Patents

Literature

393results about "Hand-operated cutting devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

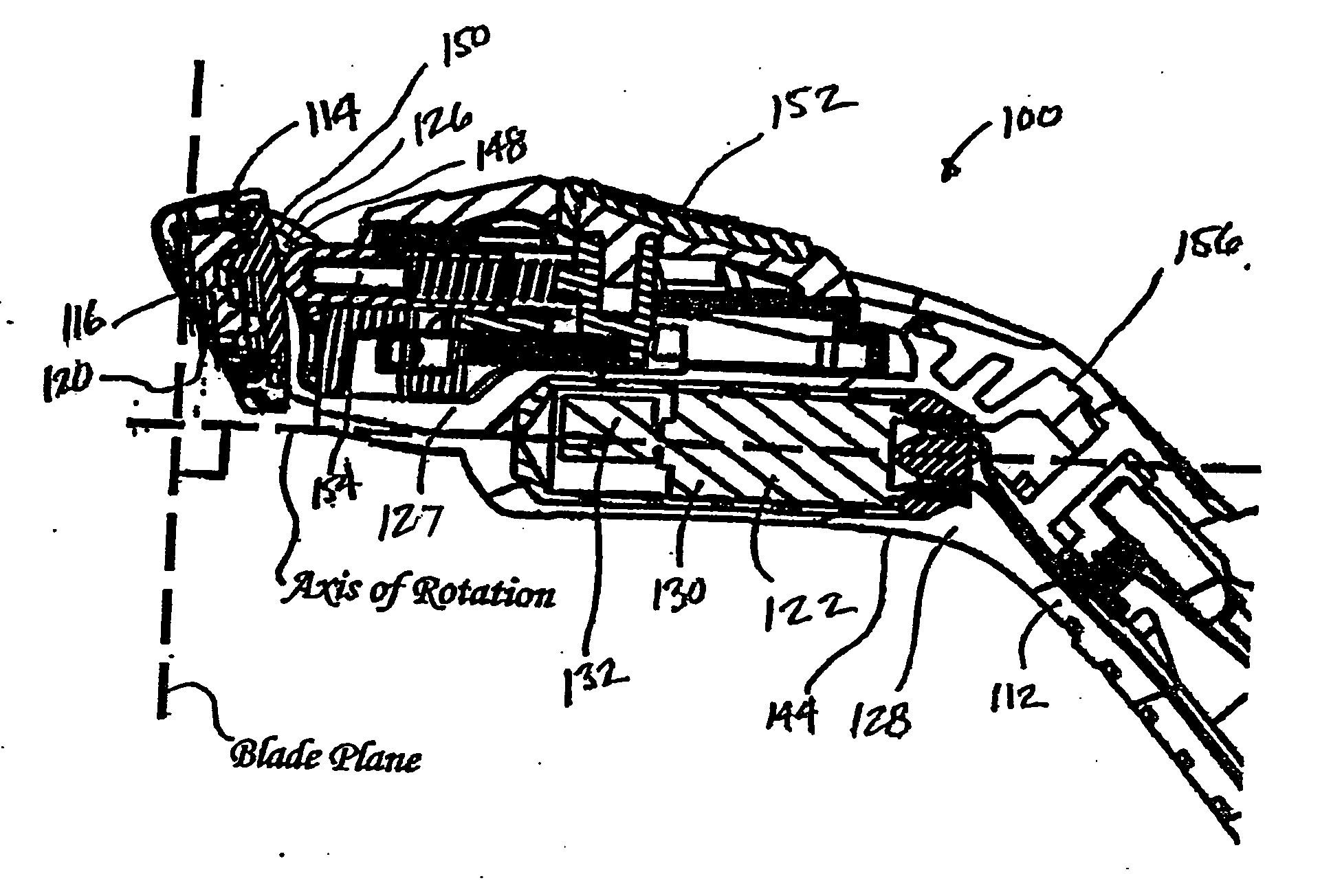

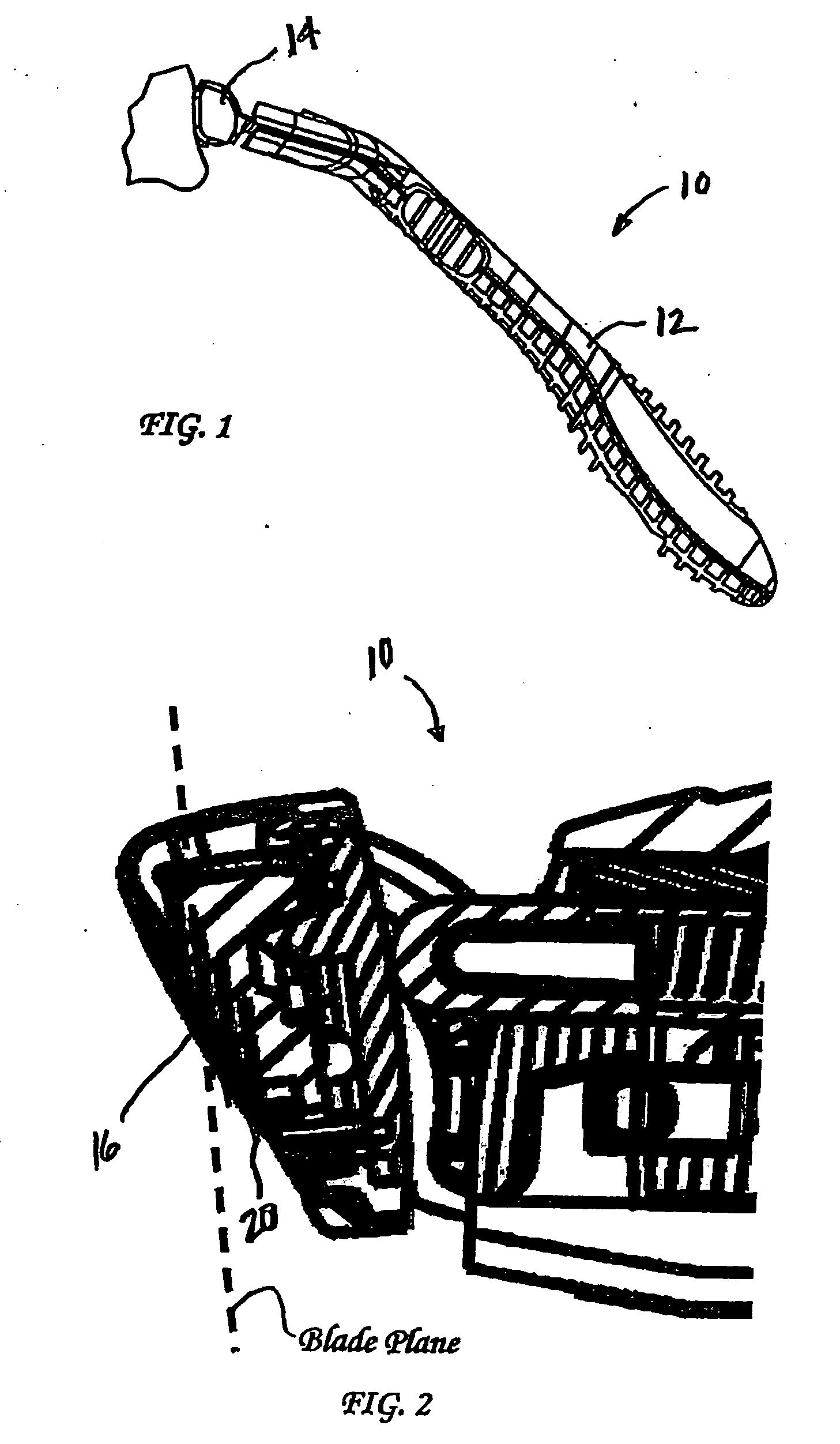

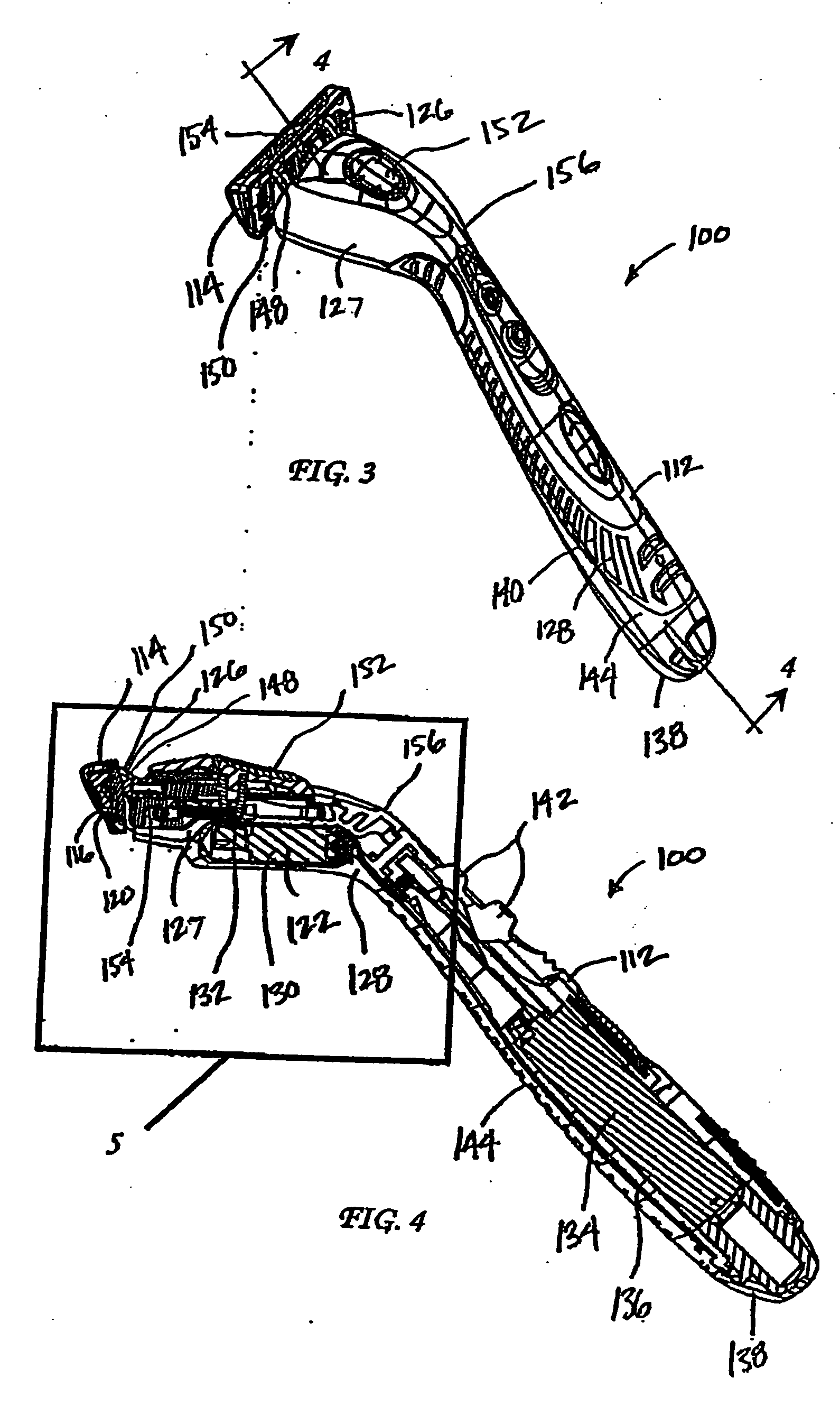

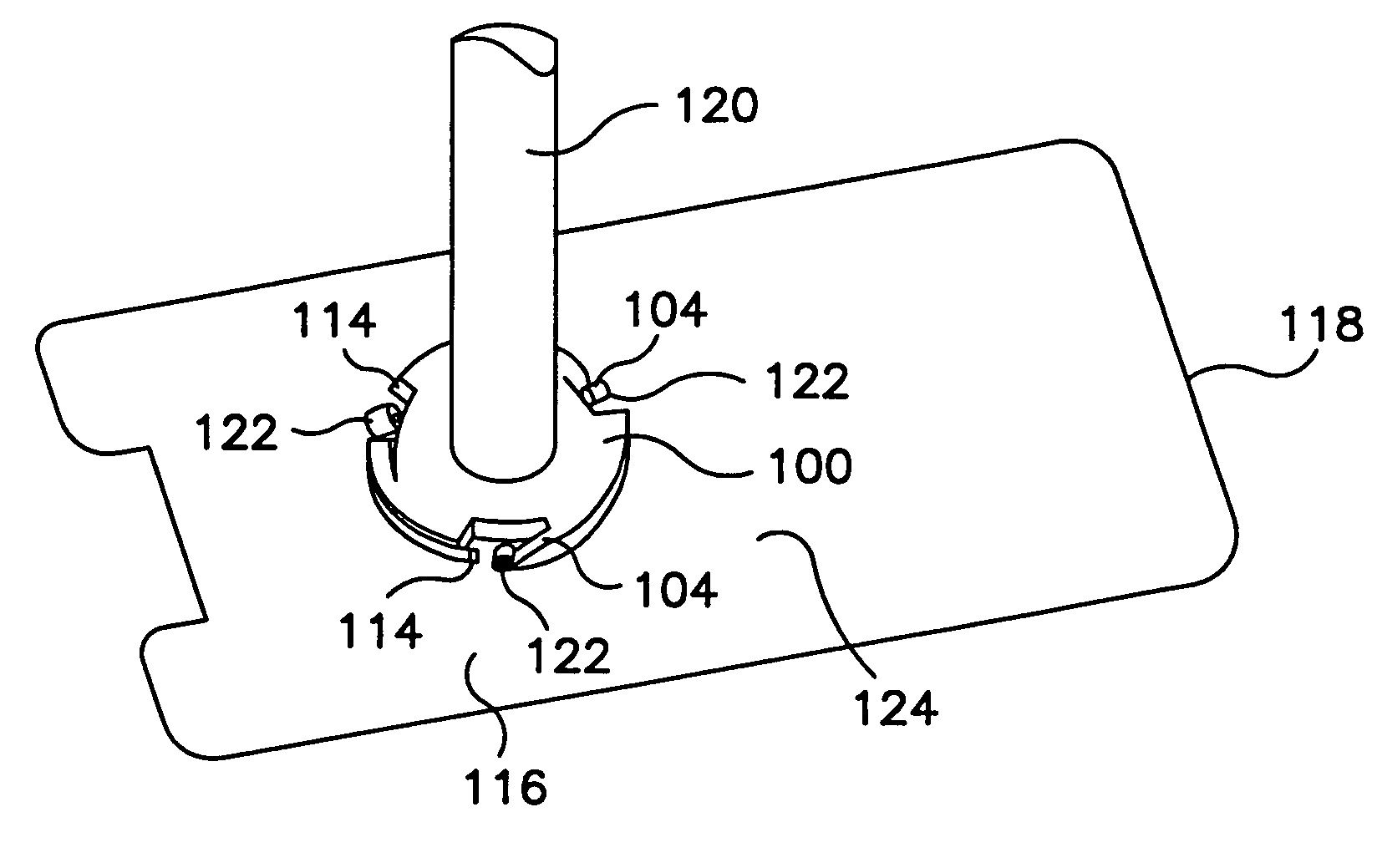

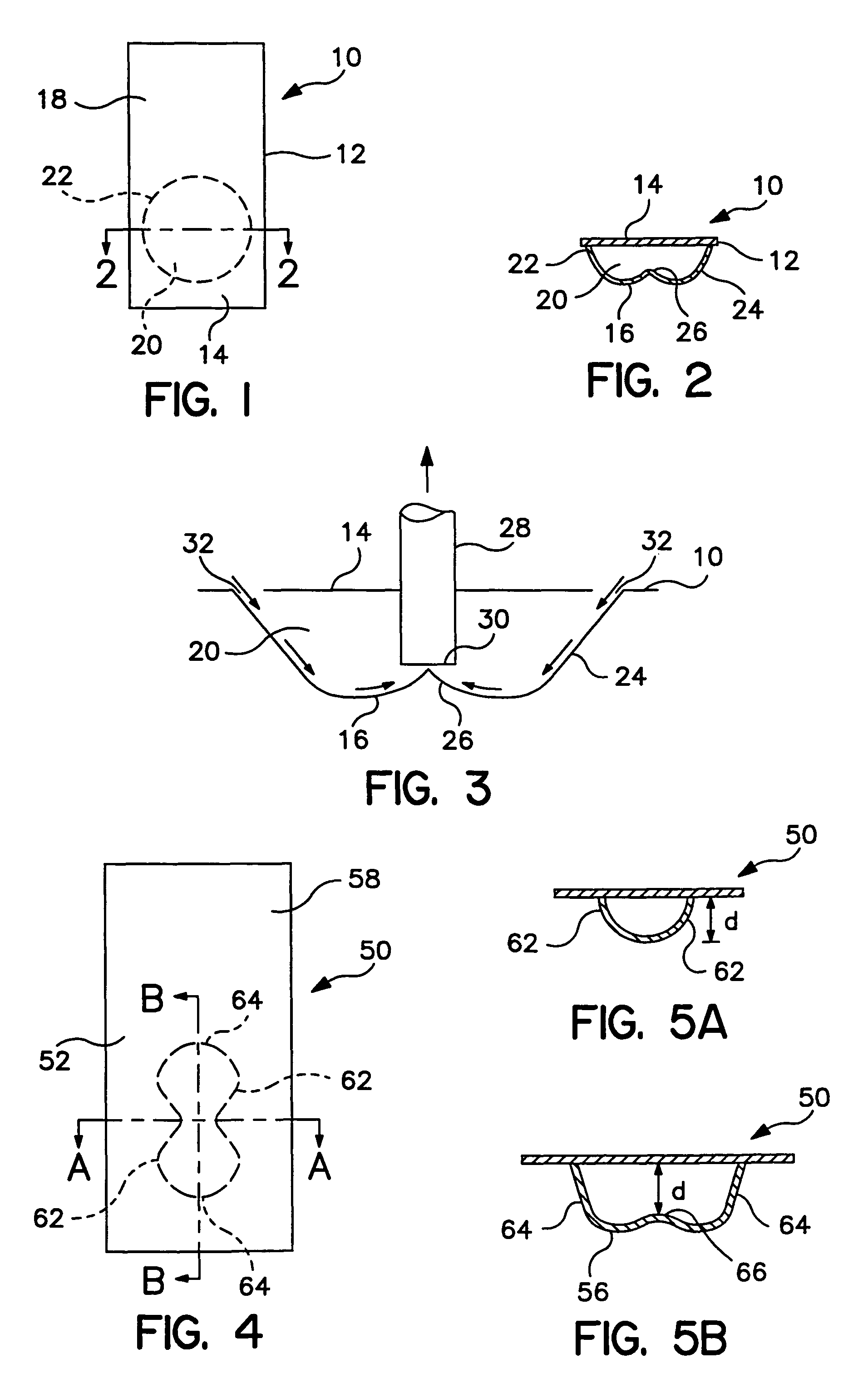

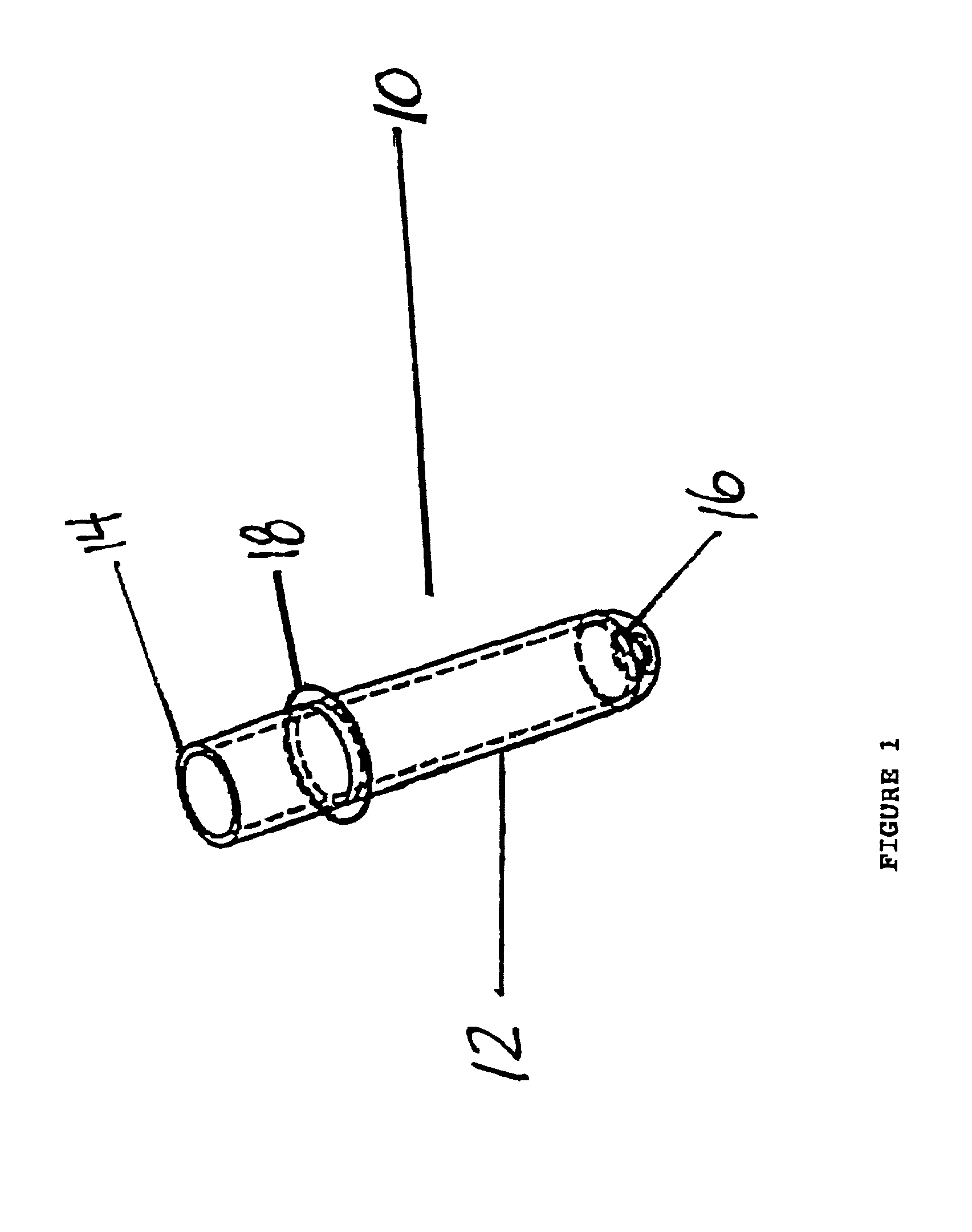

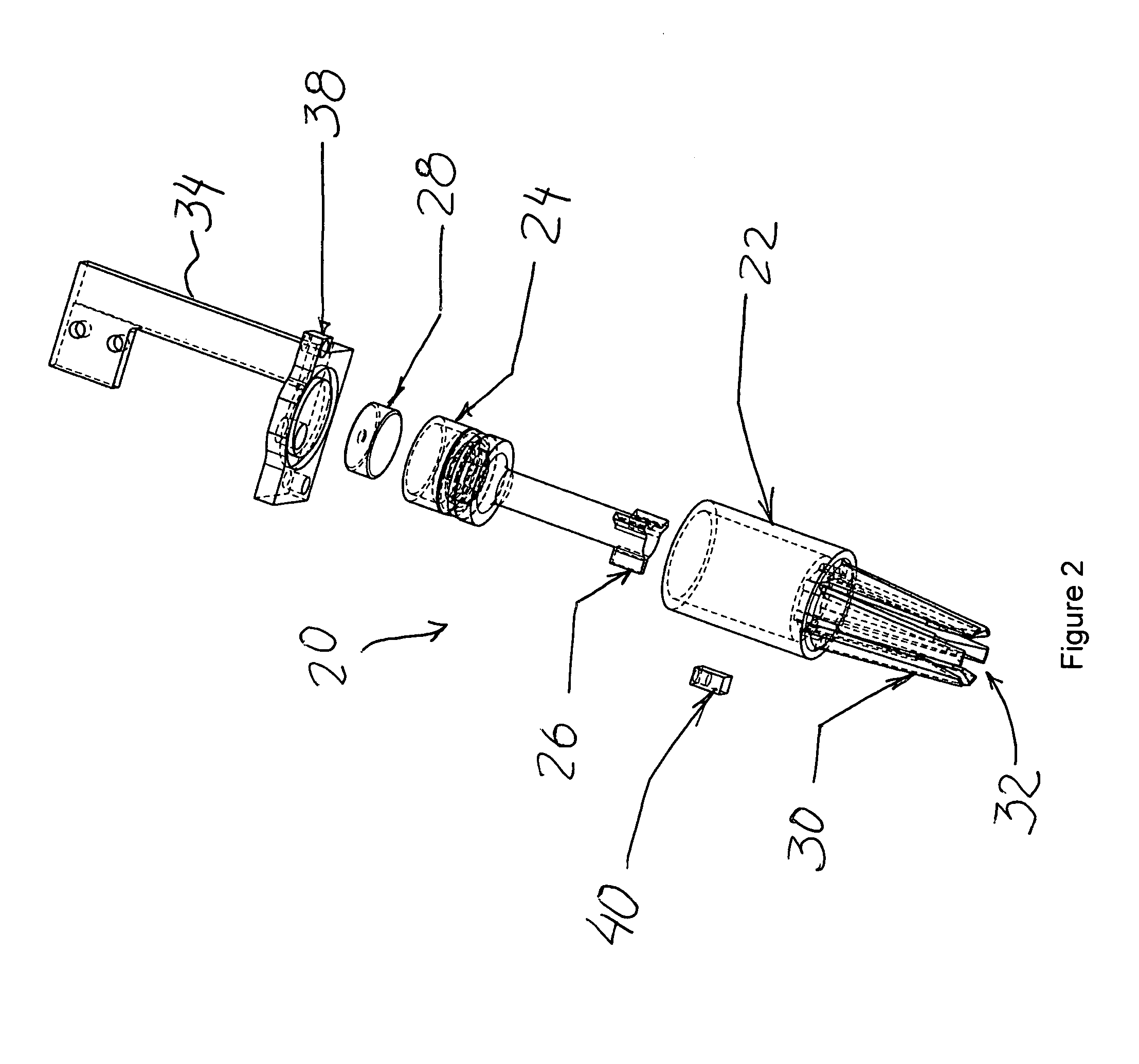

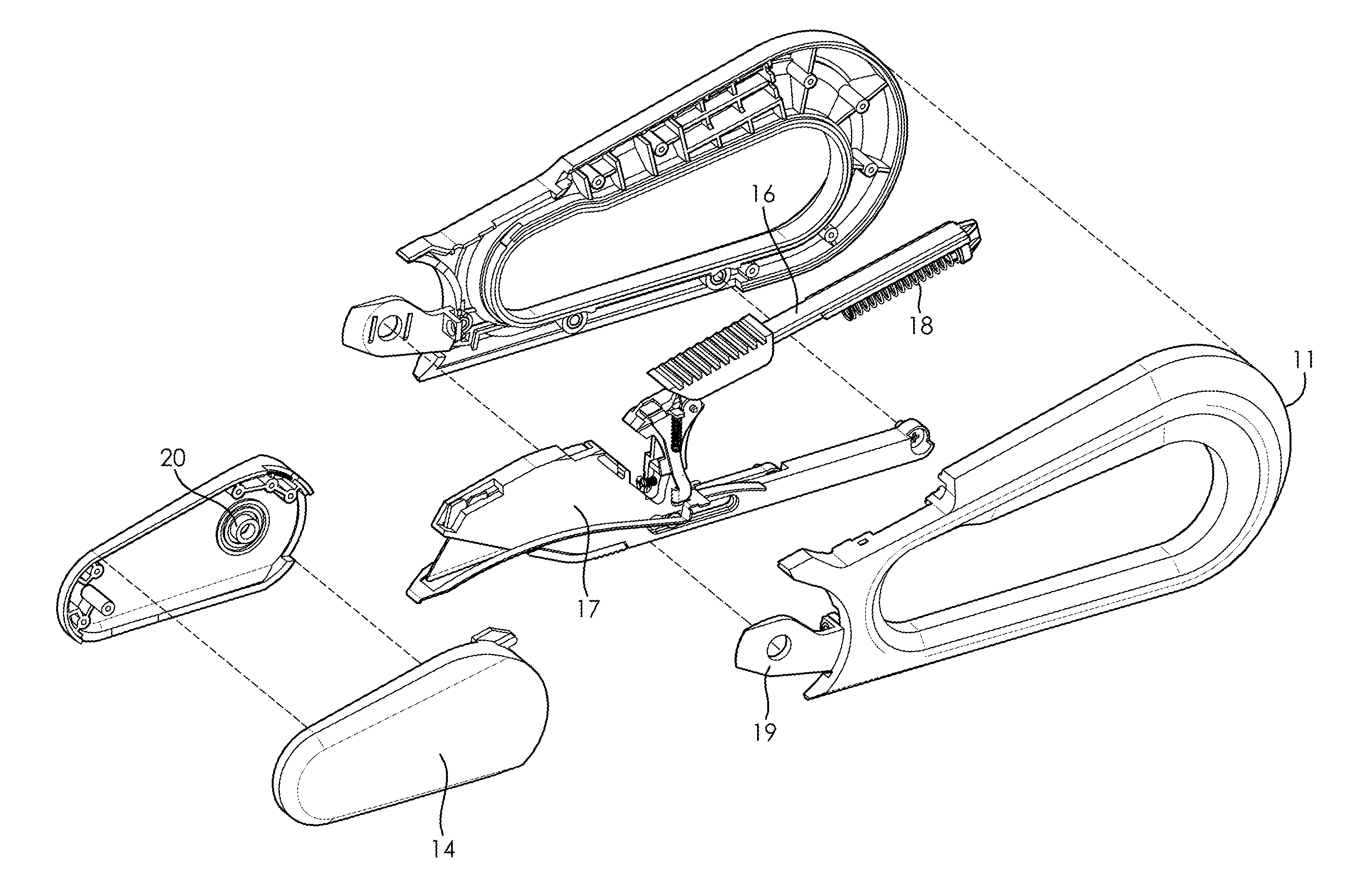

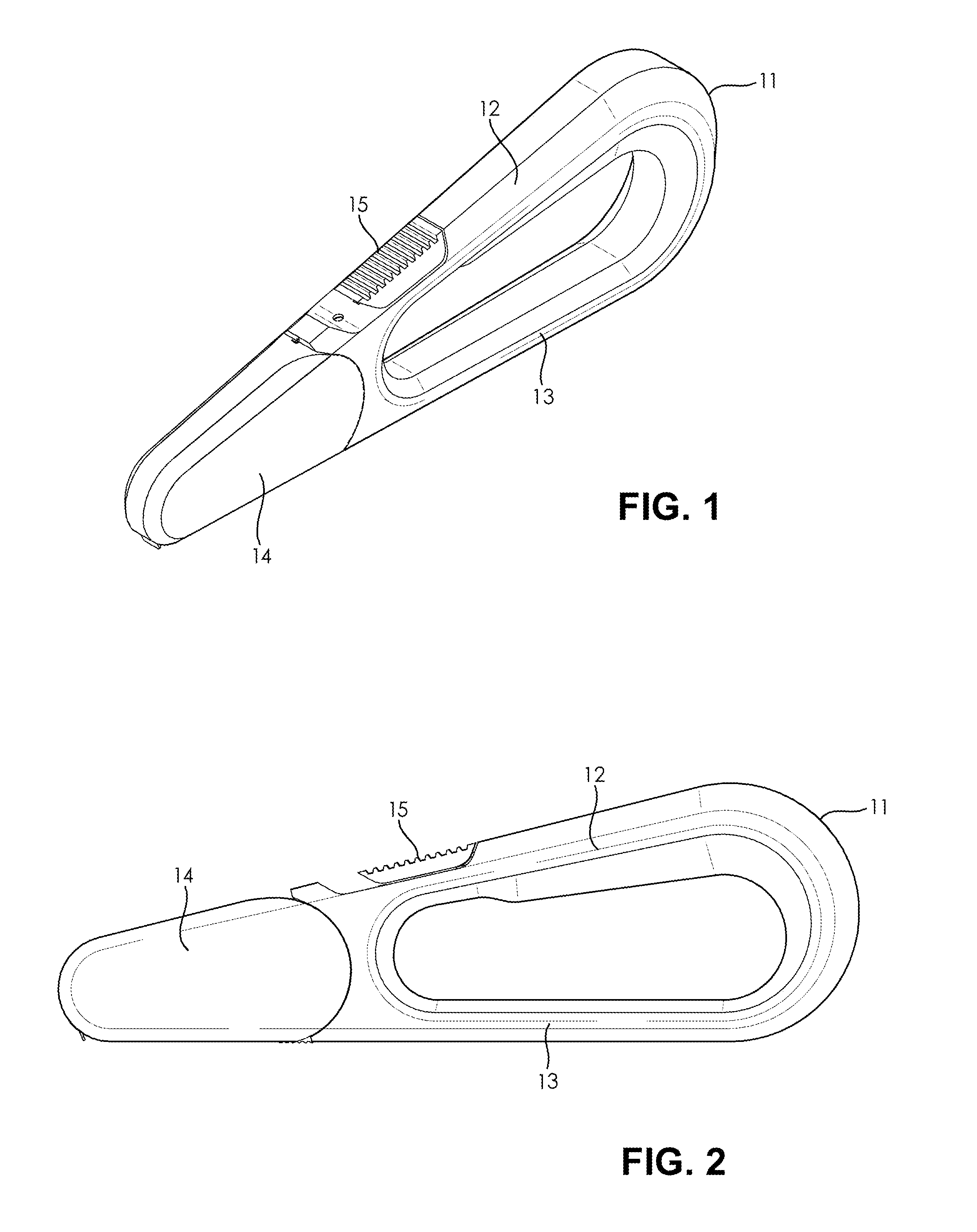

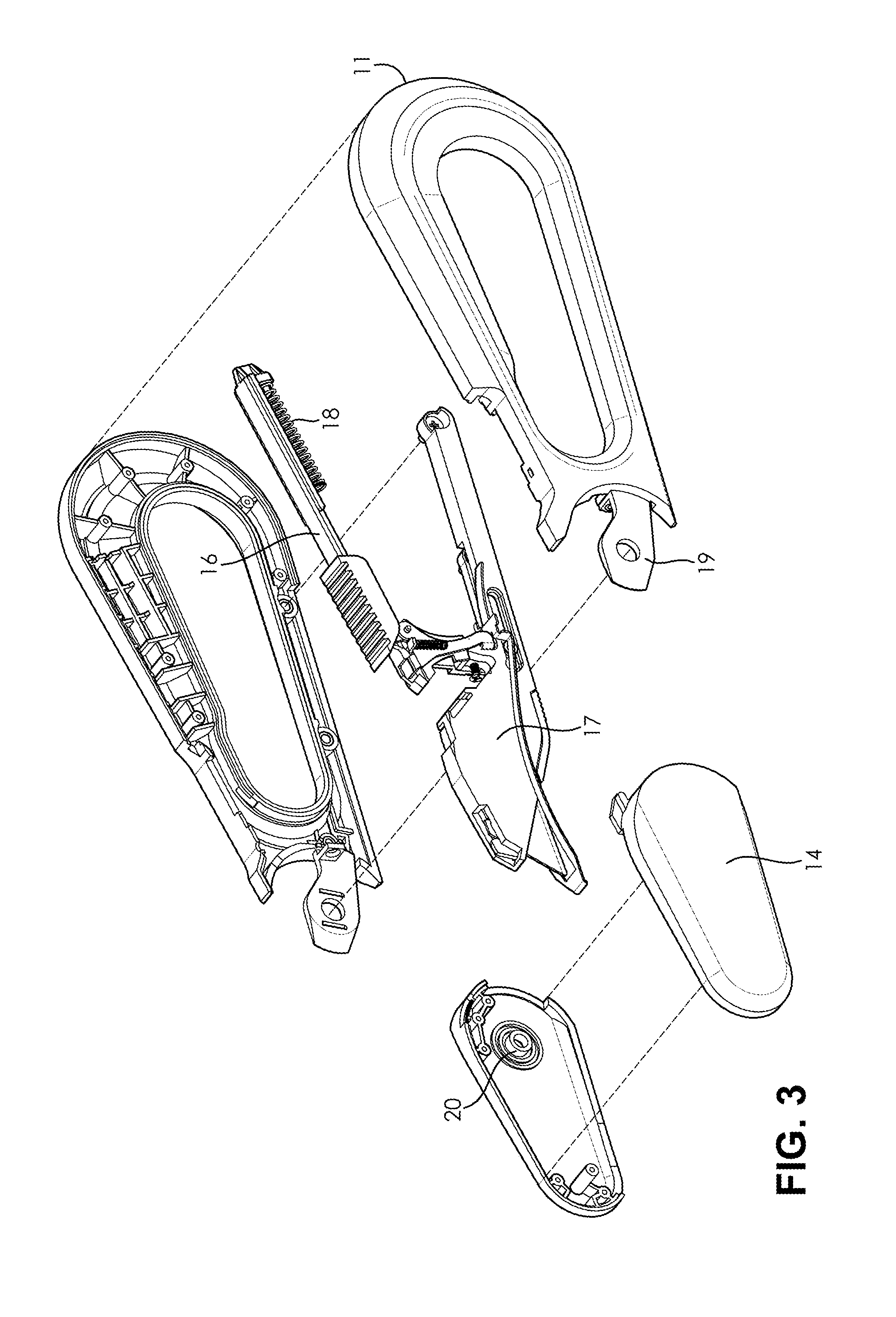

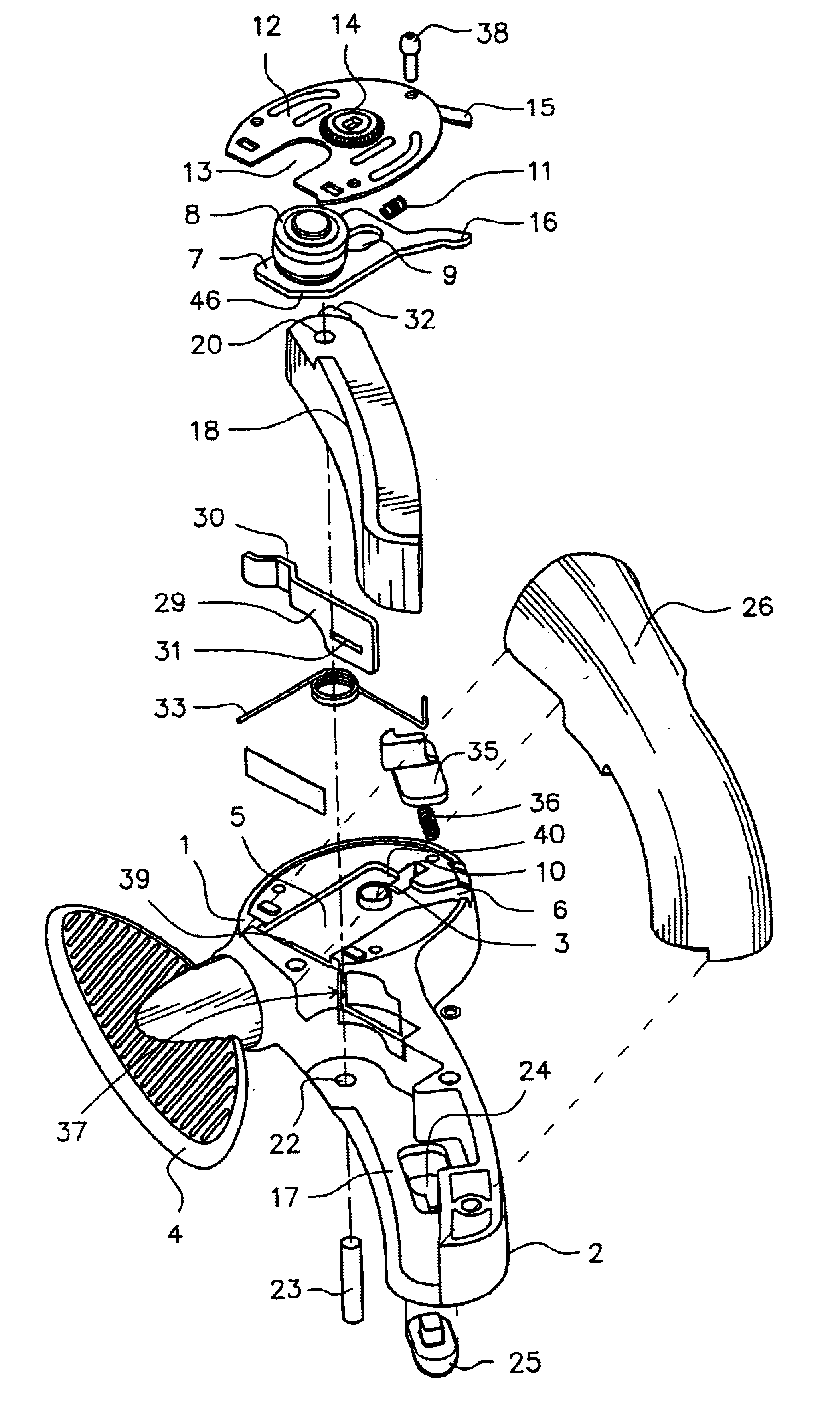

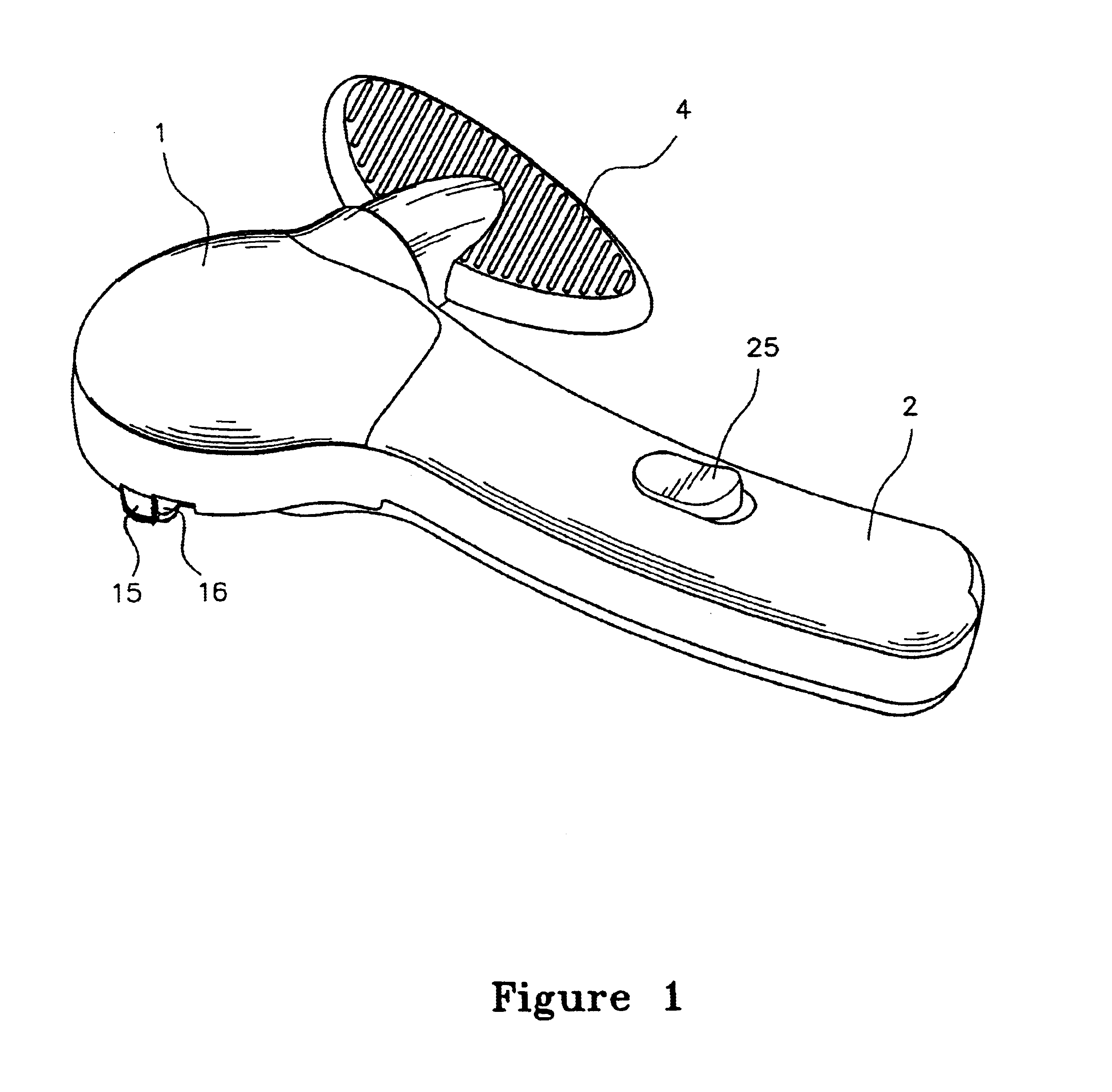

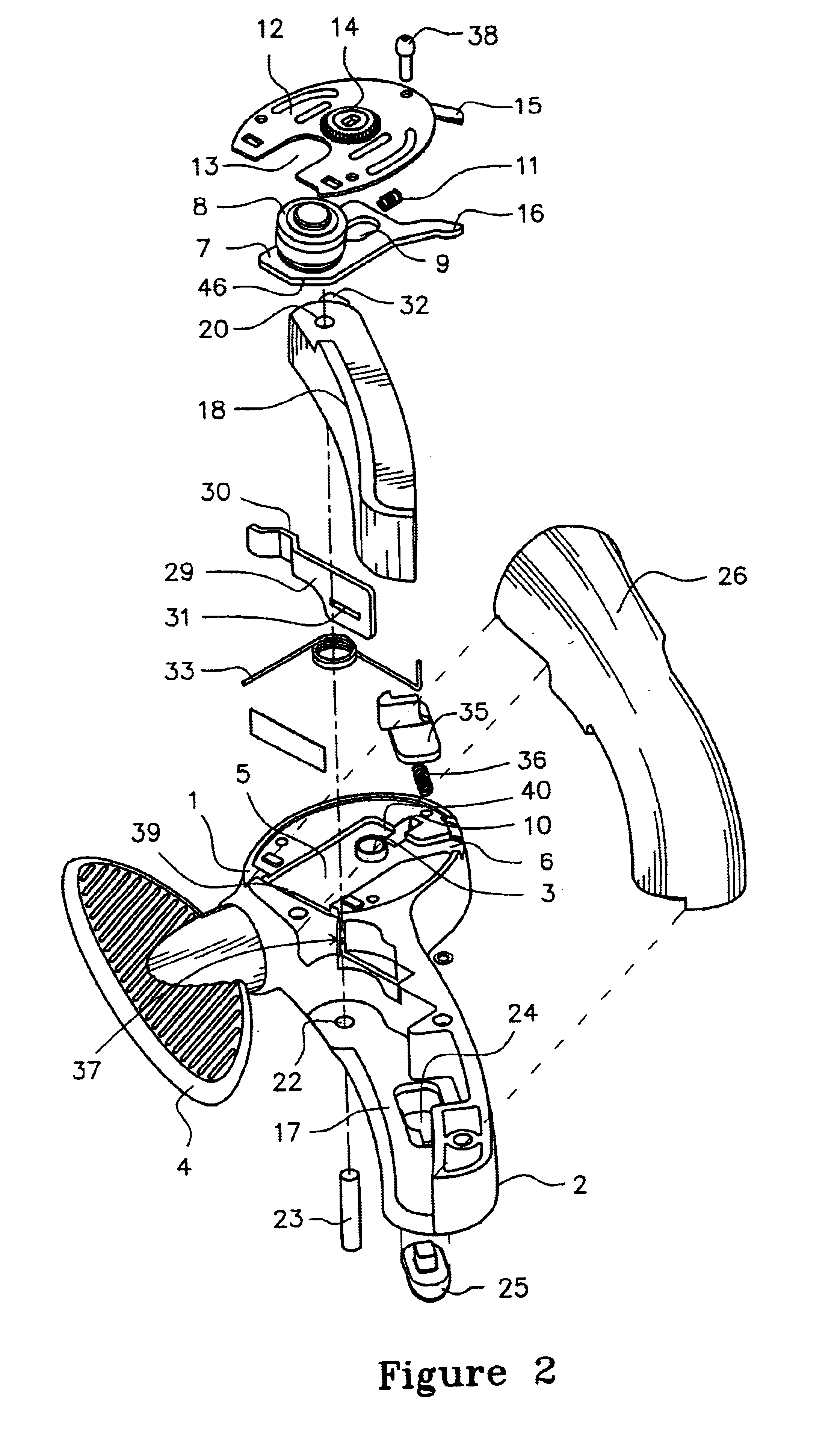

Shaving implement having a moving blade

InactiveUS20060218804A1Reduce cutting forceBottle/container closurePower operated devicesEngineeringCutting force

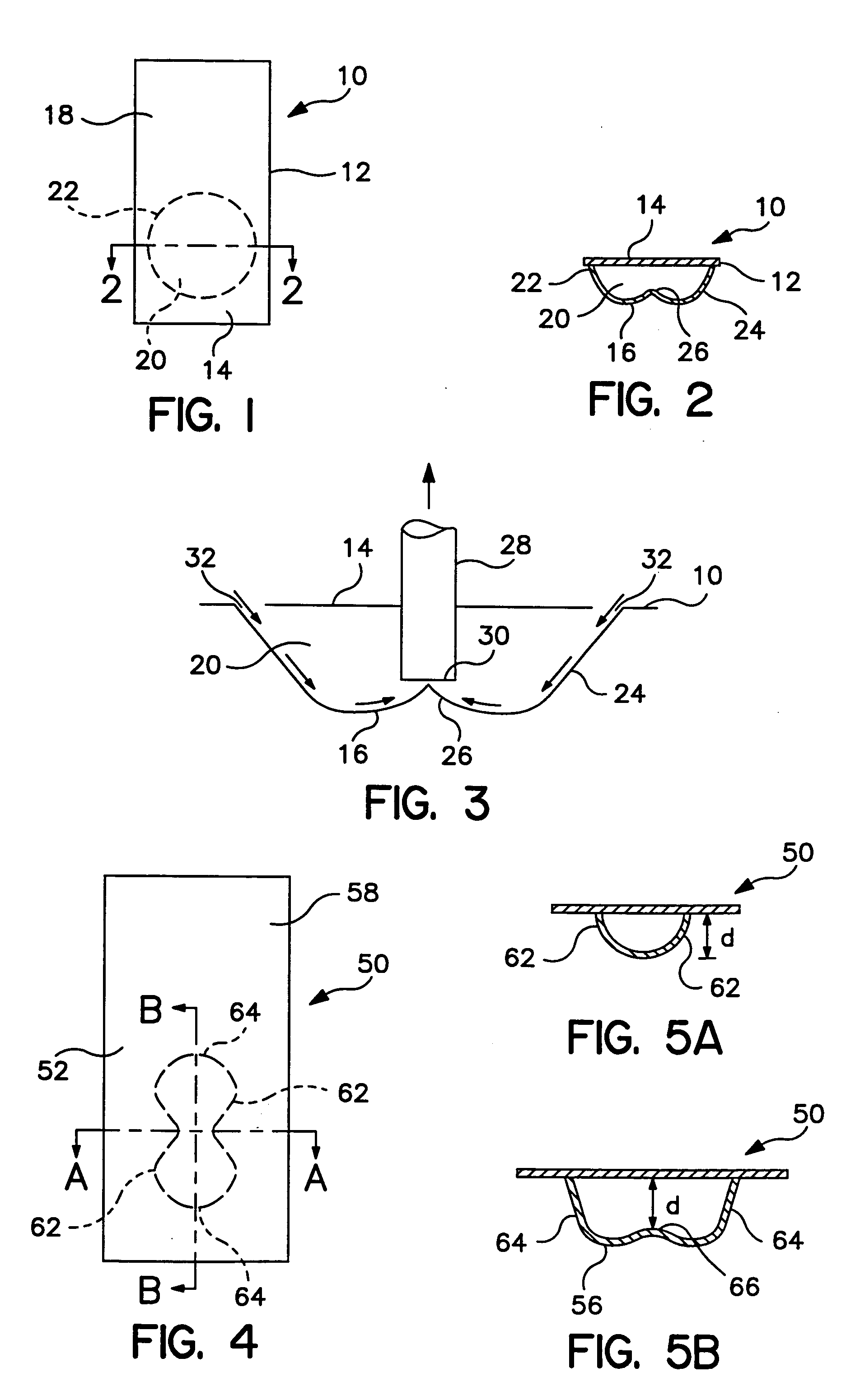

The present invention is related to a shaving implement that includes at least a razor cartridge and a mechanism. The razor cartridge includes at least one blade that has a sharpened cutting edge and defines a blade plane. The mechanism is disposed in the shaving plane and moves the blade in the blade plane during shaving. The mechanism may be either a vibration mechanism (i.e., a motorized spinning eccentric weight), or a dithering mechanism (i.e., a piezoelectric element). The cut force required to shave, when the blades are moving in the blade plane, is significantly reduced.

Owner:EVEREADY BATTERY CO INC

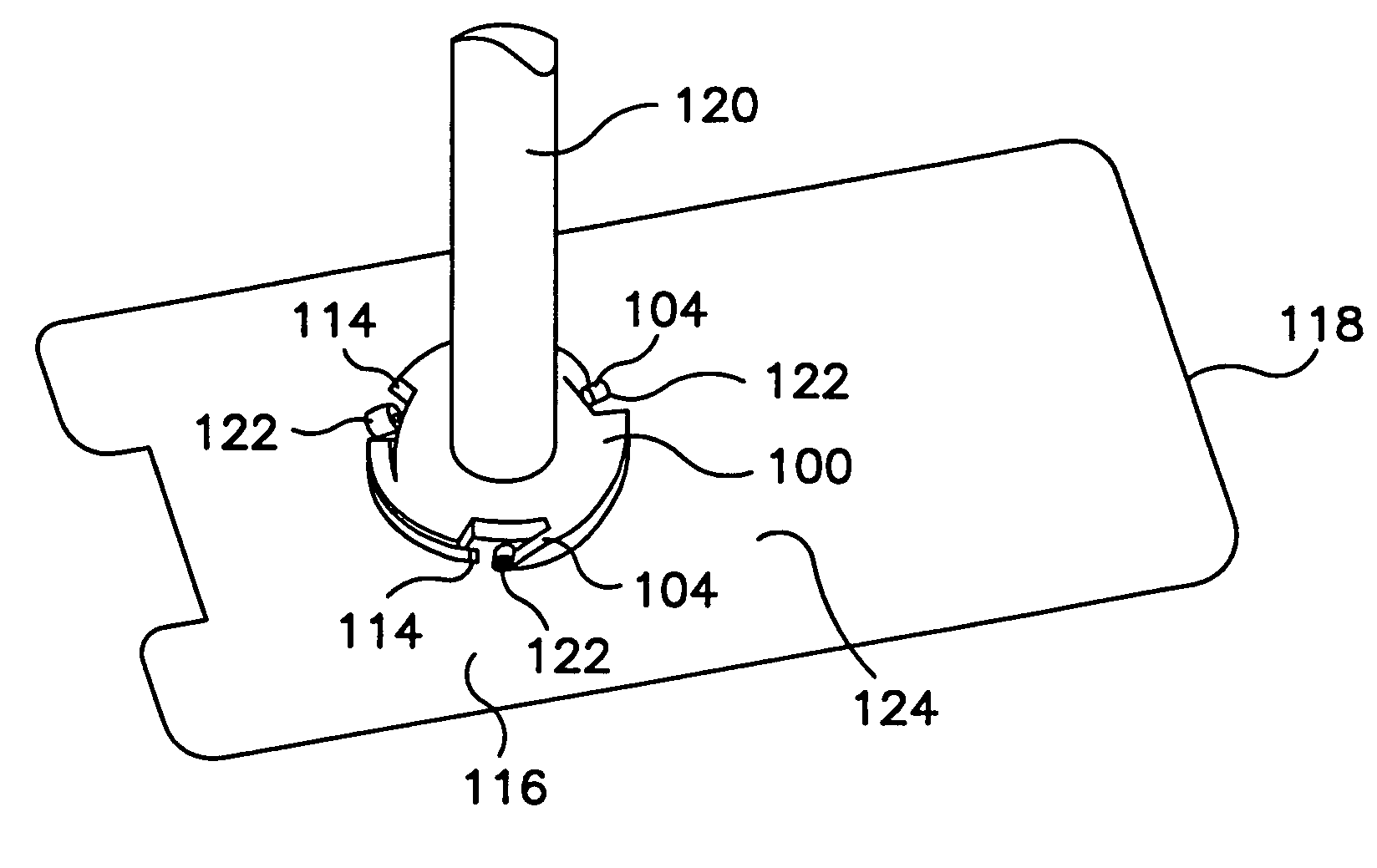

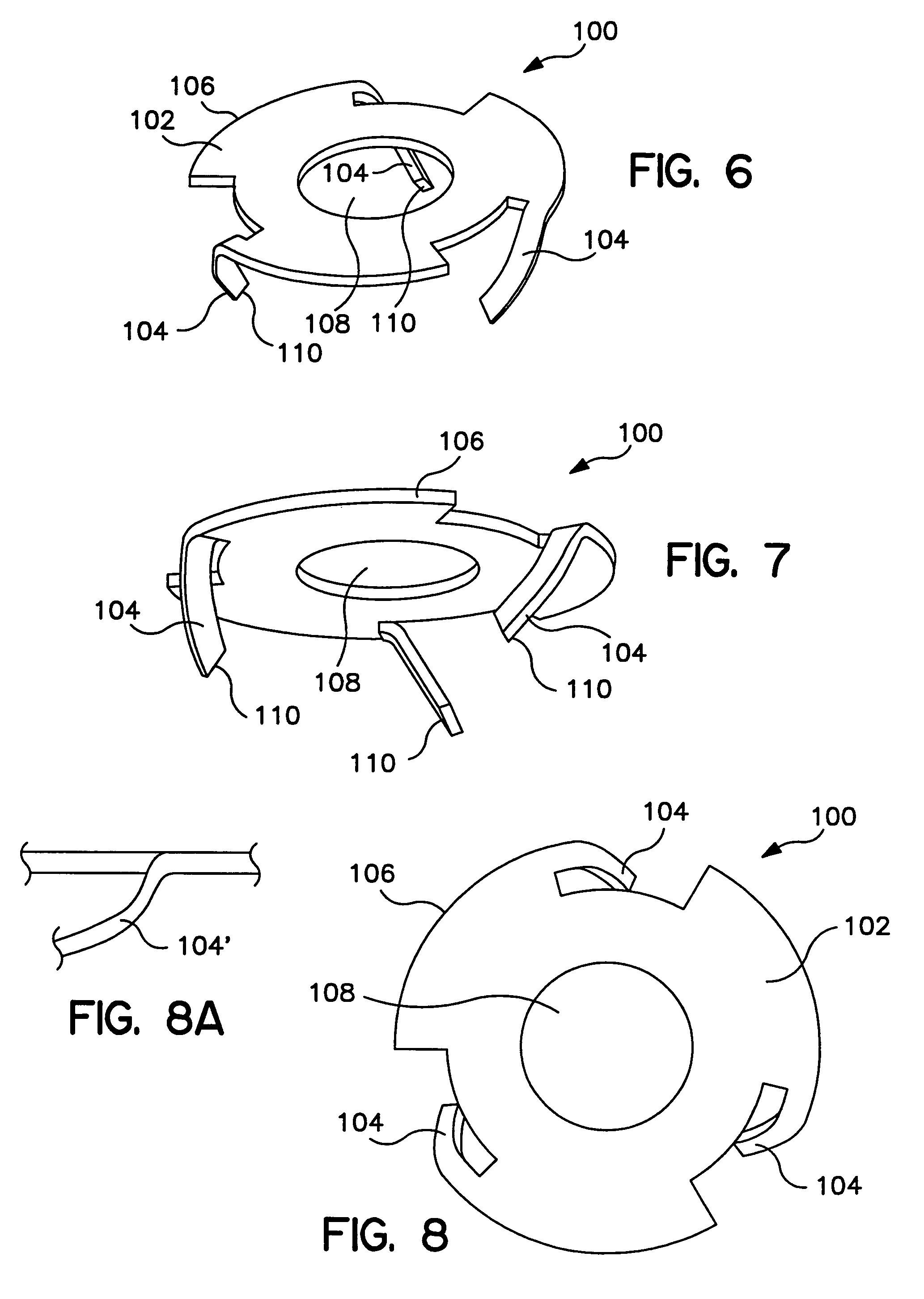

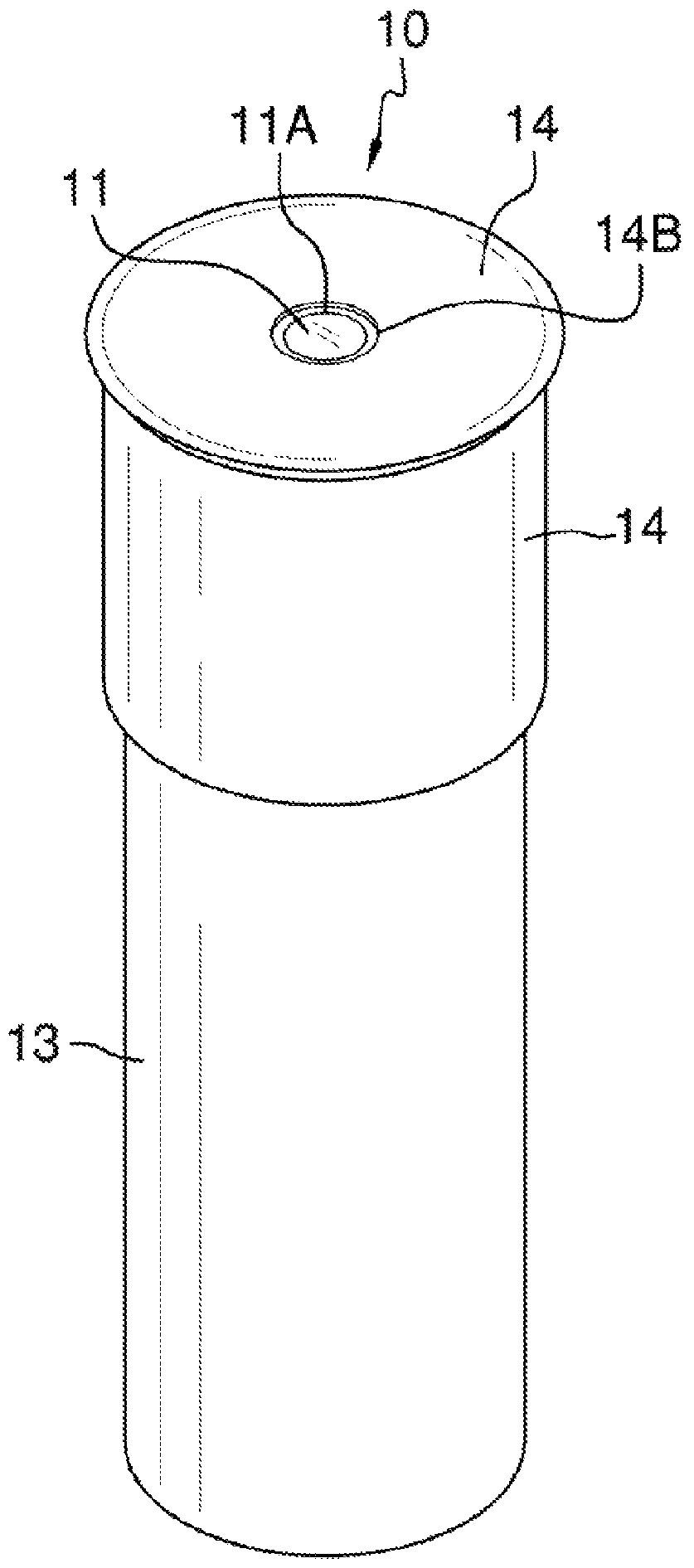

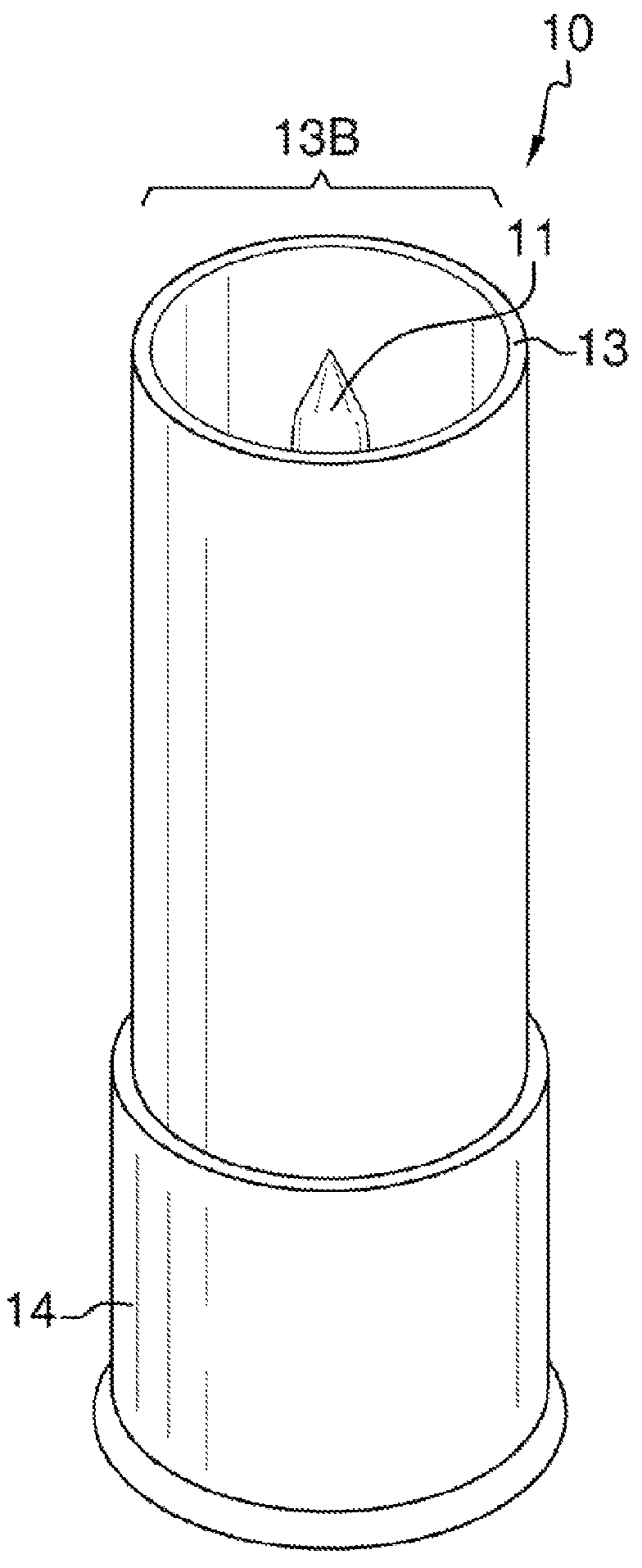

Systems devices and methods for opening receptacles having a powder to be fluidized

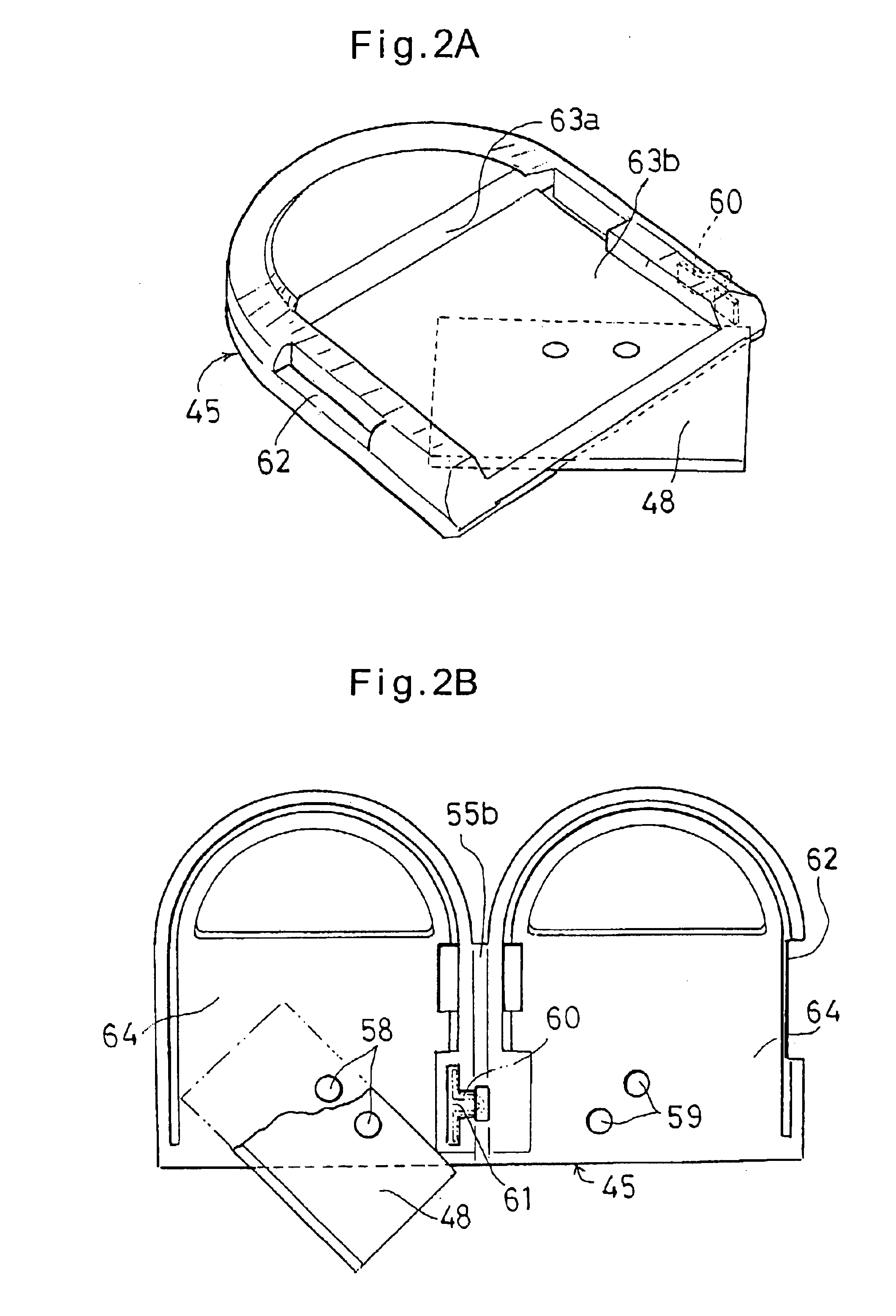

InactiveUS20050161041A1Easy extractionConveniently formedLiquid surface applicatorsPowdered material dispensingEngineeringSurface cover

A method for forming at least one opening in a receptacle comprises the steps of providing a receptacle having a cover with an exterior surface and an interior surface covering a cavity. A cutting mechanism is also provided having at least one blade. The cover is pierced with the blade, and the blade is moved through the cover to cut a portion of the cover and create an opening in the cover to provide access into the cavity. Further, the cut portion curls on top of the exterior surface as the opening is created.

Owner:NOVARTIS AG

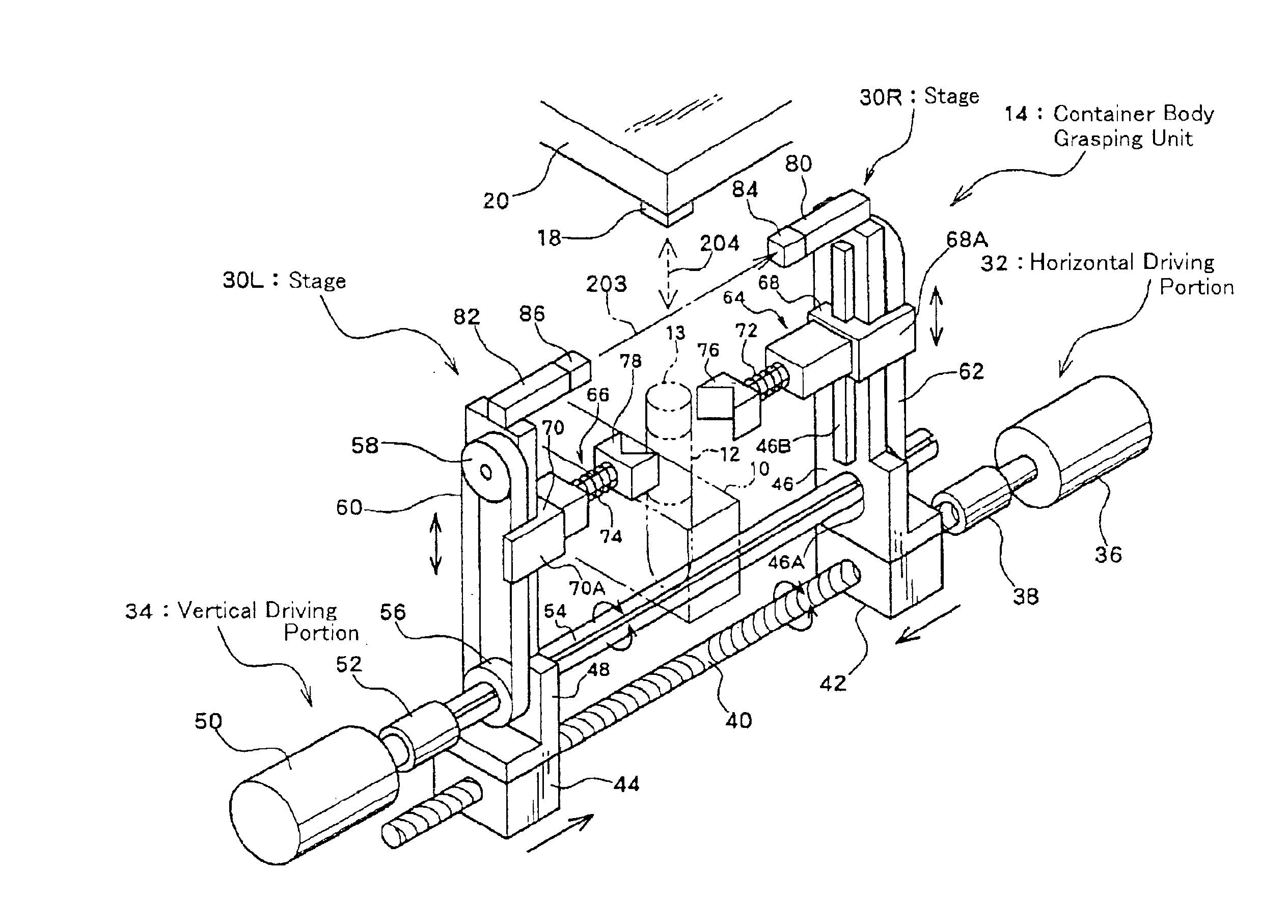

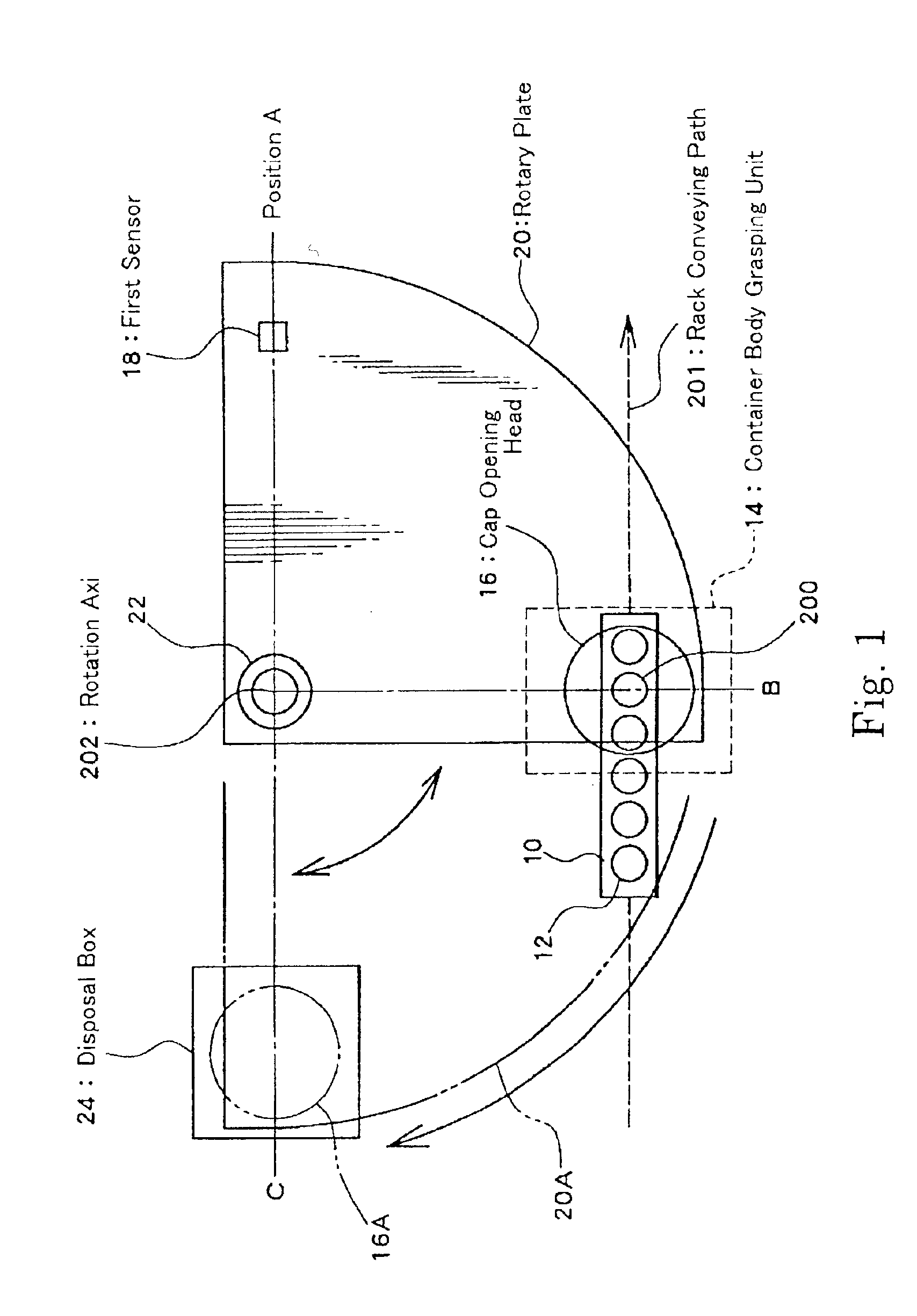

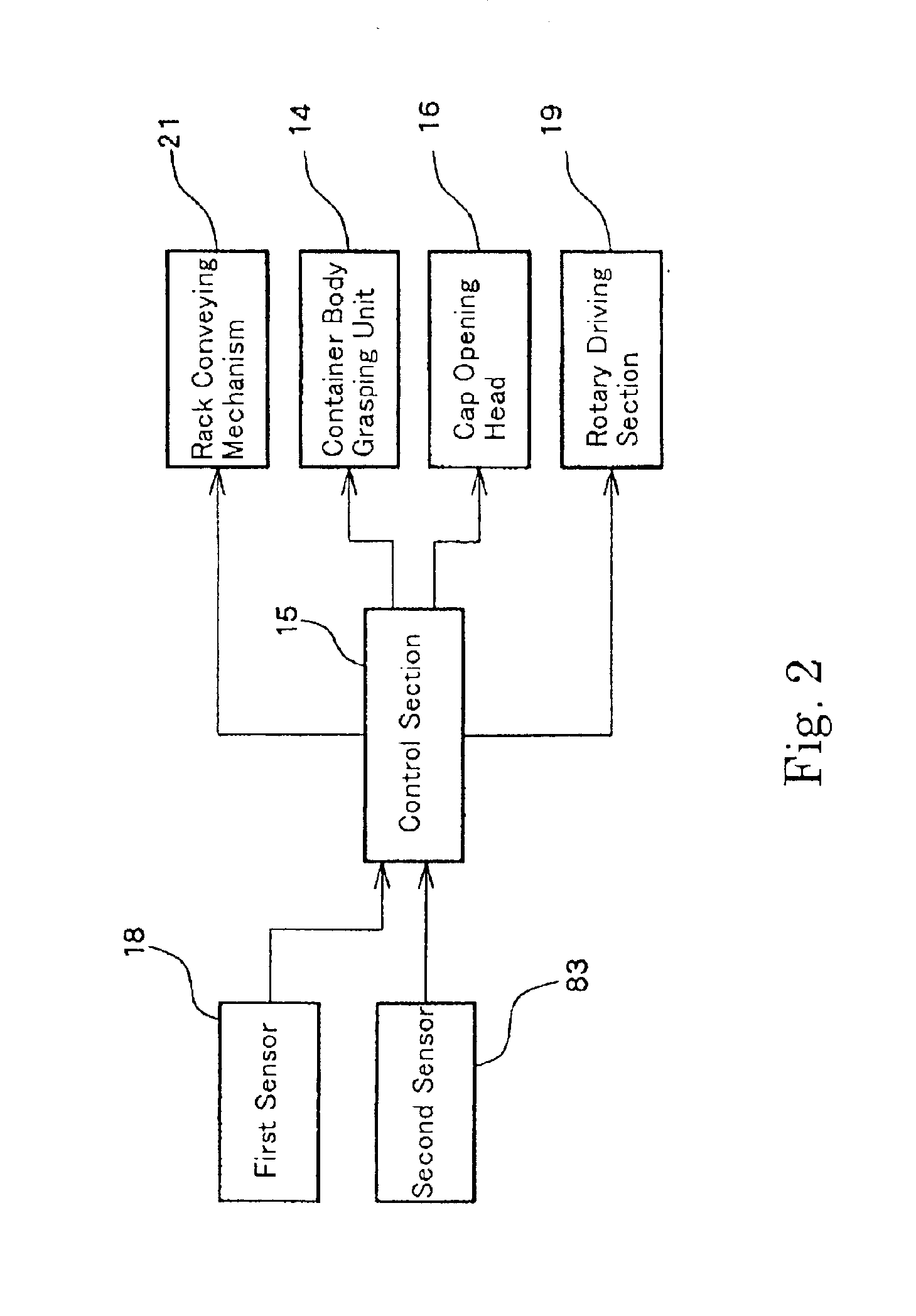

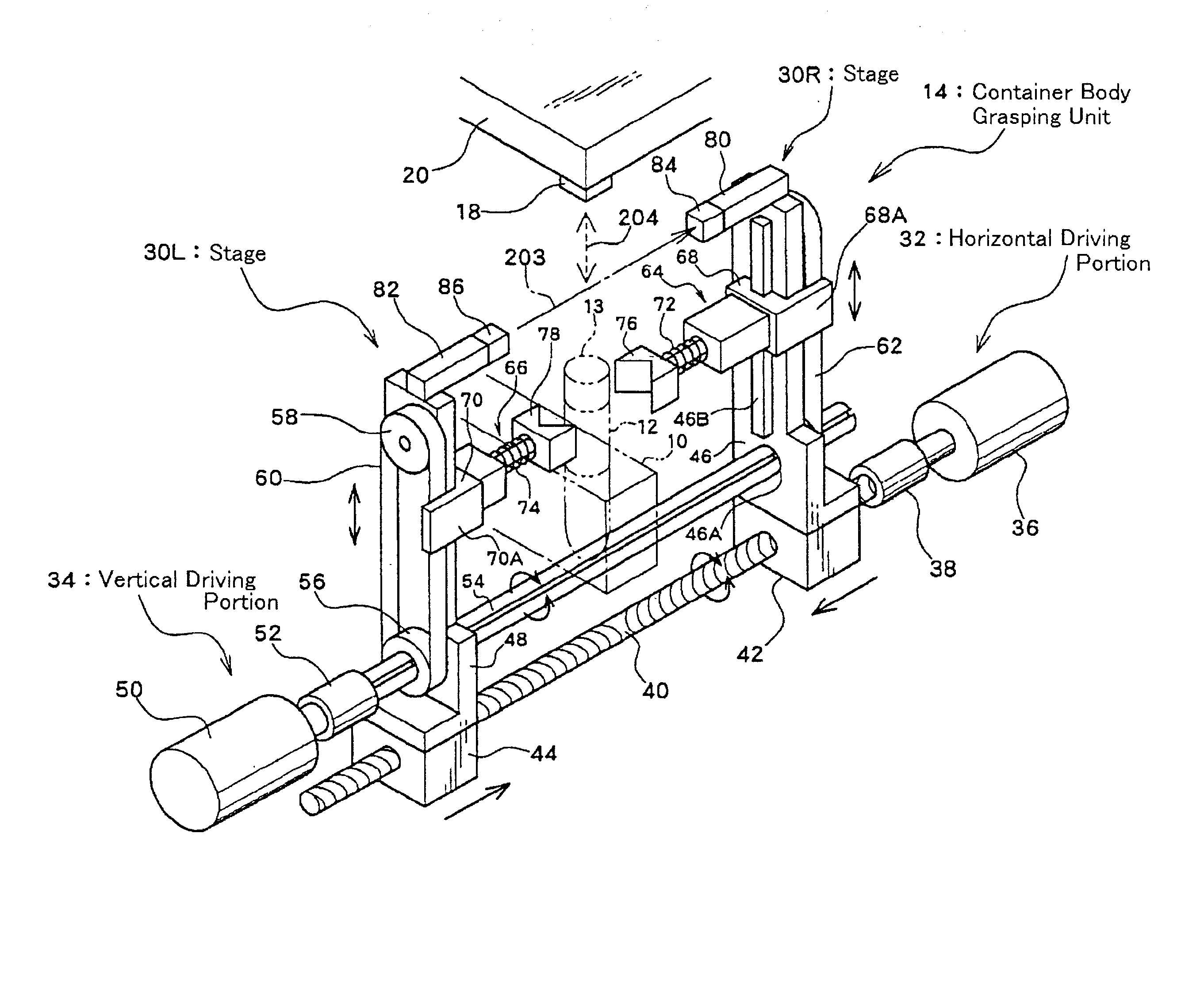

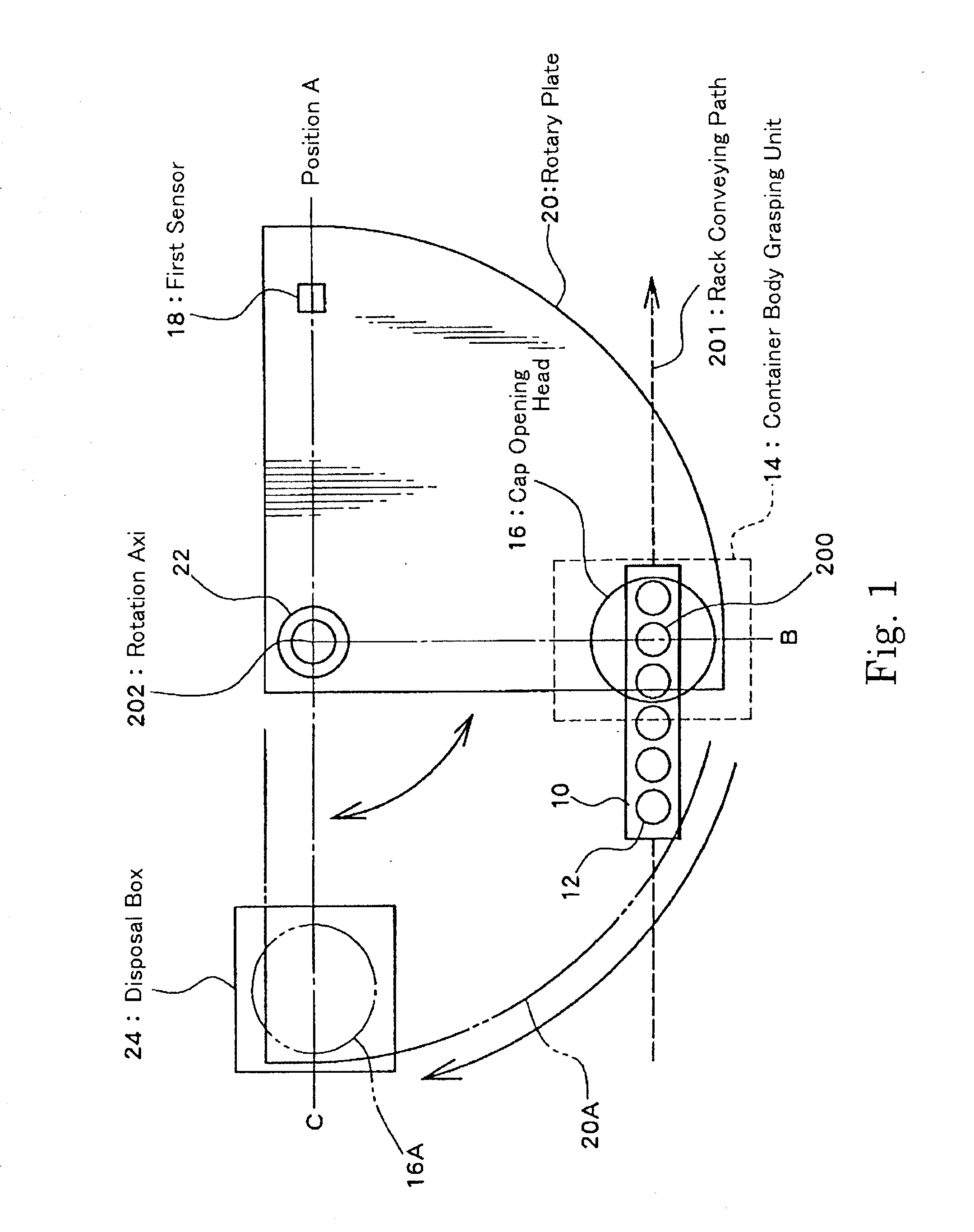

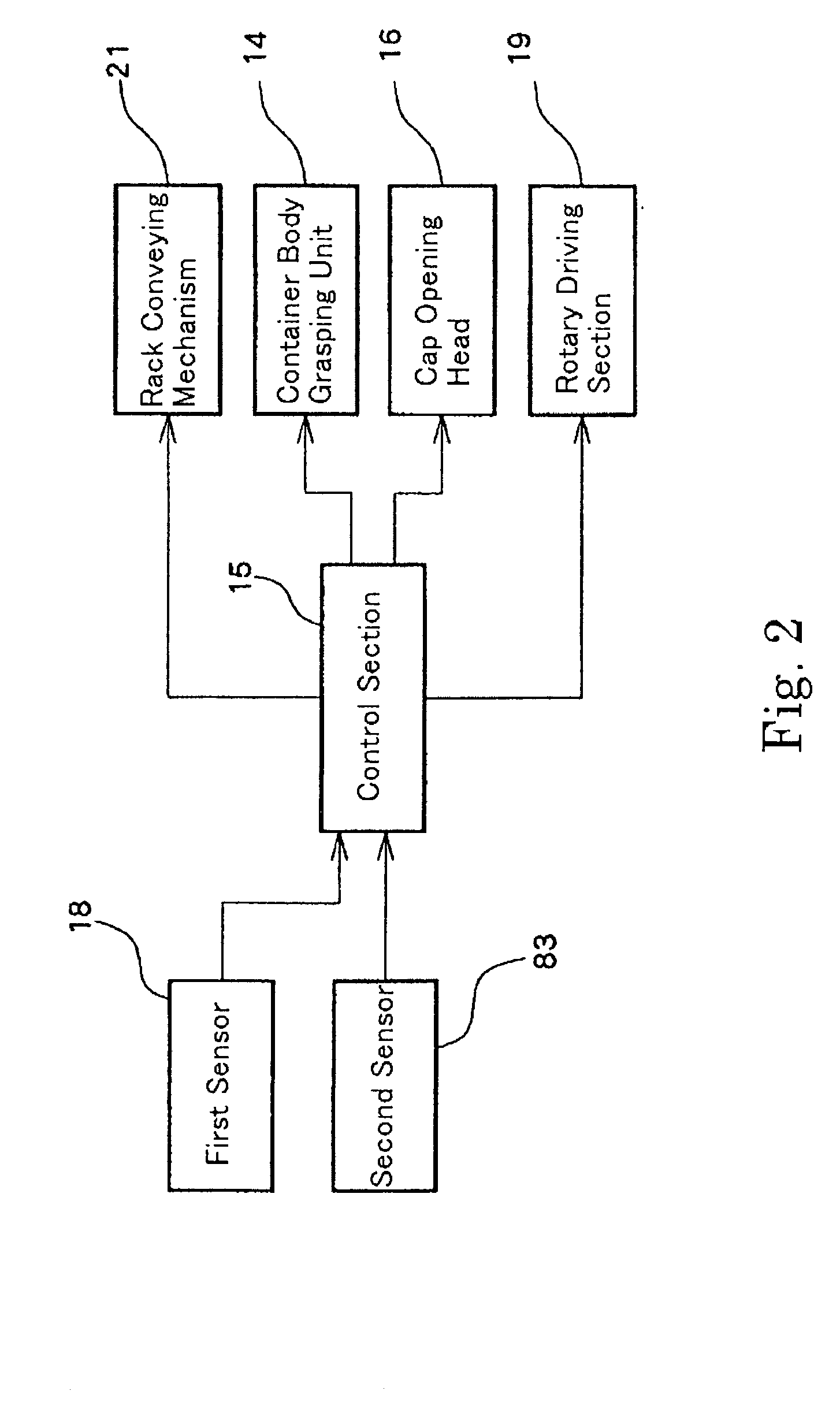

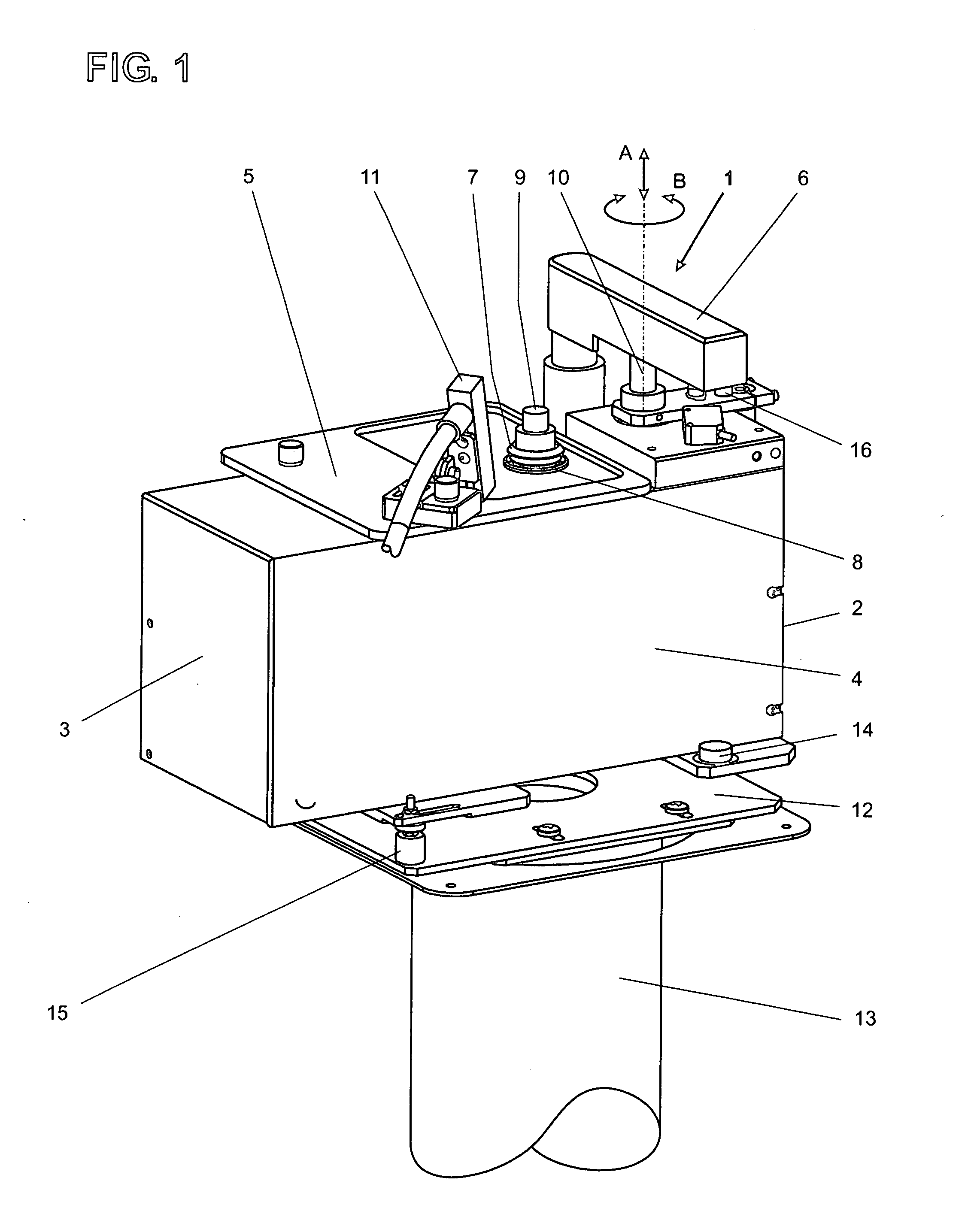

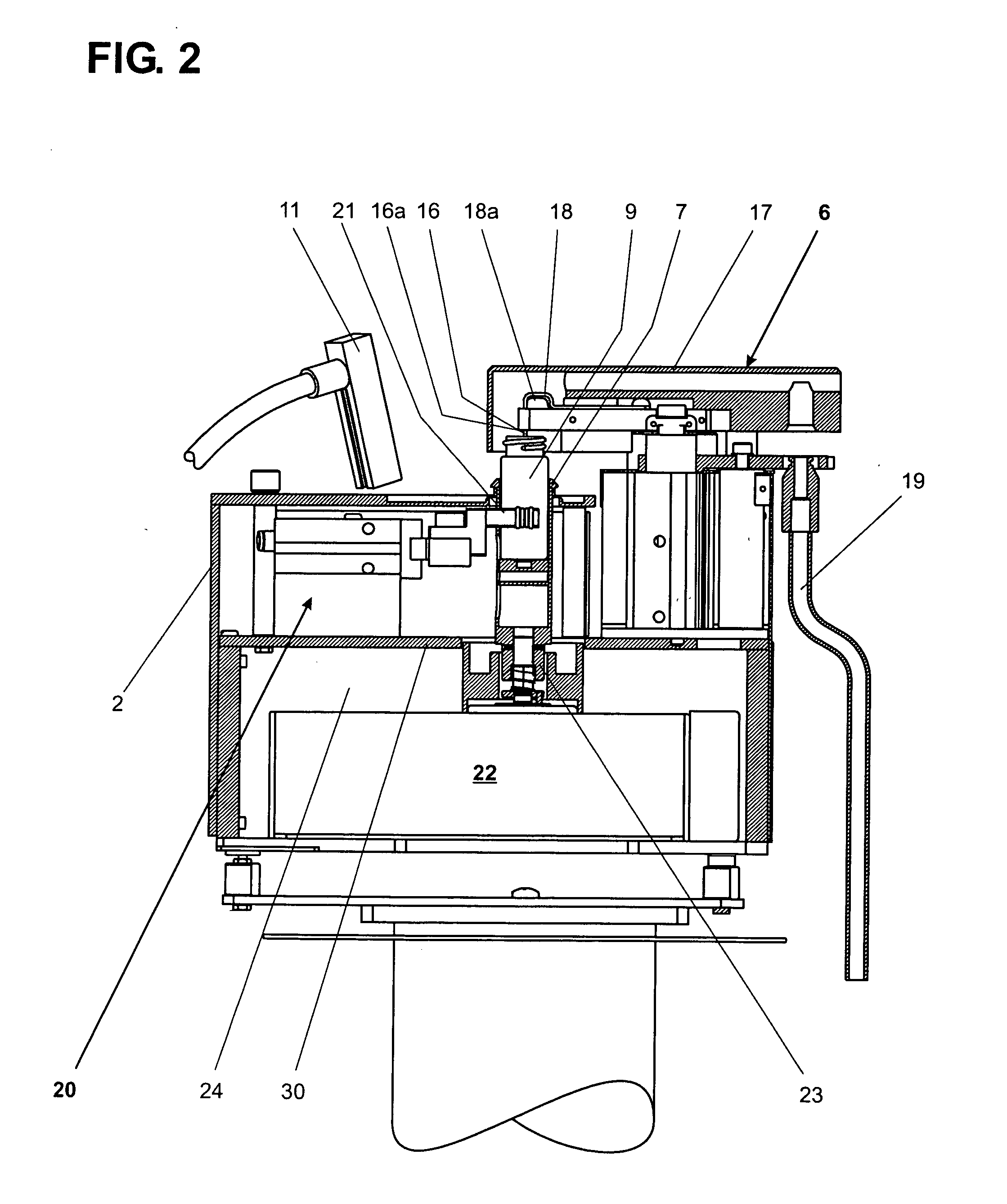

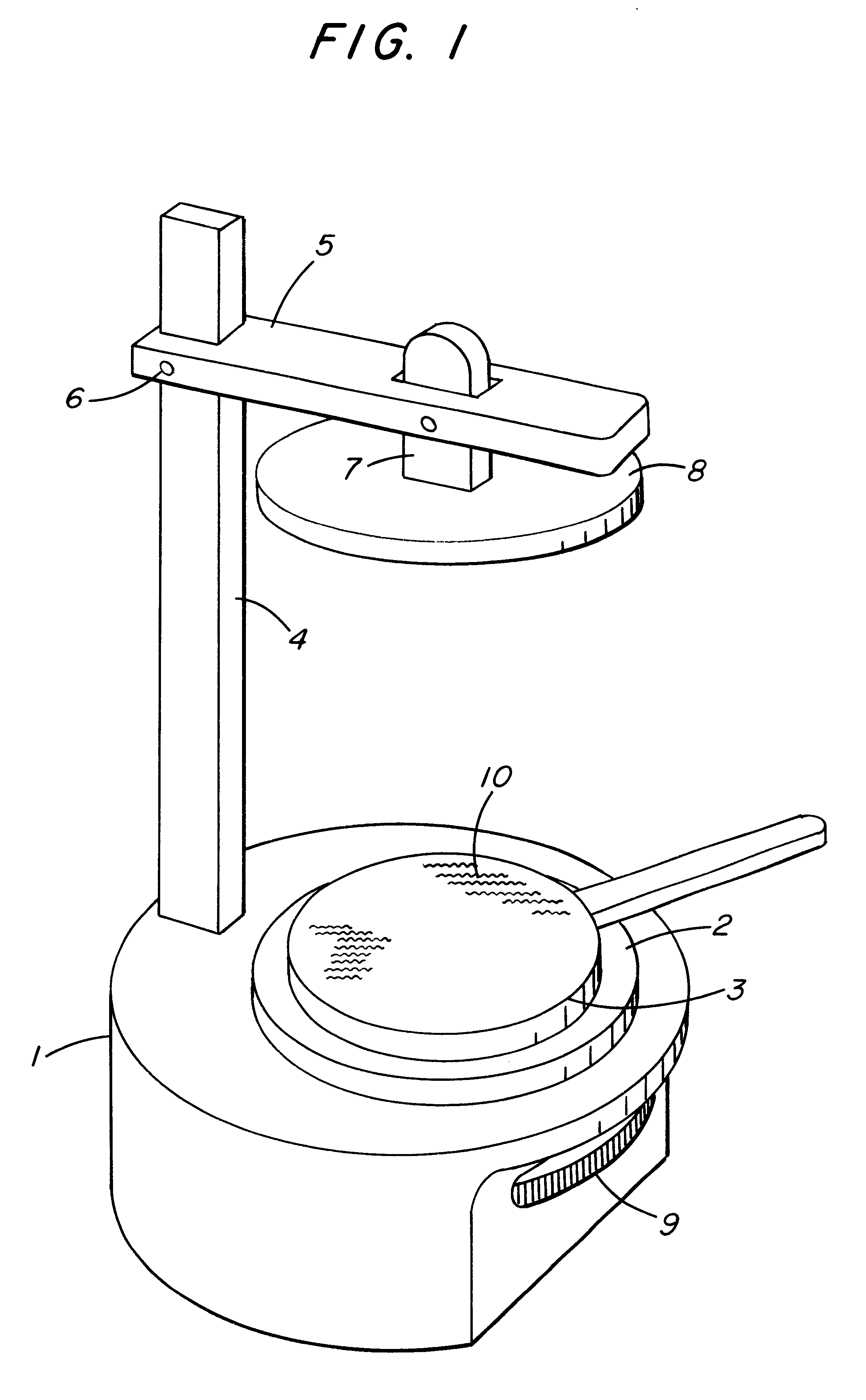

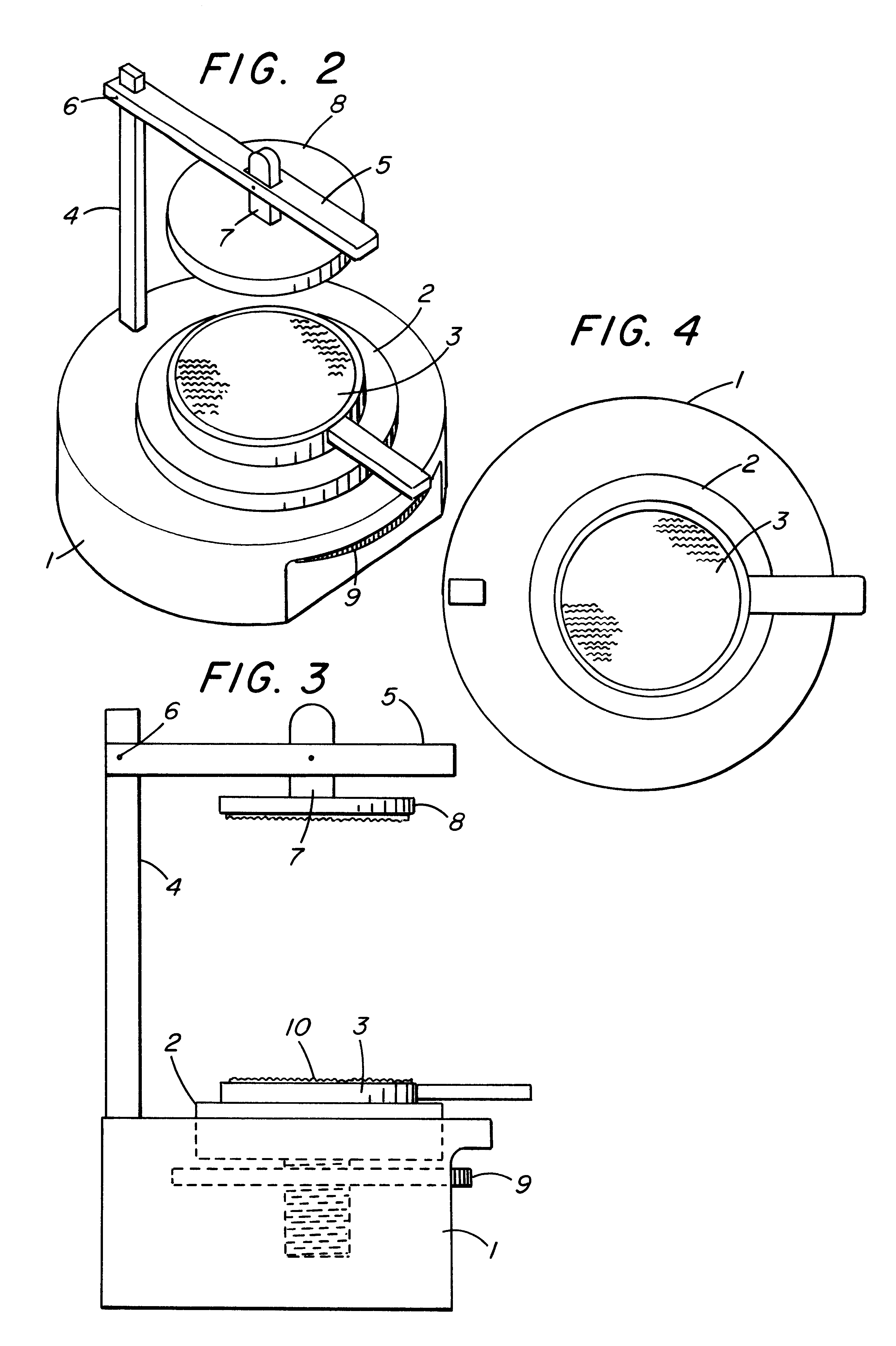

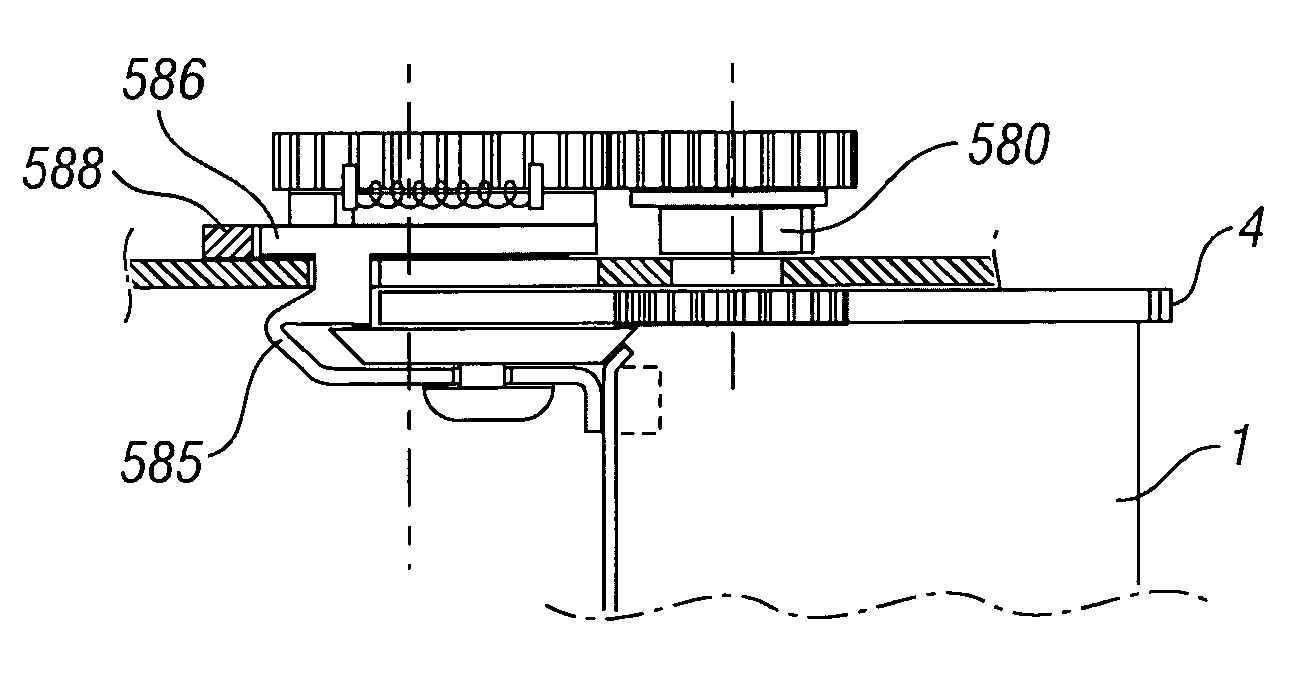

Cap opening system and method for opening cap

InactiveUS6871566B2Guaranteed uptimePrevent rotationBottle/container closurePower operated devicesEngineeringMechanical engineering

A cap opening system which can handle various containers having caps and container bodies of different sizes is disclosed. In this system, when a cap of a container is to be opened, a container body of the container is gripped by a container body holding apparatus to raise the container body upward. A top surface of the cap is detected as a reference surface when the cap interrupts an optical beam. Based on the height of the reference surface, the cap is positioned with respect to the cap handling apparatus. Alternatively, a cap receiving member is provided underneath the cap handling apparatus to perform positioning of the cap with respect to the cap handling apparatus.

Owner:HITACHI LTD +1

Systems devices and methods for opening receptacles having a powder to be fluidized

InactiveUS7814905B2Easy extractionConveniently formedLiquid surface applicatorsPowdered material dispensingEngineeringSurface cover

A method for forming at least one opening in a receptacle comprises the steps of providing a receptacle having a cover with an exterior surface and an interior surface covering a cavity. A cutting mechanism is also provided having at least one blade. The cover is pierced with the blade, and the blade is moved through the cover to cut a portion of the cover and create an opening in the cover to provide access into the cavity. Further, the cut portion curls on top of the exterior surface as the opening is created.

Owner:NOVARTIS AG

Cap opening system and method for opening cap

InactiveUS20030061911A1Reliably carry-outSimple structureBottle/container closurePower operated devicesMechanical engineeringReference surface

A cap opening system which can handle various containers having caps and container bodies of different sizes is disclosed. In this system, when a cap of a container is to be opened, a container body of the container is gripped by a container body holding apparatus to raise the container body upward. A top surface of the cap is detected as a reference surface when the cap interrupts an optical beam. Based on the height of the reference surface, the cap is positioned with respect to the cap handling apparatus. Alternatively, a cap receiving member is provided underneath the cap handling apparatus to perform positioning of the cap with respect to the cap handling apparatus.

Owner:HITACHI LTD +1

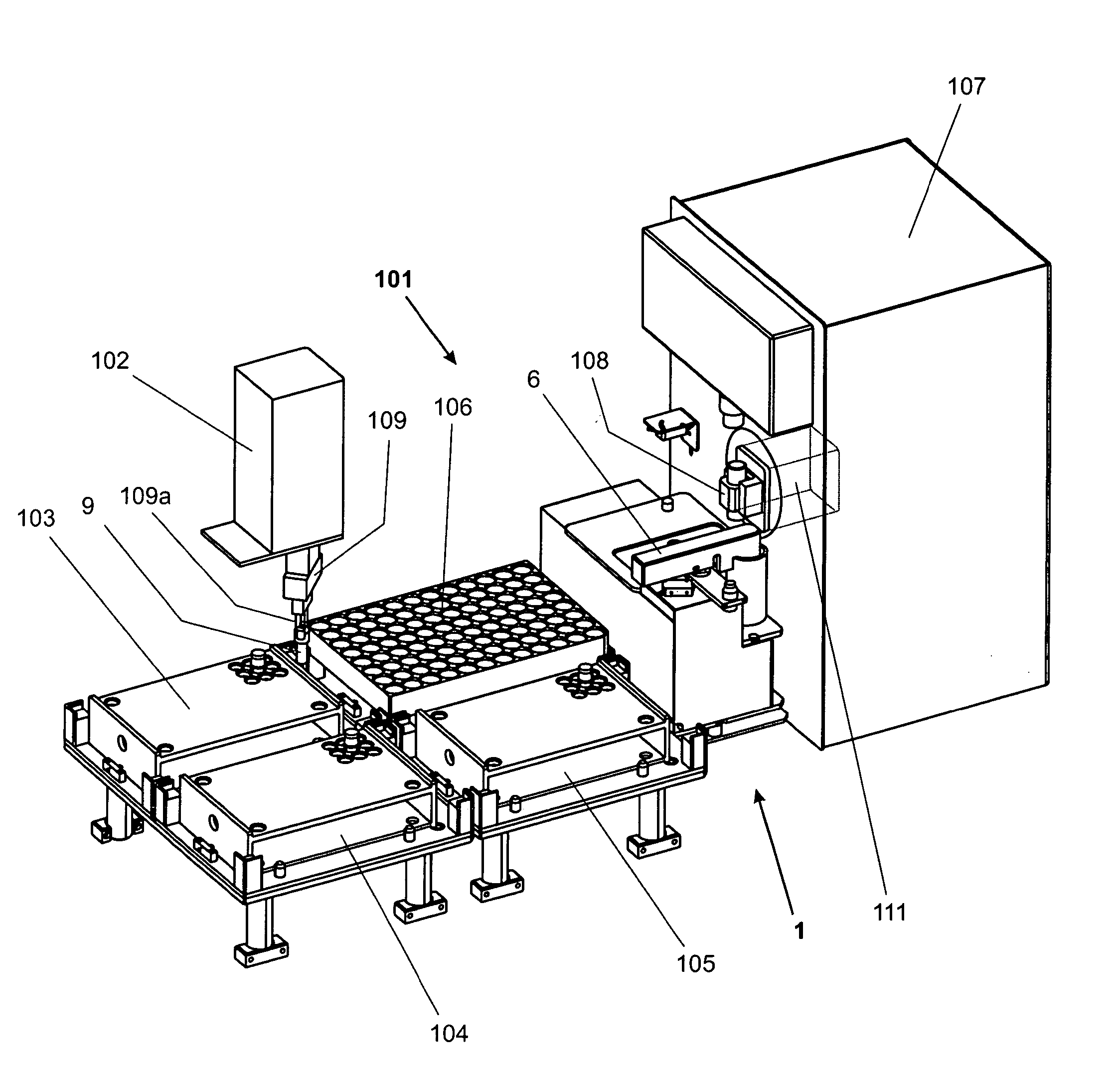

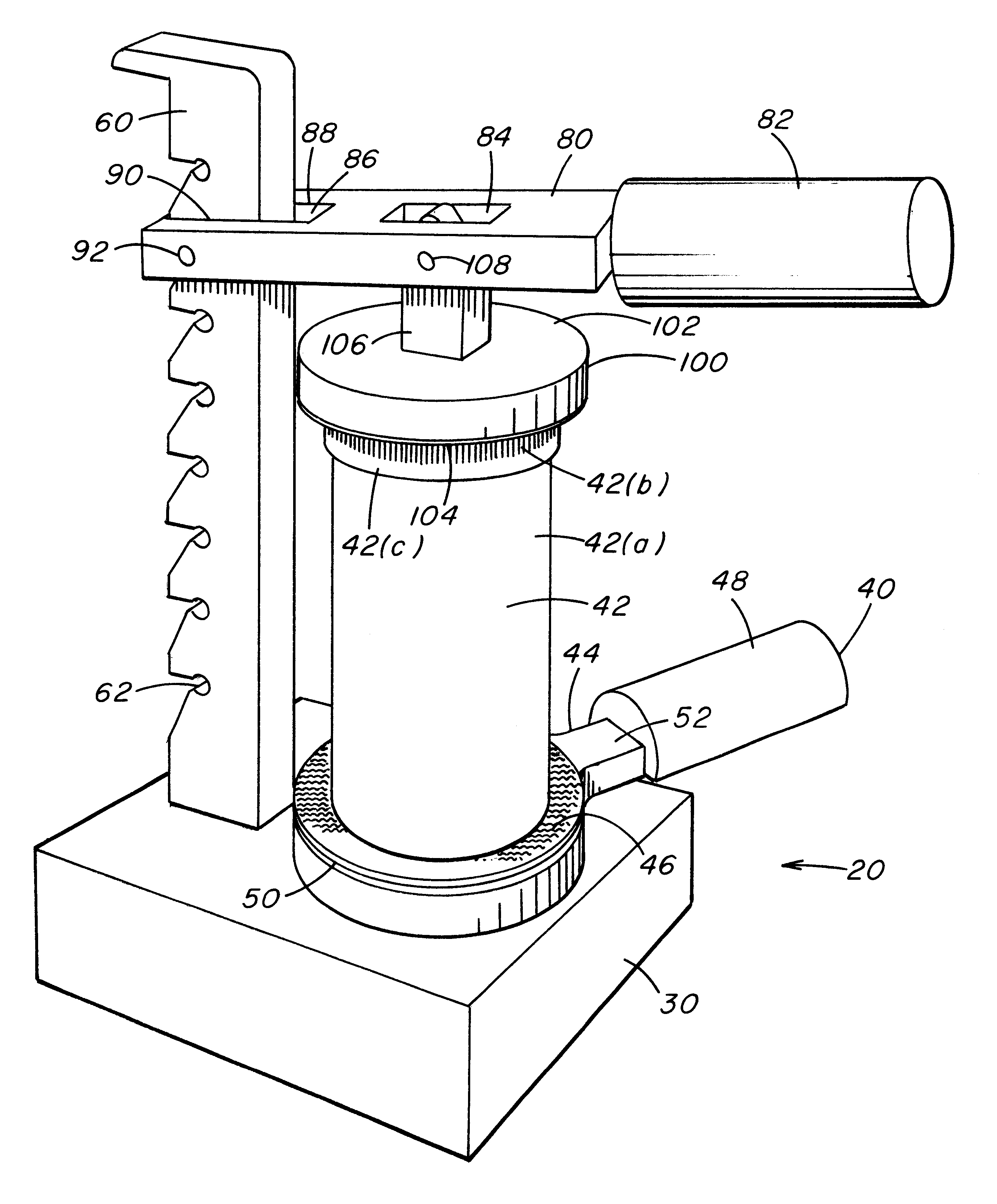

Apparatus and method for dispensing substances into containers

InactiveUS20060137760A1Avoid accumulationMinimize timeBottle/container closurePower operated devicesMechanical engineeringEngineering

An apparatus for dispensing substances, specifically powders and liquids, into a container, is designed as a compact module containing a weighing device with a load receiver, a holder device which is attached to the load receiver and serves to receive and loosely hold the container while the substances are dispensed into the container, and a liquid-dispensing device for dispensing a liquid into the container while the latter is seated in the holder device. The apparatus includes a clamping device for firmly gripping and immobilizing the container, so that a capping device that is not part of the apparatus can put a cap on the container or remove the cap from the container while the latter is seated in the holder device.

Owner:METTLER TOLEDO AG

Method and system for picking and placing vessels

ActiveUS7128874B2Avoid jarringPrevent splashBottle/container closurePower operated devicesEngineeringMechanical engineering

A method and system for picking and placing vessels are provided. The system includes a gripper assembly mounted on a positioning mechanism. The gripper assembly includes a cylinder, a plurality of flexible gripping members extending from the cylinder in a spaced-apart relationship for receiving therebetween a vessel and holding it by friction, a piston slideably inserted inside the cylinder, and a plunger connected to and movable with the piston and extending between the gripping members for engaging the vessel. The method includes the steps of positioning the gripper assembly, picking up and transferring a vessel, and placing, seating and releasing the vessel. The contents of the vessel may also be mixed simultaneously during the transferring of the vessel.

Owner:BECKMAN COULTER INC

Hooded Box Cutter

InactiveUS20140208594A1Reduce the possibilityImprove gripBottle/container closurePower operated devicesStructural engineeringKnife blades

The present invention generally relates to a box cutter. Specifically, embodiments of the present invention relate to a box cutter apparatus with an auto-locking blade guard. Embodiments of the box cutter apparatus are further comprised of a handle guard designed to protect the hand of a user.

Owner:SLICE

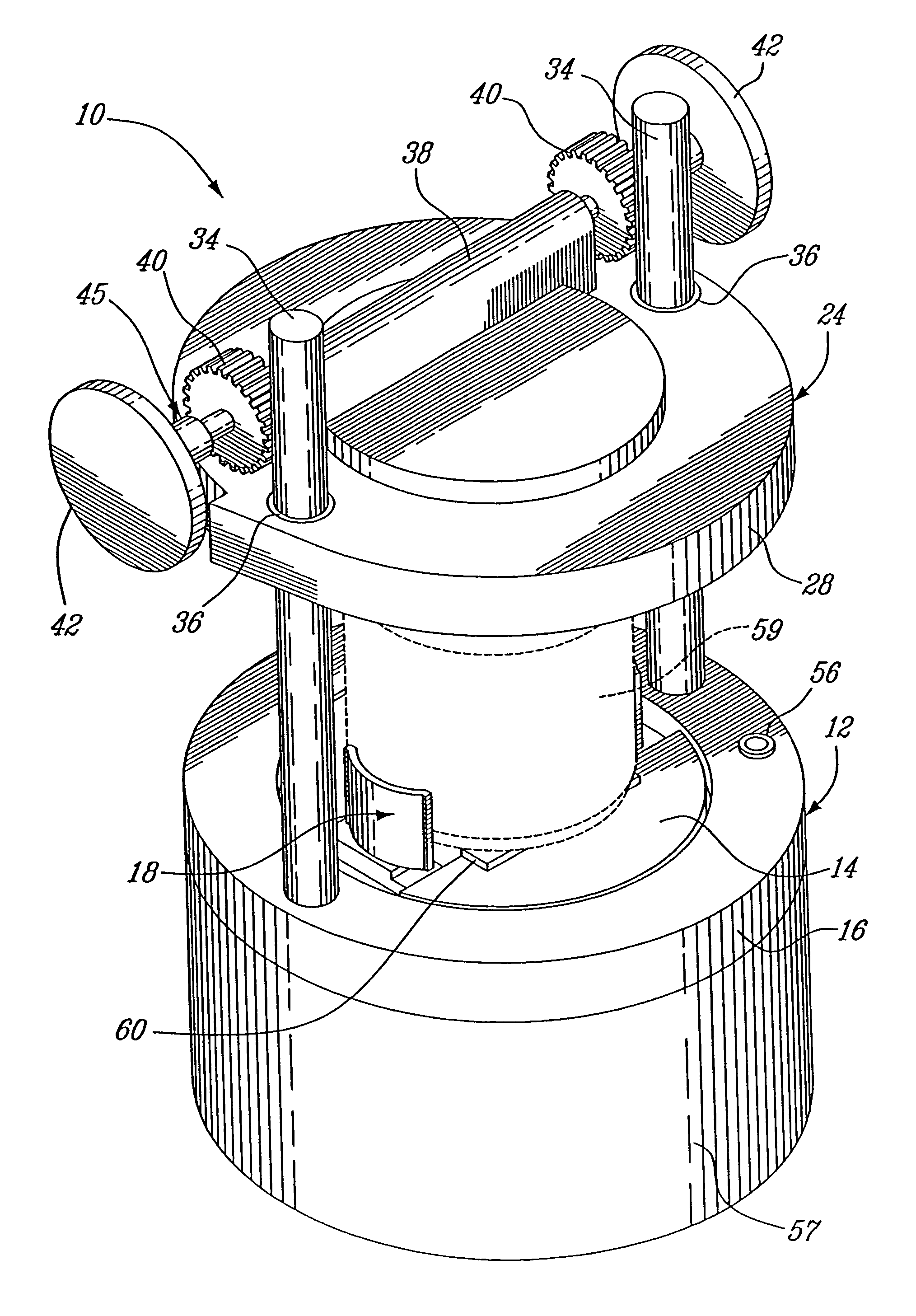

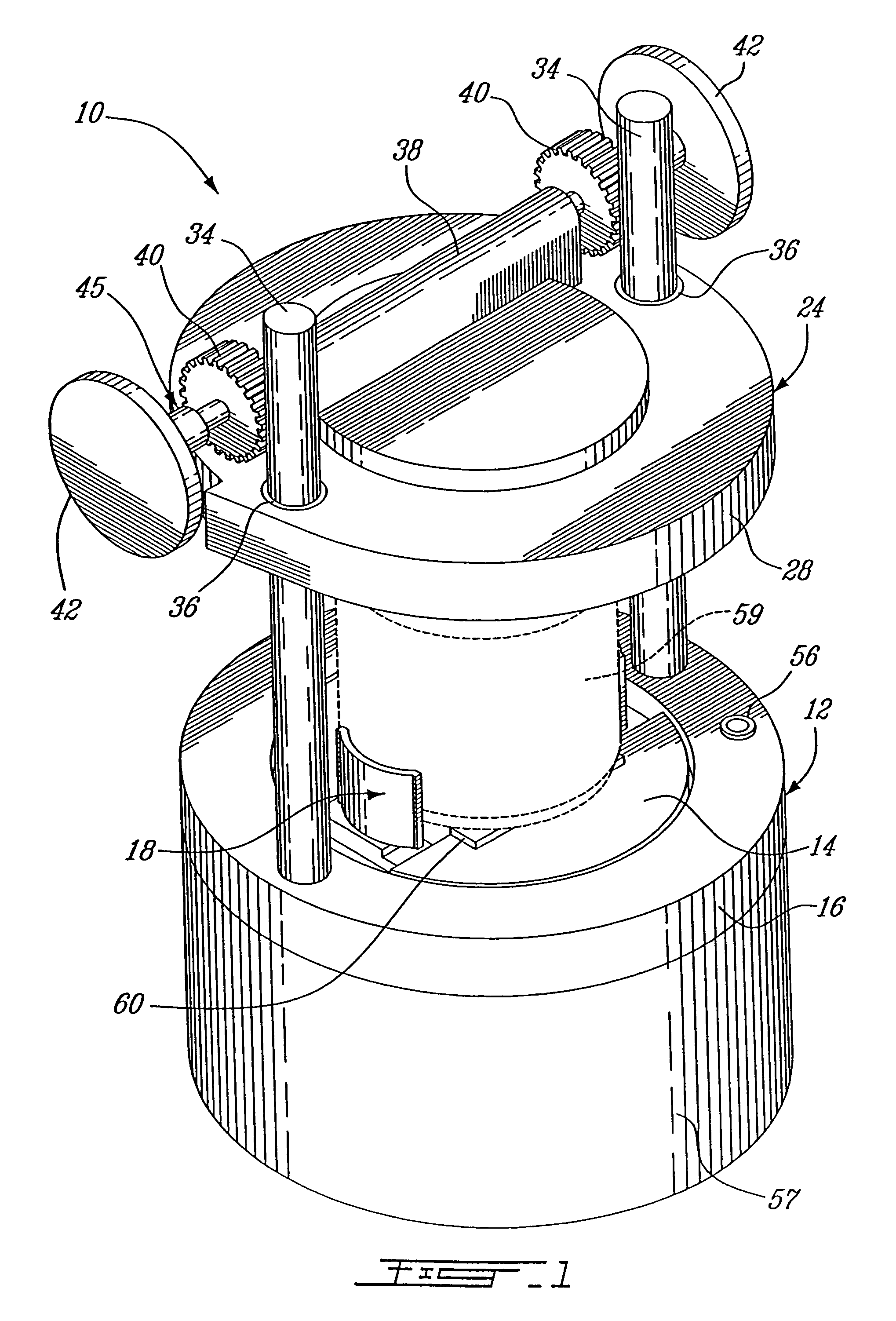

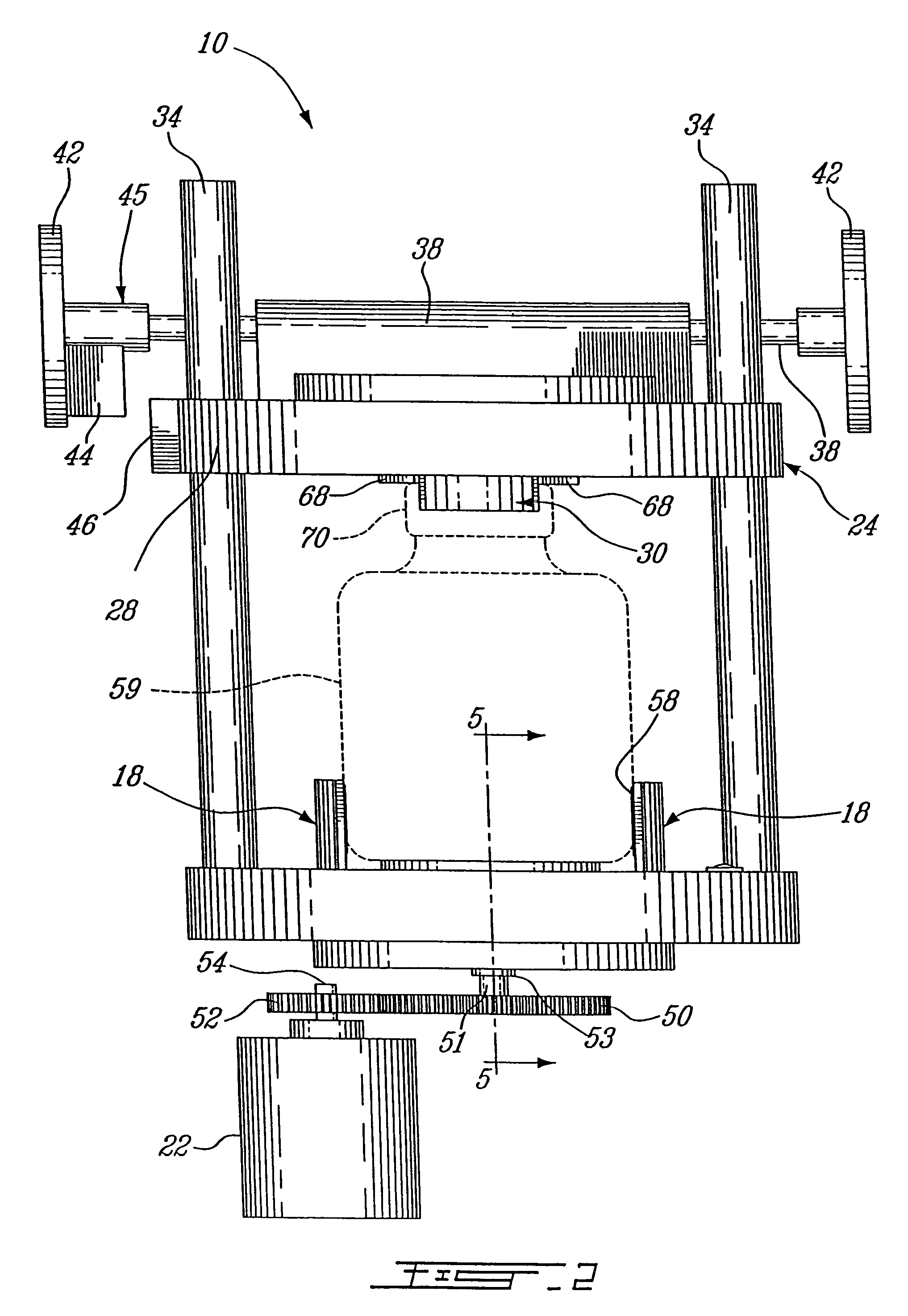

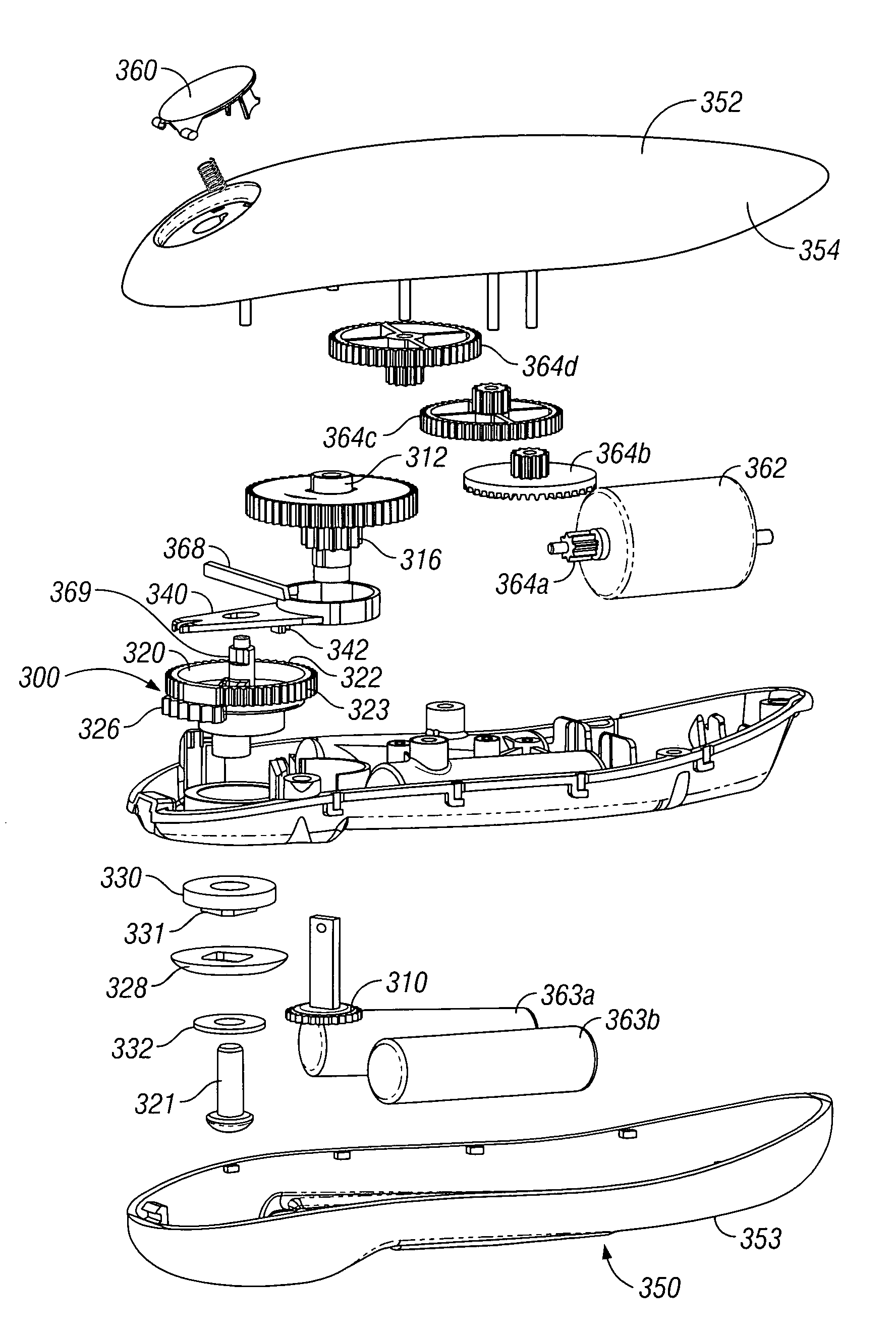

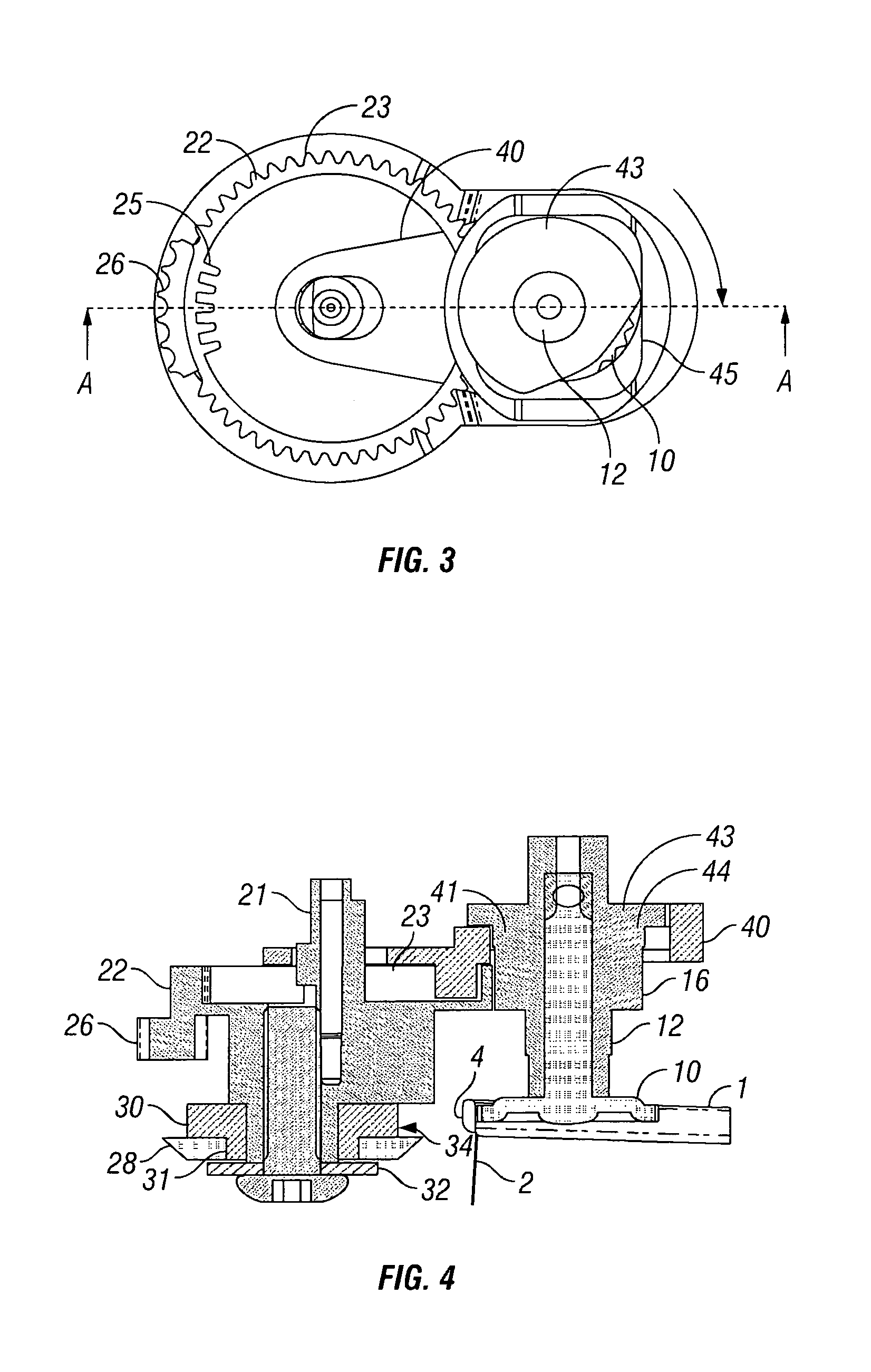

Semi-automatic jar opener

The present disclosure is a semi-automatic jar opener made up of a lower part including a run button activating an electric motor mounted under the lower part, which allows a lower plate to turn and activate a gear rack allowing the lower jaws provided with non-skid rubber strips to squeeze a jar according to the desired size, when the jar turns the friction rubber strips prevent it from sliding, and when the jar is unscrewed the electric motor stops automatically.The vertical jagged posts are mounted onto the lower part and engaged inside the apertures of an upper part including a base with an extension on which is mounted a shaft passing through gears and knobs, which in pulling on the knob including a locking means it allows to lower manually the upper part onto the posts, which includes an upper plate provided with the friction rubber strips pressing a lid and preventing it to slide, when the lower plate turns it allows automatically the jar and the upper plate to turn, which activates a gear rack allowing the upper jaws provided with non-skid rubber strips to squeeze the lid until the jar be unscrewed.The extension of the base from the upper part allows the means locking to block the knob when the jar is removed from the semi-automatic jar opener.

Owner:TREMBLAY DONALD

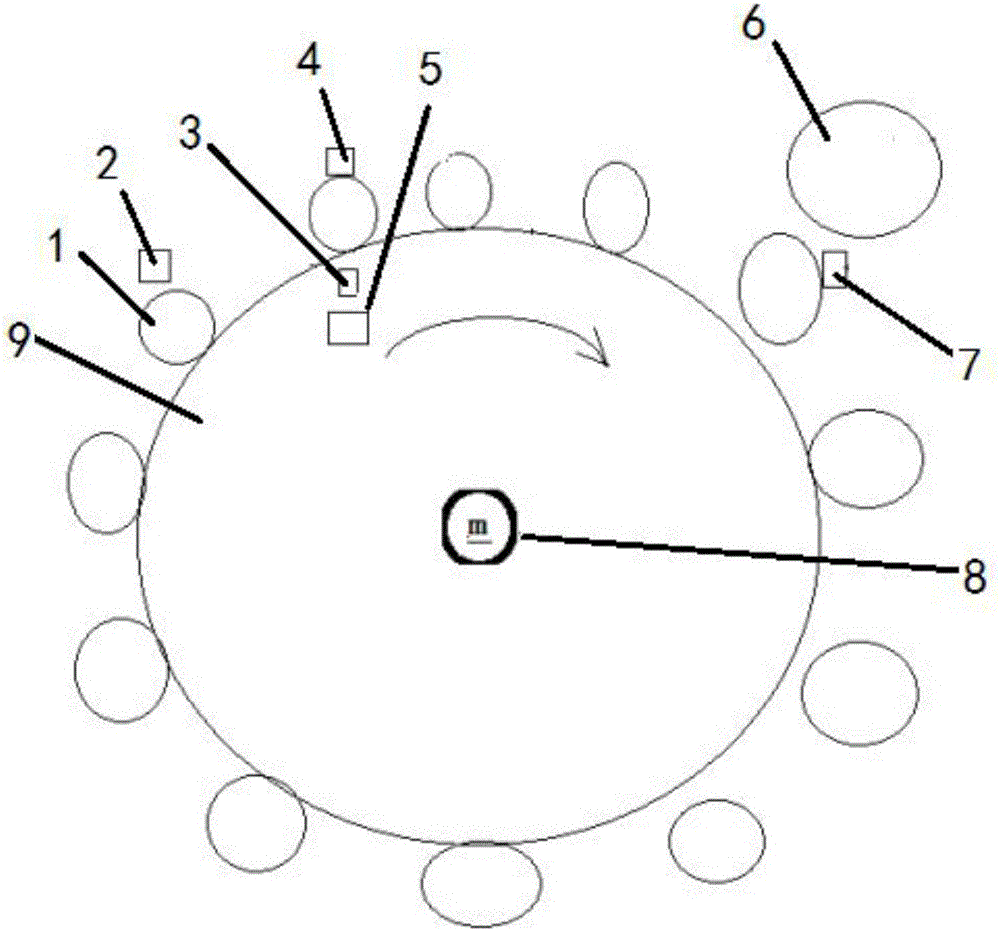

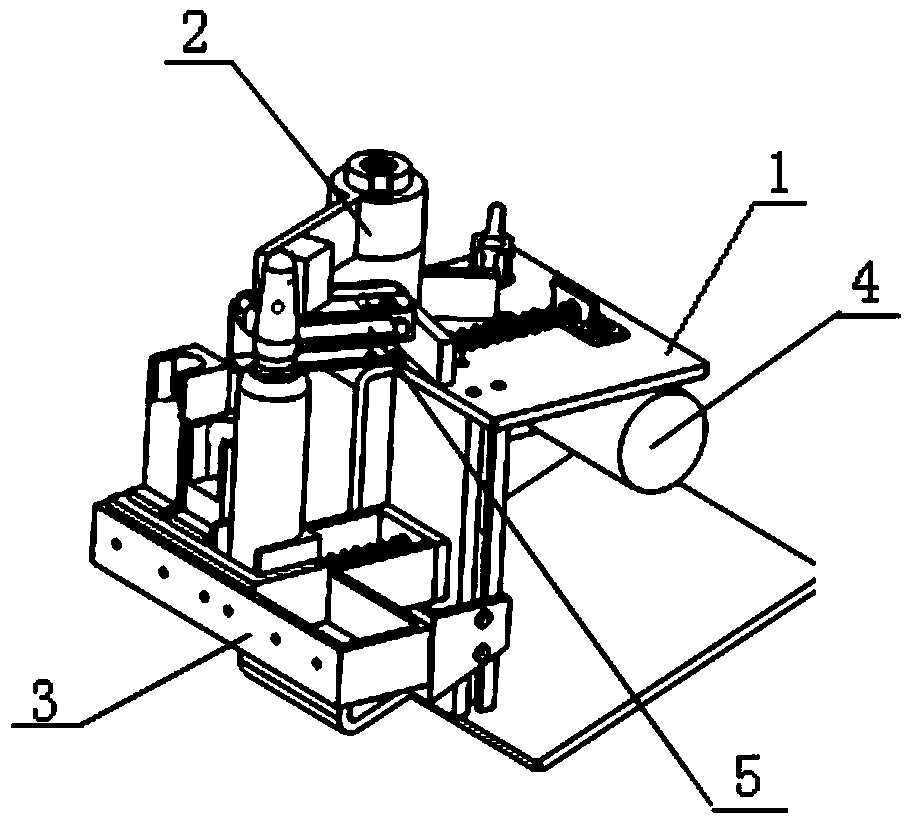

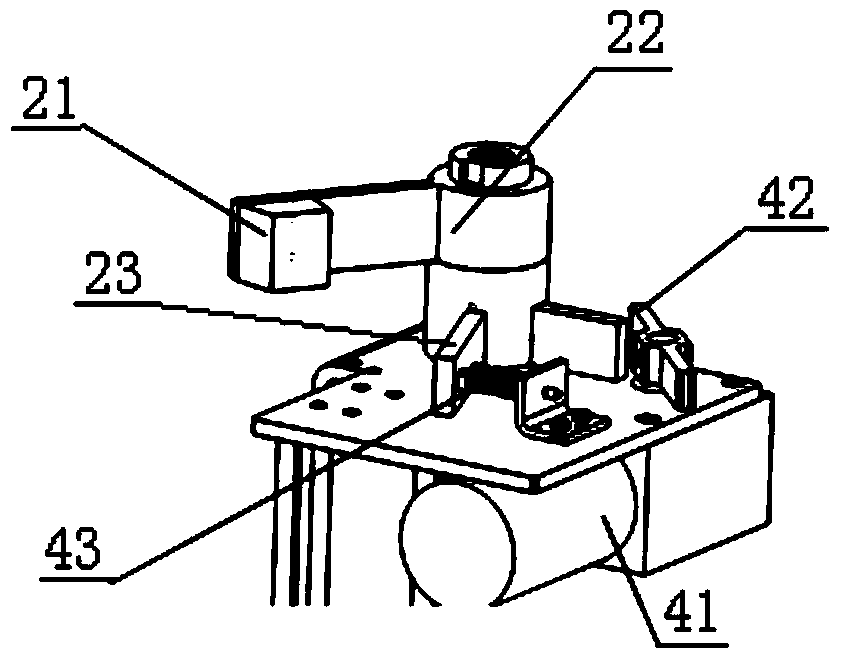

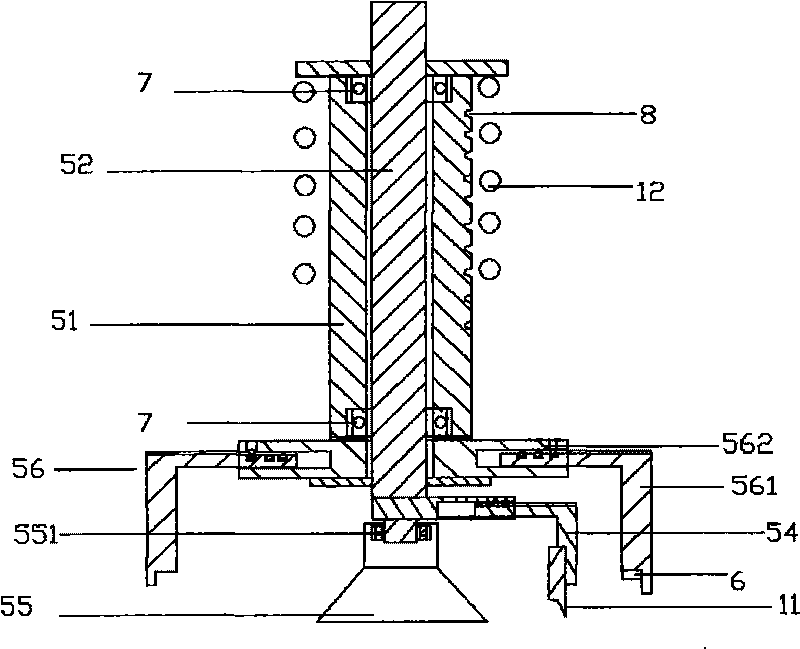

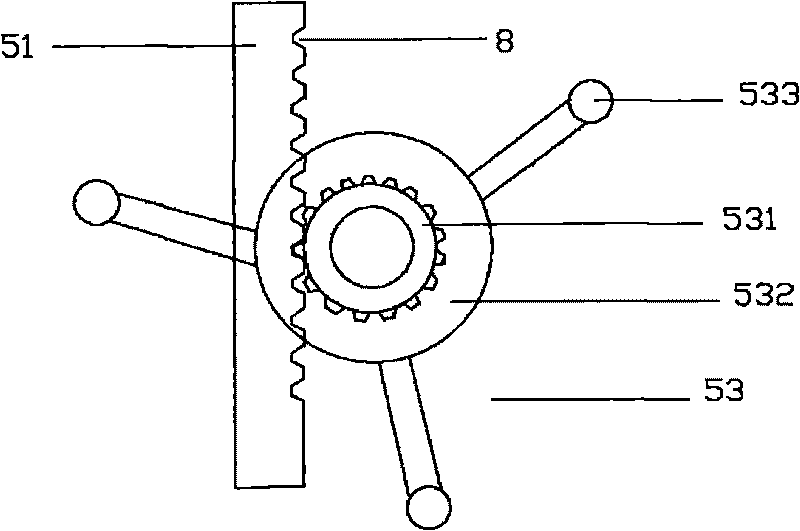

Automatic opening equipment for ampoule bottles

ActiveCN106044676AWon't breakAvoid pollutionBottle/container closurePower operated devicesAutomatic test equipmentEngineering

The invention provides automatic opening equipment for ampoule bottles. The equipment comprises a plurality of sleeve seats with a fixed movement trajectory, wherein the plurality of sleeve seats circulate sequentially and continuously along the movement trajectory; a detection station, a cutting station and a bottle opening station are sequentially arranged on one or two sides of the movement trajectory in the movement direction of the sleeve seats; a photoelectric sensing device is arranged at the detection station; an ampoule bottle cutting device is arranged at the cutting station; an ampoule bottle breaking-off device is arranged at the bottle opening station; and ampoule bottle sleeves for bearing the ampoule bottles are mounted in the sleeve seats. The equipment can be used for opening the ampoule bottles continuously and automatically, can cut, sterilize and break off bottleneck parts automatically and can collect broken ampoule bottle heads which are broken off, the bottle opening efficiency is high, bottle bodies are stable in the bottle opening process, the bottle bodies below the bottlenecks cannot be damaged, and the safety is good; and fragments can be prevented from falling into the bottle bodies in the ampoule bottle opening process, and medicine liquid pollution is avoided.

Owner:南通国峰新材料科技有限公司

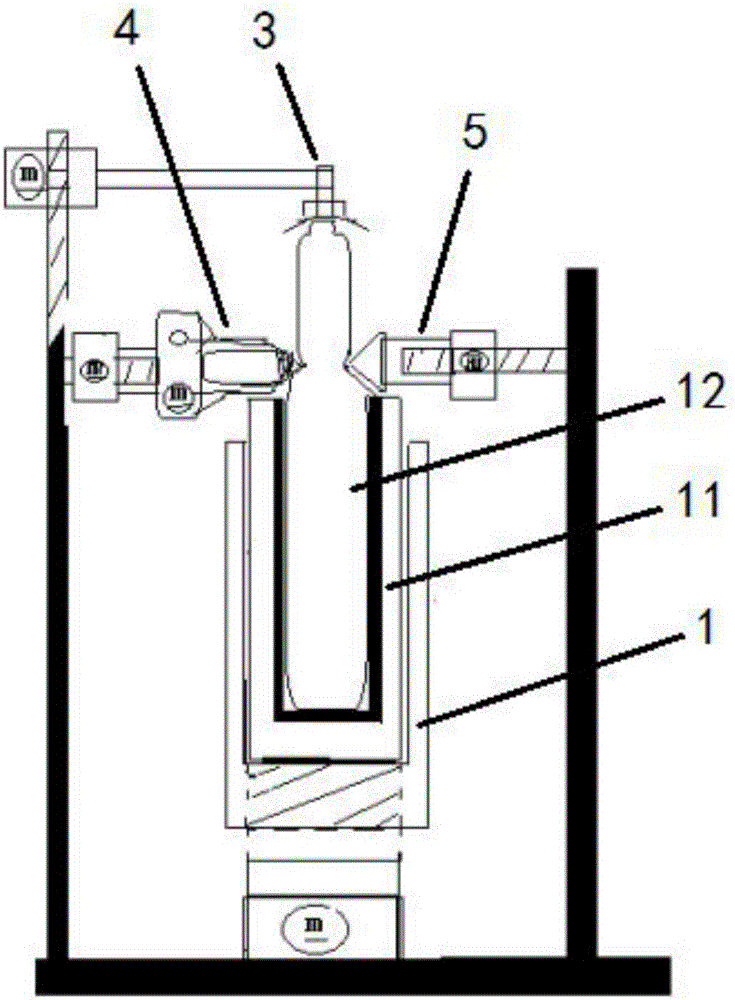

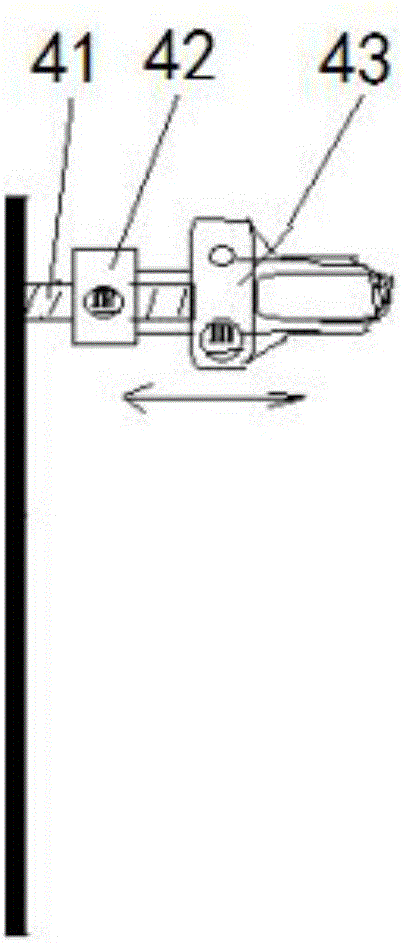

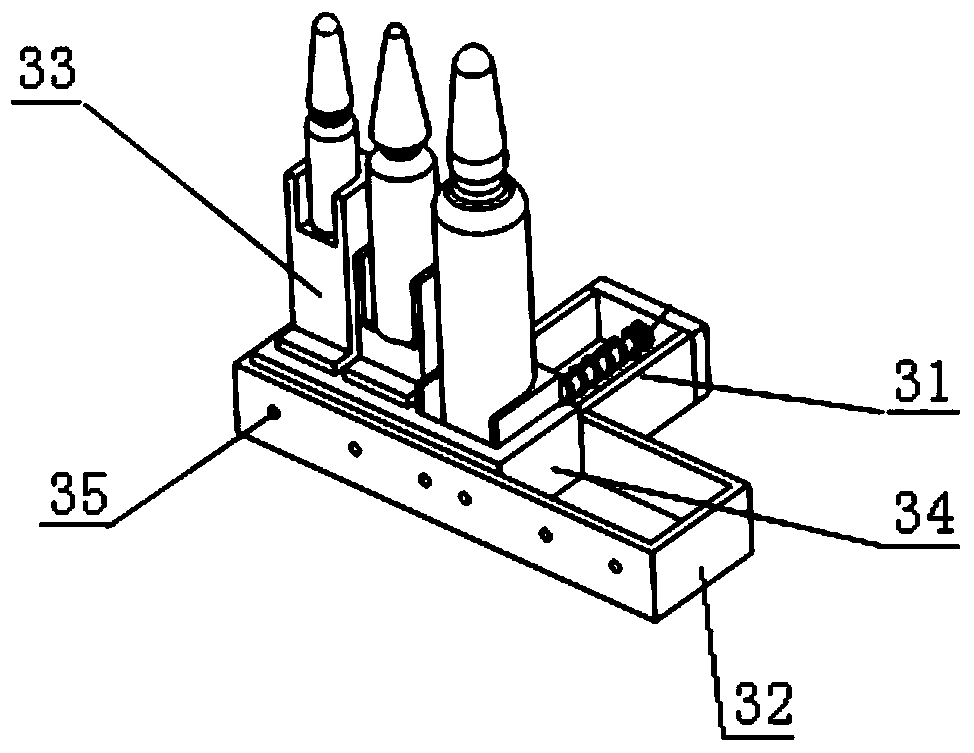

Automatic ampoule bottle opening device replacing bottle in horizontally-pushing mode

ActiveCN103803466ASimple structureEasy to operateBottle/container closurePower operated devicesEngineeringBottle

The invention relates to the technical field of ampoule bottle opening devices, in particular to an automatic ampoule bottle opening device replacing a bottle in a horizontally-pushing mode. According to the automatic ampoule bottle opening device replacing the bottle in the horizontally-pushing mode, a beating mechanism is driven by a driving mechanism to beat ampoule bottles, and the ampoule bottles with the different types are selected through a bottle replacing mechanism. The automatic ampoule bottle opening device is simple in structure and convenient to operate; the neck of each ampoule bottle can be cut easily and quickly, the workload of medical workers is reduced, and the medical workers can be effectively prevented from being cut when opening the ampoule bottles; the working intensity of the medical workers is reduced through automatic beating and bottle opening operations; the accuracy of bottle opening is guaranteed, the effect of human factors is reduced, glass powder and scraps cannot fall into bottle liquid so that the medicine cannot be polluted no matter when the bottles are opened; the automatic ampoule bottle opening device meets the requirements for opening the ampoule bottles with different standards, and the ampoule bottles with the different standards can be opened conveniently and rapidly.

Owner:董小强

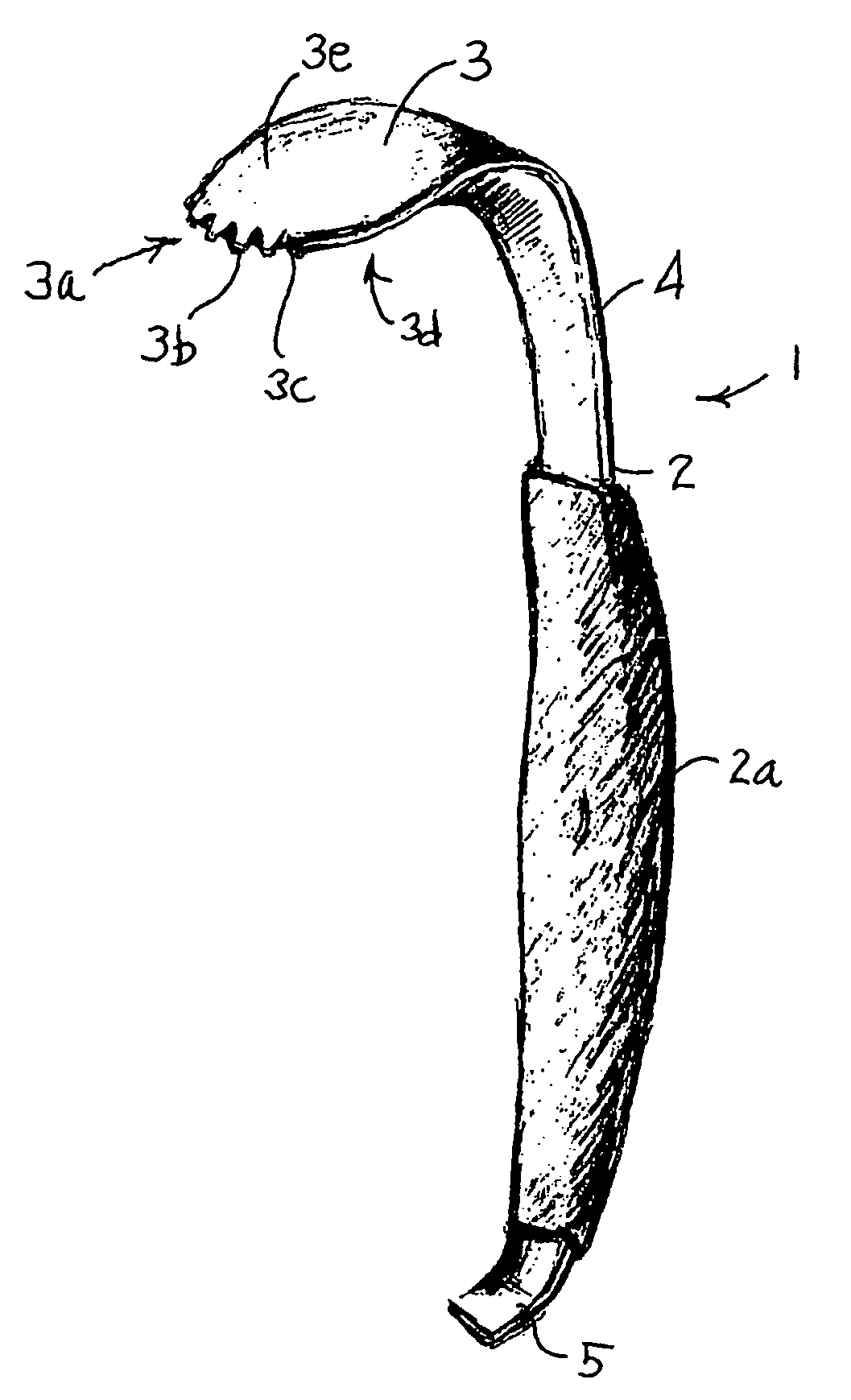

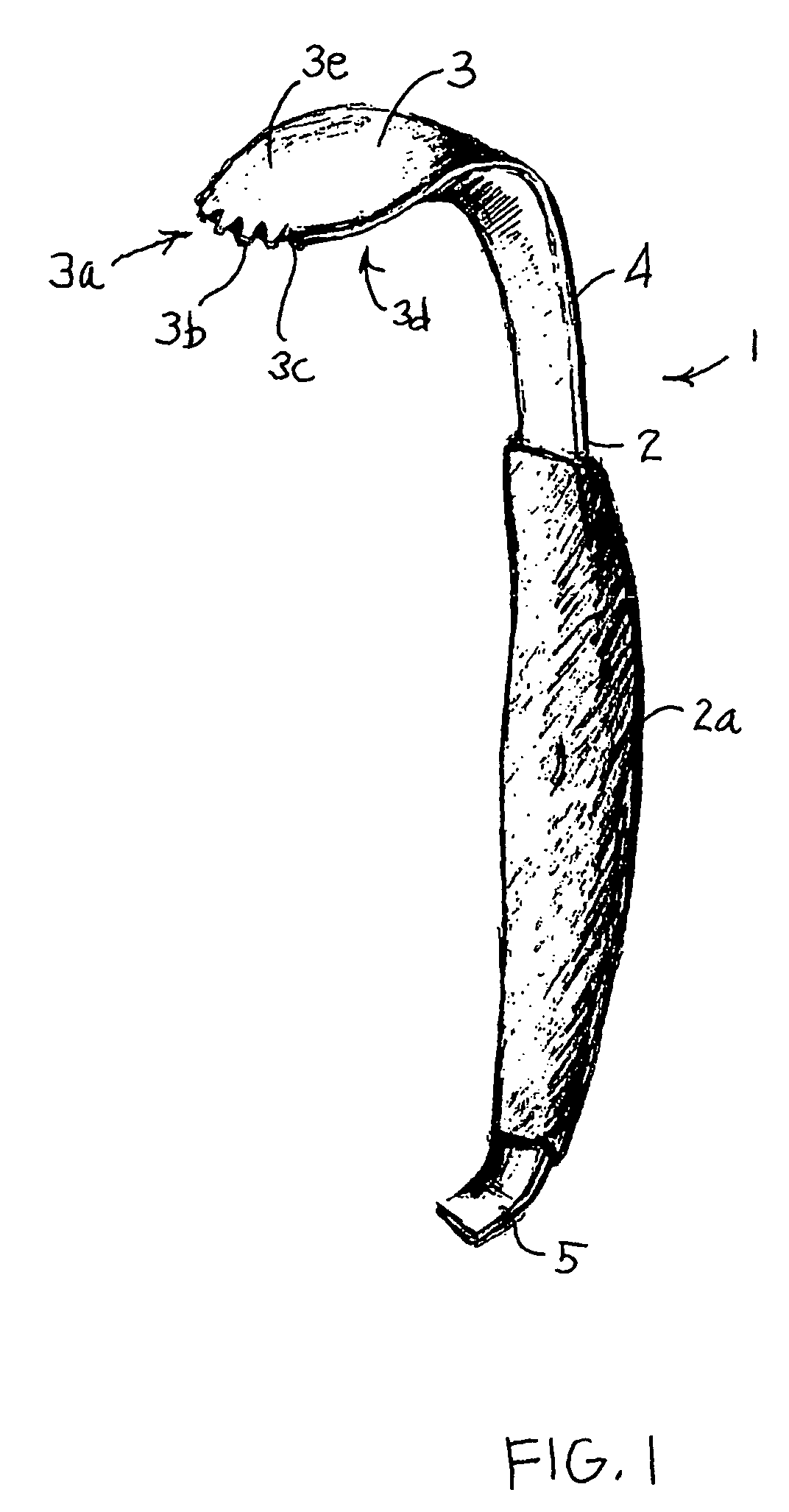

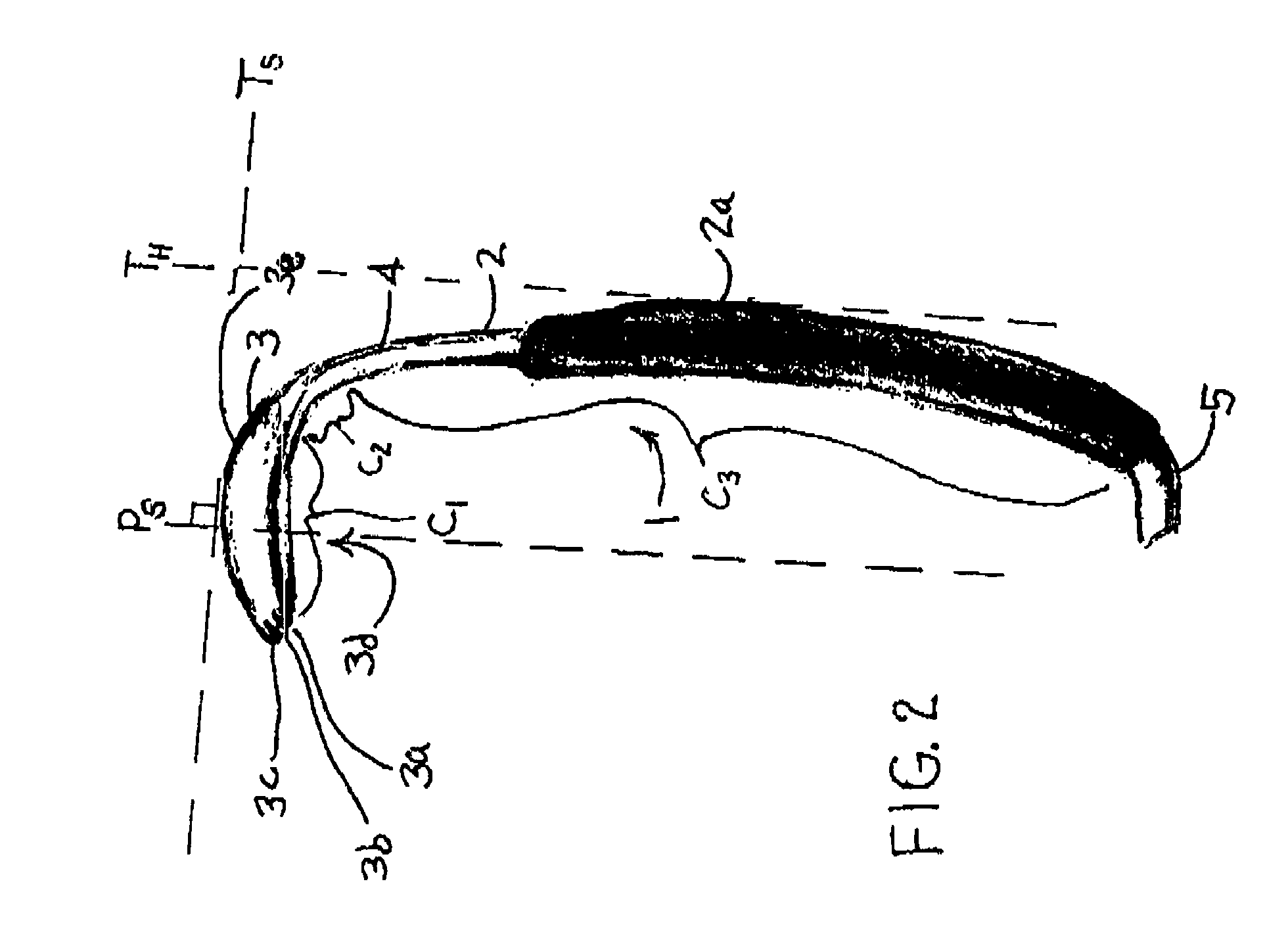

Bagel scooper

ActiveUS7458163B2Eliminates scoopingSimple structureLiquid surface applicatorsPower operated devicesLeading edgeBaked goods

A bagel scoop removes excess dough from a piece of baked goods, such as a bagel. The bagel scoop includes a handle, and a concave, preferably shallow elliptical spoon-shaped closed combined blade and scoop structure, having a downward curvature, to enable scooping and removal of dough. The outer distal end of the combined blade and scoop structure is preferably serrated, to allow for scraping and scooping of the bagel core dough at a leading edge of the blade. The combined blade and scoop structure is attached to a stem, which, in turn, is attached to the handle. A small auxiliary scraper is provided at an opposite end, for fine scraping and removing of excess dough residue not taken by the shallow elliptical spoon-shaped closed combined blade and scoop structure.

Owner:TEICH ELIZABETH CHELSEA +1

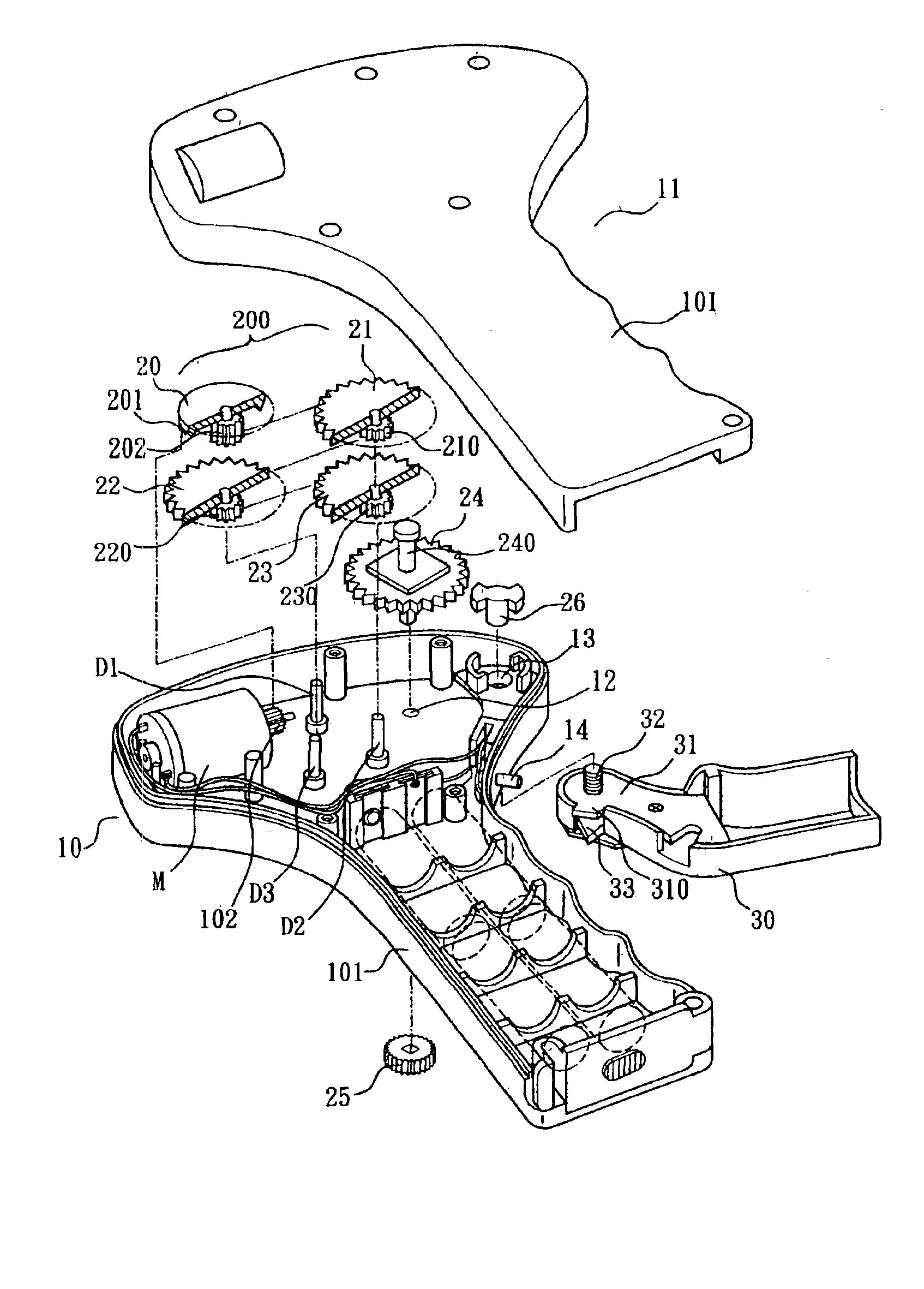

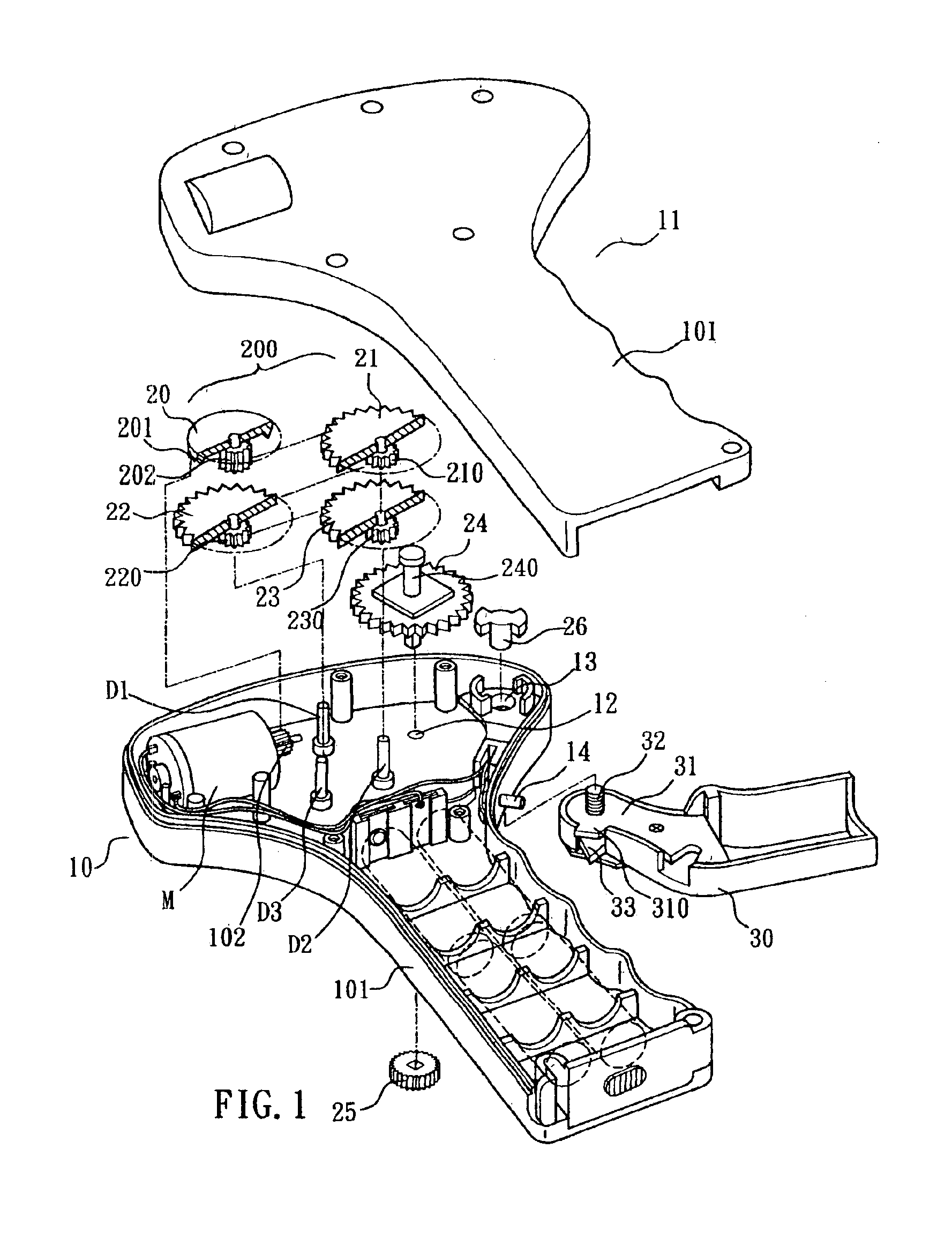

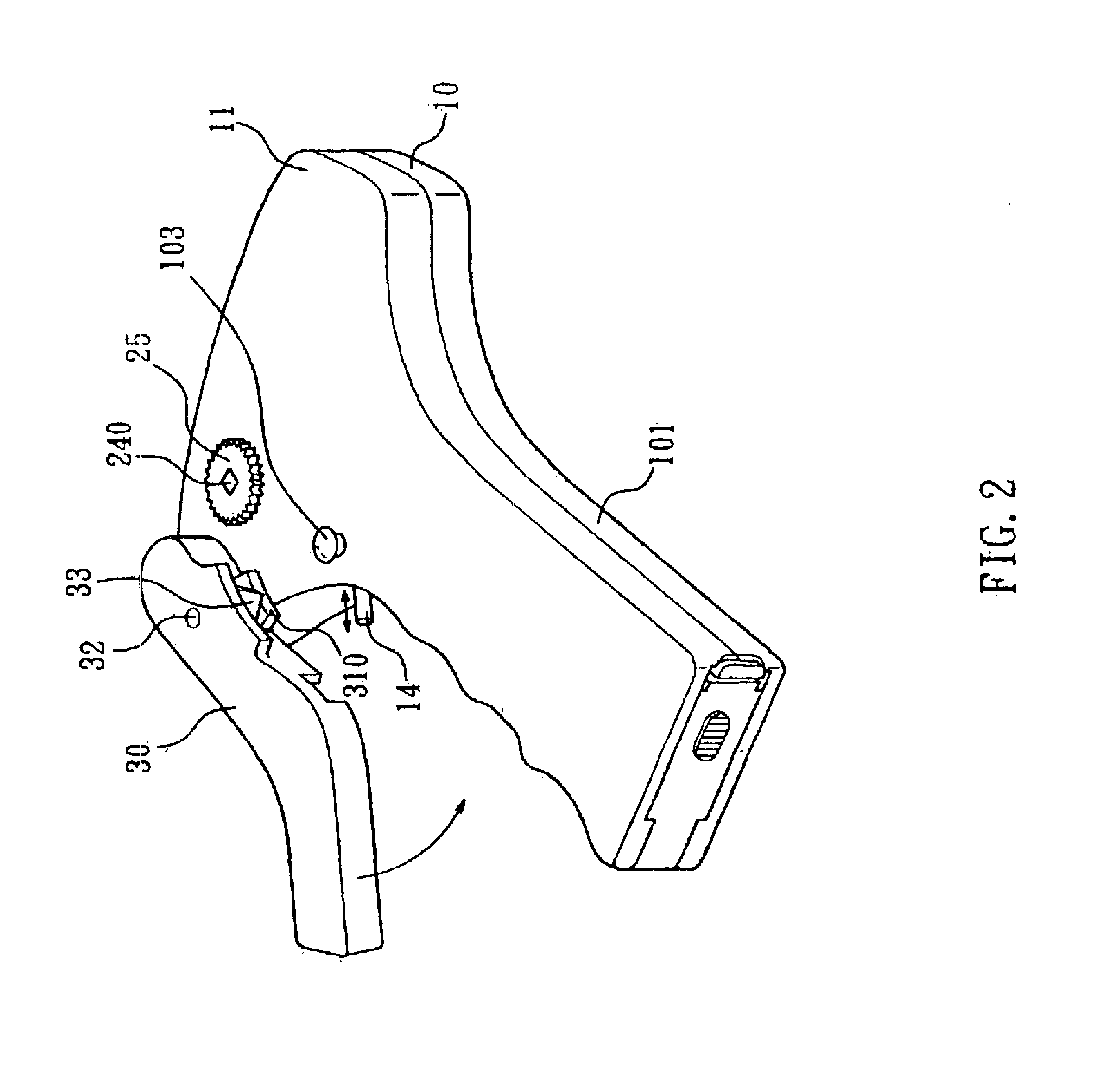

Electromotive can opener

InactiveUS6886260B1Increase torqueBottle/container closurePower operated devicesGear wheelDrive shaft

An electromotive can opener comprises a body. The body is formed by a first half and a second half. A motor, a touch switch for actuating the motor, a high twisting gear set, and a cutter handle are assembled to the body. In the high twisting gear set, a plurality of following gears and driving gear are engaged one by one and then is engaged to a driven shaft. The driven shaft is assembled with a driving gear. A knife protrudes out of a cutter handle. In operation, the knife cuts into the can and the touch switch is pressed by the cutter handle to actuate the motor and the shaft is driven. The can is driven to rotate to be cut along the periphery by the knife; and high twisting gear set formed by the plurality of gears provides a high twisting force for securing the can firmly.

Owner:LEE HUI LING

Aluminum can puncturing device

The aluminum can puncturing device is a hand-held device that resembles a shot gun shell and of which is capable of puncturing an air vent into a side of an aluminum can in order to “shotgun” a beer. The aluminum can puncturing device includes a spring-loaded pin that retracts within a shotgun shell. The aluminum can puncturing device is placed onto an outer surface of an aluminum can and pushed thereon in order to extend the pin out from under the shotgun shell in order to pierce a vent hole into the aluminum can.

Owner:PRITCHARD KYLE

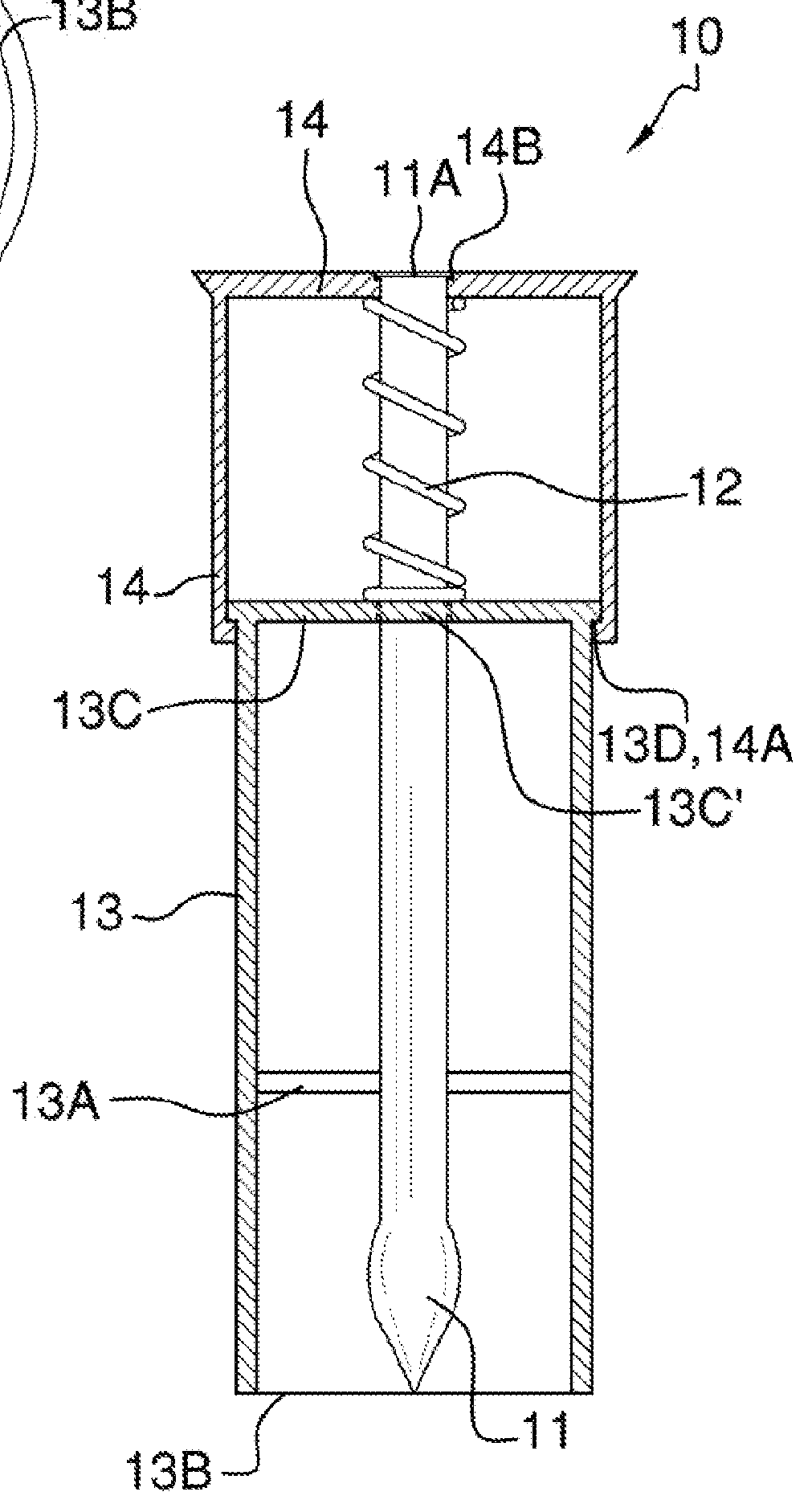

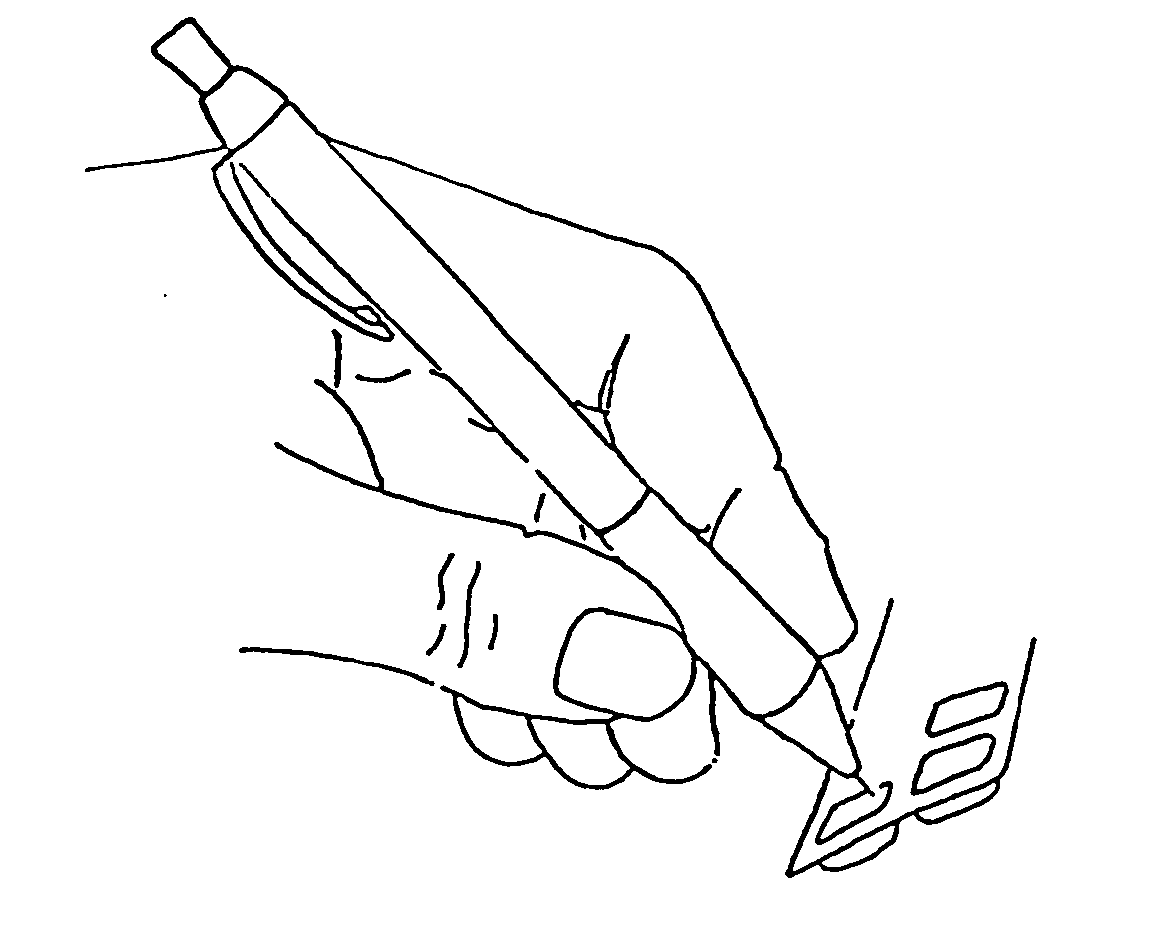

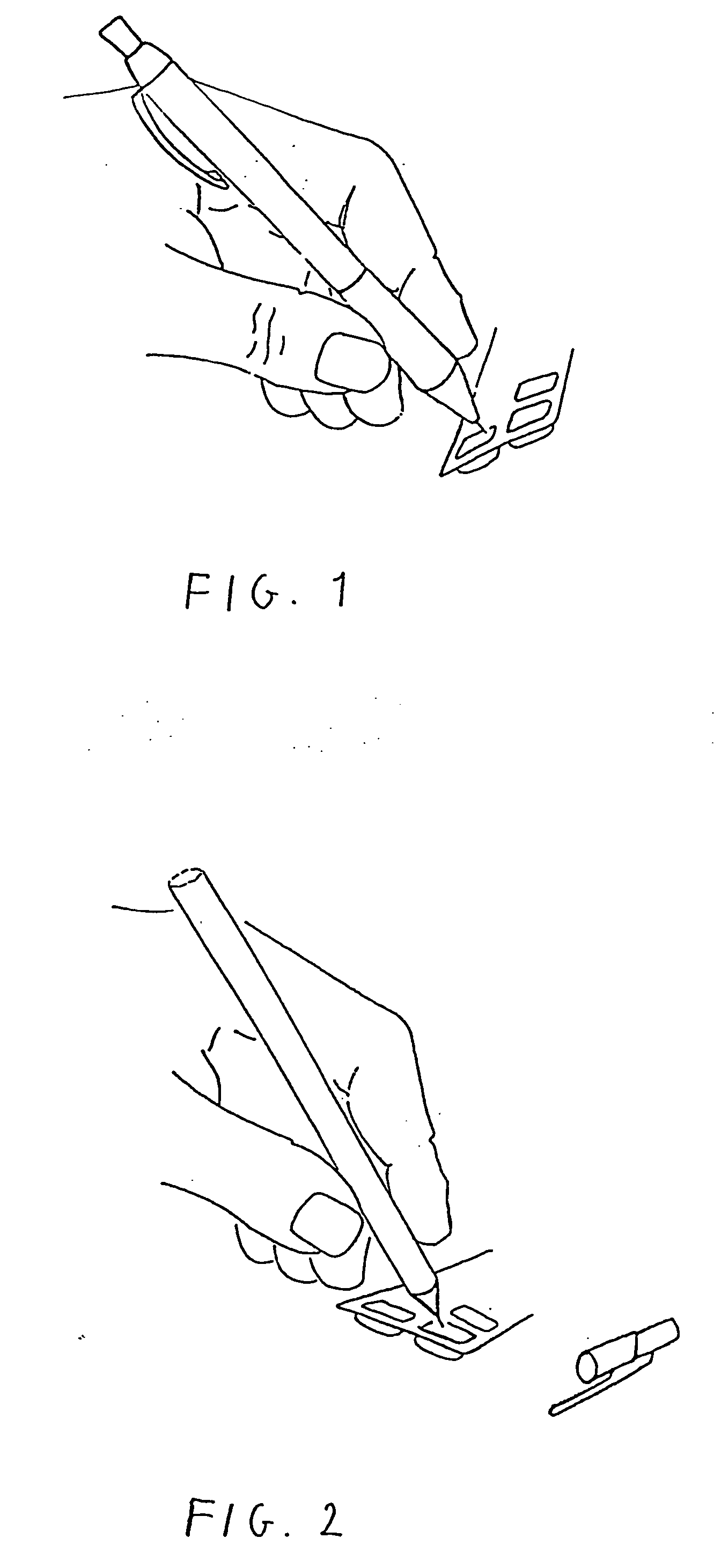

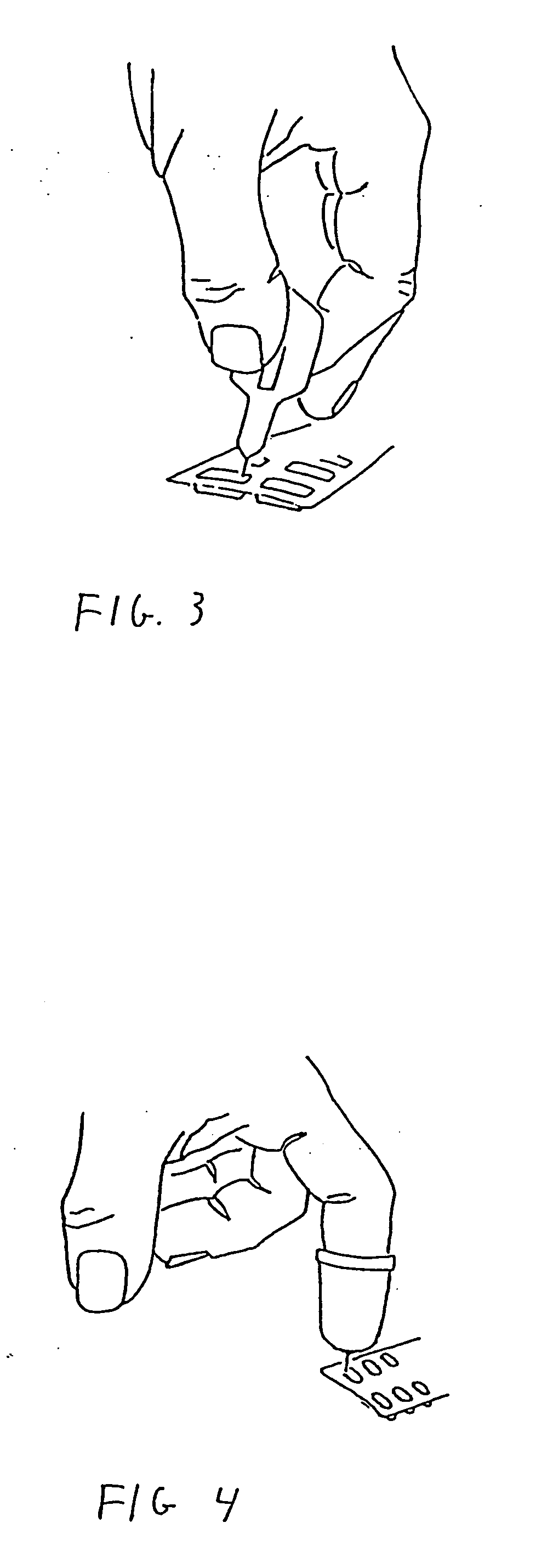

Blister knife

InactiveUS20050210682A1Reduce penetrationAvoid unintended cutsThrusting weaponsWeapon componentsBlister packBlisters

A device for opening blister packs without annular depressions around the blisters serving as guidance trails is provided comprising a handle and a cutter having a suitable transverse dimension and form of cross section at the position of the intended cutting, making it suitable for cutting the foil of the type used in blister packs, and for opening any pack or container wrapped in a foil or any other cutable material or tape used for packaging as such. A preferred cutter is having cutter formed essentially as a rod and further provided with a point in order to facilitate penetration of foils. The device may be provided with means for protection of the cutter in order to avoid unintended cuts during storage and transport. The handle of the device may be shaped in order to facilitate the use by elderly and / or patients suffering from a rheumatic disease. The device is versatile and simple to use and may provide a relief of a long felt problem for nurses and other medical staffs, elder patients and in particular patients suffering from a rheumatic disease.

Owner:BARTHOLIN HENRIK

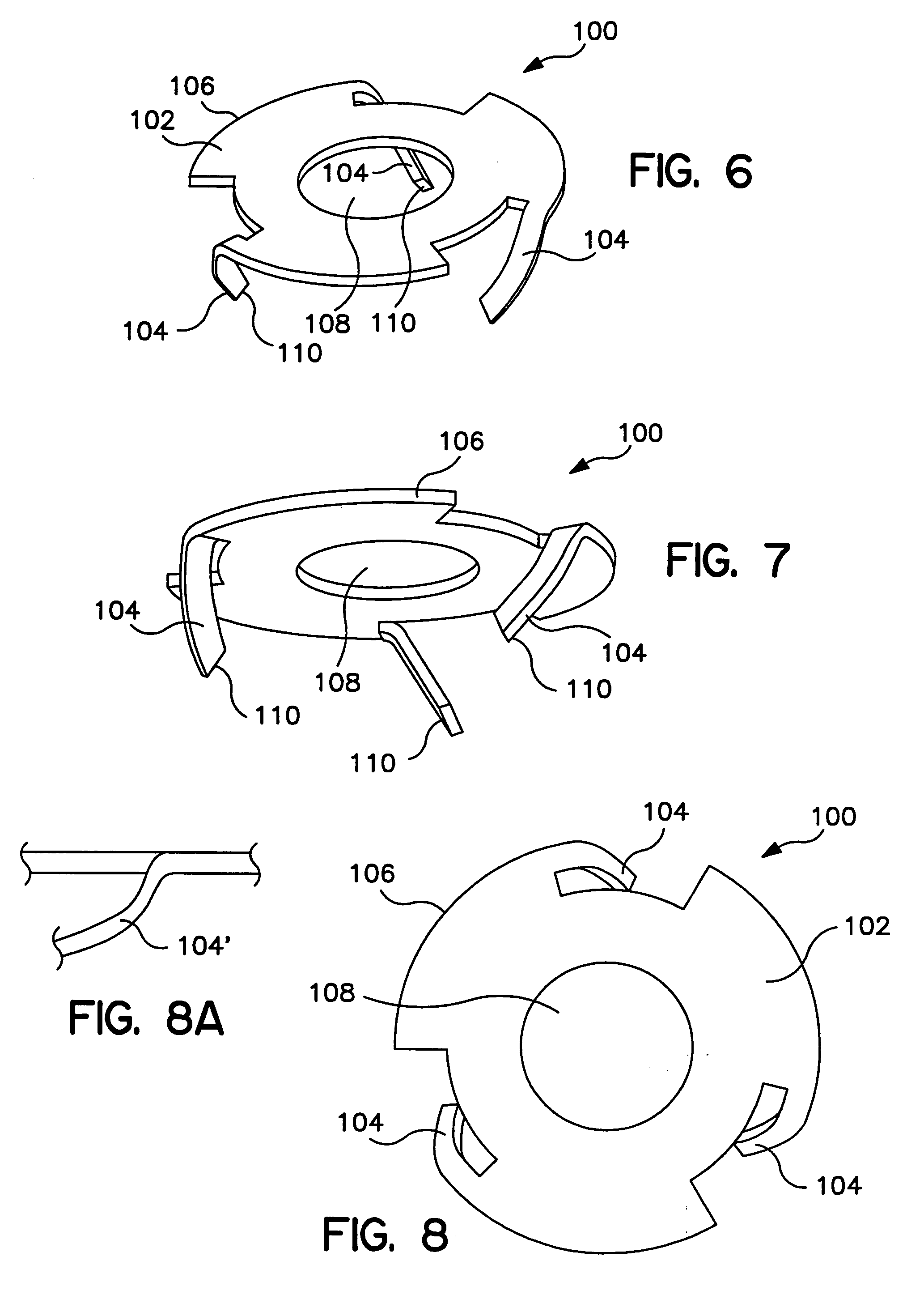

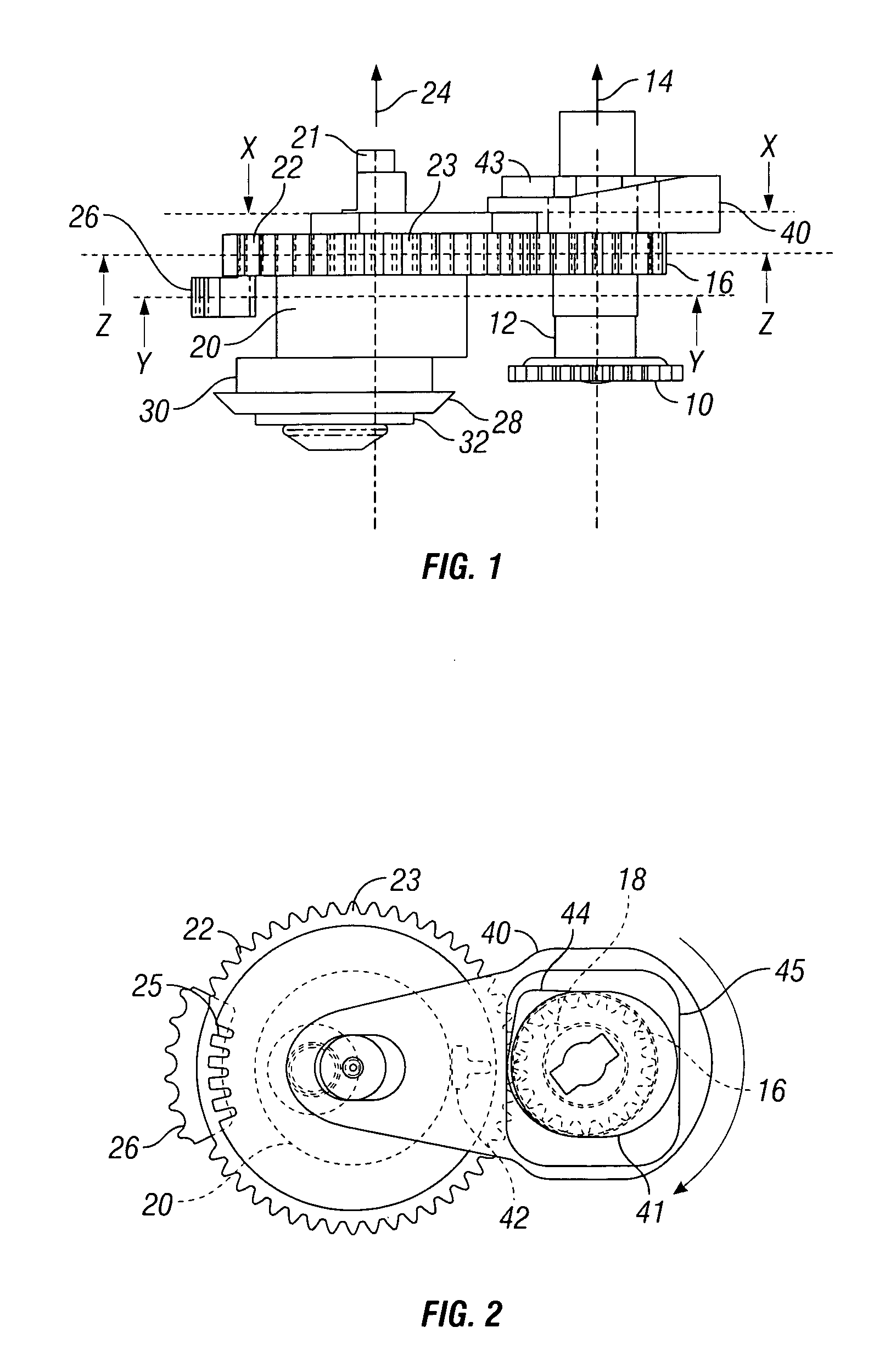

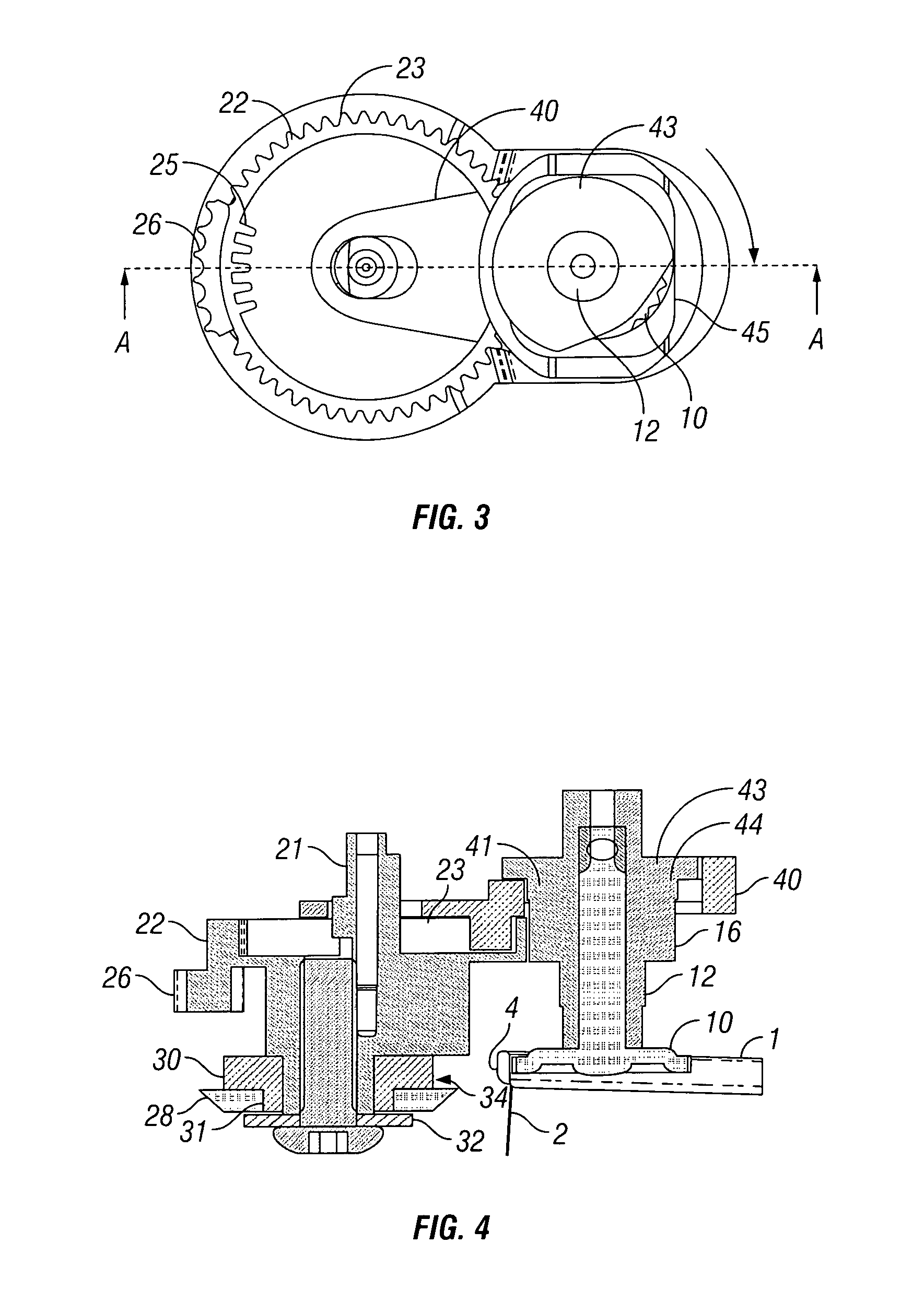

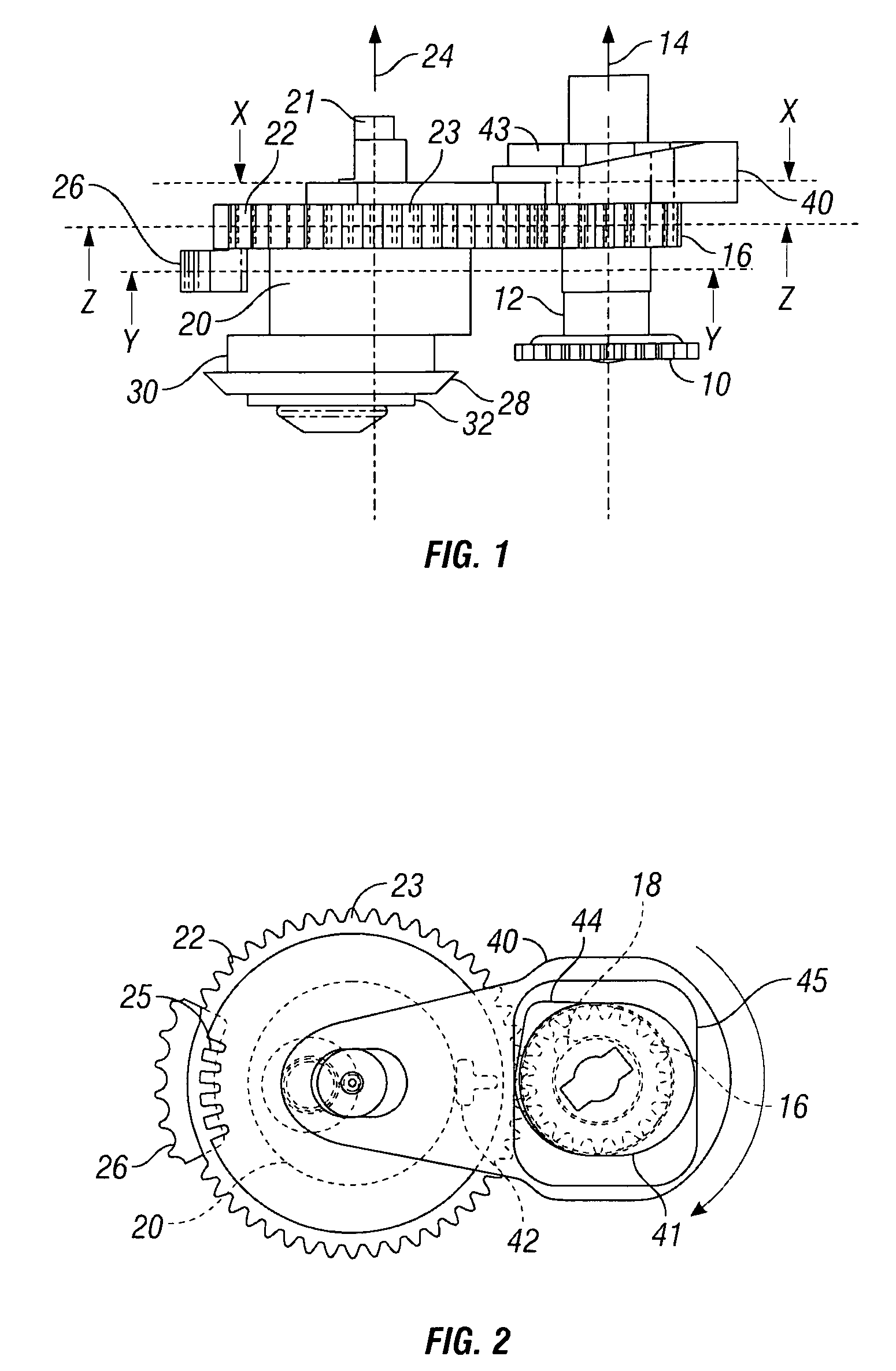

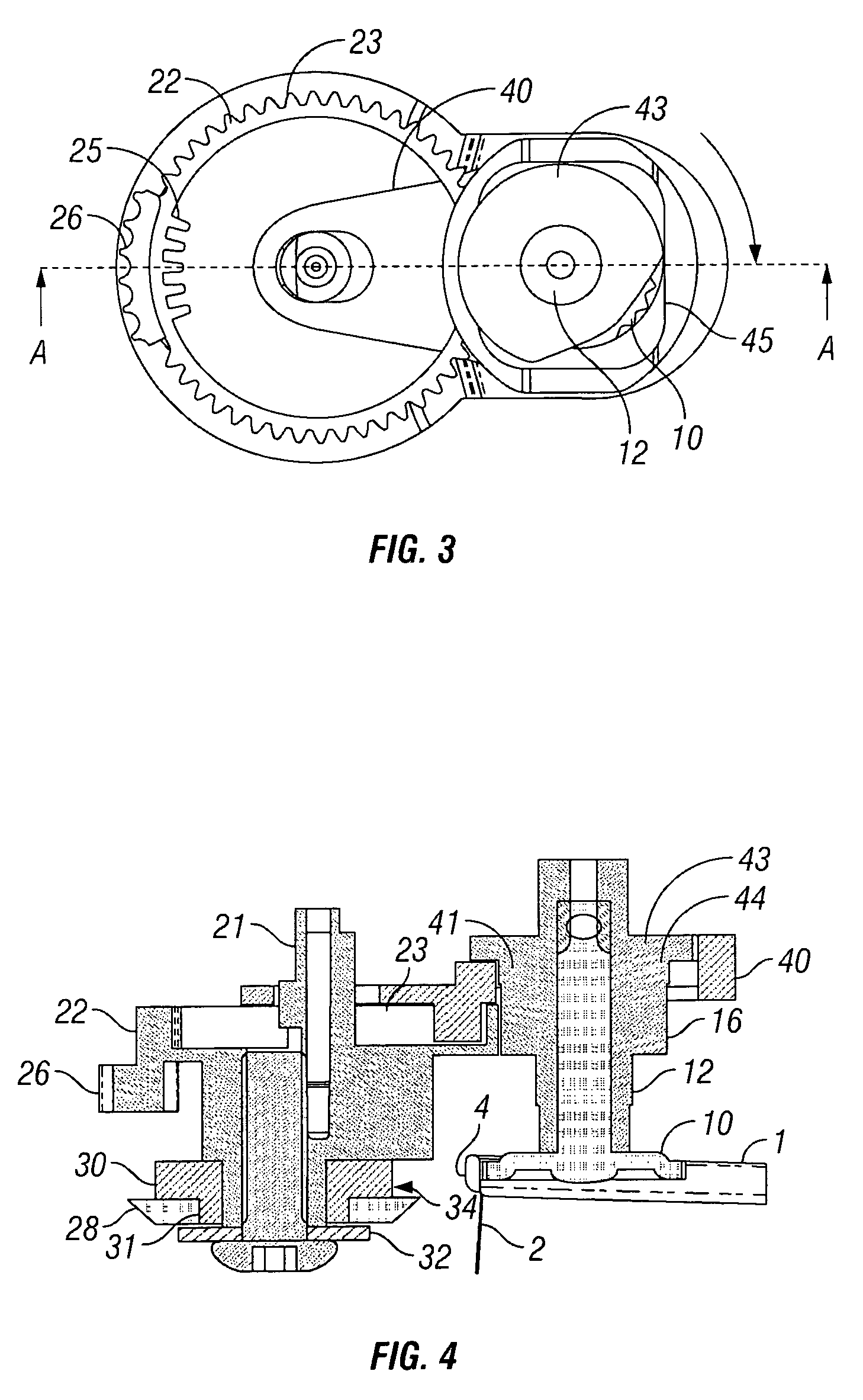

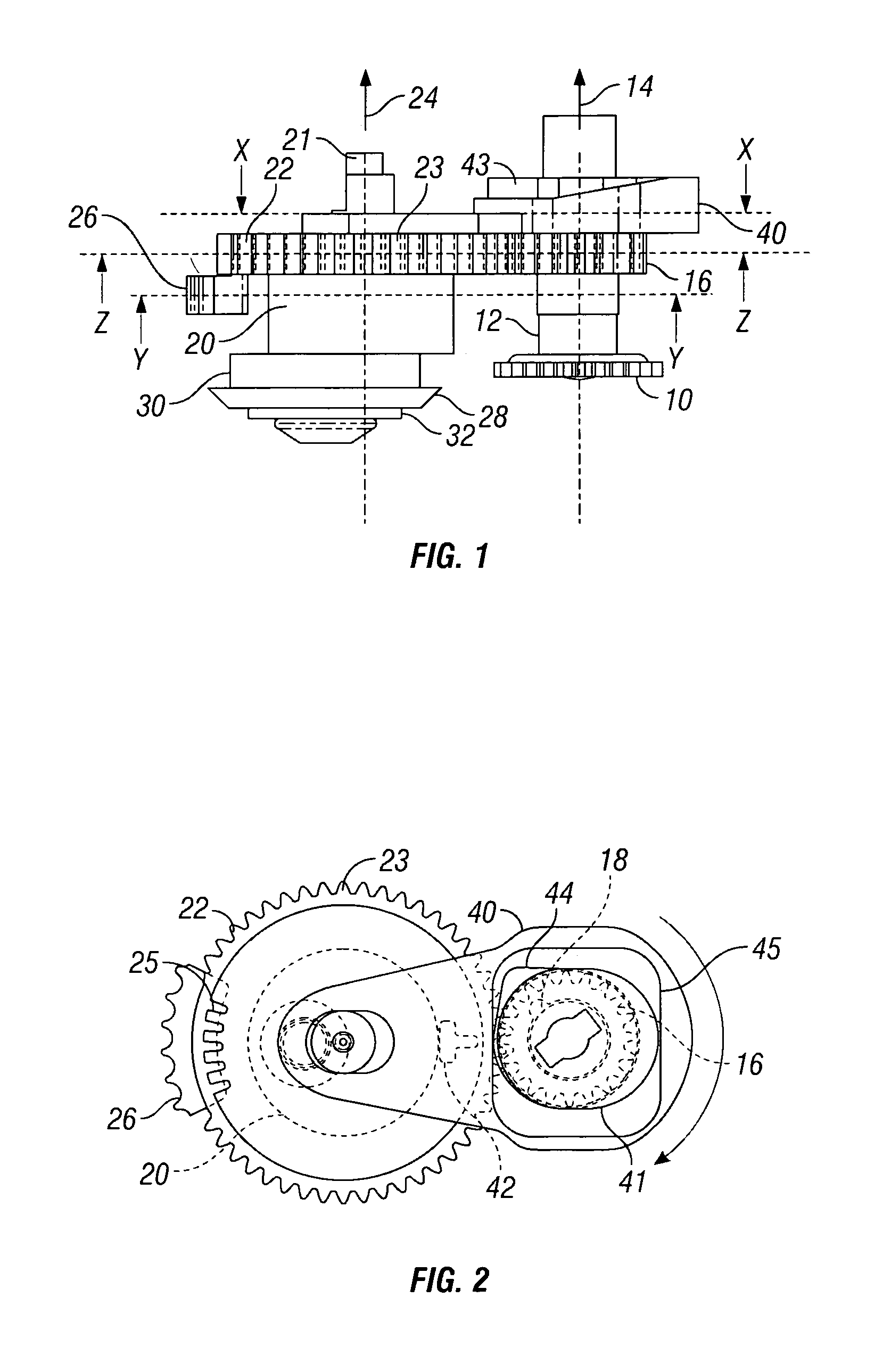

Mechanism for can opener

ActiveUS7437825B2Prevent rotationWider toleranceBottle/container closurePower operated devicesDrive wheelEngineering

A mechanism is provided for use in a can opener comprising a body; rotationally mounting to the body about a first axis a drive wheel for engaging the rim of a can; rotationally mounting to the body about a second axis and drivably rotatable by the drive wheel, a cutter wheel; eccentrically mounting to said cutter wheel, a cutting knife movable on rotation of the cutter wheel to a cutting position in which the cutter knife forms a nip with the drive wheel such that the cutting knife penetrates through the cylindrical wall of the can, to provide a cut therein as the opener orbits relatively therearound, wherein the cutting position is defined by a cutting interval corresponding to a segment of rotation of the cutter wheel in which the cutting knife is sufficiently proximal to the drive wheel to form the nip.

Owner:DAKA RESEARCH INC

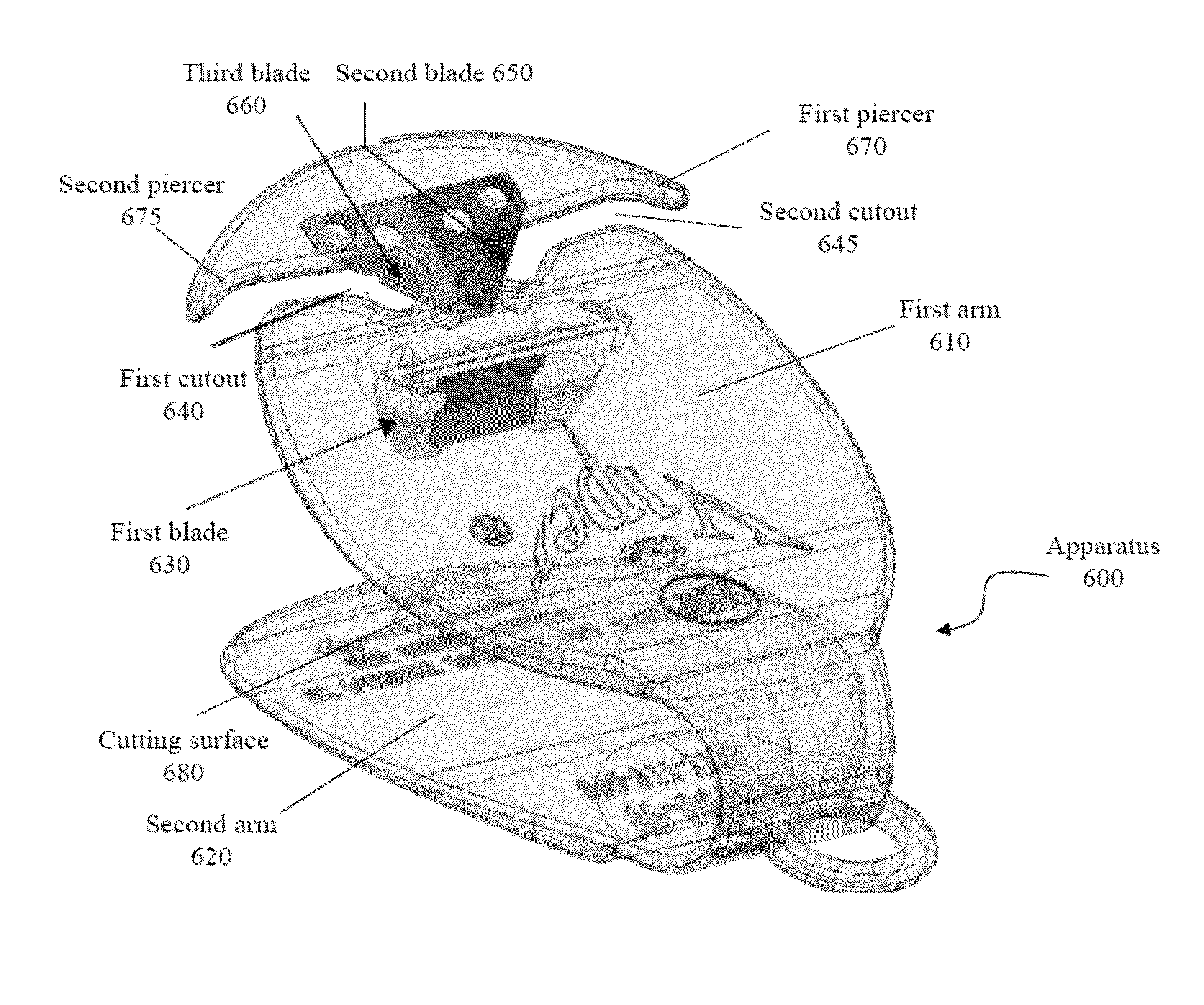

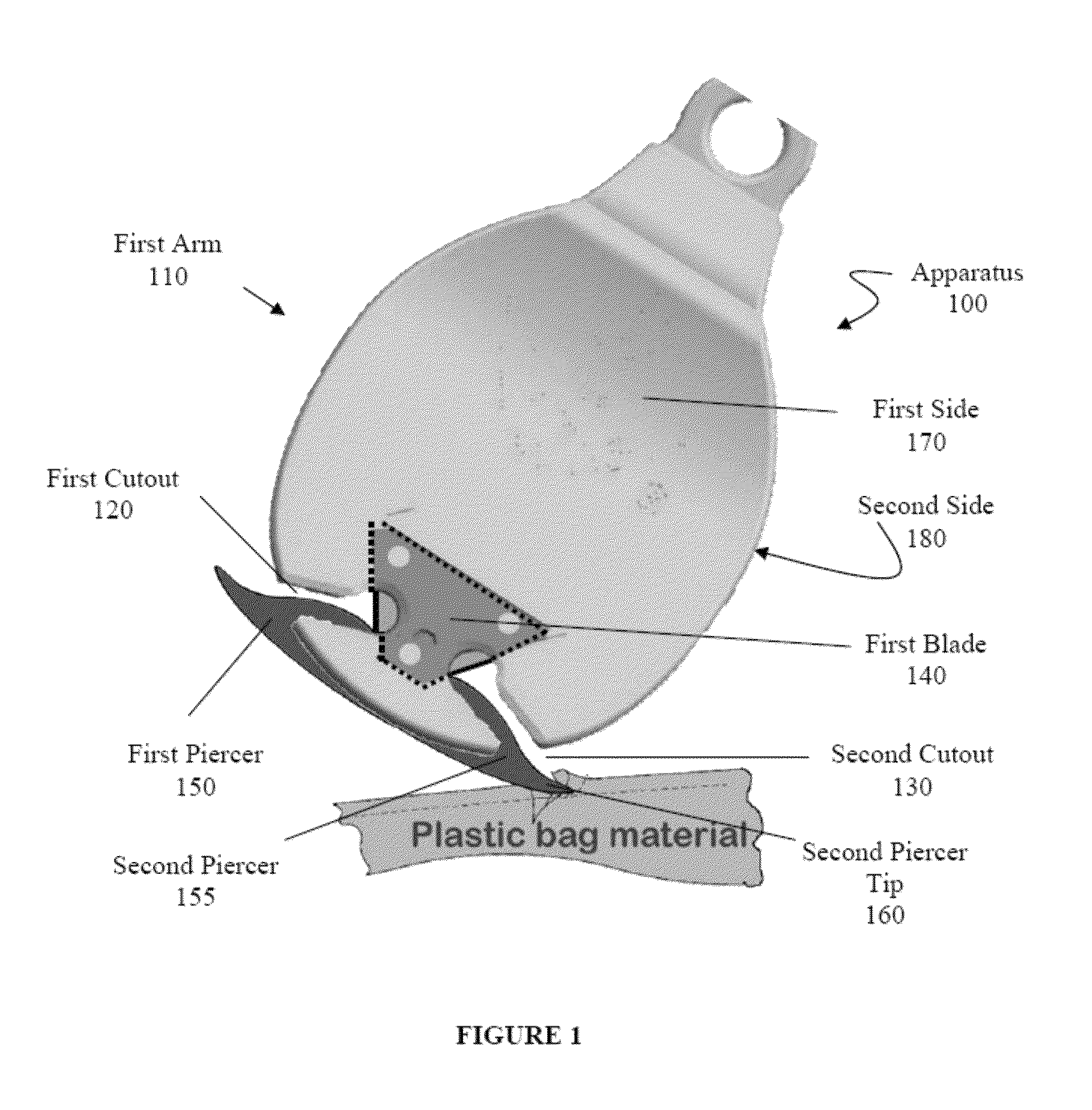

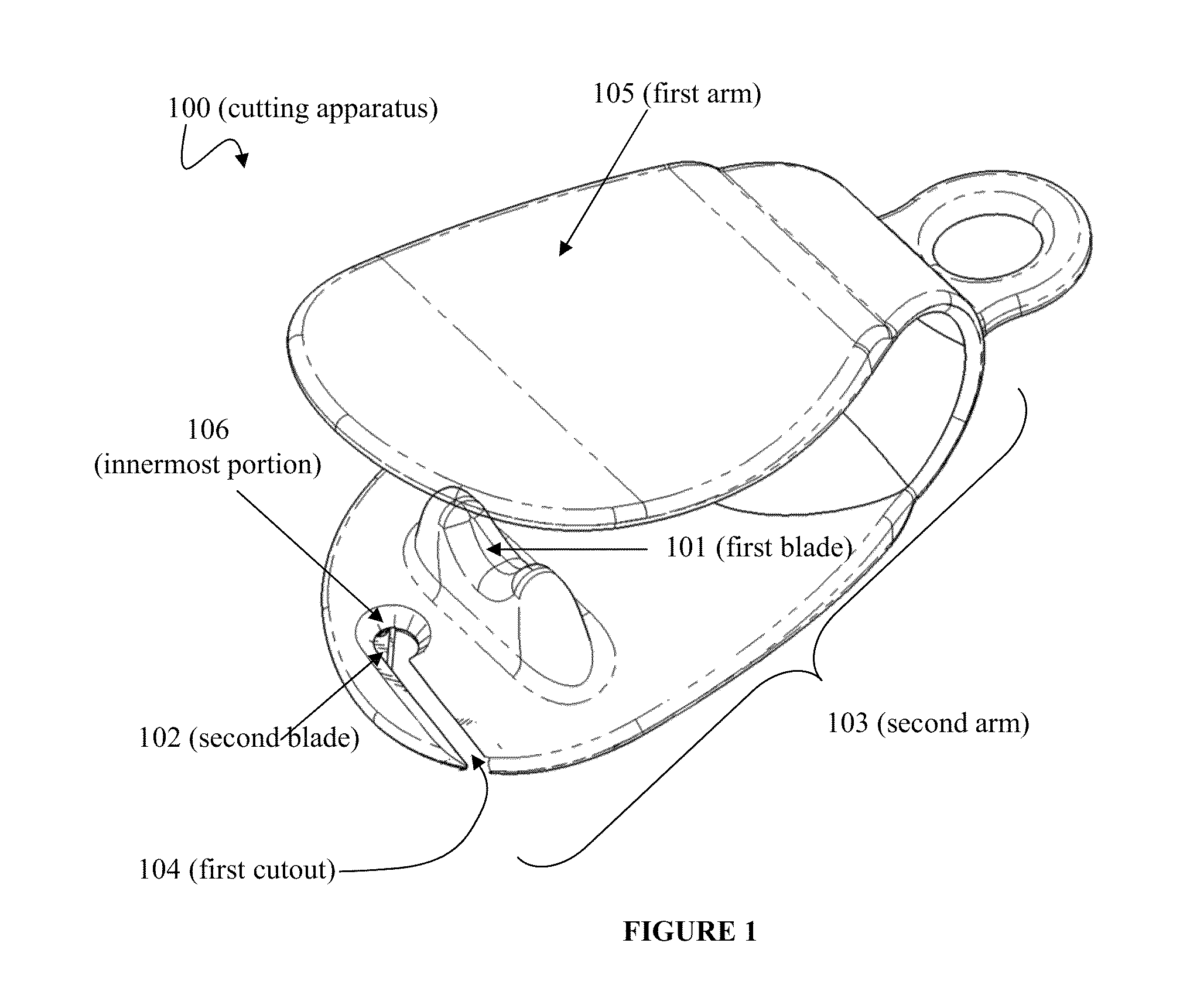

Bag cutter and piercer

ActiveUS8869408B2Safe and durableBottle/container closurePower operated devicesEngineeringMechanical engineering

A bag cutter for opening a sealed package using at least one of a blade and a piercer. Preferably, at least one blade is disposed partially within a cutout of an arm in a manner that exposes an edge of the blade. A piercer can comprise an extension of a cutout edge or be located on any other suitable portion of an arm. Another blade can be provided that is substantially perpendicular to the blade within a cutout, and juxtaposable against a cutting surface.

Owner:SPELLBOUND DEVMENT GROUP INC

Mechanism for can opener

ActiveUS7596874B2Prevent rotationWider toleranceBottle/container closurePower operated devicesDrive wheelEngineering

There is provided a mechanism for use in a can opener comprising a body; rotationally mounting to the body about a first axis, a drive wheel for engaging the rim of the can; rotationally mounting to the body about a second axis and drivably rotatable by the drive wheel, a cutter wheel; eccentrically mounting to the cutter wheel, a cutting knife movable on rotation of the cutter wheel to a cutting position in which the cutting knife forms a nip with the drive wheel such that the cutting knife penetrates through the cylindrical wall of the can, and in which an electrical sensor can be used to reverse the position of the cutting wheel back to a start position and in which a mechanical sensor can be used in conjunction with a locking bar to advance the cutting wheel back to a start position.

Owner:DAKA RESEARCH INC

Mechanism for can opener

ActiveUS7574808B2Prevent rotationWider toleranceBottle/container closurePower operated devicesDrive wheelEngineering

There is provided a mechanism for use in a can opener comprising a body; rotationally mounting to the body about a first axis, a drive wheel for engaging the rim of the can; rotationally mounting to the body about a second axis and drivably rotatable by the drive wheel, a cutter wheel; eccentrically mounting to the cutter wheel, a cutting knife movable on rotation of the cutter wheel to a cutting position in which the cutting knife forms a nip with the drive wheel such that the cutting knife penetrates through the cylindrical wall of the can, and in which an electrical sensor can be used to reverse the position of the cutting wheel back to a start position and in which a mechanical sensor can be used in conjunction with a locking bar to advance the cutting wheel back to a start position.

Owner:DAKA RESEARCH INC

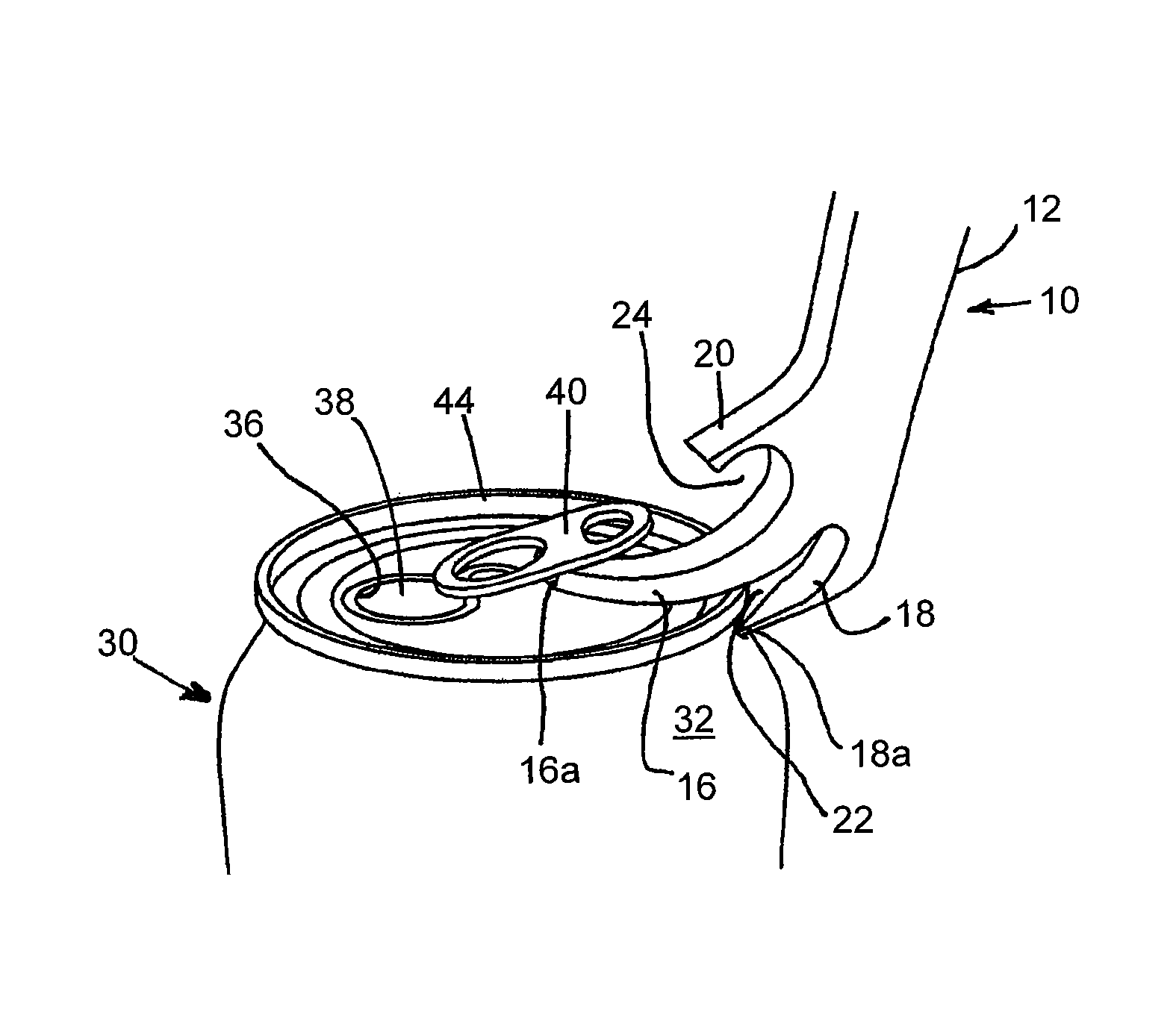

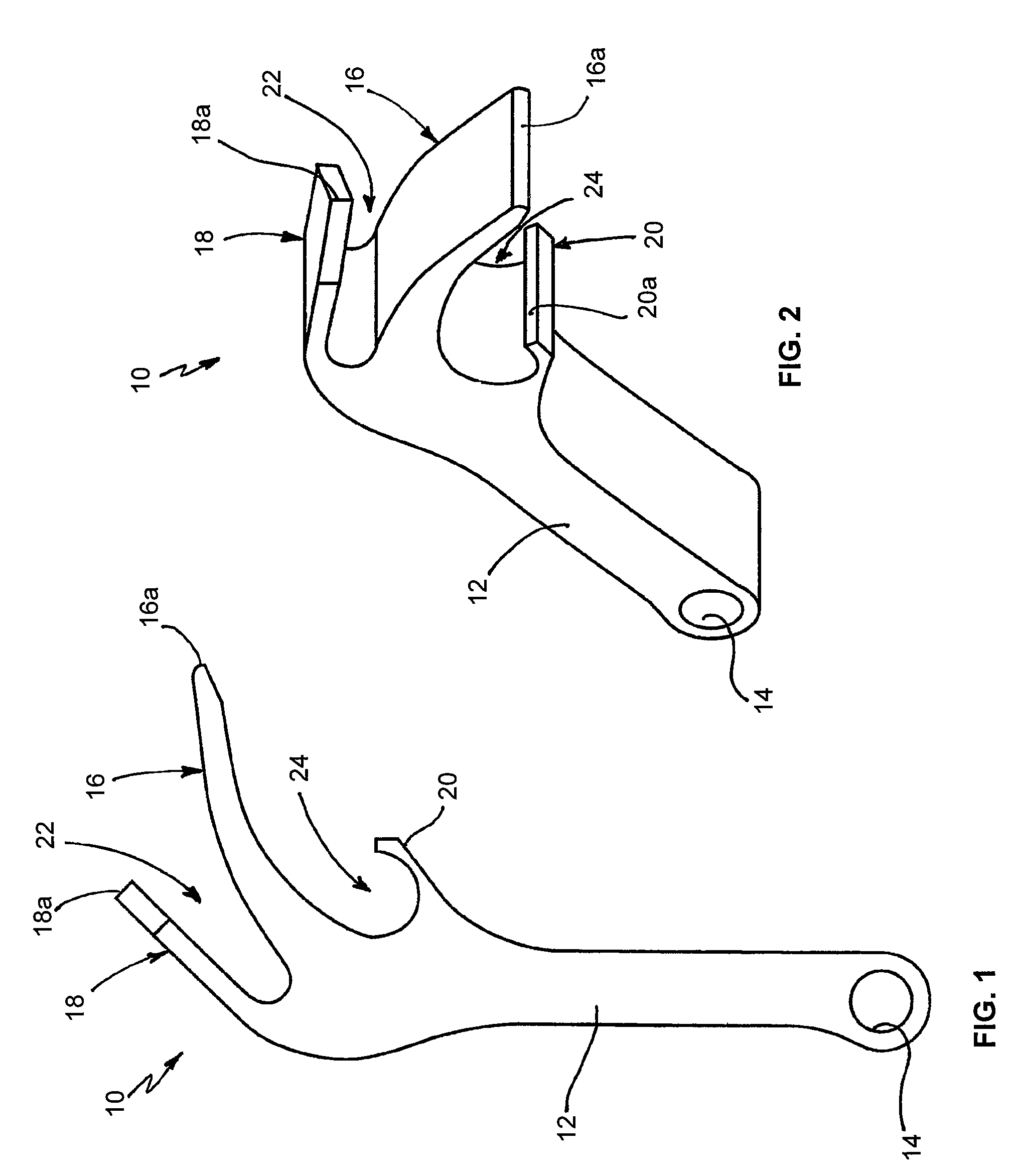

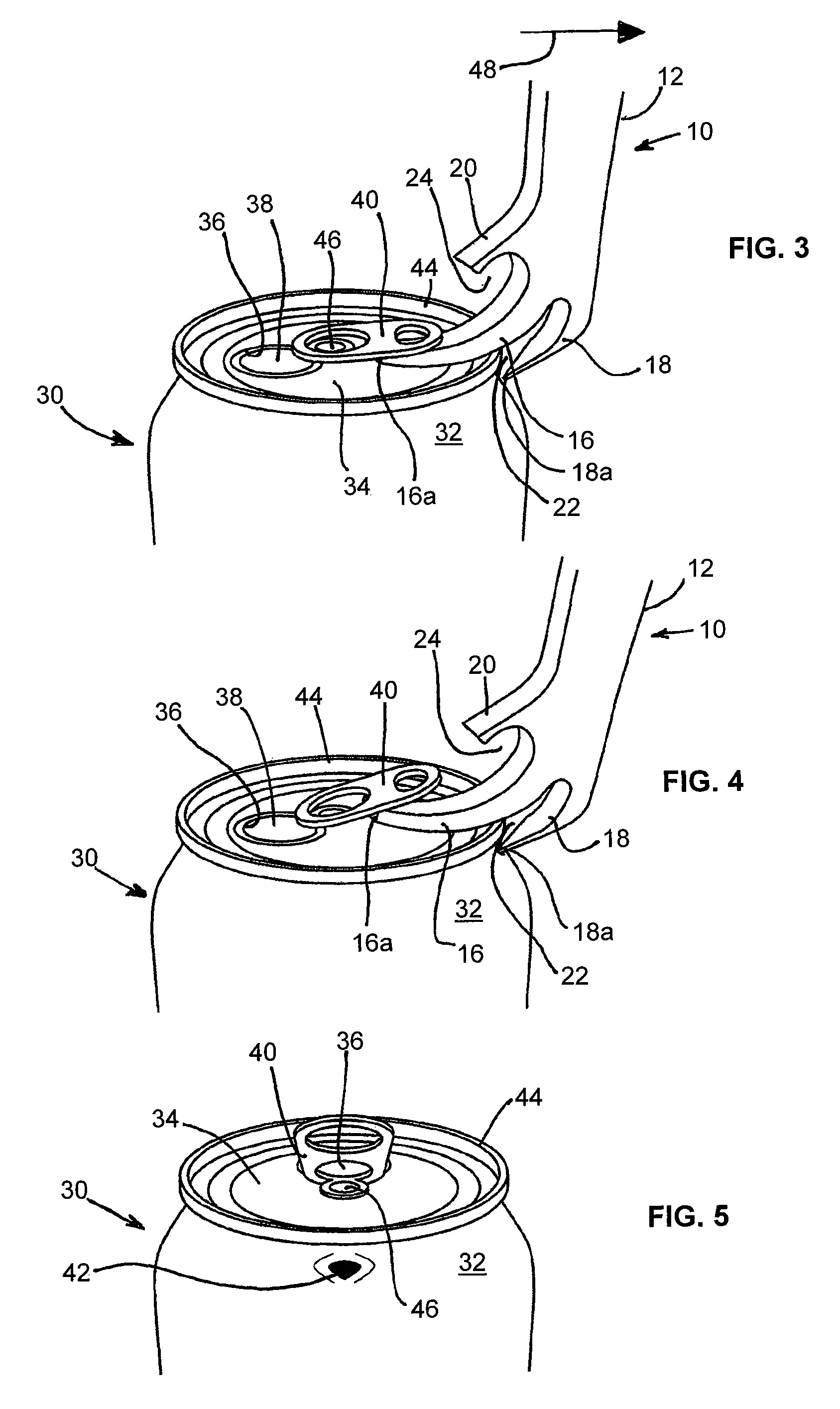

Pop-top can opener

ActiveUS8695457B2Emptied more quicklyInhibition formationBottle/container closurePower operated devicesEngineeringMechanical engineering

A can opener is adapted for engaging and lifting a tab attached to the flat upper surface (top) of a sealed can, with the upraised tab engaging and downwardly displacing a sealing member for opening the can. The opener includes a handle with first and second arms extending therefrom. The curvilinear first arm is adapted for positioning between the can's upper surface and the tab and for raising the tab when the handle is pivotally moved outwardly from the can's upper edge which acts as a fulcrum in engaging a lower portion of the curvilinear first arm. A second arm extending from the handle and disposed in closely spaced relation from the first arm includes a pointed end portion adapted to engage and puncture an upper lateral portion of the can to prevent formation of an air lock in the can for facilitating the discharge of the liquid contents of the can.

Owner:ROZMUS MICHAEL J +1

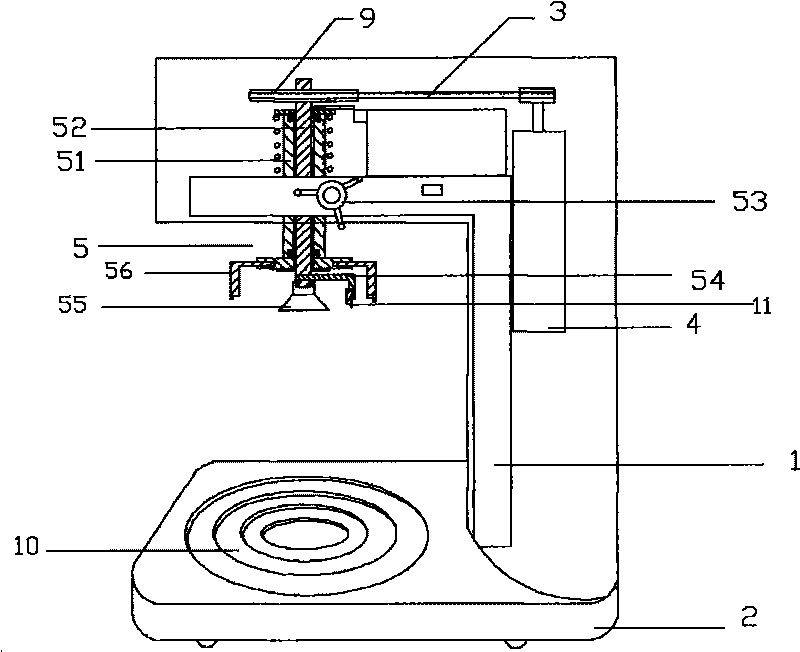

Electric can opener

InactiveCN101734589ASuitable for useReduce labor intensityBottle/container closurePower operated devicesAgricultural engineeringElectric machinery

The invention relates to an electric can opener which comprises a main column frame, a base, a motor, a driving mechanism and a cutting device, wherein the lower end of the main column frame is fixedly connected with the base, the motor is arranged on the lateral surface of the main column frame, the motor is connected with the driving mechanism which is connected with the cutting device, the cutting device is arranged on a main column crossarm and comprises an outer shaft, a rotating shaft, a manual lifting wheel, a fixed jaw, a tool rest and a suction disc, wherein the rotating shaft is positioned in a central cavity of the outer shaft, the upper end of the rotating shaft is connected with a driving part, the lower end of the rotating shaft is connected with the tool rest and the suction disc, the outer shaft penetrates through the main column crossarm, teeth are arranged at one side of the outer shaft and engaged with teeth of the manual lifting wheel, a spring is sleeved above the outer shaft, and the lower end of the outer shaft is connected with the fixed jaw. The invention has the advantages of high speed, no manpower consumption as well as convenient and safe operation, and is suitable for can manufacturing enterprises and grand hotels.

Owner:胡海明

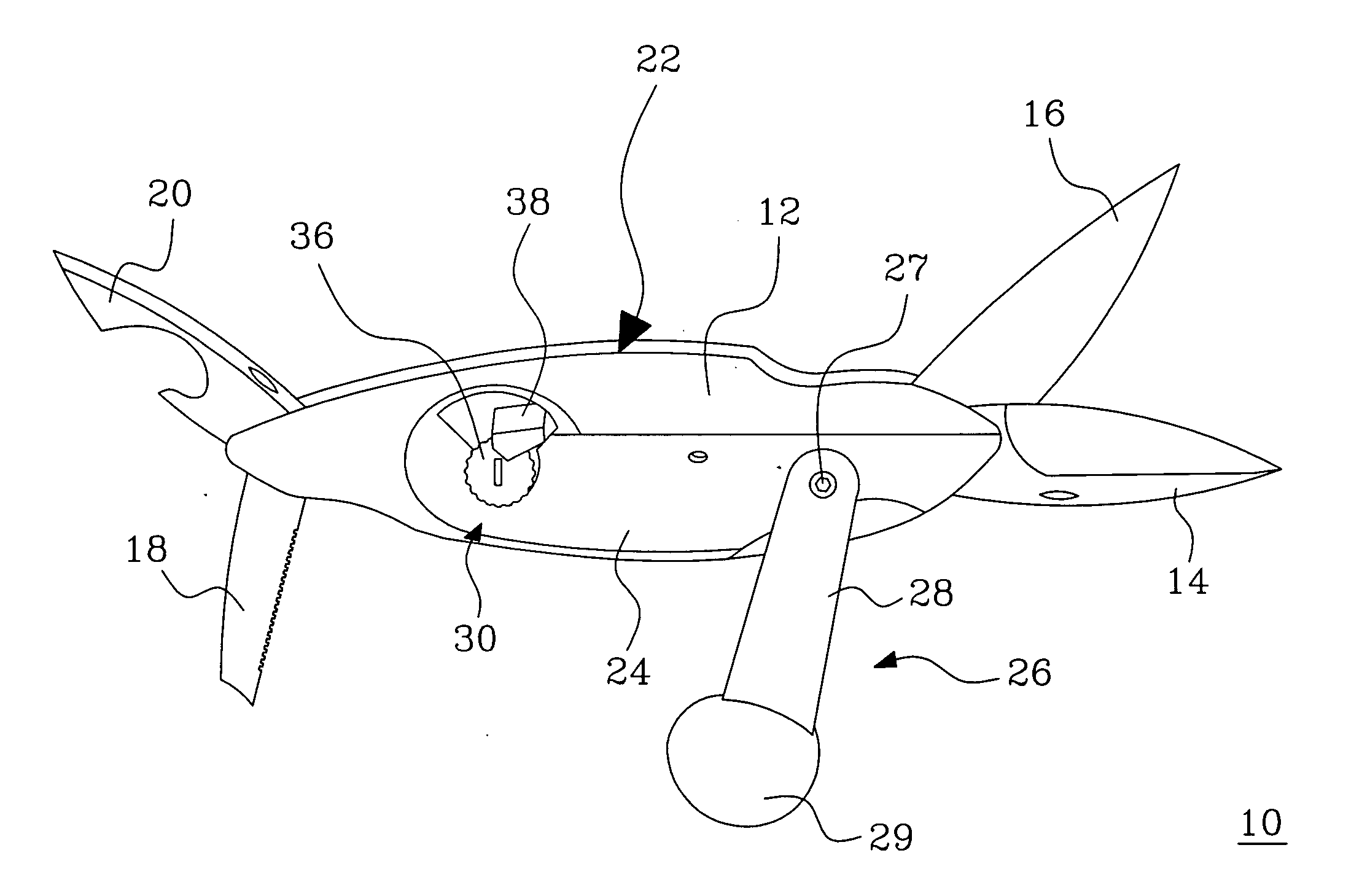

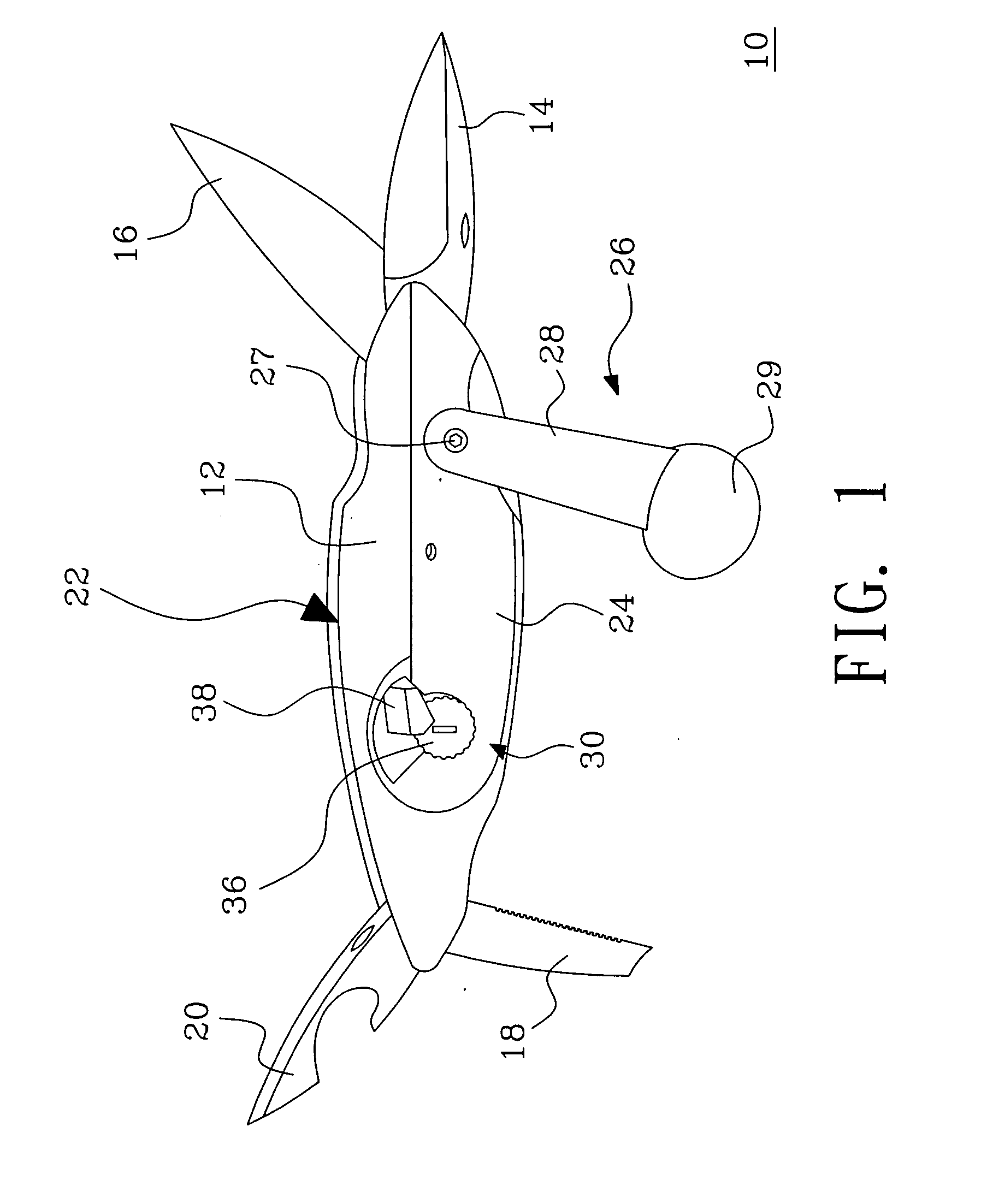

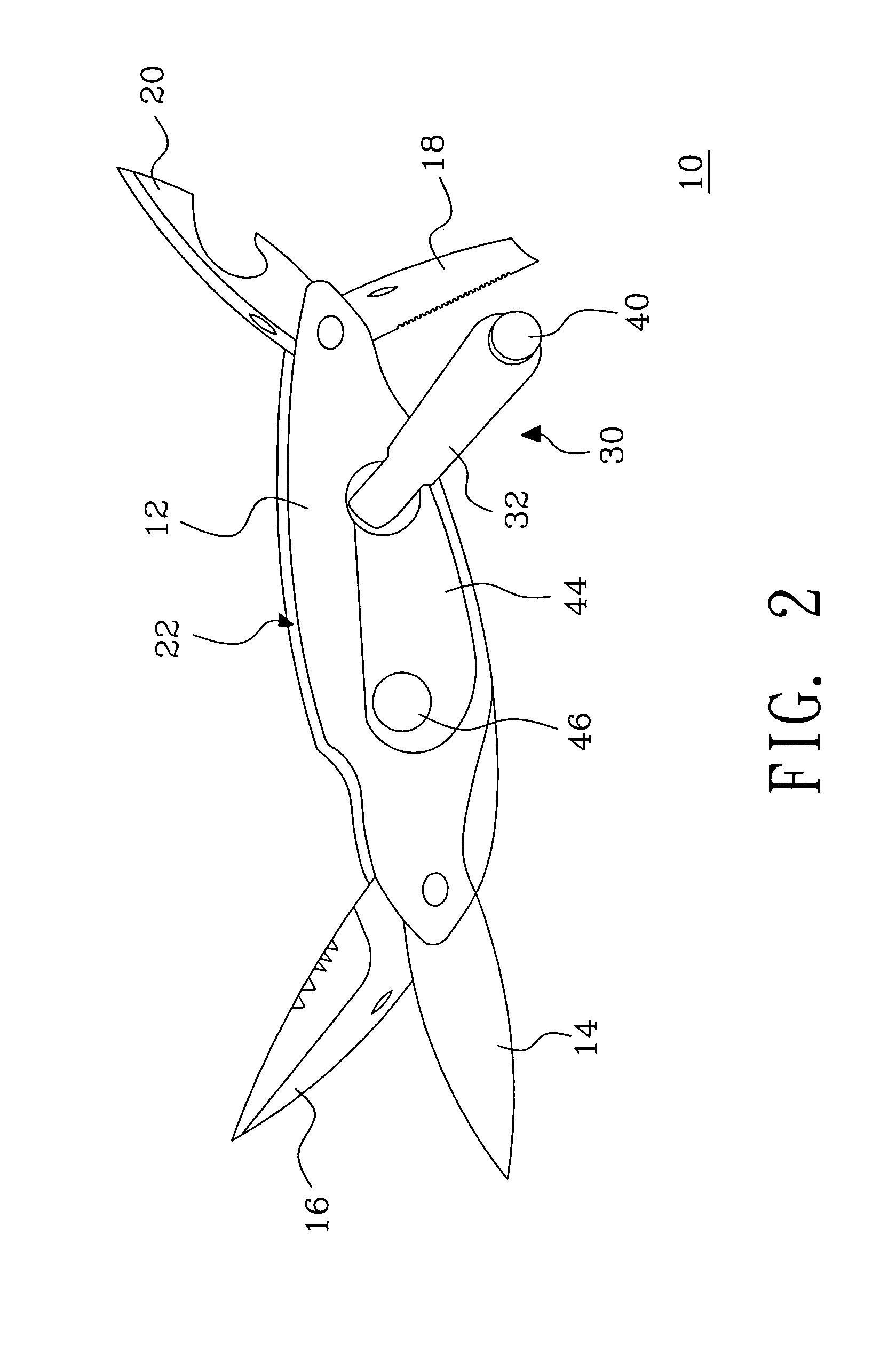

Pocket knife

InactiveUS20060207112A1Small sizeConvenient openingBottle/container closurePower operated devicesGear wheelEngineering

The present invention relates to a pocket knife having a rotation type can opener for opening a can. The rotation type can opener has a crank, a shaft, a gear and a cutting blade; the upper rim of the can is put to be infixed between the cutting blade and the gear, with the top end of the can holding the cutting blade; the crank is rotated to drive the rotation of the shaft, the rotated shaft further drives the rotation of the gear, and the rotated gear engages the upper rim of the can and drives the rotation of the can; the top end of the rotated can produces a pressure against the cutting blade so that the cutting blade first penetrates and then rotationally cuts apart the top end of the can.

Owner:UNIPACK INT

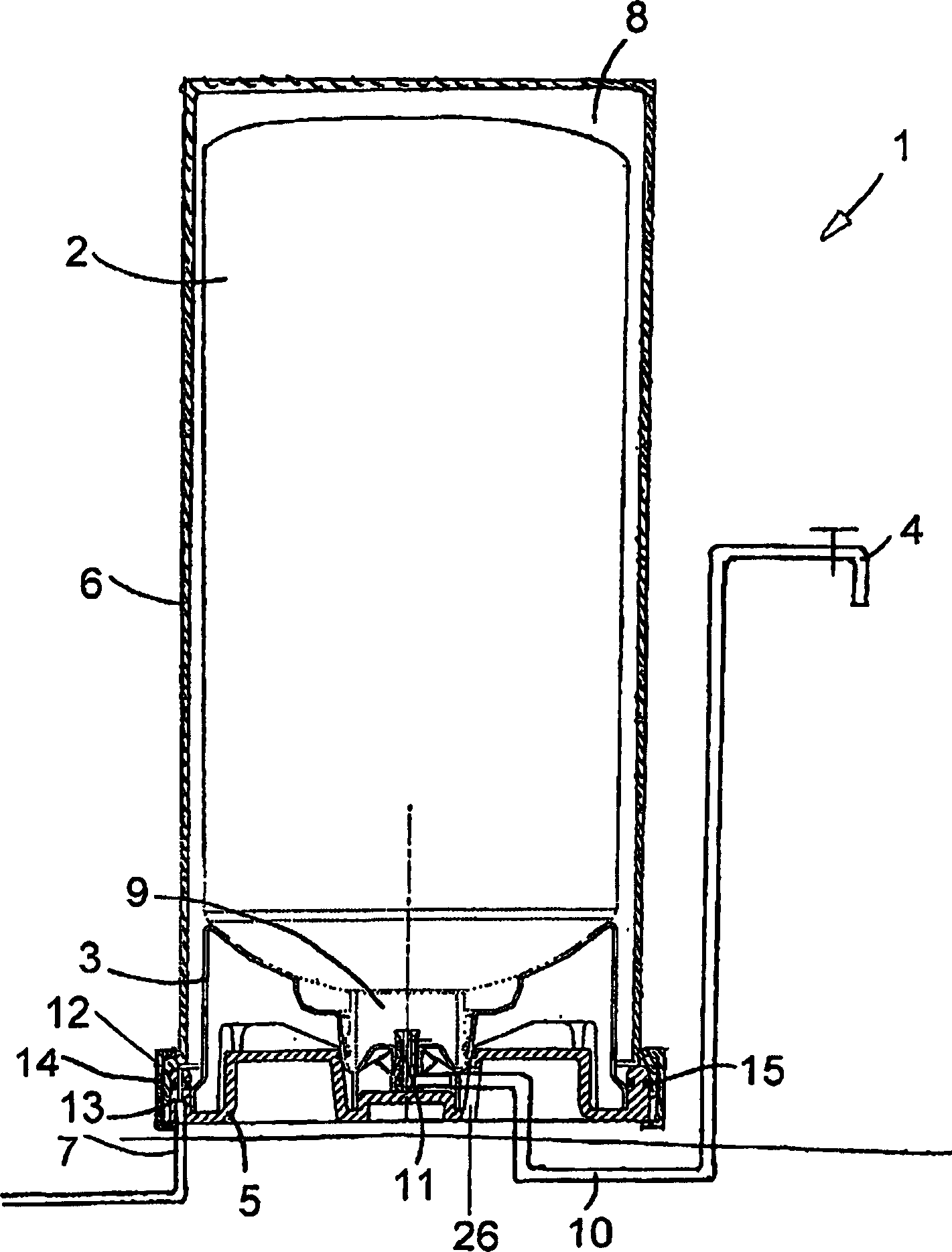

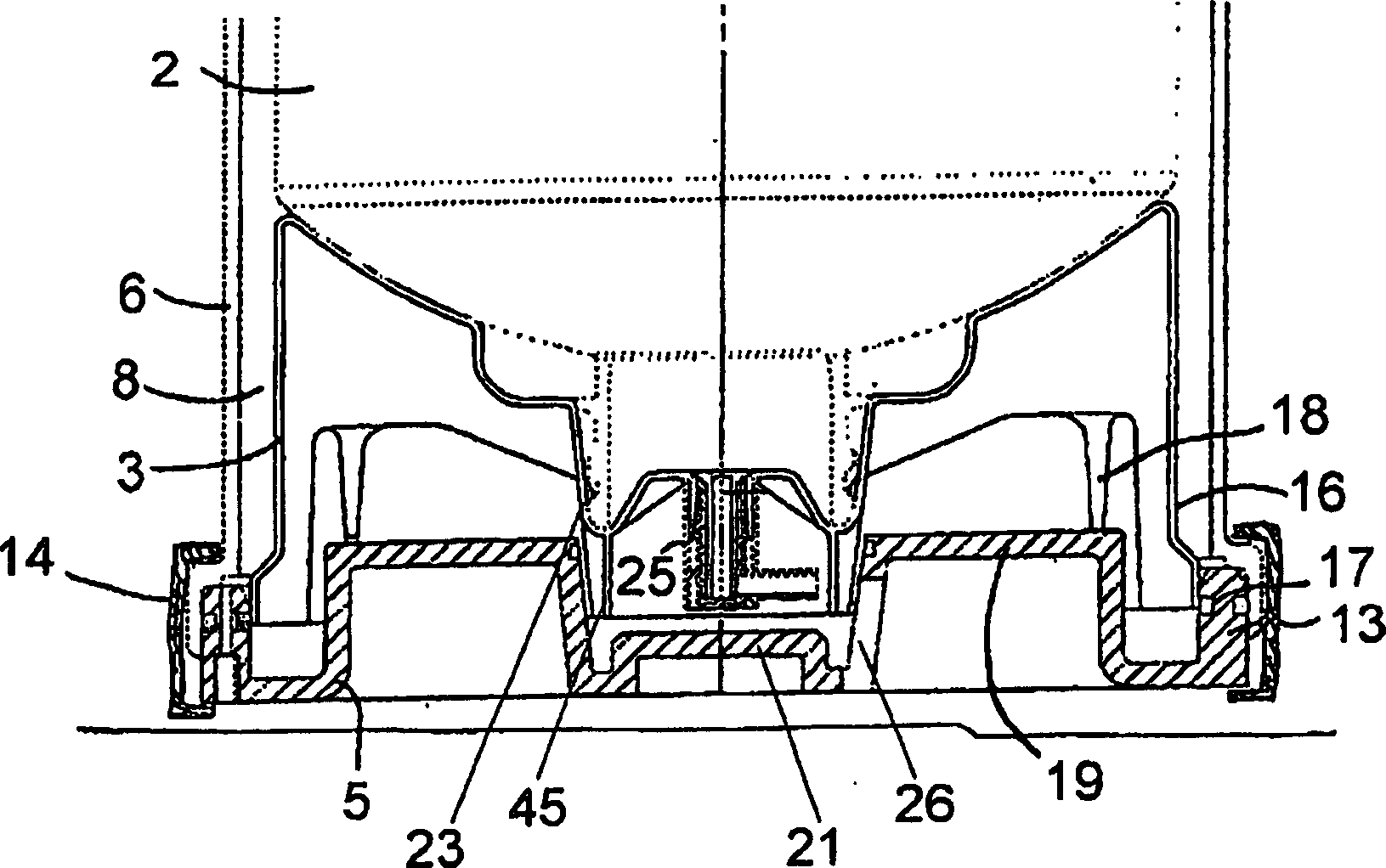

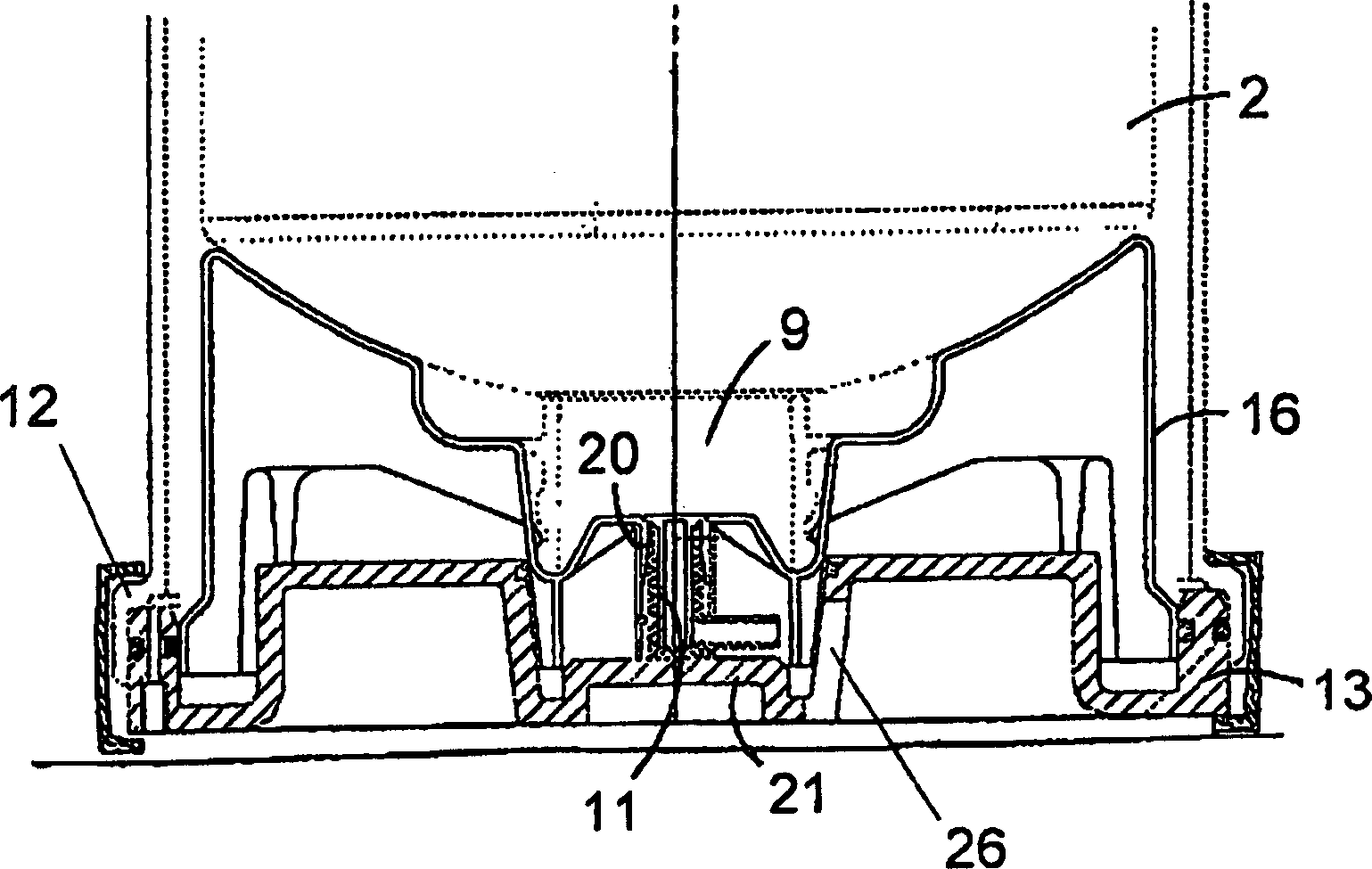

A method for dispensing a beverage and devices therefor

ActiveCN1784354ARelieve pressurePrevent tamperingBottle/container closurePower operated devicesAir tightnessBiomedical engineering

Owner:CARLSBERG BREWERIES AS

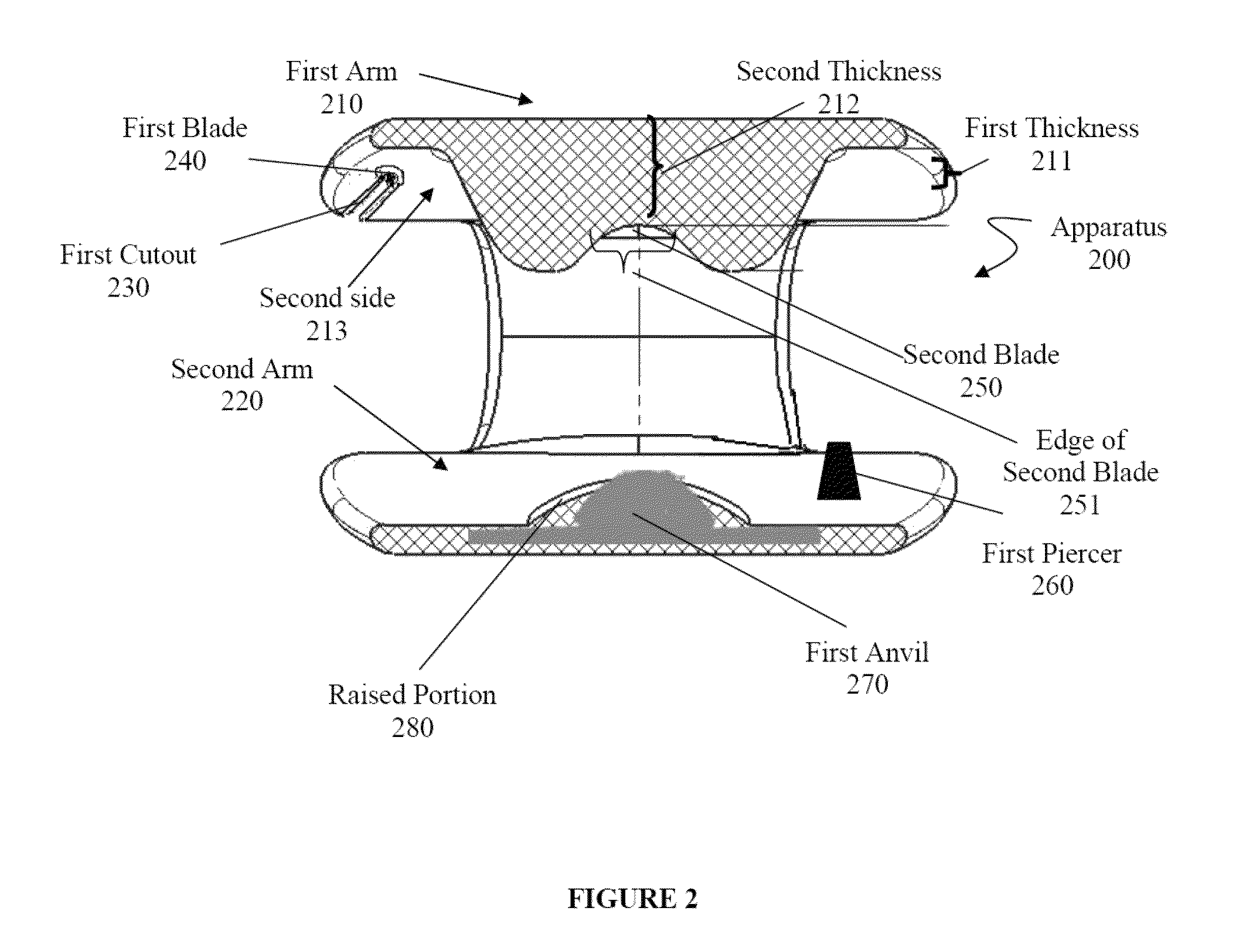

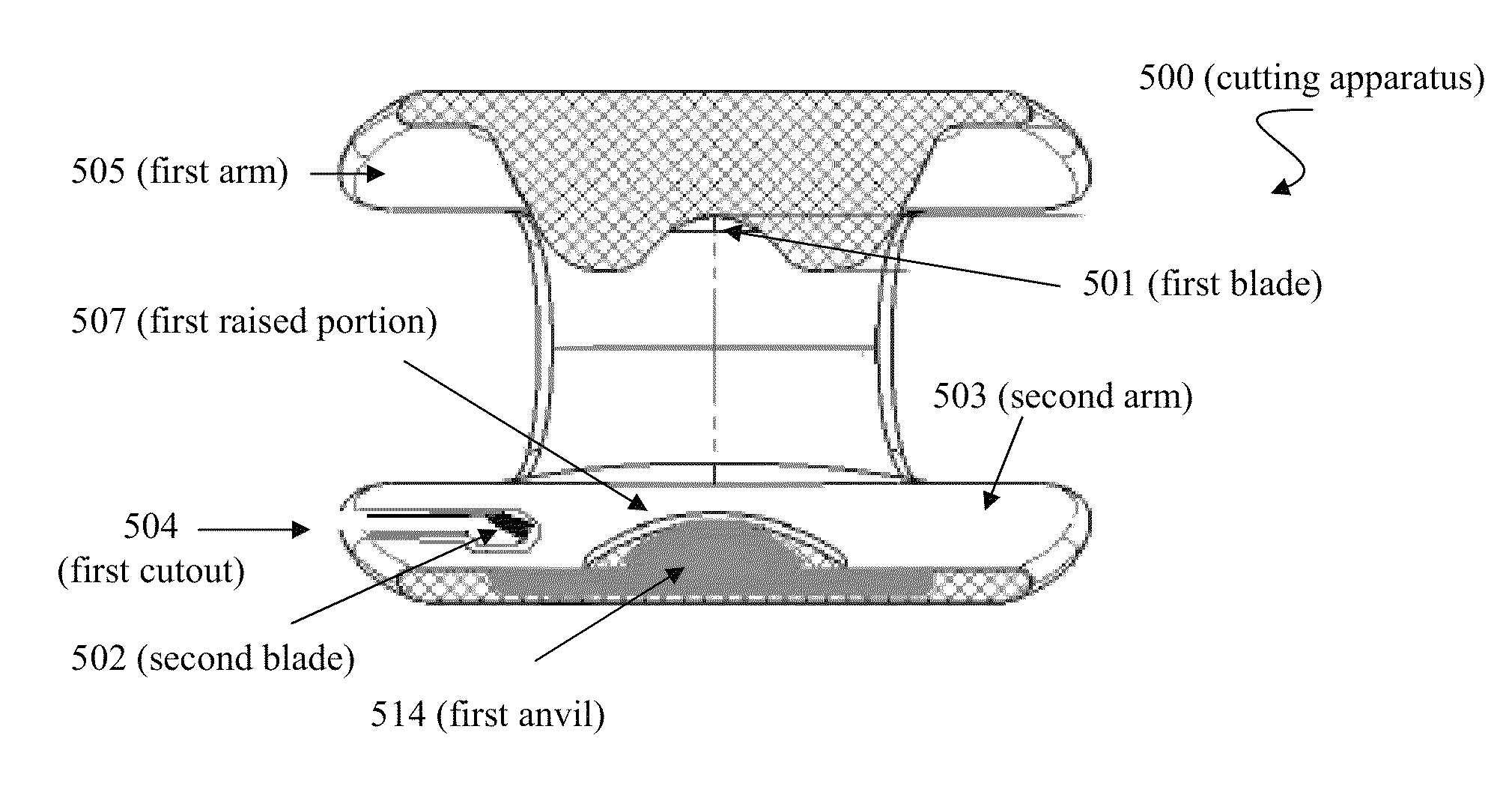

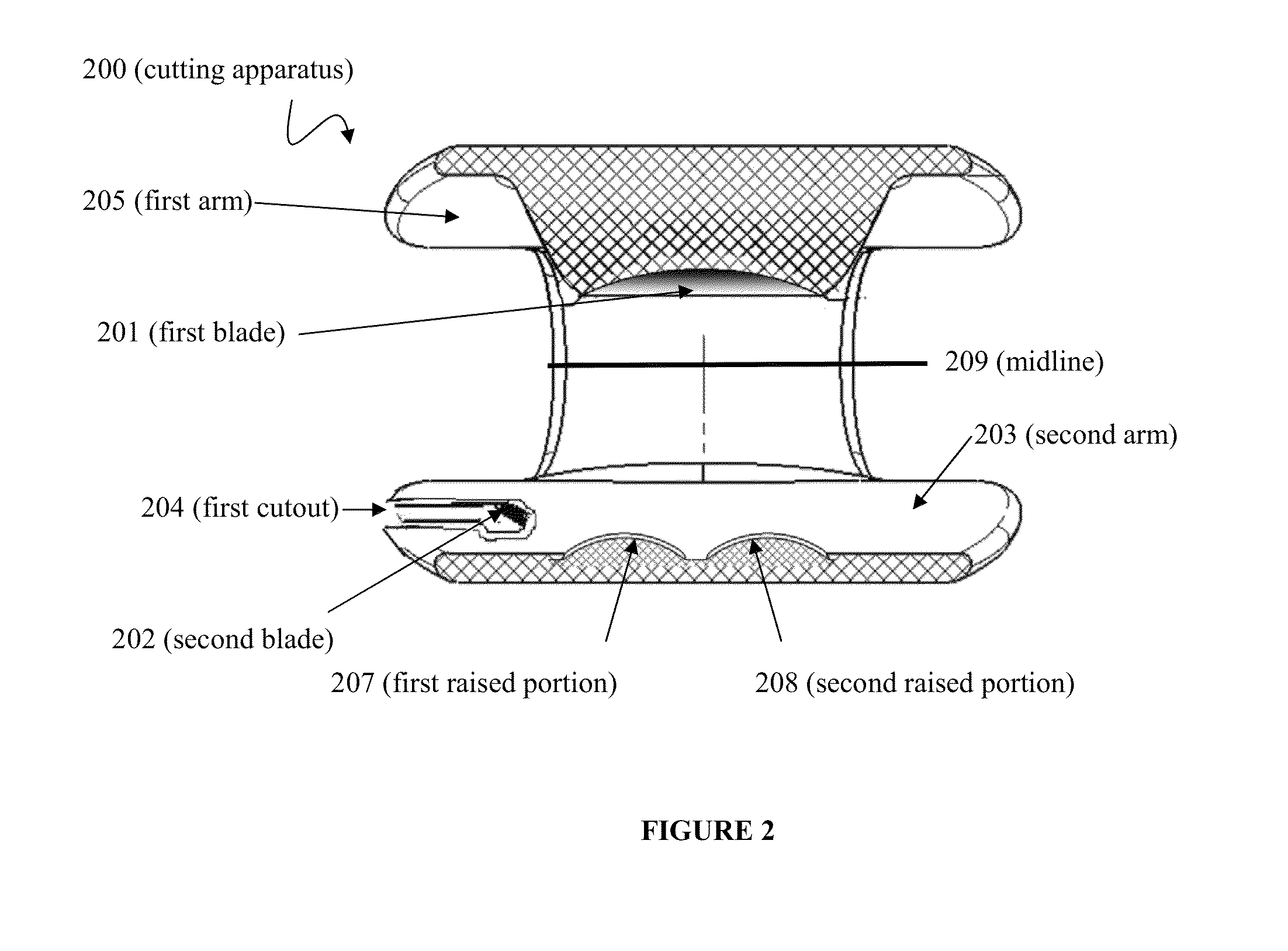

Multi-blade bag cutter

A multi-blade bag cutting apparatus for opening a sealed package using one of at least two methods has a first arm partially enclosing a first blade and a first or second arm having a cutout exposing a second blade. The two arms can be injection molded as a single piece of plastic or comprise two separate pieces coupled to a pivot. Preferably, the first blade is partially juxtaposable against a cutting surface, which can be, among other things, a raised portion and / or an anvil.

Owner:SPELLBOUND DEVMENT GROUP

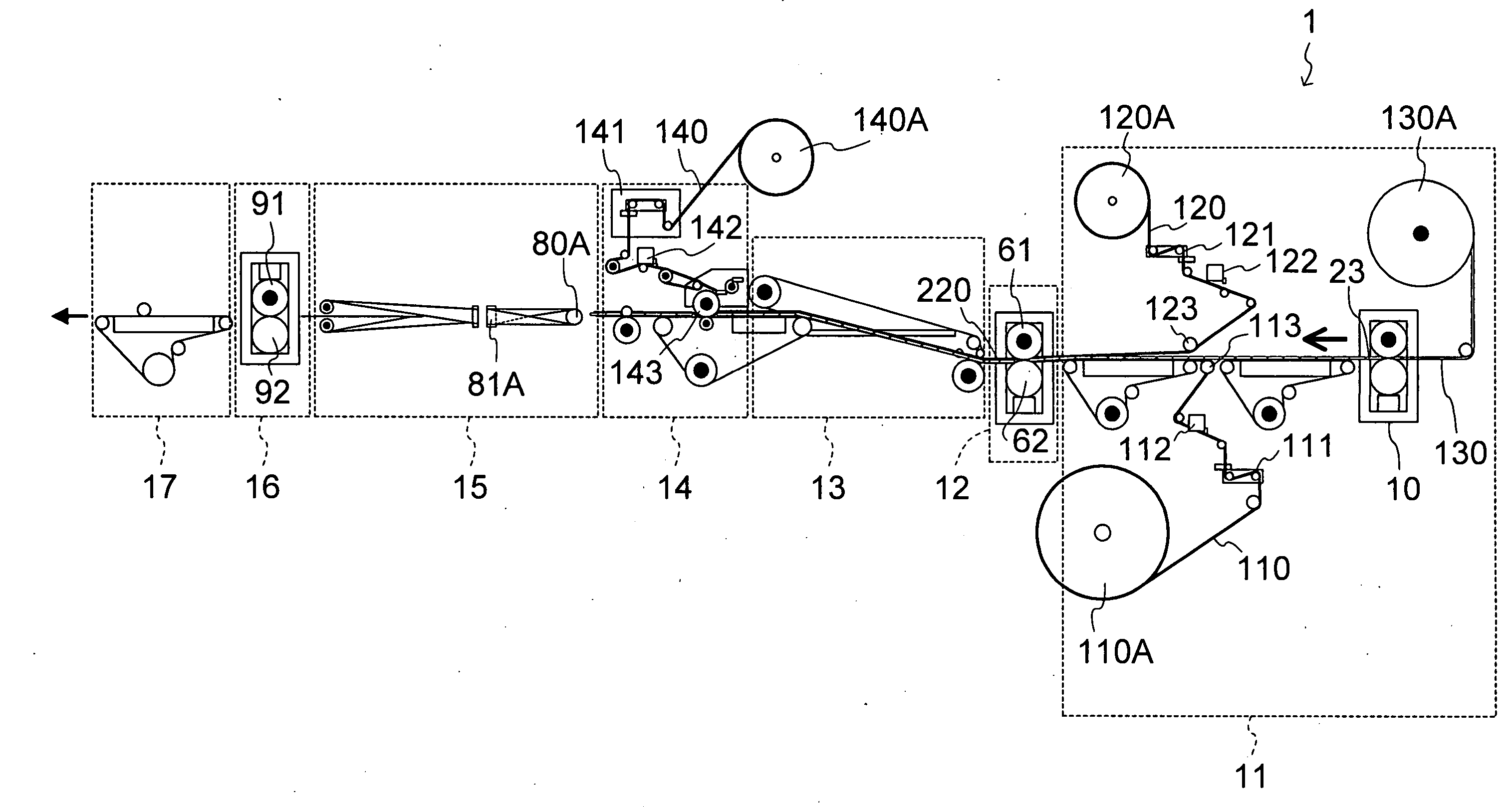

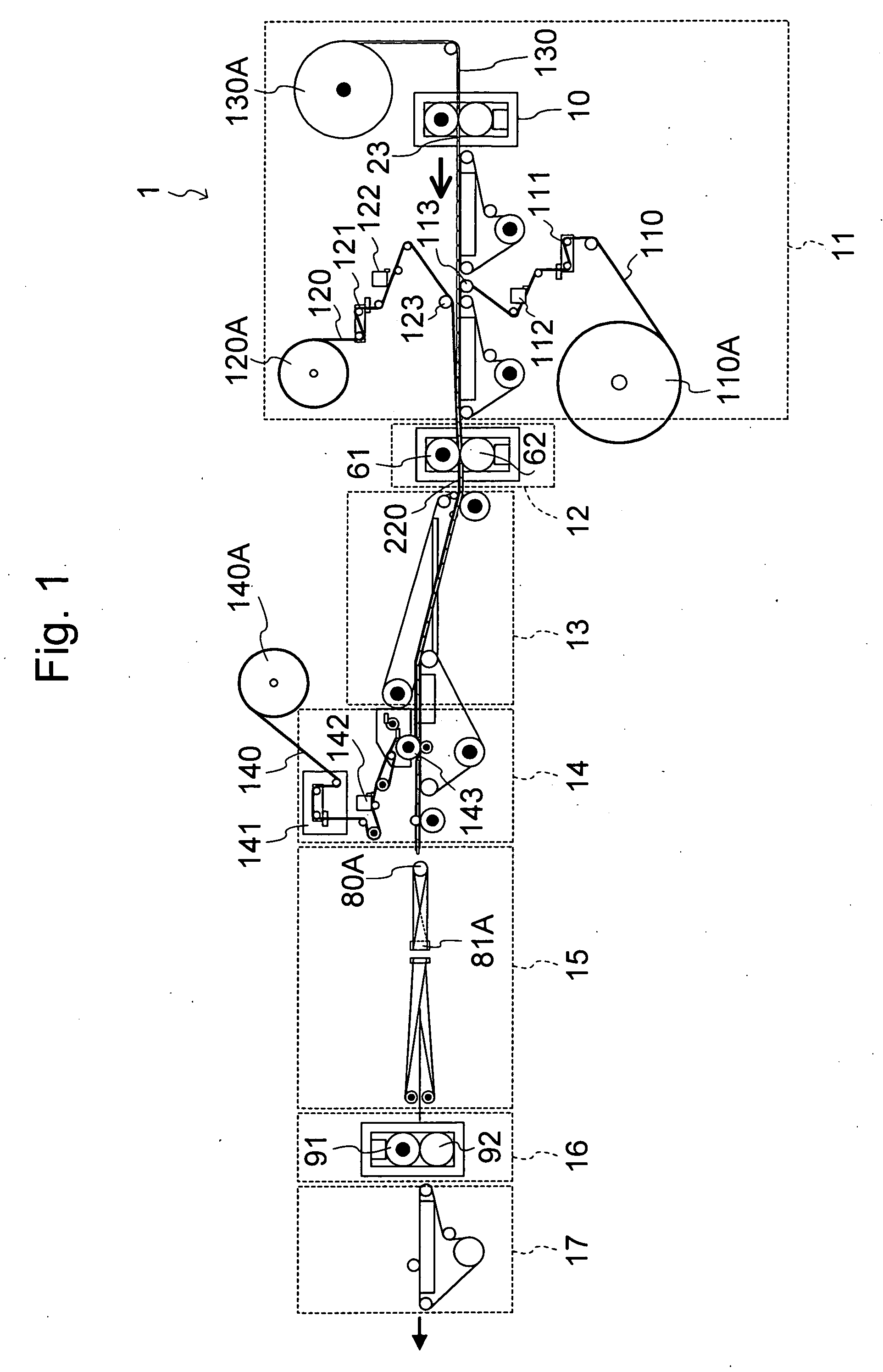

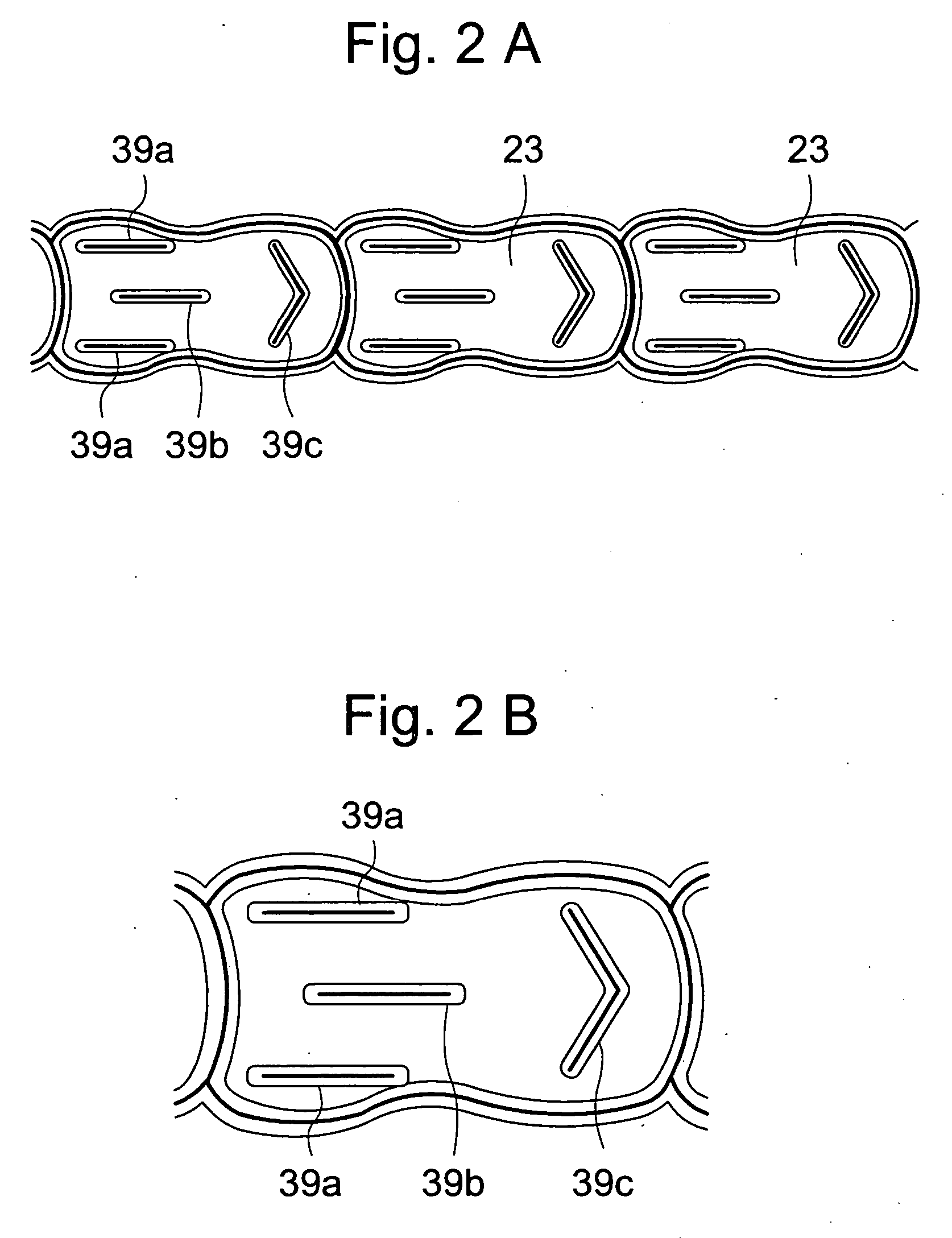

Cutter, cutting method, apparatus for producing interlabial pad, and method for producing the same

InactiveUS20040216569A1Easy dischargeIncrease ratingsBottle/container closurePower operated devicesBiomedical engineeringSheet material

The present invention relates, for example, to a cutter, an apparatus for producing an interlabial pad having the cutter, a cutting method, and a method for producing the interlabial pad including the cutting method. The cutter cuts out a member from continuous sheet base material. In accordance with the present invention, separation of the members and the remaining base material is ensured so that disclocation of the cut-out member is prevented from occuring.

Owner:UNI CHARM CORP

Package opening cutter

InactiveUS6938343B2Accurately and safely and efficiently openWithout fear of getting cutBottle/container closurePower operated devicesComing outEngineering

A package opening cutter is provided which can accurately, safely and efficiently open the package without damaging the merchandise inside and in which the cutter will not come out during use. It comprises an angle ruler, retaining portions provided at both sides of the angle ruler, a clamp body provided so as to be pushed into and pulled out of the retaining portion for clamping a cutter, and an arrangement for preventing the clamp body from coming out of the retaining portion. The arrangement for preventing the clamp body from coming out has a bolt slidably provided between the cutter retaining portions and the cutter clamp body. The bolt is operated by a knob provided on an outer surface of the cutter retaining portion.

Owner:PALTAC CORP

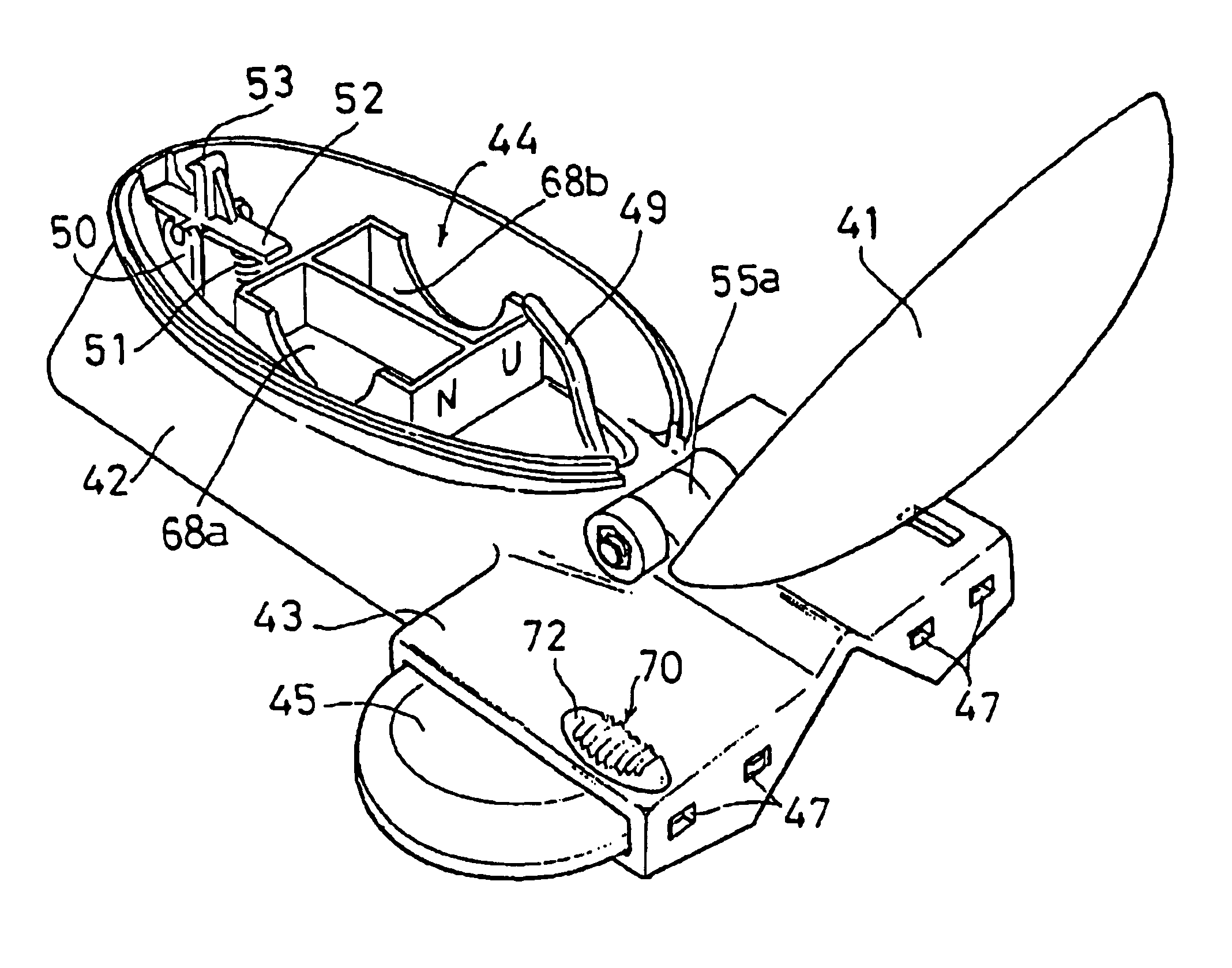

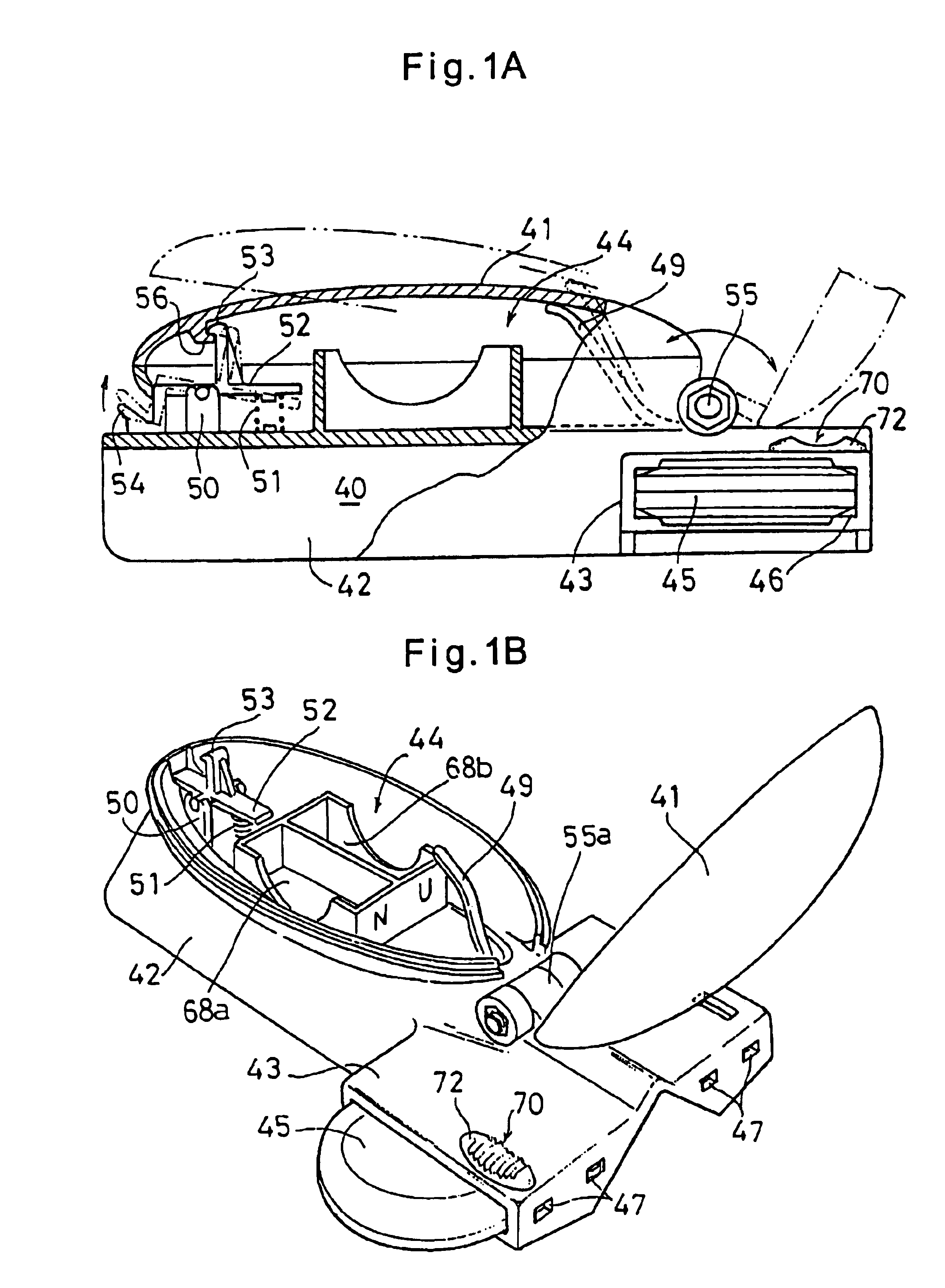

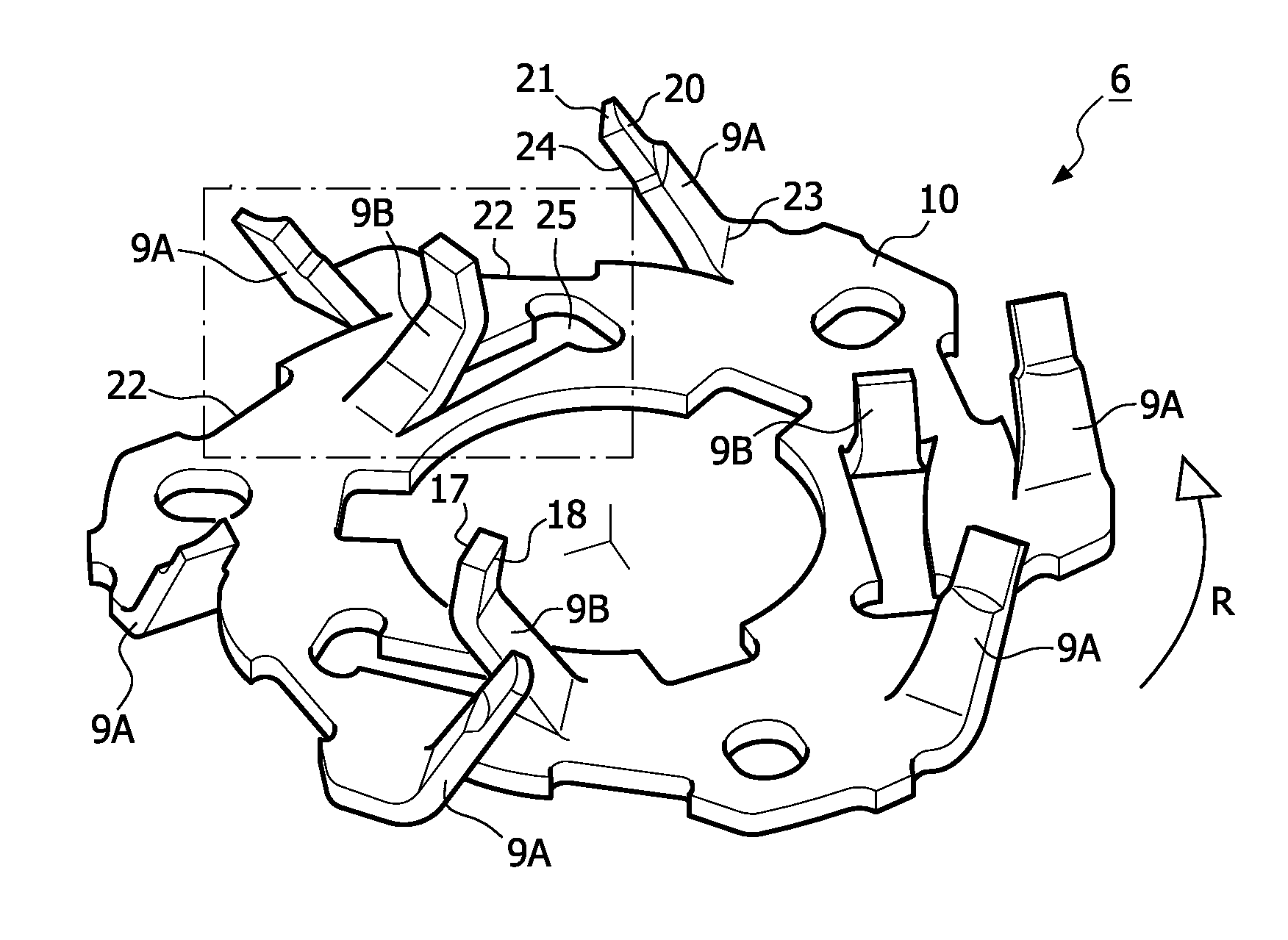

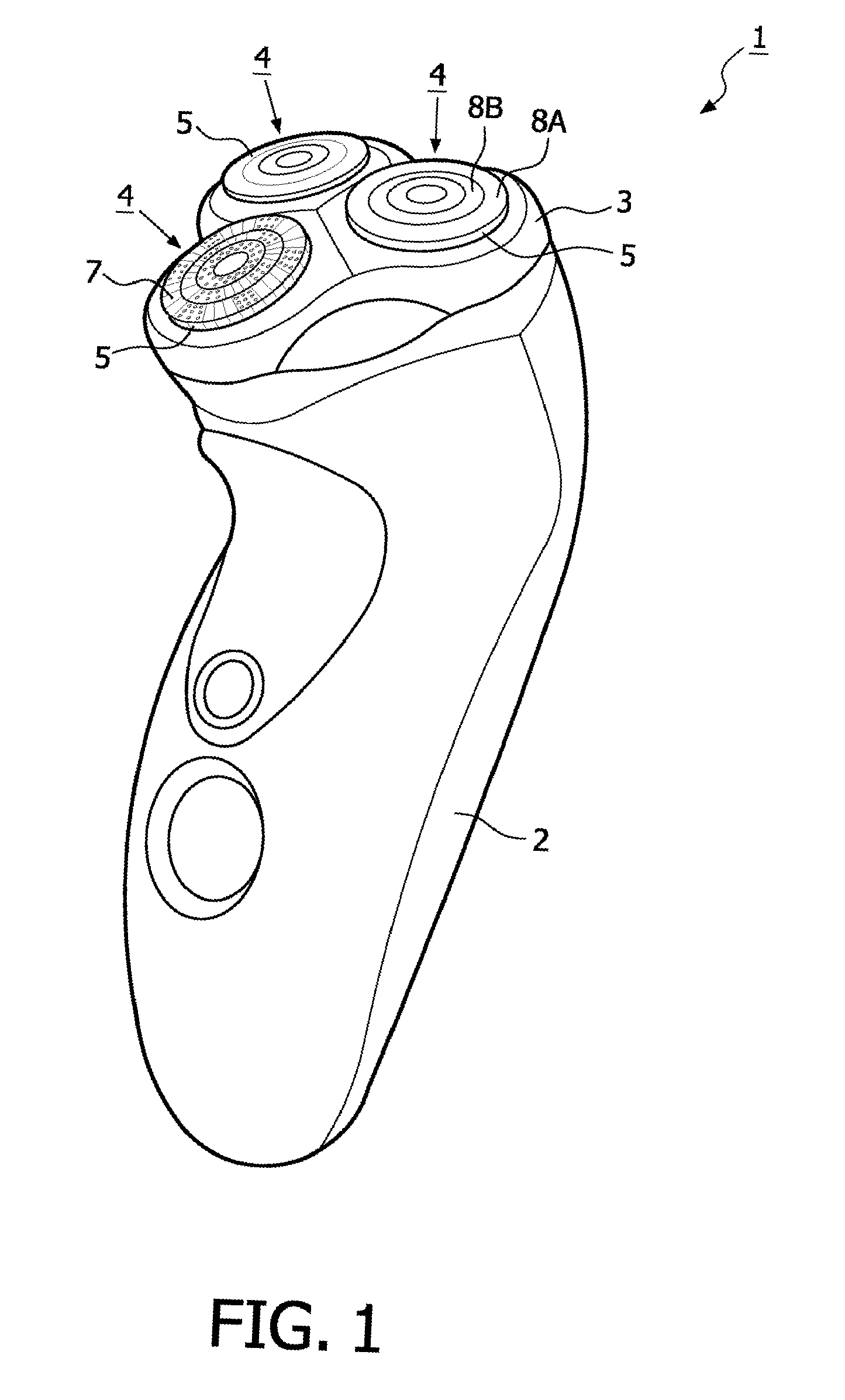

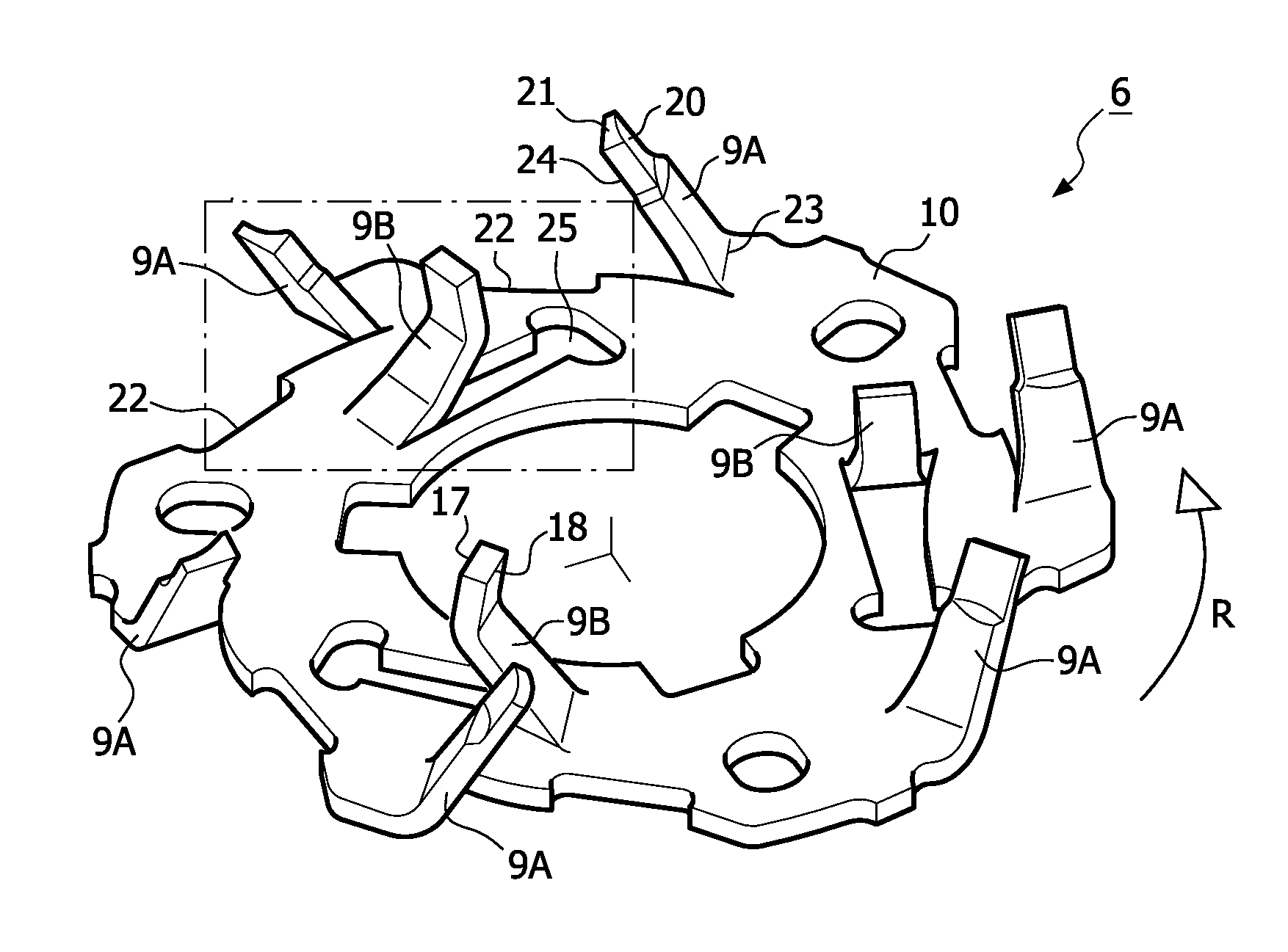

Method of manufacturing a cutting member of a shaver

ActiveUS20100095531A1Reduction of strength of carrierInhibits locationBottle/container closurePower operated devicesRazor stropPunching

The invention relates to a method of manufacturing a cutting member (6) of a shaver (1). The method comprises the steps of providing a plate-shaped carrier (10), cutting at least one cutting element (9a, 9b) free from the carrier except for a residual connection between a base (15, 23) of the cutting element and the carrier, and bending the cutting element relative to the carrier. According to the invention the steps of cutting free and bending are performed simultaneously using a tool (11) having a combined punching and bending effect. By using such a tool the action of cutting free is obtained by a tearing process which does not lead to a free space and a loss of material between the cutting element (9a, 9b) and the carrier (10). As a result the strength of the carrier is not reduced by such a free space or loss of material.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Can opener

A can opener includes a body with a handle, a traction wheel rotatably mounted on the body, an operating element for turning the traction wheel, and a cutter. The cutter is moveable between an inoperative position for receiving a rim of a can between the traction wheel and cutter, and an operative position for engaging said rim of the can between the traction wheel and cutter. A cam with a lobe engages the cutter and moves it between the inoperative and operative positions. The cam is operated by a lever.

Owner:UNION LUCKY IND LTD

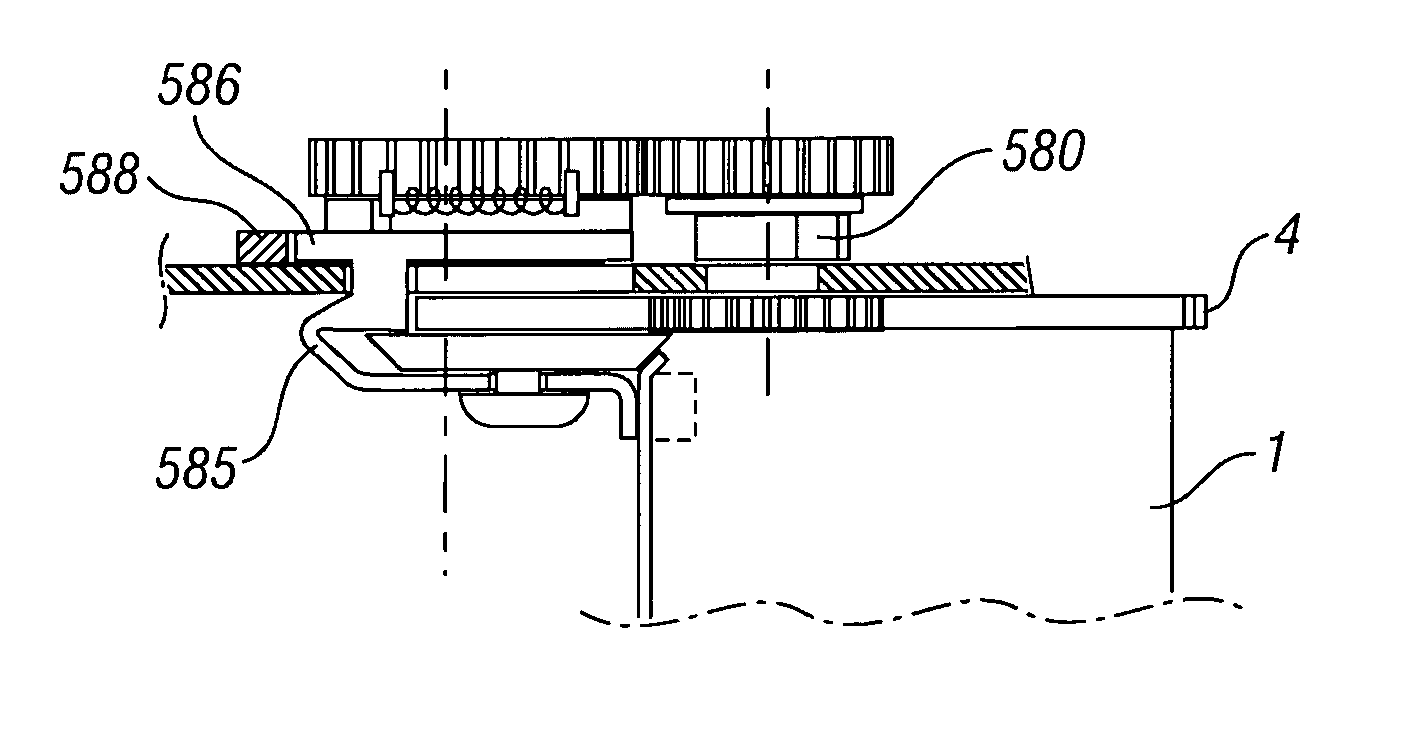

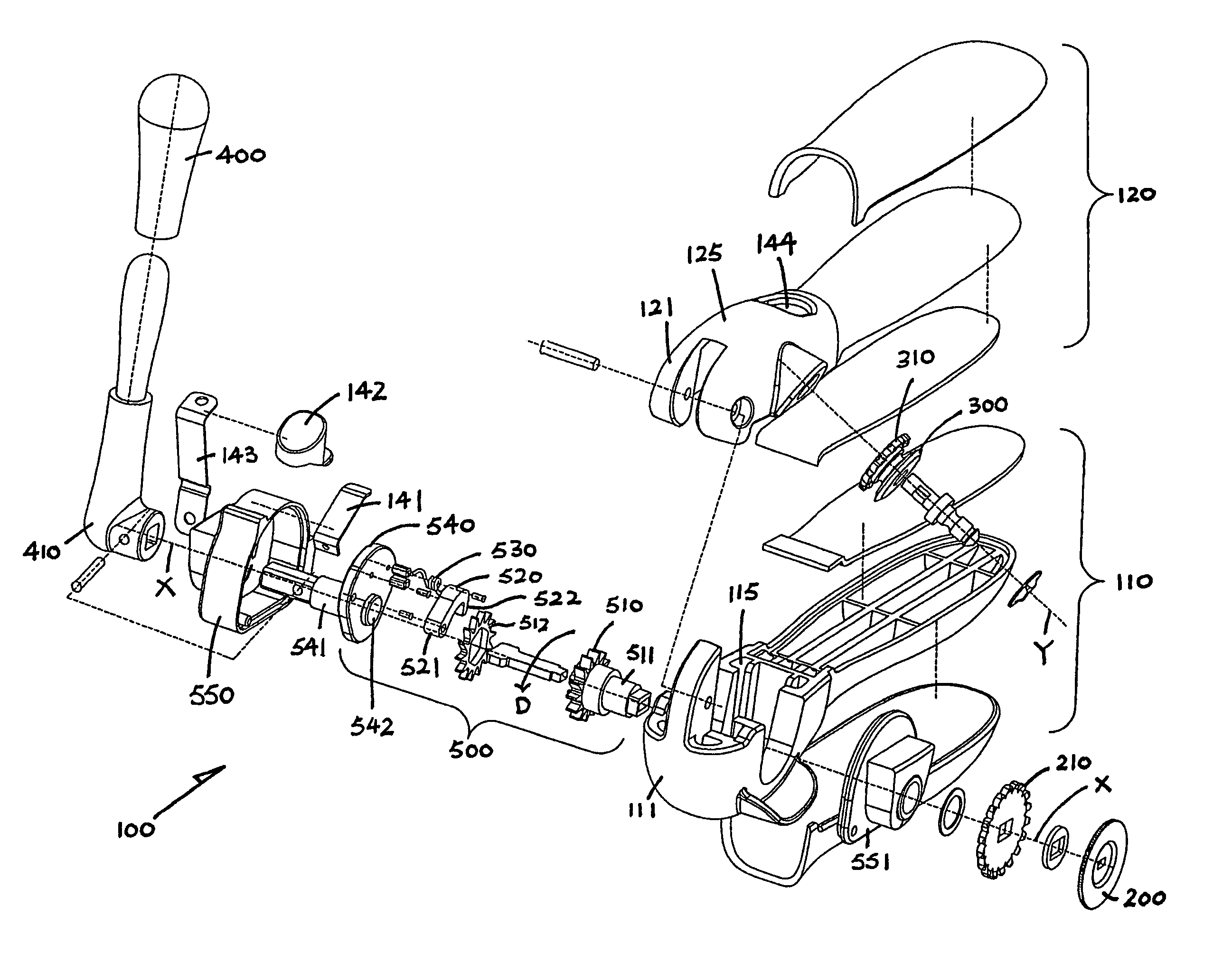

Can opener

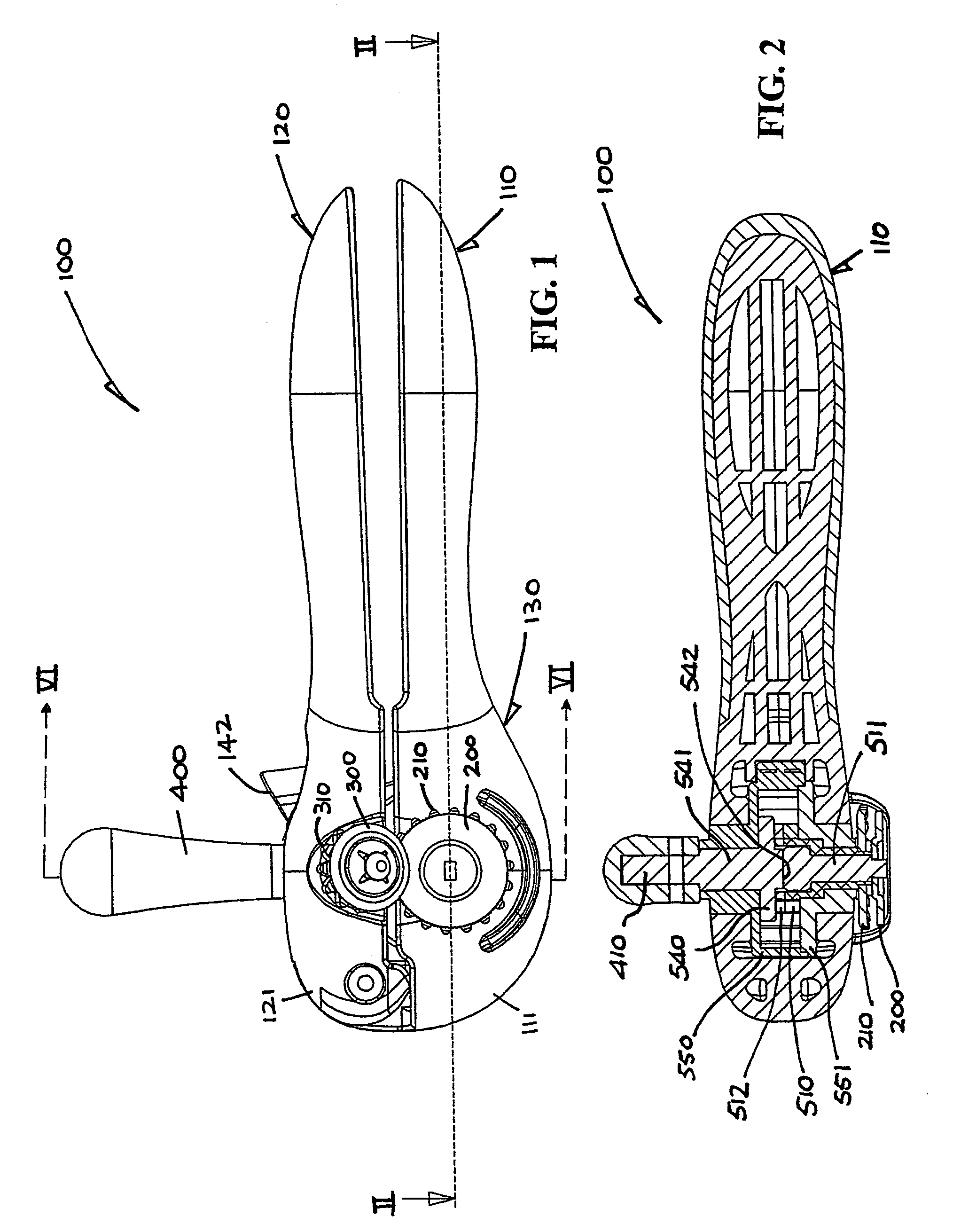

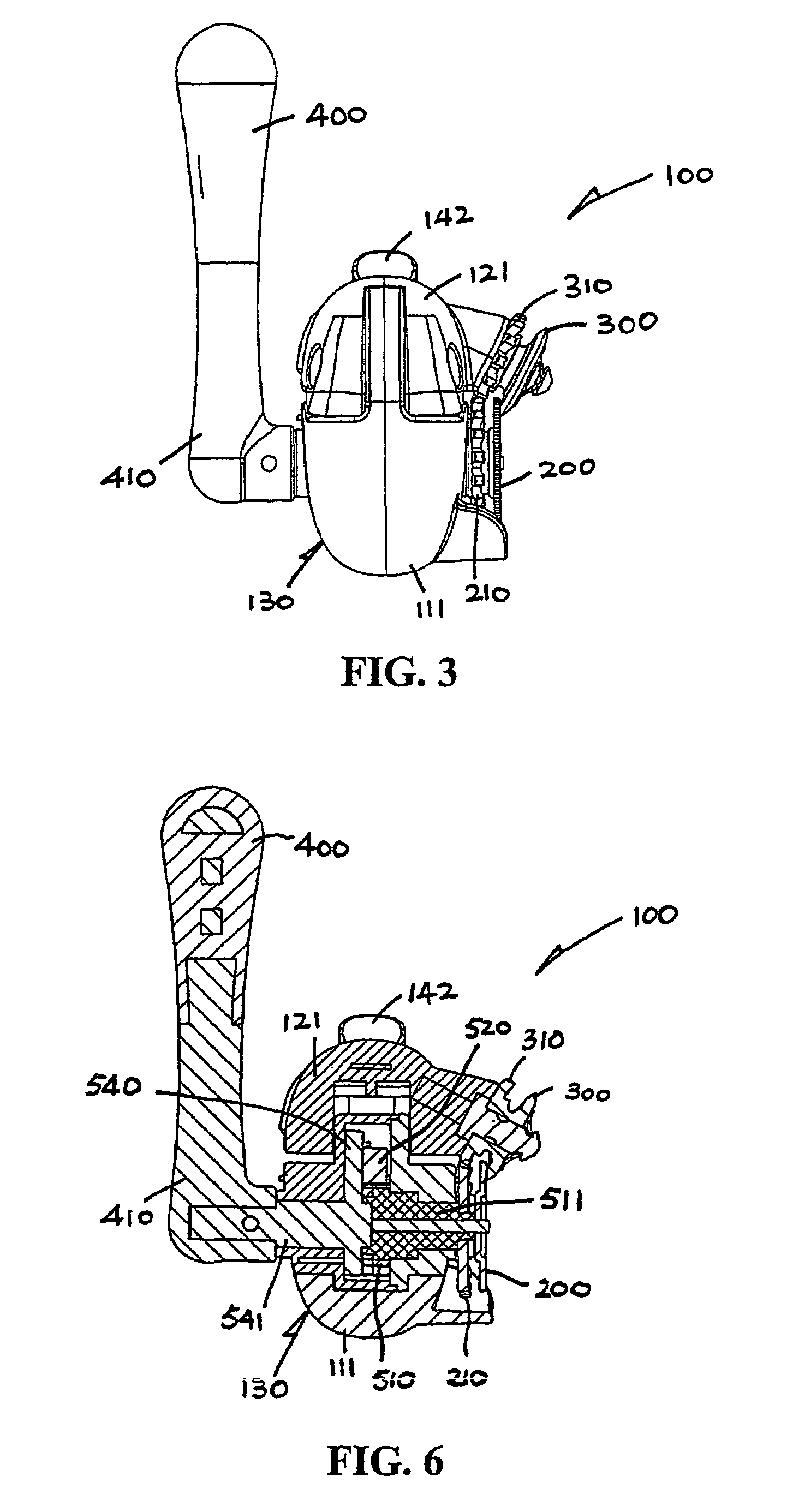

A can opener (100) has two pivotal handles (110 and 120), a traction wheel (200) and a cutter blade (300) movable by respective handles (110 and 120) for cutting open a can, and a pivotable lever (400). There is a ratchet assembly (500) driven by the lever (400) upon reciprocation for operating the traction wheel (200) and cutter blade (300), which has a ratchet wheel (510) connected with the traction wheel (200) and a spring-loaded pawl (520) movable by the lever (400) for turning the ratchet wheel (510) in a driving direction (D) upon reciprocation of the lever (400). The pawl (520) has front and rear ends (521 and 522) taken in the driving direction (D), with the front end (521) in engagement with the lever (400) and the rear end (522) engageable with the ratchet wheel (510) for turning the same.

Owner:KI MEE KITCHENWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com