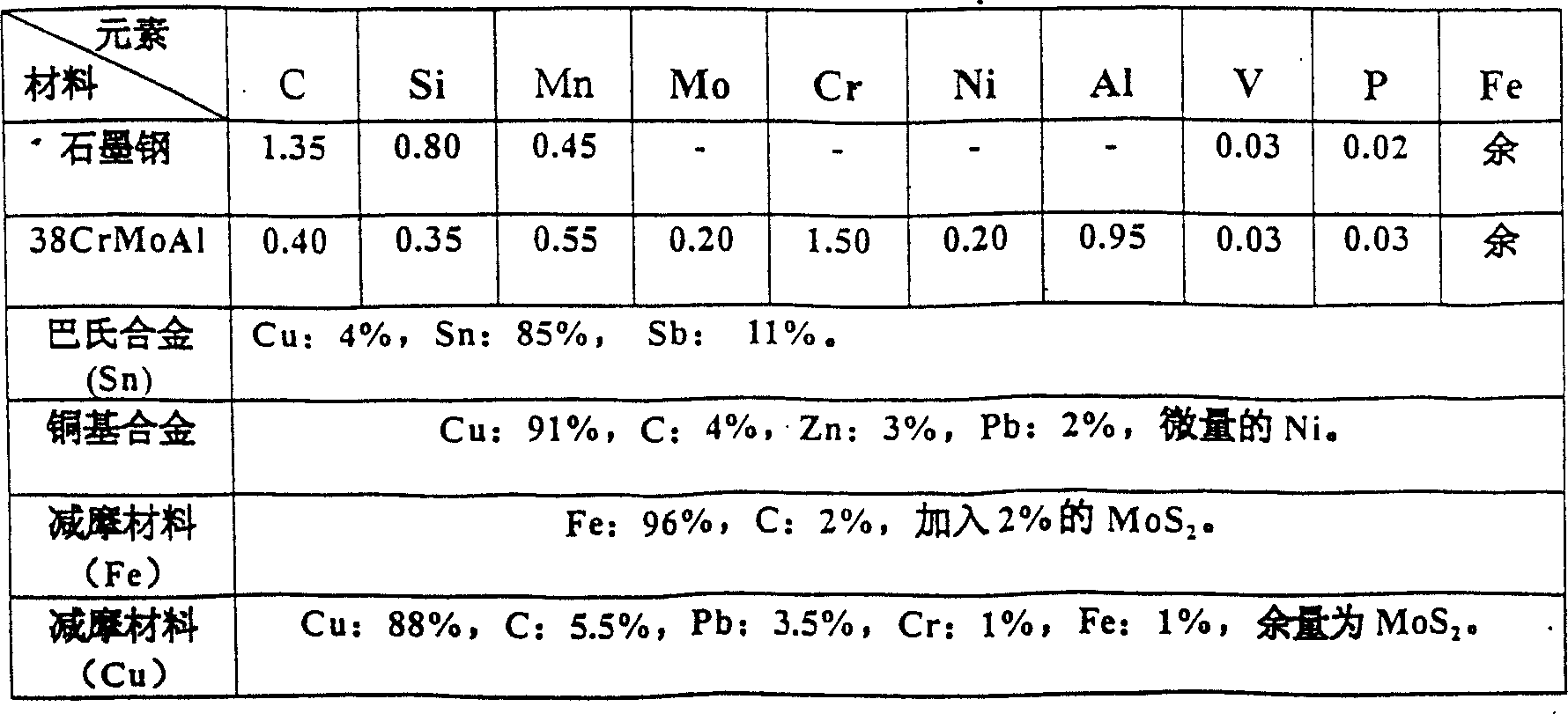

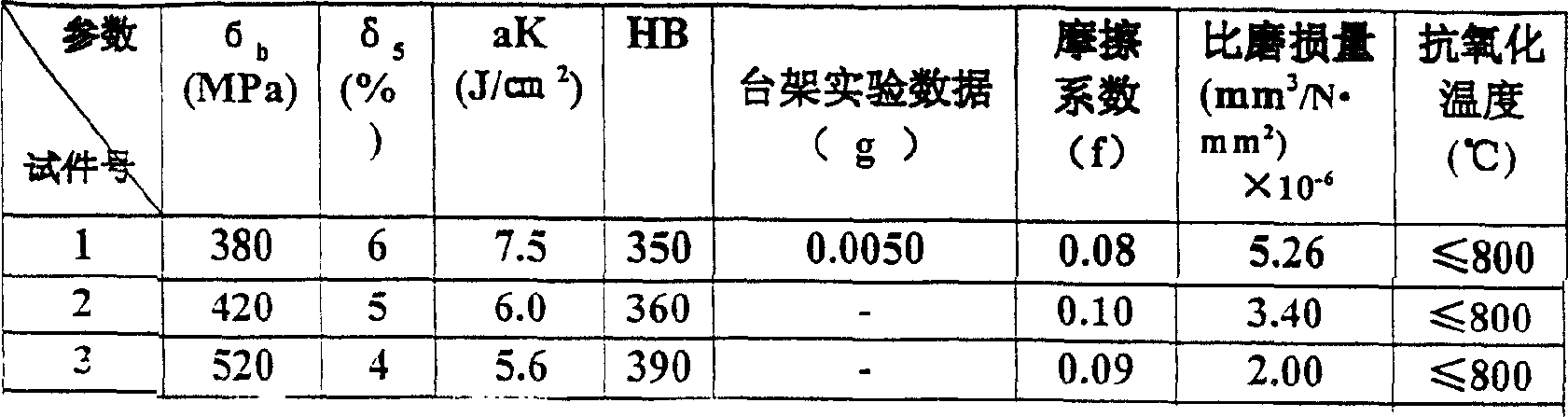

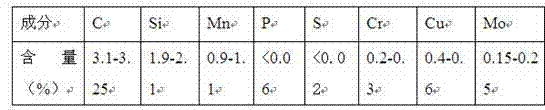

Self-lubricating antiwear composite material

InactiveCN1188538CGood self-lubricating performanceGuaranteed mechanical performance requirementsRare earthMechanical property

An integrally self-lubricating antiwear composite material contains C (0.35-3.2%), Si (0.8-1.6%), Mn (0.8-1.4 %), S (1.0-5.0%), Cr (0.5-3.5%), Mo (0.2-0.9%), W (0.2-0.8%), RE (0.1-0.2%), Al (0.6-0.9%), V (0.1-0.2%), Ti (less than 0.2%), P (less than 0.05%) and Fe (the rest). It can also contains Cu and / or Ni for higher casting and mechanical performance. Its advantages are excellent self-lubricating performance, better mechanical performance, and low cost.

Owner:高福池 +1

A scalable platform for power controllers

ActiveCN104065250BRealize three-dimensional layoutUse of internal spacePower conversion systemsCapacitancePower controller

Owner:NO 513 INST THE FIFTH INST OF CHINA AEROSPACE SCI & TECH

Manufacturing technology for natural aerodynamic cylinder

ActiveCN103600021BHigh dimensional accuracyHigh surface finishFoundry mouldsFoundry coresSurface finishManufacturing technology

The invention discloses a manufacturing technology for a natural aerodynamic cylinder and aims to solve the problems that a conventional cast natural aerodynamic cylinder is low in precision and intensity and has multiple casting defects. The manufacturing technology disclosed by the invention mainly comprises the working procedures of contour and sand core manufacturing, baking, molten iron smelting, vermicularizing treatment and pouring. The natural aerodynamic cylinder manufactured by the manufacturing technology has the characteristics of high contour size precision, high surface smoothness, high intensity and high mechanical property, and the manufacturing technology is particularly suitable for manufacturing of the natural aerodynamic cylinder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A precise control method for side bending of large-scale, large-wall-thickness, and multi-cavity aluminum profiles

ActiveCN108188192BUniform deformationReasonable lengthExtrusion control devicesQuenching devicesEngineeringLateral bending

Owner:龙口市丛林铝材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com