Weather-resistant heat-insulating PC/PMMA composite material and preparation method thereof

A composite material and weather-resistant technology, applied in the field of PC composite materials, can solve the problems of low impact strength and heat resistance, and achieve the effects of improving thermal conductivity, high light transmittance, and improving stability and light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

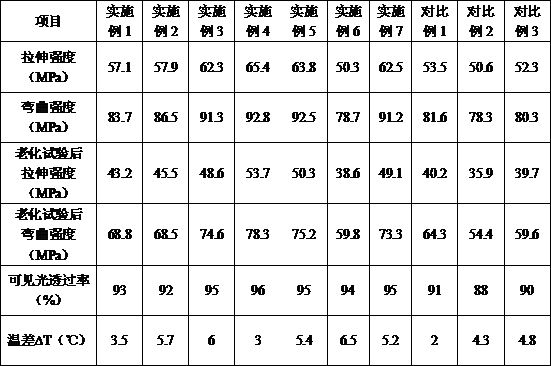

Examples

Embodiment 1

[0045] A PC / PMMA composite material with weather resistance and heat insulation performance, the preparation process is as follows: Weigh PC resin (60%), PMMA resin (15%), core-shell structure MBS toughening agent (1.5%), organic silicon core Shell structure toughening agent (0.5%), compatibilizer SMA (1%), compatibilizer EMA (1%), chain extender ADR-4468 (0.2%), titanate coupling agent TC-2 (3 %), antioxidant 1010 (0.12%), antioxidant 168 (0.08%), nano ATO (5%), graphene FGE (6%), boron nitride BN (6%), white oil (0.1%) ), silane polymer (0.2%), benzotriazole (0.1%), benzophenone (0.1%), carbon black (0.1%), dry, mix raw materials and additives at high speed for 20 minutes and put them into double The main feeding bin of the screw extruder, the main feeding screw speed is 25rpm, the feeding screw is fed into the main barrel of the extruder, the main machine speed is 150rpm, and the temperature of each heating section of the main barrel is controlled (from the feeding port to ...

Embodiment 2

[0047]A PC / PMMA composite material with weather resistance and heat insulation performance, the preparation process is as follows: Weigh PC resin (65%), PMMA resin (10%), core-shell structure MBS toughening agent (2%), organic silicon core Shell structure toughening agent (1%), compatibilizer SMA (2%), compatibilizer EMA (1%), chain extender ADR-4468 (0.3%), titanate coupling agent TC-2 (2 %), antioxidant 1010 (0.06%), antioxidant 168 (0.04%), nano-ATO (8%), graphene FGE (4%), boron nitride BN (4%), white oil (0.1%) ), silane polymer (0.2%), benzotriazole (0.1%), benzophenone (0.1%), carbon black (0.1%), dry, mix raw materials and additives at high speed for 20 minutes and put them into double The main feeding bin of the screw extruder, the main feeding screw speed is 25rpm, the feeding screw is fed into the main barrel of the extruder, the main machine speed is 150rpm, and the temperature of each heating section of the main barrel is controlled (from the feeding port to the e...

Embodiment 3

[0049] A PC / PMMA composite material with weather resistance and heat insulation performance, the preparation process is as follows: Weigh PC resin (65%), PMMA resin (12%), core-shell structure MBS toughening agent (1.5%), organic silicon core Shell structure toughening agent (0.5%), compatibilizer SMA (1.5%), compatibilizer EMA (1%), chain extender ADR-4468 (0.3%), titanate coupling agent TC-2 (3 %), antioxidant 1010 (0.2%), antioxidant 168 (0.1%), nano-ATO (8%), graphene FGE (2%), boron nitride BN (4%), white oil (0.1%) ), silane polymer (0.3%), benzotriazole (0.2%), benzophenone (0.2%), carbon black (0.1%), dry, mix the raw materials and additives at high speed for 20 minutes and put them into the double The main feeding bin of the screw extruder, the main feeding screw speed is 25rpm, the feeding screw is fed into the main barrel of the extruder, the main machine speed is 150rpm, and the temperature of each heating section of the main barrel is controlled (from the feeding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com