900Mpa heavy-gauge and high-toughness hot rolled steel strip and preparation method thereof

A thick-gauge, high-toughness technology, applied in the field of structural steel, can solve problems such as low cost and high performance, increased cost of steel plate alloys, and low low-temperature toughness, so as to save off-line tempering process, reduce production cost, and achieve good The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 900

[0040] The technical process of the 900MPa grade thick gauge high toughness hot-rolled steel strip of the embodiment of the present invention is:

[0041] Converter smelting→LF→(vacuum circulation degassing refining furnace) RH→slab→slab heating→hot rolling rough rolling→hot rolling finish rolling→cooling→coiling, in which casting slab heating: 1180~1220℃, soaking time 1h, the starting temperature of rough rolling is 1080-1150°C, the temperature of finishing rolling is 980-1070°C, and an intermediate billet with a thickness of 48-58mm is obtained. Then carry out 5 to 7 passes of finishing rolling on the intermediate billet. The starting temperature of finishing rolling is 950-1000°C, the temperature of finishing rolling is 850-880°C, and the reduction of each pass of finishing rolling is controlled at 15-40%. The thickness of the rear steel strip is 12-20mm. After finish rolling, the steel strip is cooled to 300°C at a speed of 15-20°C / s for coiling.

[0042] Table 1 Unit: w...

Embodiment 2

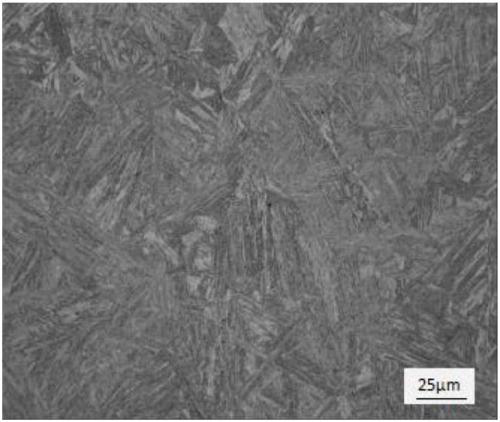

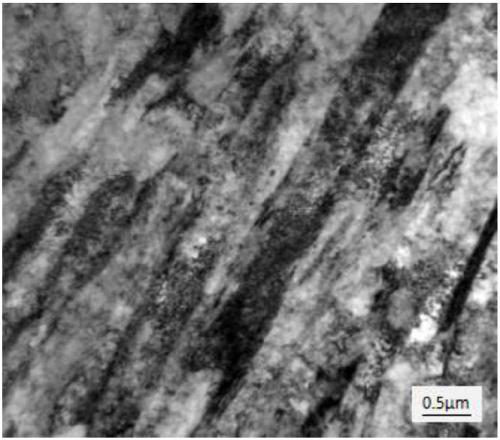

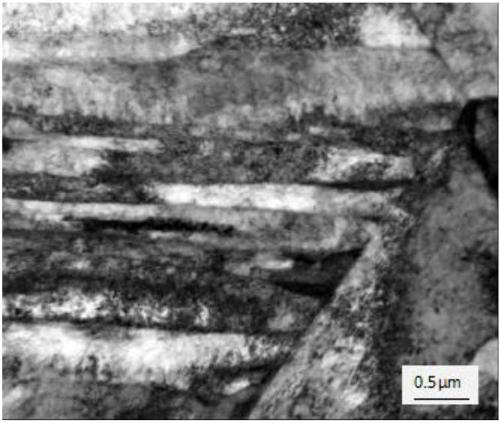

[0051] The typical transmission electron microscope photo of the 900MPa level thick gauge high toughness hot-rolled steel strip steel plate prepared in embodiment 2 is shown in image 3 . The typical impact test curve of the 900MPa level thick gauge high toughness hot-rolled steel strip plate prepared in embodiment 1 is shown in Figure 4 ,From Figure 4 It can be seen that the impact energy of the prepared 900MPa-grade thick gauge high-toughness hot-rolled steel strip at -40°C is ≥180J.

Embodiment 1

[0052] The typical stress-strain curve of the 900MPa grade thick gauge high-toughness hot-rolled steel strip steel plate prepared in embodiment 1 is shown in Figure 5 , it can be concluded that the yield strength of the prepared 900MPa-grade thick gauge high-toughness hot-rolled steel strip is 950MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com