PC/ABS alloy material and application thereof

An alloy and composition technology, applied in the field of PC/ABS alloy materials, can solve the problems of halogen-based flame retardants that are not environmentally friendly, poor in mechanical properties and weather resistance, and achieve the guarantee of weather resistance, improved mechanical properties, and improved alloy properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

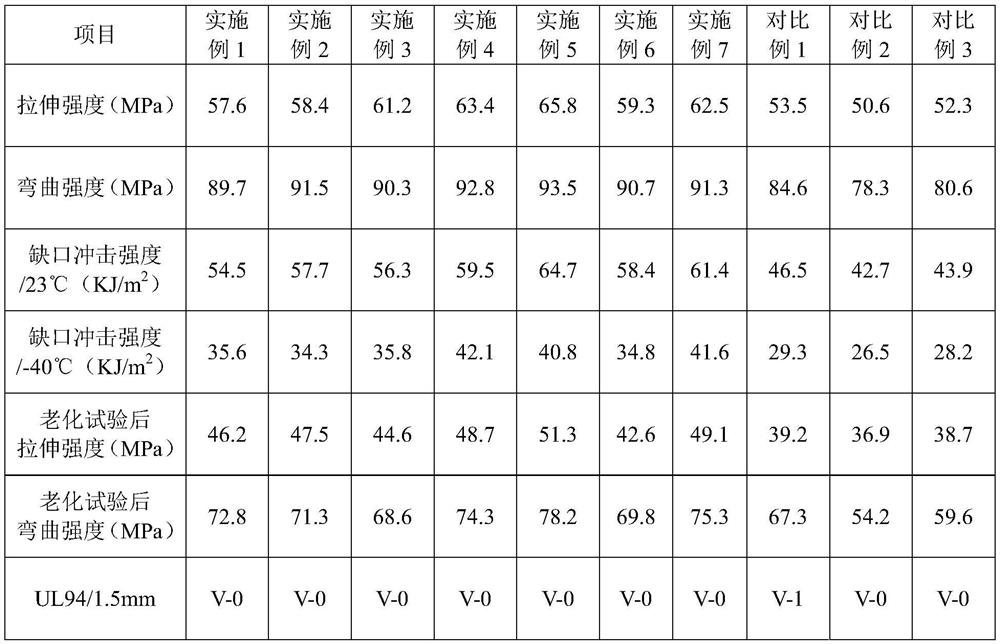

Embodiment 1

[0055] This example is to illustrate the PC / ABS alloy material prepared by using the PC / ABS alloy composition of the present invention.

[0056] The preparation process of the PC / ABS alloy material is as follows:

[0057] (1) prepare alloy composition, take the gross weight of this alloy composition as a basis, the content of the phosgene method PC resin that melt index is 10g / 10min is 45% by weight, and melt index is the transesterification method PC resin of 22g / 10min The content of is 20% by weight, after calculation, the weight ratio of the two is 2.25:1;

[0058] The content of ABS resin is 20% by weight, wherein ABS is prepared from 35% by weight of acrylonitrile, 15% by weight of butadiene and 50% by weight of styrene;

[0059] Toughening agent: the content of the core-shell structure MBS toughening agent is 3% by weight, and the content of the organosilicon core-shell structure toughening agent is 1% by weight;

[0060] Compatibilizer: the content of reactive high-ef...

Embodiment 2

[0070] This example is to illustrate the PC / ABS alloy material prepared by using the PC / ABS alloy composition of the present invention.

[0071] Prepare PC / ABS alloy material according to the method identical with embodiment 1, difference is:

[0072] The content of the alloy composition is different, specifically:

[0073] (1) prepare alloy composition, take the gross weight of this alloy composition as a basis, the content of the phosgene method PC resin that melt index is 10g / 10min is 50% by weight, and melt index is the transesterification method PC resin of 15g / 10min The content of is 20% by weight, and the weight ratio of the two is calculated to be 2.5:1; and;

[0074] The content of the ABS resin is 15% by weight, wherein the ABS is prepared from 30% by weight of acrylonitrile, 15% by weight of butadiene and 55% by weight of styrene;

[0075] Toughening agent: the content of core-shell structure MBS toughening agent is 2.5% by weight, and the content of silicone core...

Embodiment 3

[0085] This example is to illustrate the PC / ABS alloy material prepared by using the PC / ABS alloy composition of the present invention.

[0086] Prepare PC / ABS alloy material according to the method identical with embodiment 1, difference is:

[0087] The content of the alloy composition is different, specifically:

[0088] (1) prepare alloy composition, take the gross weight of this alloy composition as a basis, the content of the phosgene method PC resin that melt index is 13g / 10min is 60% by weight, and melt index is the transesterification method PC resin of 22g / 10min The content of is 20% by weight, and the weight ratio of the two is calculated to be 3:1; and;

[0089] The content of the ABS resin is 10% by weight, wherein the ABS is prepared from 40% by weight of acrylonitrile, 15% by weight of butadiene and 45% by weight of styrene;

[0090] Toughening agent: the content of the core-shell structure MBS toughening agent is 2% by weight, and the content of the silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com