Thermal treatment method for carrying out carburizing and quenching on low-carbon alloy steel workpiece

A technology of low carbon alloy steel and heat treatment method, applied in metal material coating process, coating, solid-state diffusion coating and other directions, can solve the problems of reducing the surface hardness of the product, increasing the deformation of the product, and a large amount of carbides in the product. The effect of reducing carbide and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

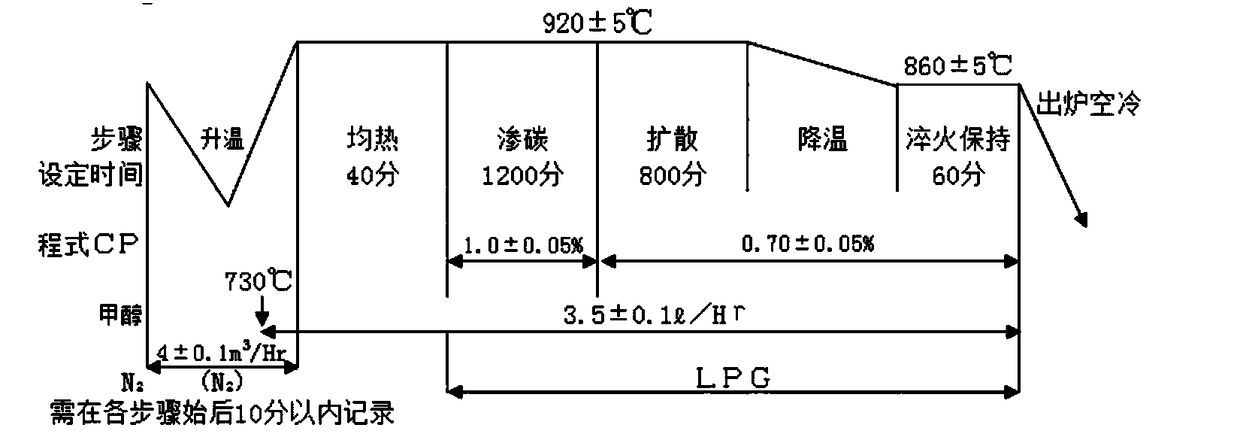

[0042] Carburizing and quenching the large internal gear ring produced by a certain company. The material is 18CrNiMo. After the preliminary heat treatment and rough machining of the company, the product is first cleaned on the surface. After cleaning the product, the product is not The surface of the working face shall be treated with anti-seepage treatment. Carburizing process such as figure 1 As shown, the equipment is processed in a well-type carburizing furnace. The carburizing temperature is 920±5°C. First, after heating to temperature, keep it warm for 40 minutes to make the overall temperature of the product uniform. Then carburizing treatment is carried out at 920°C±5°C, the time is set to 1200 minutes, the carbon potential needs to be adjusted to 1.0±0.05%, and then diffusion treatment is carried out at the same temperature, and the setting time is 800 minutes (the time ratio of carburization and diffusion is 3:2), the carbon potential needs to be adjusted to 0.7±0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com