Process for forging round steel by using superfine chromium-molybdenum hot-work die steel

A hot work die steel, ultra-fine technology, applied in the field of hot work die steel forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

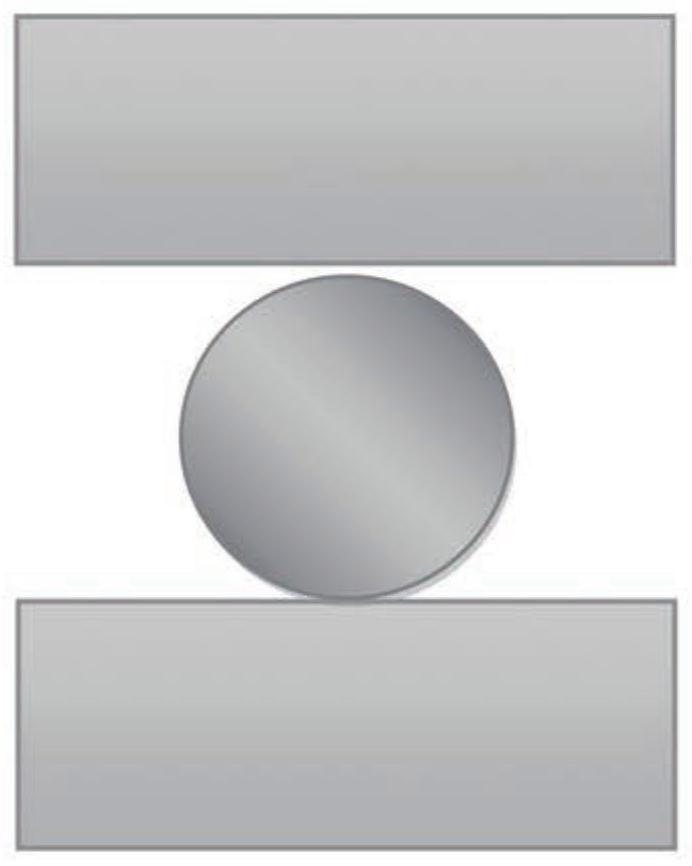

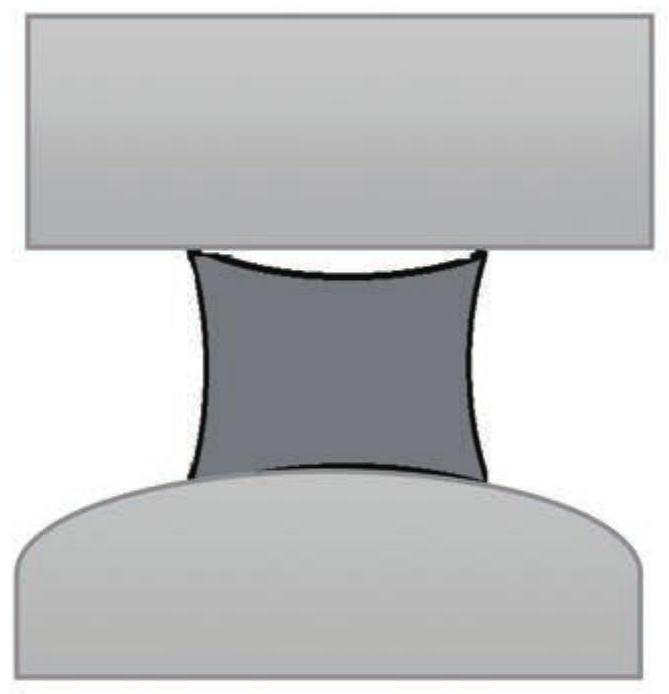

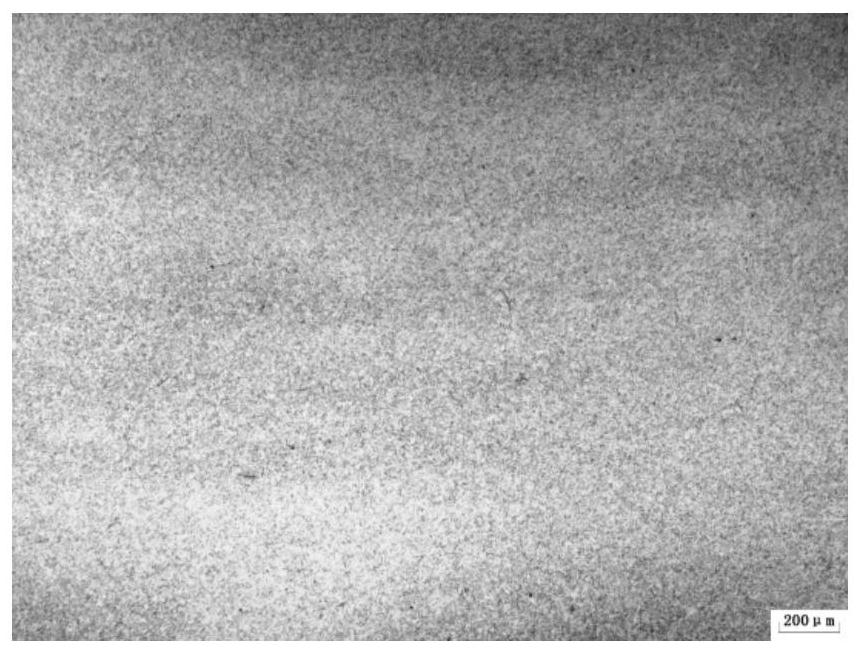

Method used

Image

Examples

Embodiment 1

[0038]The size and shape of the finished product is round steel Ф635mm.

[0039]⑴Adopt EAF+LF+VD+ESR method to smelt, LF furnace adopts white slag time for 32min; VD vacuum degree is not more than 0.67mbar, keep for 10min, pouring φ700mm round electrode rod, pouring temperature is 1537℃, electrode rod is sent for annealing in red. Using binary slag system CaF when electroslag remelting2:Al2O3= 70: 30, the constant fuse electric slag heavy melt voltage is controlled at 62V to 74V, and the weight is controlled at 15000A to 20000A, and the remelted fusion is controlled at 13.5 kg / min, and the electric slag melted ingot is φ1100mm electric slag. Ingots, the temperature of the electric slag ingot will be sent. The analysis results of the chemical composition of the electric slag ingot are shown in Table 1.

[0040]Table 1 Analysis of chemical composition analysis

[0041]

[0042](2) φ1100mm electroslastic preoperative high temperature diffusion treatment, diffusion temperature 1240 ° C ~ 1250 ° C...

Embodiment 2

[0053]The production of finished products is a round steel ф685mm.

[0054](1) EAF + LF + VD + ESR method smelting, the LF furnace is 31min; VD vacuum is not more than 0.67 mbar, remains 10 min, pouring φ700mm round electric pole, the casting temperature is 1541 ° C, the electrode rod is red to retreat. Electroslags use binary slag to use CAF2: Al2O3= 70: 30, the constant fuse electric slag heavy melt voltage is controlled at 62V to 74V, and the weight is controlled at 15000A to 20000A, and the remelted fusion is controlled at 13.5 kg / min, and the electric slag melted ingot is φ1100mm electric slag. Ingots, the temperature of the electric slag ingot will be sent. The results of the analysis of the chemical composition of the electric slag ingot are shown in Table 4.

[0055]Table 4 Chemical composition analysis results

[0056]

[0057](2) φ1100mm electroslastic preoperative high temperature diffusion treatment, diffusion temperature 1240 ° C ~ 1250 ° C diffusion time 45 h.

[0058](3) φ1100mm e...

Embodiment 3

[0068]The production of finished products is a round steel ф785 mm.

[0069](1) EAF + LF + VD + ESR method smelting, the LF furnace is 34min; VD vacuum is not greater than 0.67 mbar, remains 10 min, cast φ700mm round electric pole, the casting temperature is 1533 ° C, the electrode rod is red and retreat. Electroslags use binary slag to use CAF2: Al2O3= 70: 30, the constant fuse electric slag heavy melt voltage is controlled at 62V to 74V, and the weight is controlled at 15000A to 20000A, and the remelted fusion is controlled at 13.5 kg / min, and the electric slag melted ingot is φ1100mm electric slag. Ingots, the temperature of the electric slag ingot will be sent. The analysis results of the chemical composition analysis of the electric slag ingot are shown in Table 7.

[0070]Table 7 Analysis of chemical composition analysis

[0071]

[0072](2) φ1100mm electroslastic preoperative high temperature diffusion treatment, diffusion temperature 1240 ° C ~ 1250 ° C diffusion time 45 h.

[0073](3) φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com