Self-lubricating antiwear composite material

A composite material, self-lubricating technology, applied in the field of casting alloy materials, can solve the problems of long production cycle, low mechanical properties, difficult to control the consistency of product quality, etc., and achieve huge social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

[0027] The specific implementation of the design idea of the present invention is as follows:

[0028] Use a general intermediate frequency induction furnace to melt the alloy components except S in a general method, and finally add a sulfur-containing master alloy made by powder metallurgy. The tapping temperature is 1520-1560 ℃, and the sedation is 2 3 minutes, then pouring into test pieces.

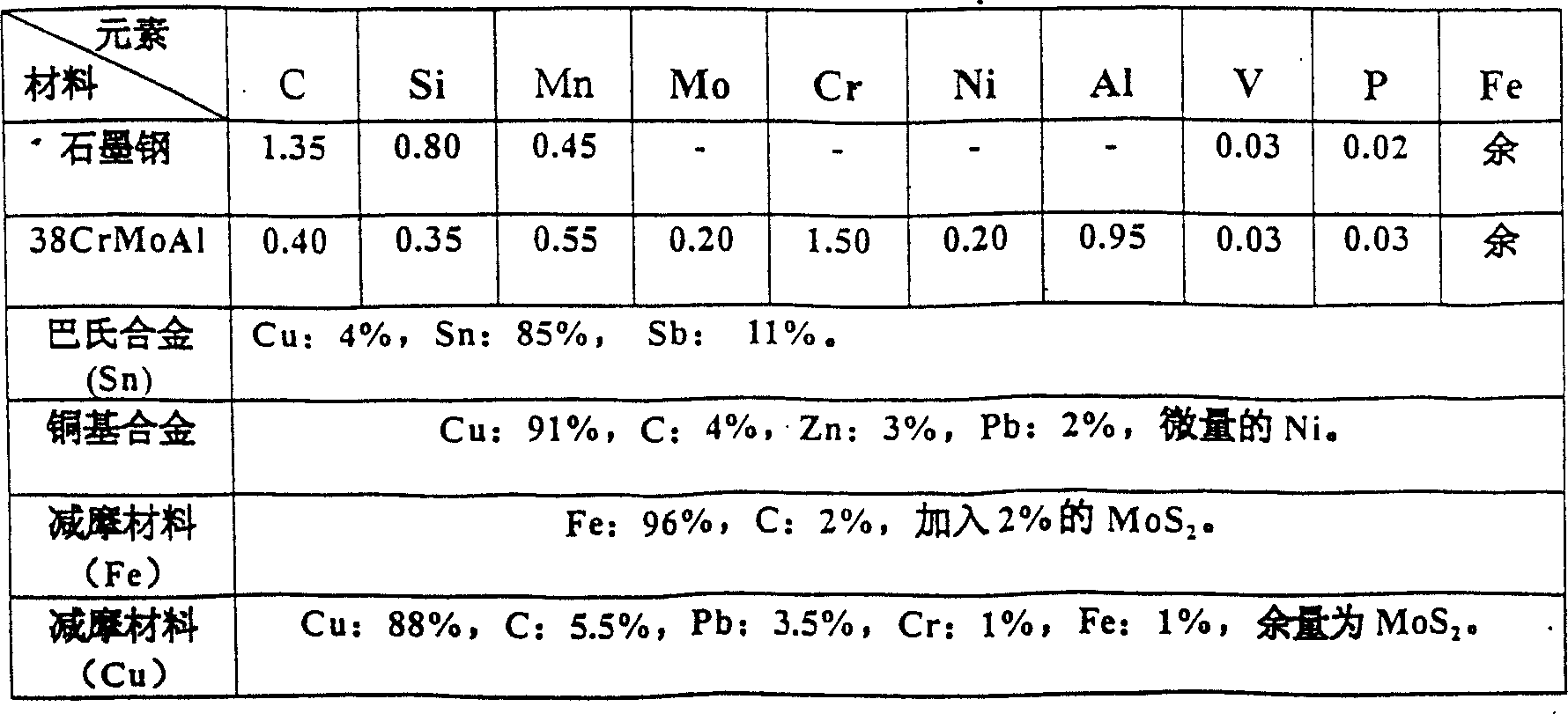

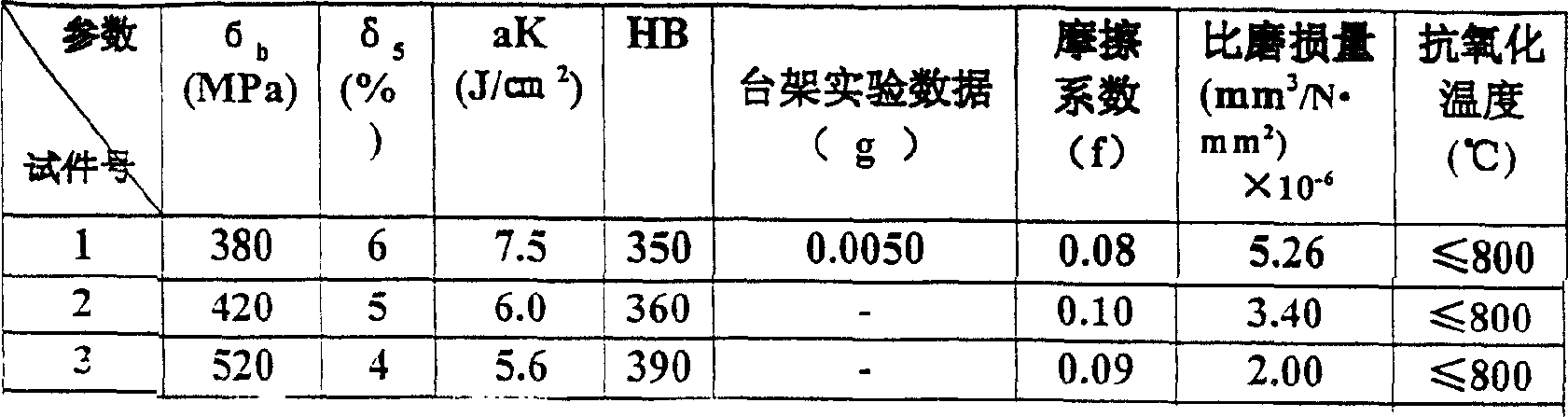

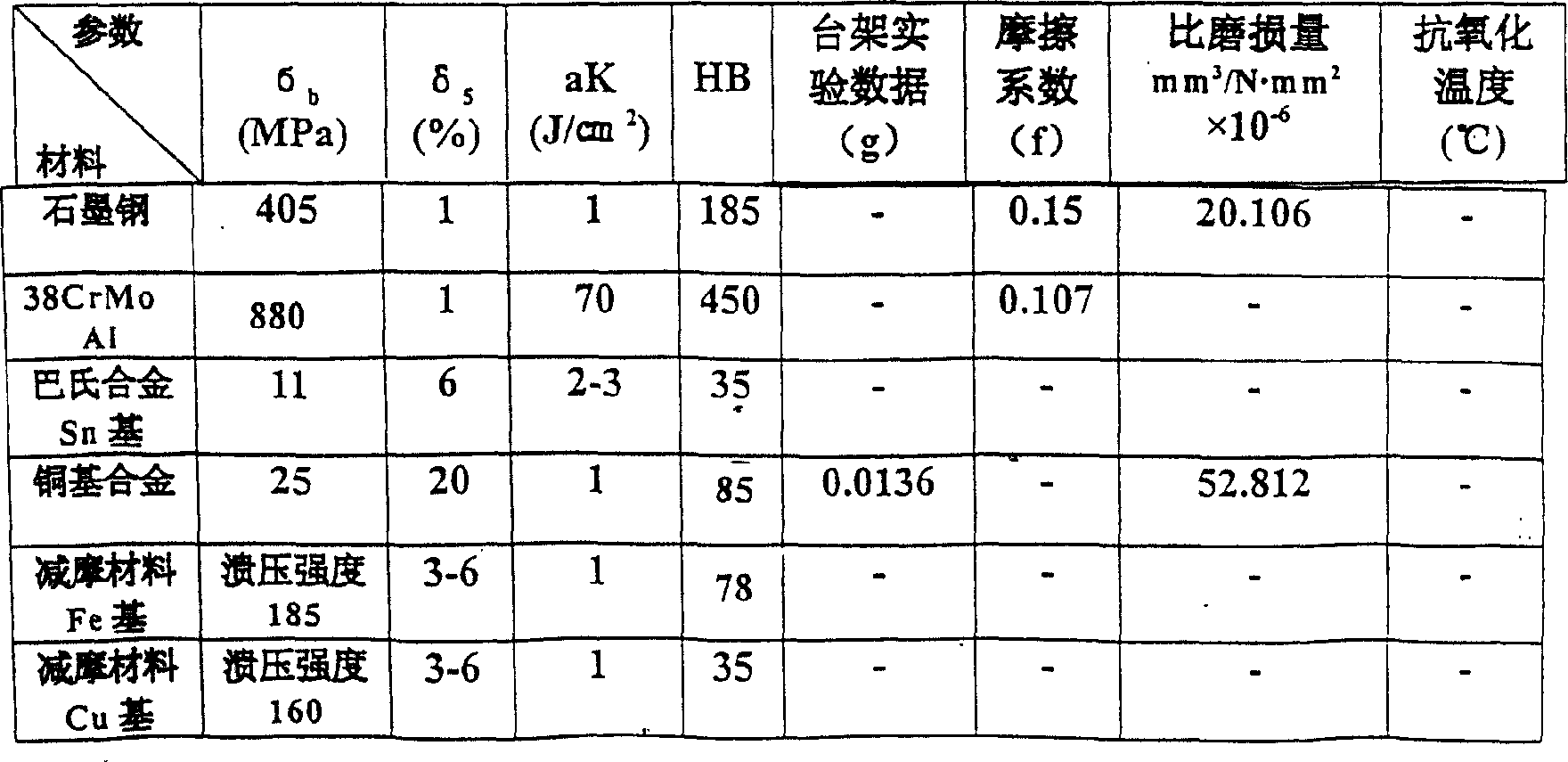

[0029] The chemical composition of the test piece is listed in Table 1, Table 2 is the chemical composition of several wear-resistant materials in the prior art for comparison, Table 3 is the mechanical properties of each test piece in Table 1, and Table 4 is used in Table 2. Compare the mechanical properties of various materials.

[0030] Specimen 1

Specimen 2

Specimen 3

C

0.39

0.65

0.85

Si

1.20

0.8

1.0

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com