Heat treatment process for large 35CrMo steel axis forgings

A forging and large-scale technology, which is applied in the field of heat treatment of 35CrMo steel large shaft forgings, can solve the problems of slow forging and forming processing speed, insufficient machine tool processing capacity, coarse grains in the core of forgings, etc., to reduce energy consumption and ensure mechanical properties. Performance requirements, effect of shortened heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

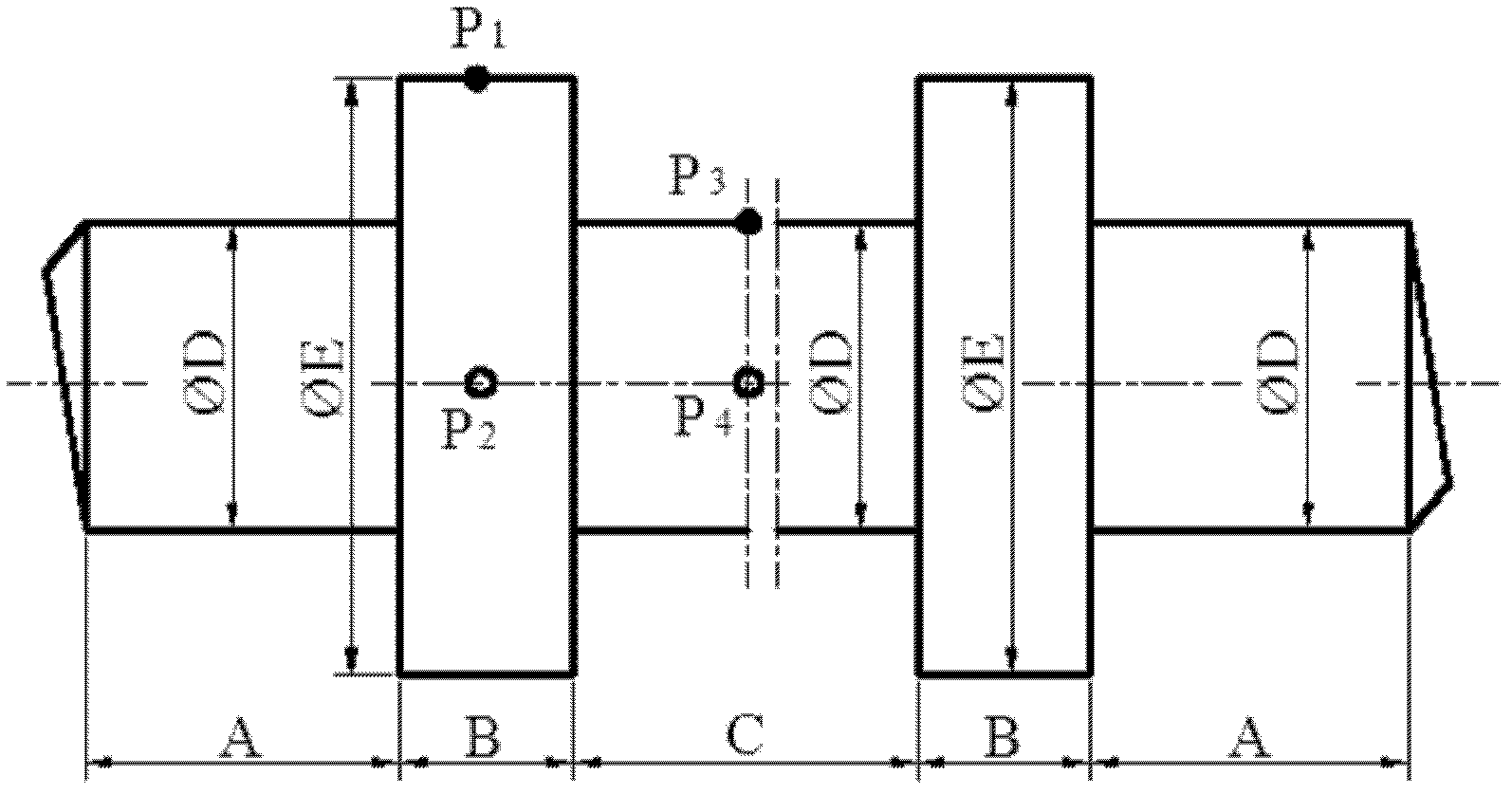

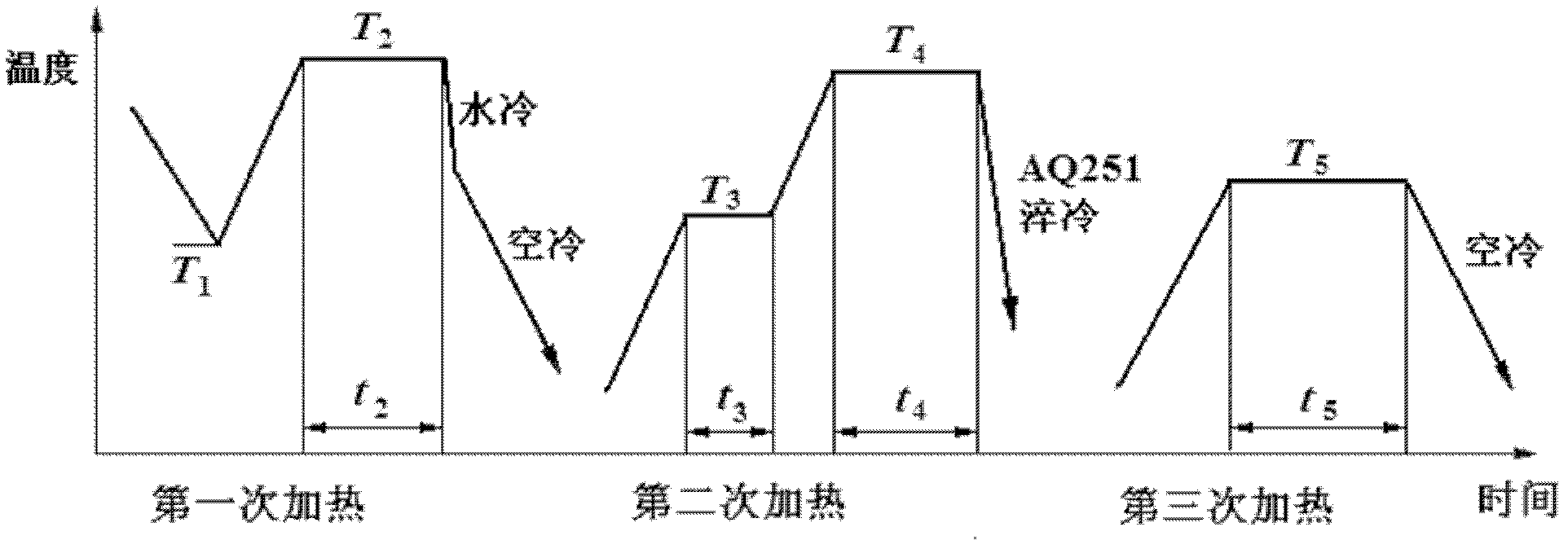

[0034] Such as figure 1 As shown, the diameter of the main body of a 35CrMo steel large-scale shaft forging is D=230mm. The large-scale shaft forging has two thickened sections (flanges), which separate the large-scale shaft forging into two end sections and a middle section; The length of the head section A=300mm, the length of the middle section C=14000mm, the length of the two thickened sections B=110mm; the diameter of the thickened section E=450mm; the middle section is the main body of a large shaft forging, and its diameter D=230mm. The total weight of the large shaft forging is 5 tons. The material components of 35CrMo steel except iron are all in the range of Table 1.

[0035] First of all, according to the requirements of the conventional forging process, one-fire forging is completed, that is, the standard steel ingot is forged into figure 1 Shaft forging shown with stock removals required for roughing and finishing. When the forging is just completed, the surfac...

Embodiment 2

[0047] Such as figure 1 As shown, a 35CrMo steel large-scale shaft forging has a main body diameter D=280mm, and the large-scale shaft forging has two thickened sections (flanges), which separate the large-scale shaft forging into two end sections and a middle section; The length of the head section A=200mm, the length of the middle section C=10000mm, the length of the two thickened sections B=120mm; the diameter of the thickened section E=500mm; the middle section is the main body of a large shaft forging, and its diameter D=280mm. The total weight of the large shaft forging is 5.36 tons. The material components of 35CrMo steel except iron are all in the range of Table 1.

[0048] First of all, according to the requirements of the conventional forging process, one-fire forging is completed, that is, the standard steel ingot is forged into figure 1 Shaft forging shown with stock removals required for roughing and finishing. When the forging is just completed, the surface te...

Embodiment 3

[0060] Such as figure 1 As shown, the main body diameter of a 35CrMo steel large-scale shaft forging is D=325mm. The large-scale shaft forging has two thickened sections, which divide the large-scale shaft forging into two end sections and a middle section; the length of the two end sections is A = 200mm, the length of the middle section C = 5300mm, the length of the two thickened sections B = 2650mm; the diameter of the thickened section E = 350mm; the middle section is the main body of a large shaft forging, and its diameter D = 325mm. The total weight of the large shaft forging is 7.67 tons. The material components of 35CrMo steel except iron are all in the range of Table 1.

[0061] First of all, according to the requirements of the conventional forging process, one-fire forging is completed, that is, the standard steel ingot is forged into figure 1 Shaft forging shown with stock removals required for roughing and finishing. When the forging is just completed, the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com