Steel for high-pressure pipeline valve and manufacturing method thereof

A technology of high-pressure pipeline and manufacturing method, which is applied in the field of metallurgy to achieve the effects of ensuring stability, ensuring welding performance requirements, and enhancing fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

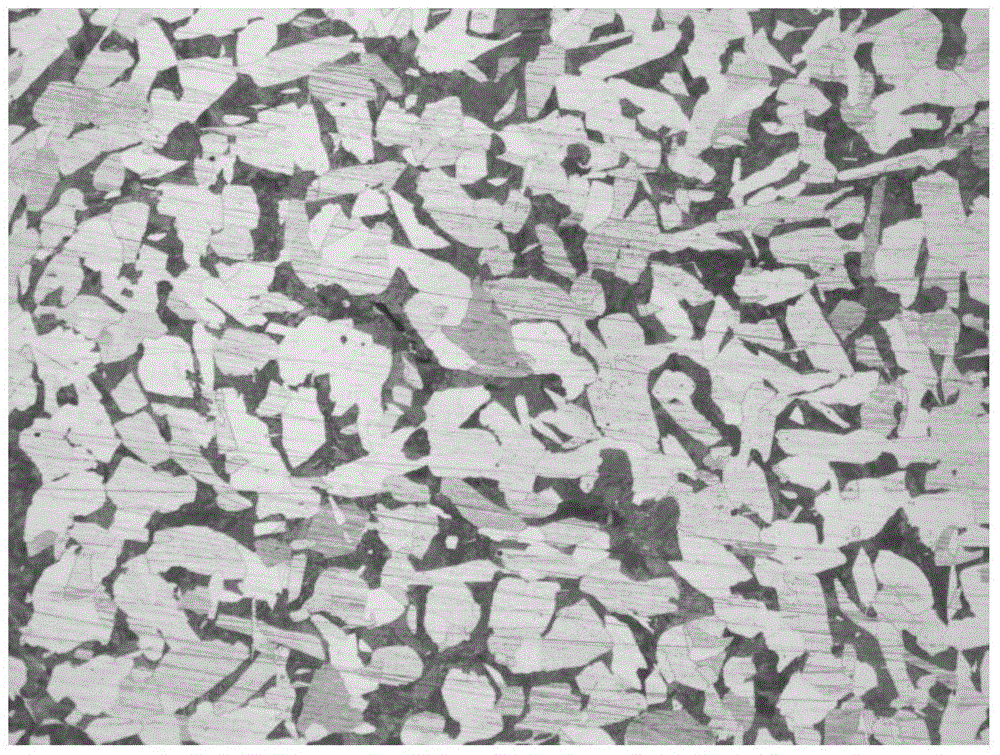

Image

Examples

Embodiment Construction

[0033] The invention adopts UHP (Ultra High Power Electric Furnace) → LF (Outside Furnace Refining) → VD (Vacuum Degassing) → Continuous Casting (Electromagnetic Stirring) → Slow Cooling in Pit → Rolling → Finishing process to produce steel.

[0034] The following examples specifically illustrate how the present invention is implemented by using the production process of Φ190mm steel.

[0035] The specific process steps are:

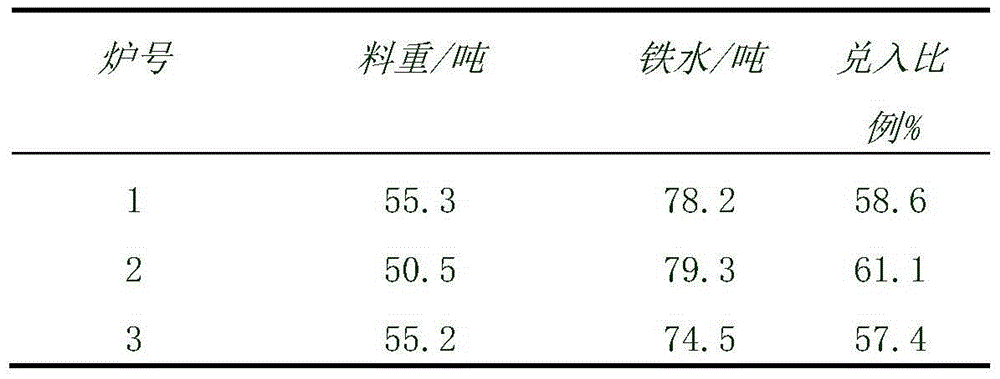

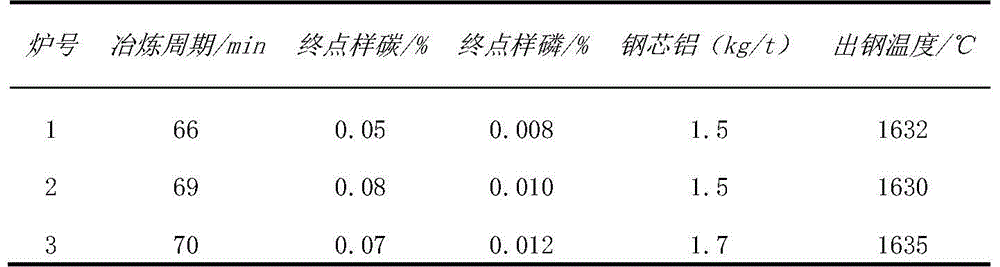

[0036] 1) Electric furnace metallurgy: The charge structure is scrap steel + molten iron, and the proportion of molten iron (or pig iron) is controlled to be 55% to 65%. 4 furnace wall oxygen lances are mainly used for decarburization, and 1 furnace door oxygen lance is used for oxygen decarburization combined with oxygen blowing, blowing carbon powder to create foam slag; adding 35㎏ / t~40㎏ / t lime to make slag and dephosphorization; eccentric furnace bottom tapping, leaving steel and slag operation; tapping process, Bottom blown argon and stirred, the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com