BIM based production management system for galvanized sheet angle iron flange air duct product

A technology of galvanized sheet and angle iron, applied in general control system, control/adjustment system, comprehensive factory control, etc., can solve problems such as easy mistakes, reduce project cost, meet the needs of modern projects, and have a beautiful and clean appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

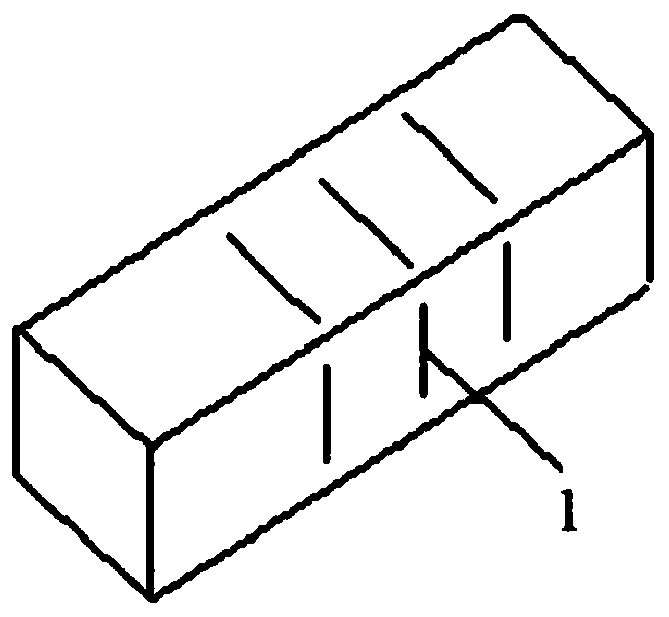

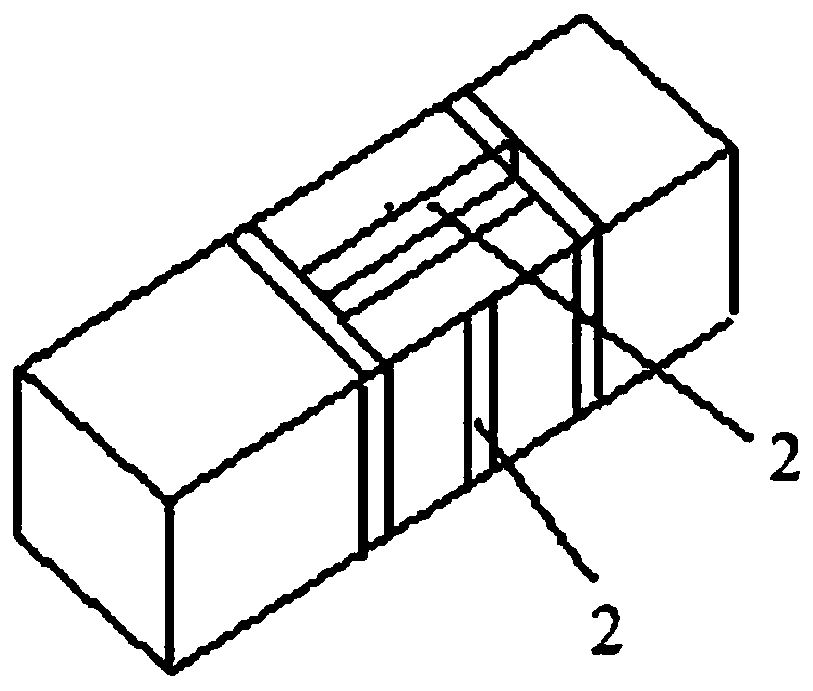

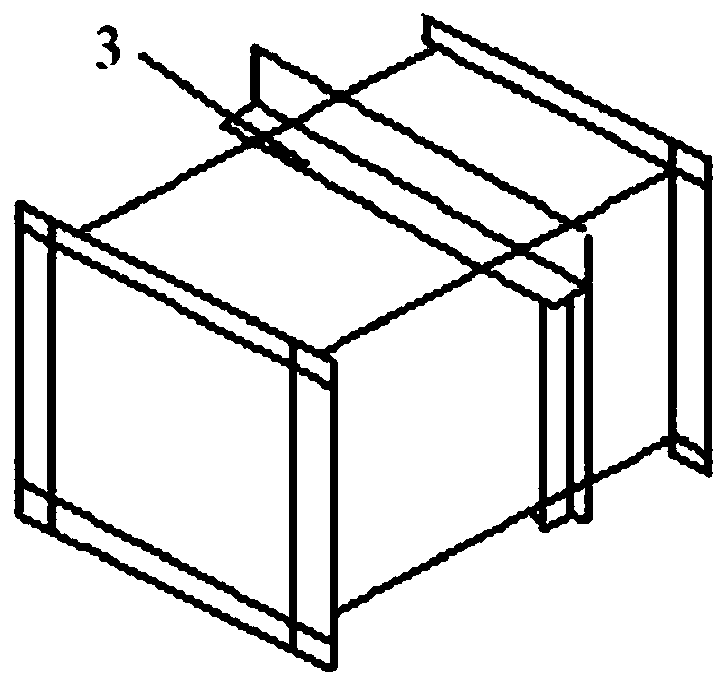

[0080] Galvanized sheet angle iron flange air duct can be used in industrial plants, civil buildings, commercial buildings, rail transit, mainly used in ventilation systems with high wind pressure, equipment exhaust, and smoke exhaust systems. For example, it is used for equipment exhaust and smoke exhaust systems in industrial plants; it is used for roof fan exhaust and smoke exhaust systems in commercial buildings or civil buildings; it is used for new exhaust systems in rail transit. The inner wall of the angle iron flange air duct is smooth, the resistance is small, the ventilation loss is small, the energy consumption is reduced, the operating cost is saved, the airtightness and airtightness are good, the compressive strength is high, and the good fire performance is also the angle iron flange air duct Reasons for wide application in engineering. The production management method of galvanized sheet angle iron flange air duct products based on BIM, the specific preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com