Manufacturing technology for natural aerodynamic cylinder

A manufacturing process and power cylinder technology, which is applied in the field of manufacturing process of natural gas power cylinder block, can solve the problems of unreasonable proportion of resin sand, low surface finish, sand inclusion and expansion of sand, etc. The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

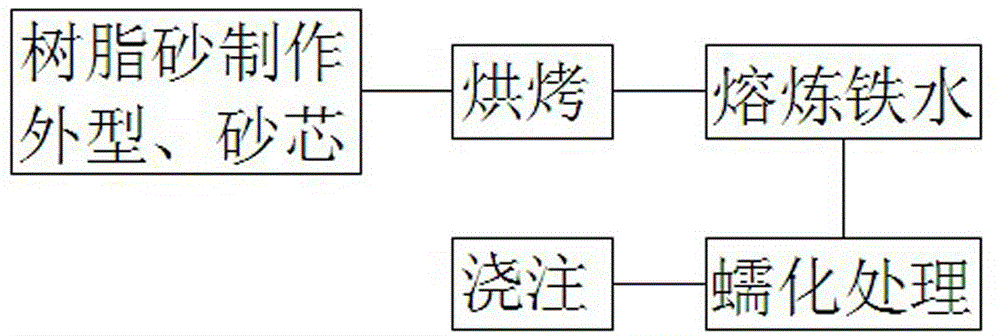

[0113] The manufacturing process of the natural gas power cylinder block of the present embodiment comprises the following steps;

[0114] (1) Use raw sand with a particle size of 40 mesh, furan resin accounting for 1.2% of the original sand weight, and 0.36% p-toluenesulfonic acid mixed resin sand to make the shape and sand core; after making the shape, take it out Molding, shaping and brushing zircon powder paint twice; after making sand cores, carry out mold taking, shaping and brushing zircon powder first and tellurium powder paint again.

[0115] (2) Put the finished shape and sand core into the drying furnace, heat the temperature to 210°C, keep it warm for 4.5 hours, and then adjust the temperature to 95°C for heat preservation treatment until the box is closed.

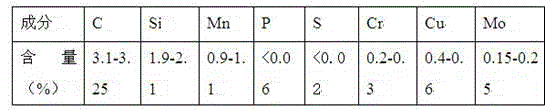

[0116] (3) Smelting molten iron:

[0117] The weight percentage composition of molten iron is: carbon 3.55-3.65%, silicon 1.6-1.8%, manganese 0.5-0.6%, phosphorus 0-0.06%, sulfur 0-0.02%, chromium 0.15-0.25%,...

Embodiment 2

[0130] The manufacturing process of the natural gas power cylinder block of the present embodiment comprises the following steps;

[0131] (1) Use raw sand with a particle size of 70 mesh, furan resin accounting for 1.5% of the weight of the original sand, and resin sand accounting for 1.05% of the weight of the original sand to be mixed with p-toluenesulfonic acid to make the shape and sand core; after making the shape, take it out Molding, shaping and brushing zircon powder paint twice; after making sand cores, carry out mold taking, shaping and brushing zircon powder first and tellurium powder paint again.

[0132] (2) Put the finished shape and sand core into the drying furnace, heat the temperature to 230°C, keep it warm for 3.5 hours, and then adjust the temperature to 105°C for heat preservation treatment until the box is closed.

[0133] (3) Smelting molten iron:

[0134] The weight percentage composition of molten iron is: carbon 3.55-3.65%, silicon 1.6-1.8%, mangane...

Embodiment 3

[0147] The manufacturing process of the natural gas power cylinder block of the present embodiment comprises the following steps;

[0148] (1) Use raw sand with a particle size of 50 mesh, furan resin accounting for 1.4% of the weight of the original sand, and resin sand accounting for 0.5% of the weight of the original sand to be mixed with p-toluenesulfonic acid to make the shape and sand core; after making the shape, take it out Molding, shaping and brushing zircon powder paint twice; after making sand cores, carry out mold taking, shaping and brushing zircon powder first and tellurium powder paint again.

[0149] (2) Put the finished shape and sand core into the drying furnace, heat the temperature to 220°C, keep it warm for 4 hours, then adjust the temperature to 100°C for heat preservation treatment, until the box is closed.

[0150] (3) Smelting molten iron:

[0151] The weight percentage composition of molten iron is: carbon 3.55-3.65%, silicon 1.6-1.8%, manganese 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com