Low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel and production method thereof

A production method and dew point corrosion technology, which is applied in the field of metallurgy, can solve problems such as surface defects of unsuitable sulfuric acid dew point corrosion resistant steel, and achieve the effects of avoiding surface defects, reducing residues, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

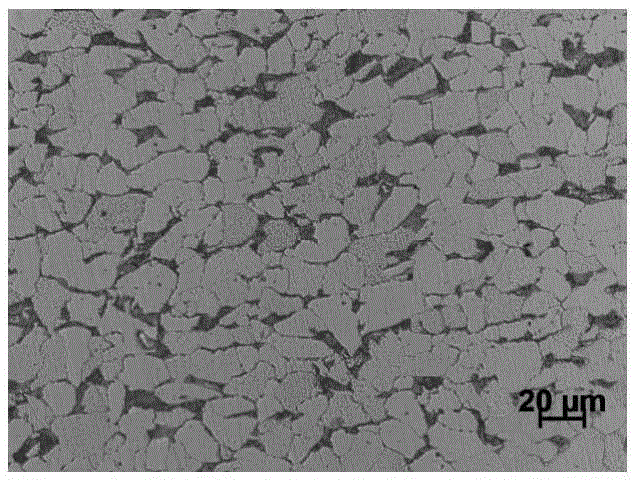

Image

Examples

Embodiment 1

[0020] This embodiment provides a method for producing 8mm low-cost, Nb-free, thin-gauge sulfuric acid dew point corrosion-resistant steel;

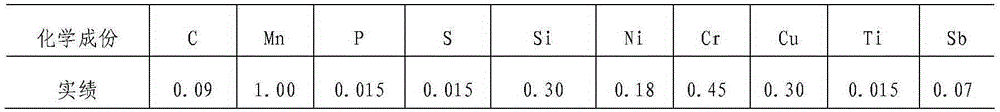

[0021] The chemical composition of the steel is shown in Table 1

[0022] Table 18mm steel plate composition performance (%)

[0023]

[0024] Main process steps:

[0025] Rolling: The temperature in the heating section of the heating furnace is 1219°C, the temperature in the soaking section is 1206°C, 3 passes for rough rolling and descaling (1st pass, turning pass, last pass) and 1-2 passes for finishing rolling and descaling ( 1st pass, 3rd or 4th pass), the initial rolling temperature of the first stage of rough rolling is 1088°C, the final rolling temperature is 853°C, the thickness of the intermediate billet is greater than or equal to 3 times the thickness of the finished product, and the cooling is controlled: the water inlet temperature is 753°C, and the reddening temperature 626°C, cooling bed: shorten the residence time i...

Embodiment 2

[0027] This embodiment provides a 10mm low-cost Nb-free thin-gauge sulfuric acid dew point corrosion-resistant steel production method

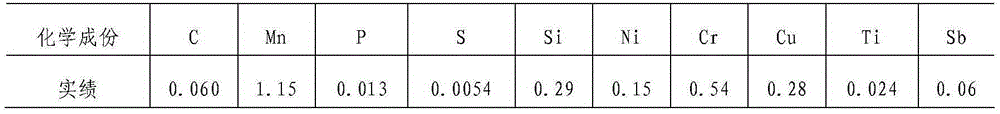

[0028] The chemical composition of the steel is shown in Table 2

[0029] Table 210mm steel plate composition performance (%)

[0030]

[0031] Main process steps:

[0032] Rolling: heating furnace heating section temperature 1220°C, soaking section temperature 1220°C, rough rolling descaling 3 passes (1st pass, turning pass, last 1 pass) finish rolling descaling pass 1-2 ( 1st pass, 3rd or 4th pass), the starting temperature of rough rolling stage I is 1100°C, the final rolling temperature is 834°C, and the thickness of the intermediate billet is greater than or equal to 3 times the thickness of the finished product.

[0033] Controlled cooling: water inlet temperature is 773°C, red return temperature is 601°C. Cooling bed: shorten the residence time in the cooling bed, and the steel plate can be rolled off the production line quickly....

Embodiment 3

[0035] This embodiment provides a 12mm low-cost Nb-free thin specification sulfuric acid dew point corrosion-resistant steel production method

[0036] The chemical composition of the steel is shown in Table 3

[0037] Table 312mm steel plate composition performance (%)

[0038]

[0039] Main process steps:

[0040] Rolling: The temperature in the heating section of the heating furnace is 1232°C, the temperature in the soaking section is 1210°C, 3 passes for rough rolling and descaling (1st pass, turning pass, last 1 pass) and 1-2 passes for finishing rolling and descaling ( 1st pass, 3rd or 4th pass), the starting temperature of rough rolling stage I is 1112°C, the final rolling temperature is 840°C, the thickness of the intermediate billet is greater than or equal to 3 times the thickness of the finished product, and the cooling is controlled: the water inlet temperature is 772°C, and the reddening temperature 612°C, cooling bed: shorten the residence time in the coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com