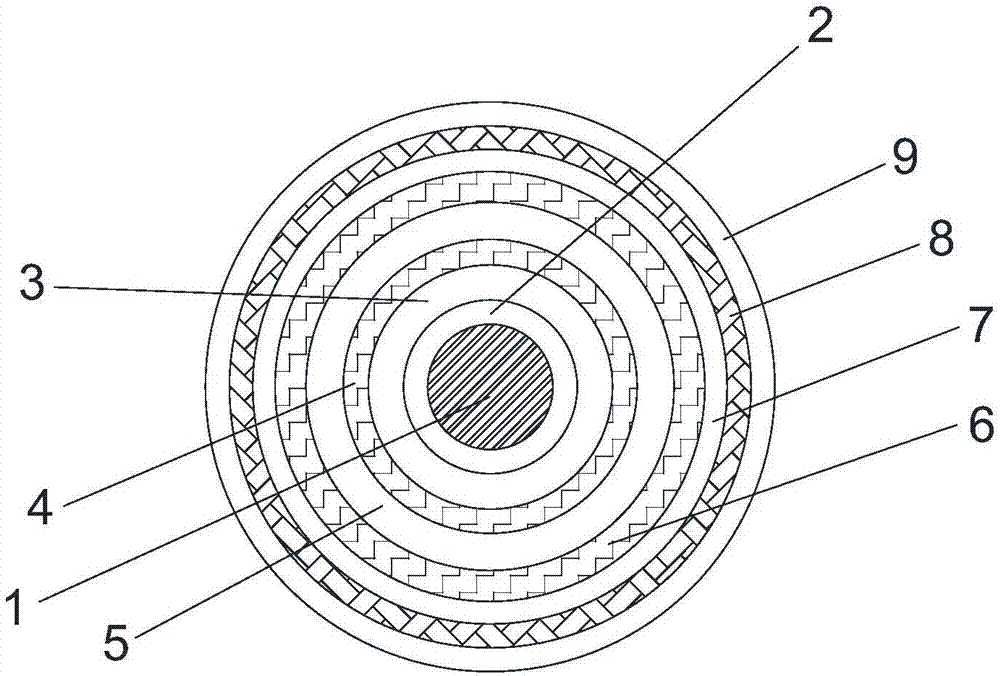

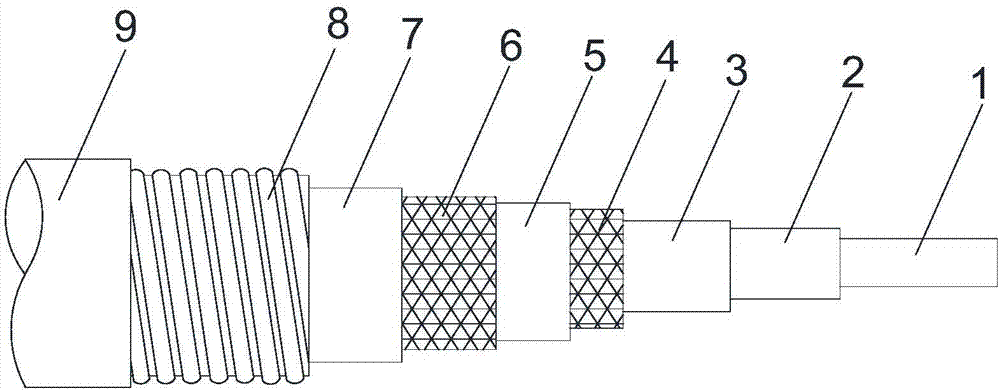

Coaxial cable for nuclear power station

A technology for coaxial cables and nuclear power plants, applied in the direction of coaxial cables, power cables, insulated cables, etc., can solve problems such as failure to meet environmental conditions and low-smoke and halogen-free requirements, achieve regular structure, improve sealing performance, and ensure The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] 1) Prepare thin-wall extruded polyether ether ketone modified cable insulation material

[0080] In parts by weight, raw materials of polyetheretherketone PEEK, a nucleophilic substitution product: 100 parts; composite antioxidant: 2 parts; US Dow Corning RM4-7081 silicone powder: 1 part; black masterbatch: 2 parts;

[0081] Composite antioxidant is pentaerythritol ester: dilauryl thiodipropionate: 2-(2'-hydroxyl-3', 5'-di-t-pentylphenyl) benzotriazole mass ratio is 1:1: 0.1 mixture;

[0082] Put it into a high-speed kneader and mix at room temperature for 3 minutes. The uniformly mixed materials are poured into a high-temperature twin-screw extruder and extruded at a temperature of 340°C. Water-cooled strands are cut into pellets, and the water temperature is controlled at 60°C.

[0083] 2) Preparation of radiation crosslinked polyolefin

[0084] In parts by weight, take polyethylene substrate: 100 parts; composite antioxidant: 2 parts; processing aid: 2 parts; black...

Embodiment 2

[0094] 1) Prepare thin-wall extruded polyether ether ketone modified cable insulation material

[0095] In parts by weight, raw materials of polyetheretherketone PEEK, a nucleophilic substitution product: 100 parts; composite antioxidant: 4 parts; US Dow Corning RM4-7105 silicone powder: 3 parts; black masterbatch: 0.1 part;

[0096] The composite antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: dioctadecyl thiodipropionate: 2-(2'-hydroxy-5'- The mass ratio of tertoctylphenyl) benzotriazole is the mixture of 1:2:0.5;

[0097] Put it into a high-speed kneader and mix at room temperature for 5 minutes. The uniformly mixed materials are poured into a high-temperature twin-screw extruder and extruded at a temperature of 390°C. Water-cooled strands are cut into pellets, and the water temperature is controlled at 40°C.

[0098] 2) Preparation of radiation crosslinked polyolefin

[0099] In parts by weight, take polyethylene substrate: 100 parts; composite...

Embodiment 3

[0109] 1) Prepare thin-wall extruded polyether ether ketone modified cable insulation material

[0110] In parts by weight, raw materials of polyetheretherketone PEEK, a nucleophilic substitution product: 100 parts; composite antioxidant: 2 parts; US Dow Corning RM4-7051 silicone powder: 3 parts; black masterbatch: 0.5 parts;

[0111] The composite antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: dioctadecyl thiodipropionate: 2-(2'-hydroxyl-3', The mass ratio of 5'-bis(a,a-dimethylbenzyl)phenyl)benzotriazole is 1:3:0.3 mixture;

[0112] Put it into a high-speed kneader and mix at room temperature for 4 minutes. The uniformly mixed materials are poured into a high-temperature twin-screw extruder and extruded at a temperature of 370°C. The strands are water-cooled and pelletized, and the water temperature is controlled at 50°C.

[0113] 2) Preparation of radiation crosslinked polyolefin

[0114] In parts by weight, take polyethylene substrate: 100 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com