A kind of cr, n-type high manganese austenitic steel plate and preparation method thereof

A technology of austenitic and steel plates, applied in the field of high manganese austenitic steel plates and its preparation, high manganese austenitic steel plates, can solve the problems of poor corrosion resistance and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

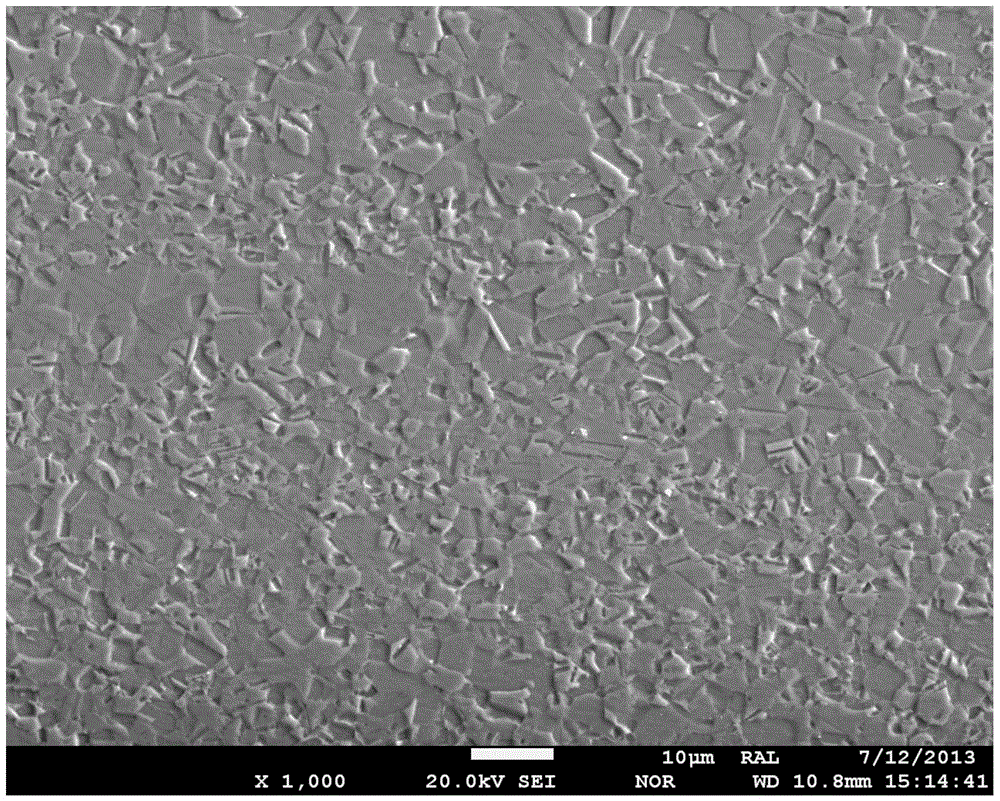

Embodiment 1

[0038] A Cr and N-type high manganese austenitic steel plate, the chemical composition of the steel plate is: C 0.28%; Mn 24.8%; Cr 2.8%; Al 2.8%; N 0.02%; P 0.015%; S 0.005 %; the balance is Fe.

[0039] A preparation method for Cr, N-type high manganese austenitic steel plate, comprising the following steps:

[0040] Step 1. Smelt molten steel according to the set chemical composition and cast it into ingots. The set chemical composition is: C 0.28%; Mn 24.8%; Cr 2.8%; Al 2.8%; N 0.02%; P 0.015% ; S 0.005%; the balance is Fe;

[0041] Step 2: Heating the ingot to 1150°C, holding it for 1.8 hours, and forging it into a slab; heating it to 1150°C, holding it for 0.8 hours, and rolling it for 4 passes, with the starting rolling temperature at 1100°C and the final rolling temperature above 1000°C; The reduction rate of the pass is 25%, the reduction rate of the second pass is 38%, the reduction rate of the third pass is 37%, and the reduction rate of the fourth pass is 39.5%; ...

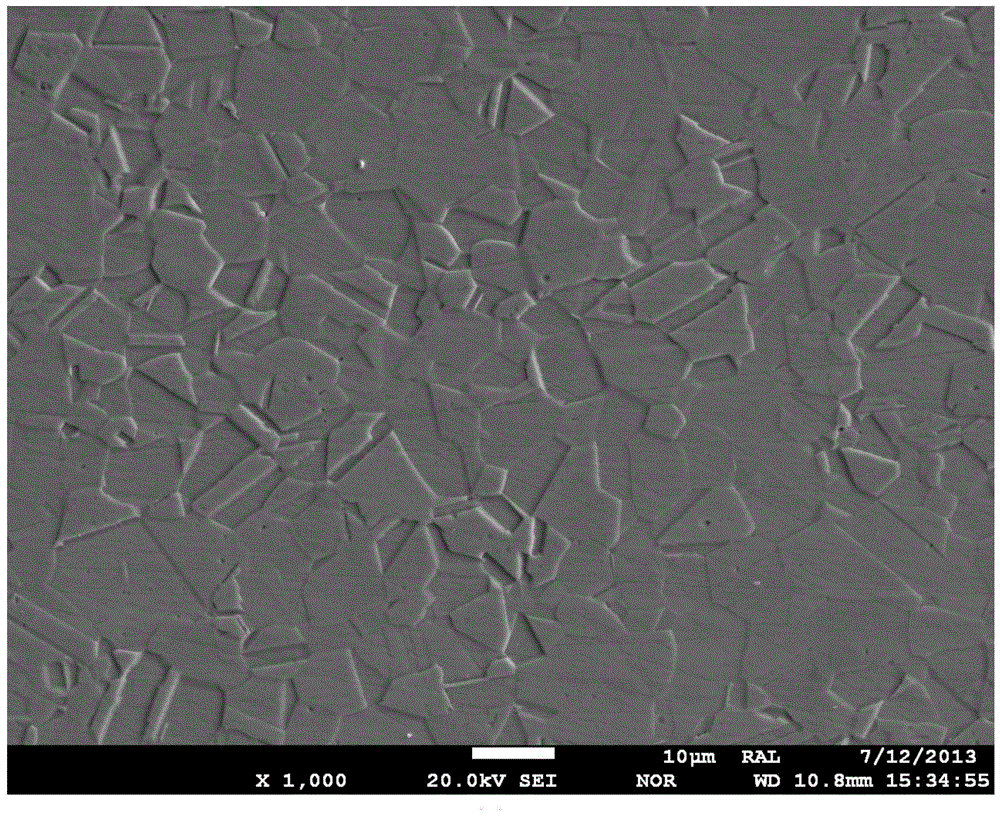

Embodiment 2

[0045] A Cr and N-type high manganese austenitic steel plate, the chemical composition of the steel plate is: C 0.32%; Mn 25.2%; Cr 3.2%; Al 3.2%; N 0.20%; P 0.015%; S 0.005 %; the balance is Fe; its organization is austenite.

[0046] A preparation method for Cr, N-type high manganese austenitic steel plate, comprising the following steps:

[0047] Step 1, smelting molten steel according to the set chemical composition and casting it into ingots, the set chemical composition is: C 0.32%; Mn 25.2%; Cr 3.2%; Al 3.2%; N 0.20%; P 0.015% ; S 0.005%; the balance is Fe; its structure is austenite;

[0048] Step 2: Heat the ingot to 1250°C, hold it for 2.2 hours, and forge it into a slab; heat it to 1200°C, hold it for 1.2 hours, and perform 4 passes of rolling. The reduction rate of the pass is 27%, the reduction rate of the second pass is 39%, the reduction rate of the third pass is 38%, and the reduction rate of the fourth pass is 0.5%;

[0049] Step 3, heat the hot-rolled shee...

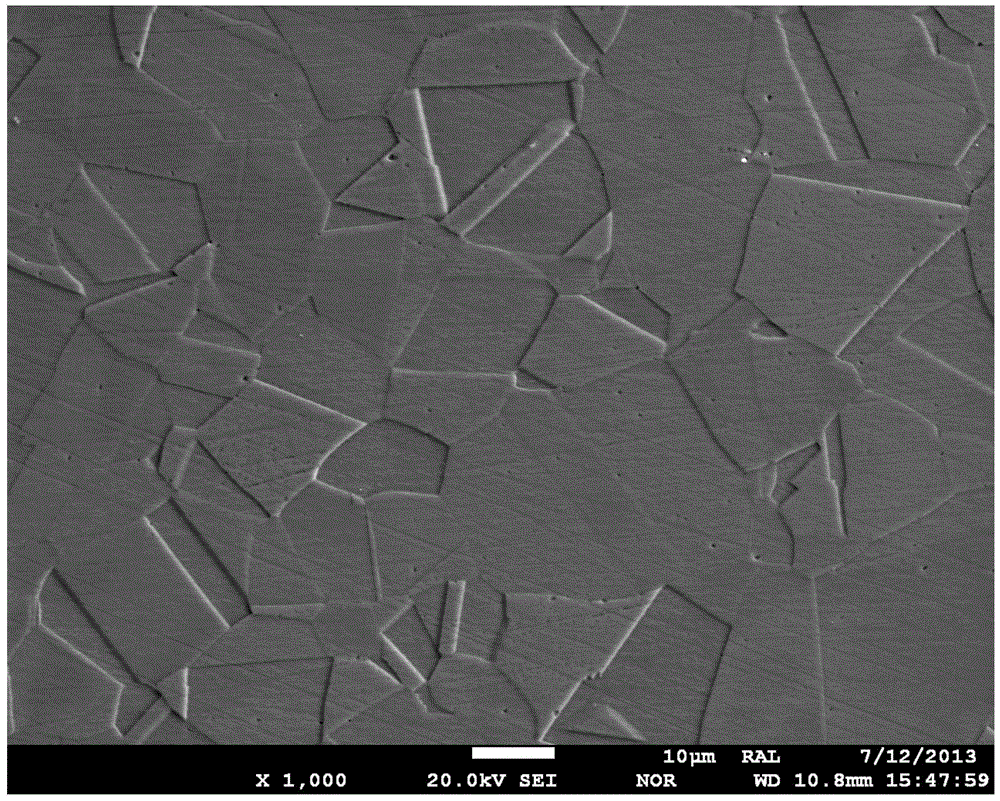

Embodiment 3

[0052] A Cr, N-type high manganese austenitic steel plate, the chemical composition of the steel plate is: C 0.3%; Mn25%; Cr 3%; Al 3%; N 0.11%; P 0.007%; S 0.002%, Its structure is austenite.

[0053] A preparation method for Cr, N-type high manganese austenitic steel plate, comprising the following steps:

[0054] Step 1. Smelt molten steel according to the set chemical composition and cast it into ingots. The set chemical composition is: C 0.3%; Mn 25%; Cr 3%; Al 3%; N 0.11%; P 0.007% ; S 0.002%, its organization is austenite.

[0055] Step 2: Heat the ingot to 1200°C, hold it for 2 hours, and forge it into a slab; heat it to 1175°C, hold it for 1 hour, and perform 4 passes of rolling. The reduction rate is 25.7%, the reduction rate of the second pass is 38.5%, the reduction rate of the third pass is 37.5%, and the reduction rate of the fourth pass is 40%. At this time, the total reduction is 83%, and the thickness of the hot-rolled sheet is 6mm.

[0056] Step 3, heat-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com