A method for making in-situ 3D printed custom masks based on facial feature extraction

A technology of facial features and 3D printing, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems such as inability to meet individual needs, long 3D printing production cycle, rough surface of plastic-absorbing products, etc., to shorten production Period, ensuring mechanical performance requirements, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

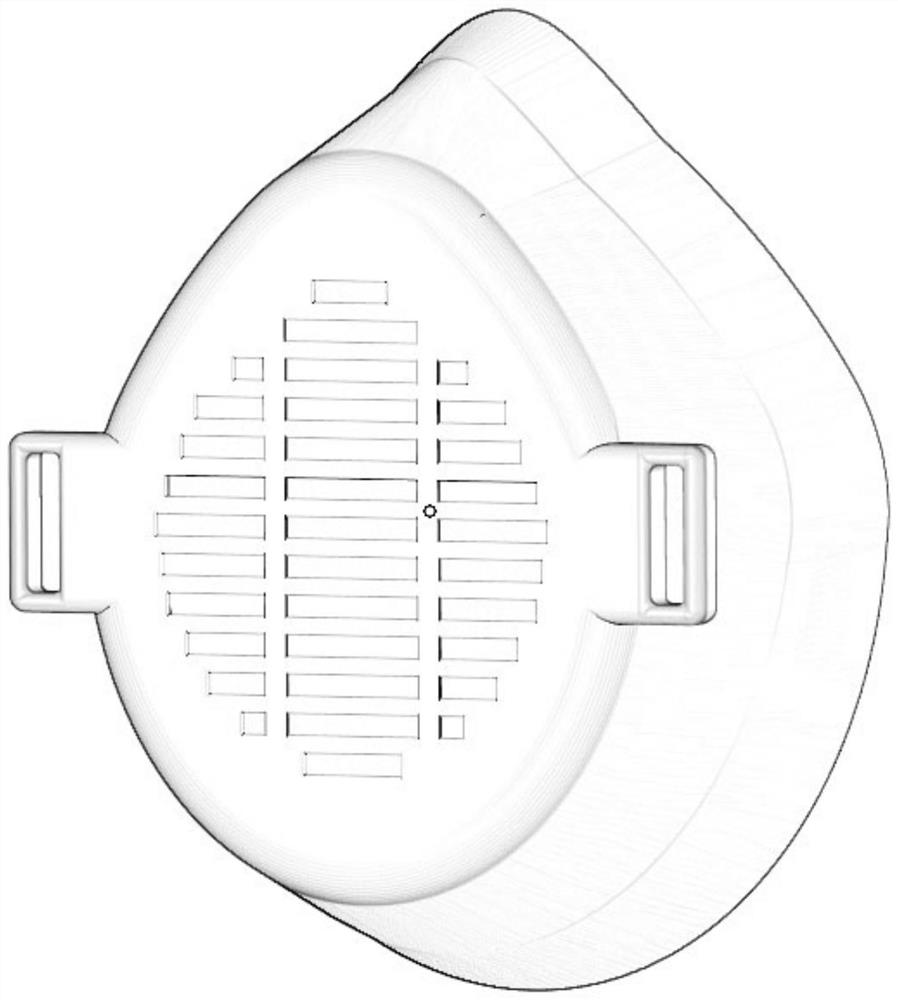

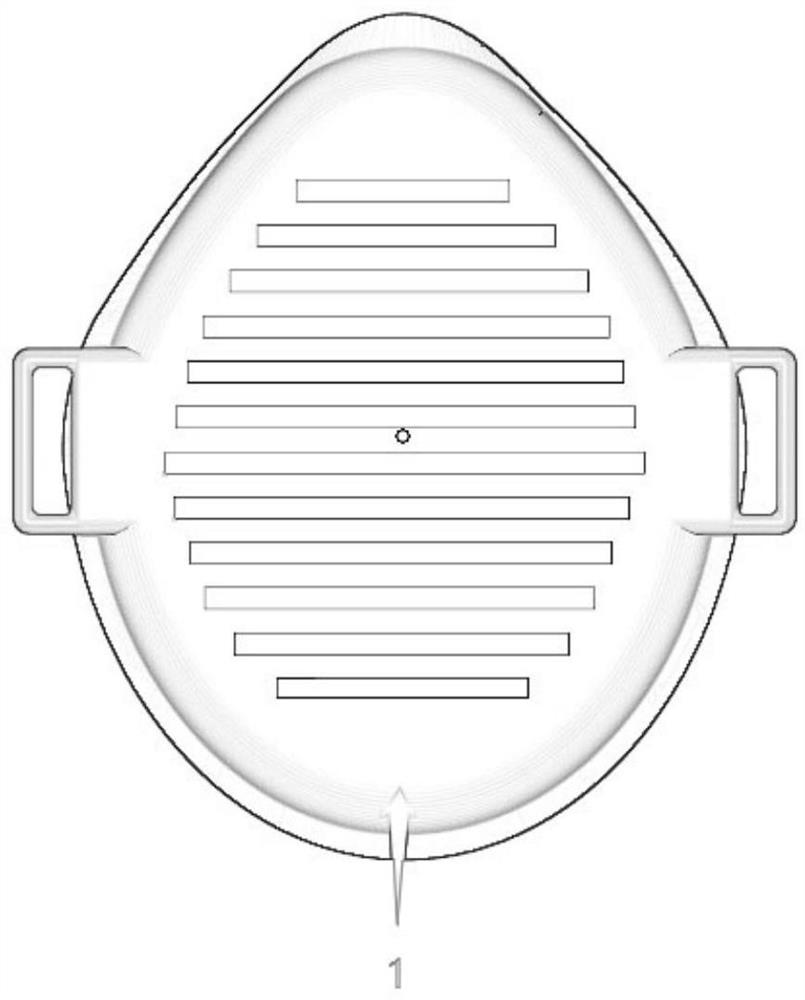

[0030] 1. Use Solidworks to design the mask structure, and increase the through-hole structure of the array on the surface of the main structure of the mask. Design baffle and filter element interlayer.

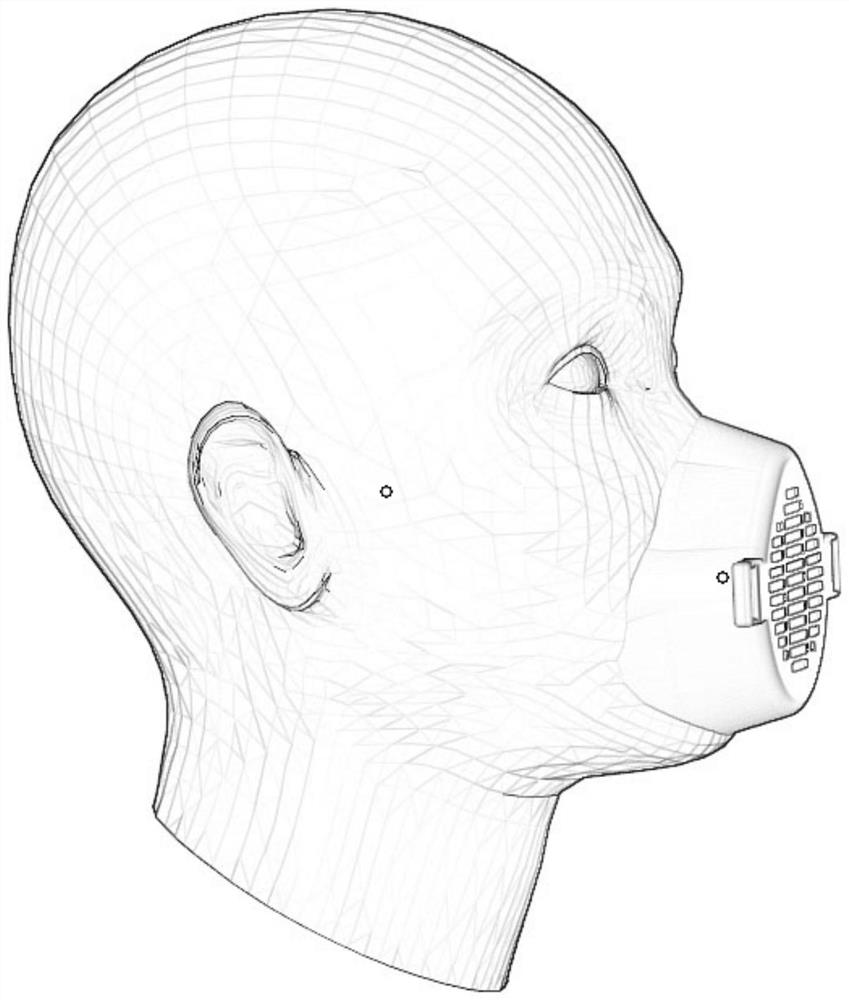

[0031] 2. Import the optimized mask and face model into Magics to obtain a customized mask based on the facial features of the face. The mask is divided into the part outside the mask at a position of 2cm perpendicular to the face direction and the part of the mask within 2cm perpendicular to the face direction, that is, close to the face, and the part outside the mask at a position perpendicular to the face direction of 2cm is produced by mold processing . The part of the mask that is close to the face within 2cm perpendicular to the face direction is reprocessed by FDM in-situ 3D printing, and finally a complete mask is generated.

[0032] 3. Use ANSYS to perform finite element simulation on the preliminary designed model

[0033] Static mechanics and crash simulation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com