A method for dispensing a beverage and devices therefor

A dispensing device and beverage technology, applied in dispensing devices, special dispensing devices, liquid distribution, conveying or transfer devices, etc., can solve the problem of high cost of pressurized sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

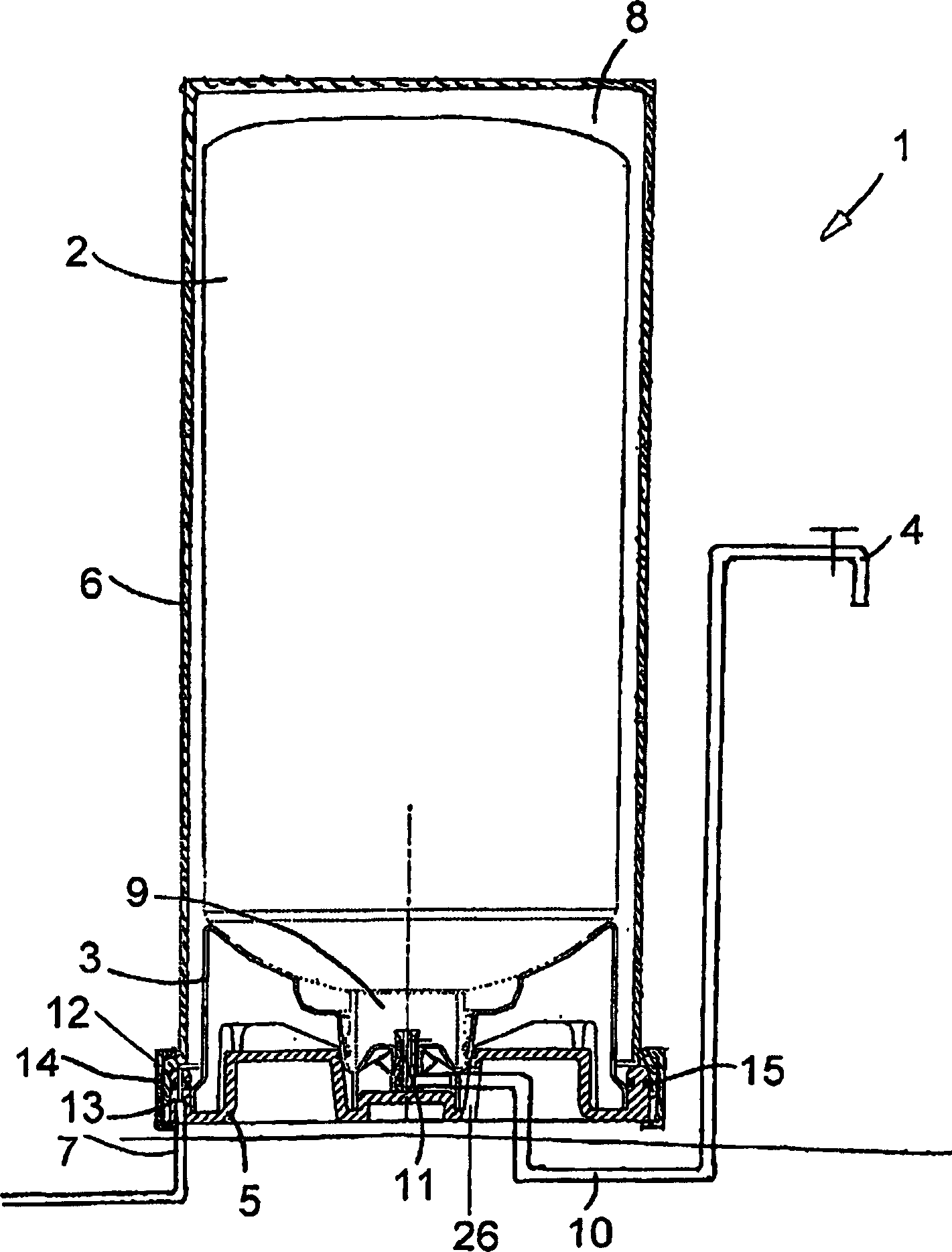

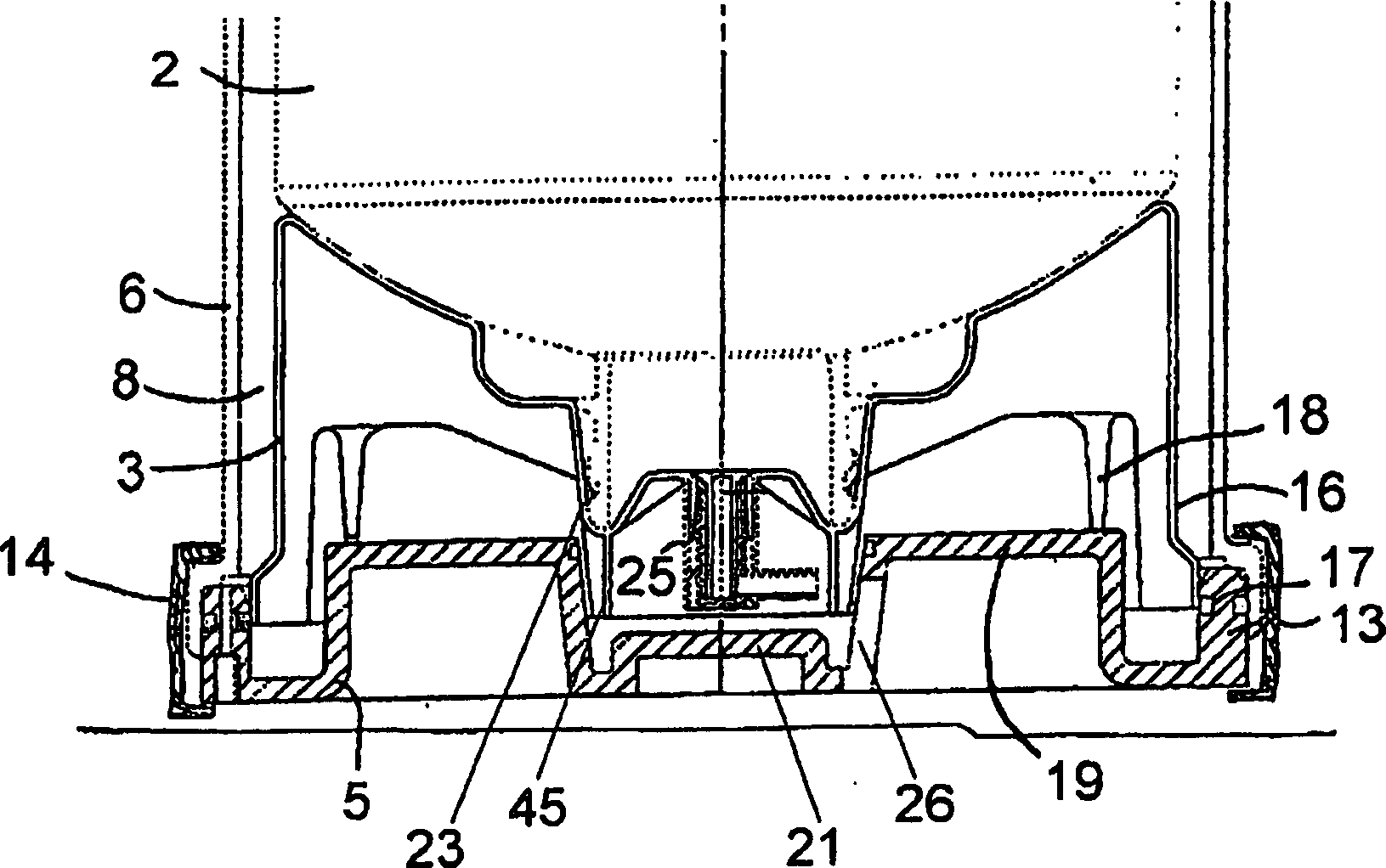

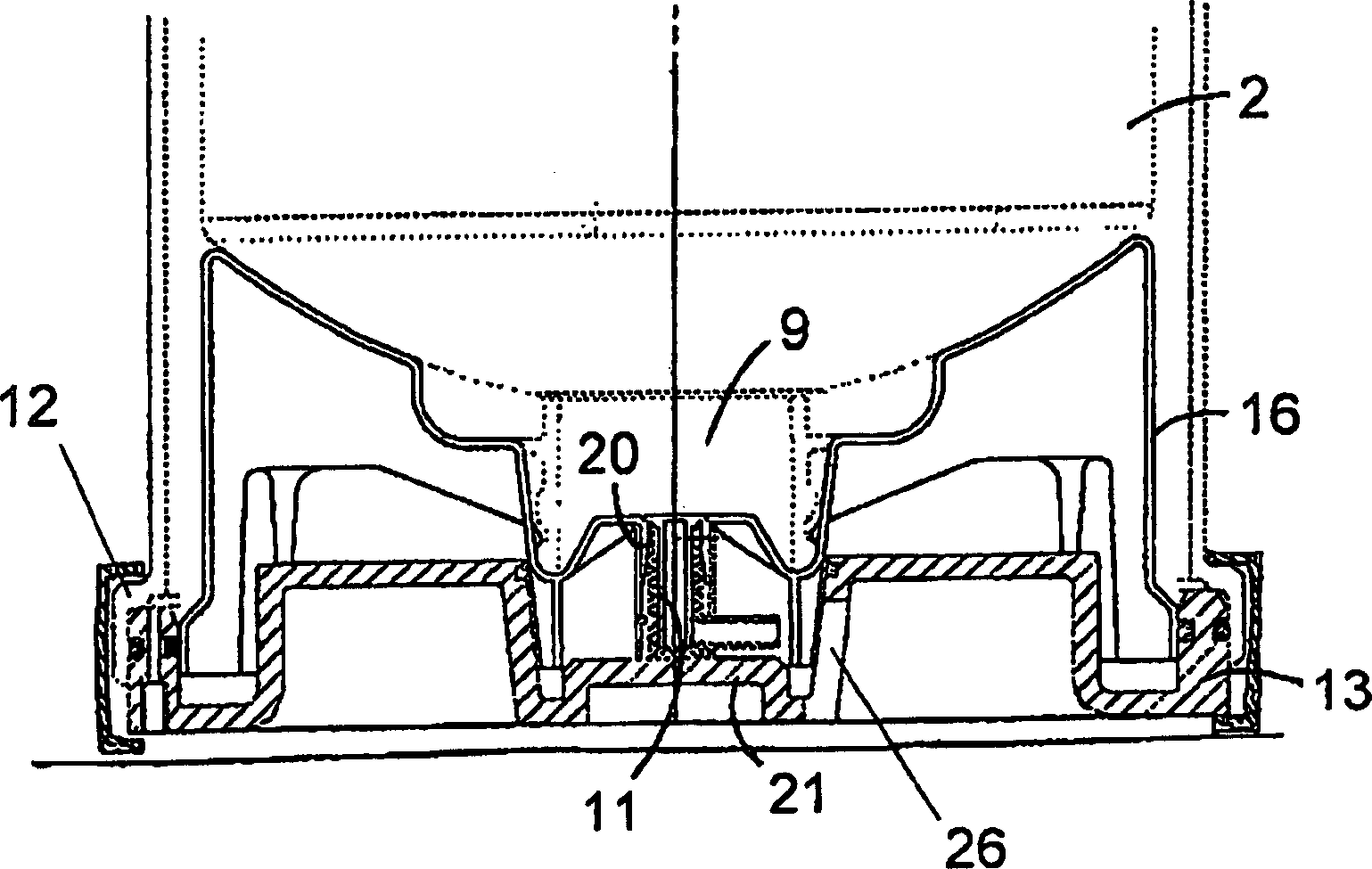

[0074] figure 1 A dispensing device 1 for dispensing beverages from a collapsible container 2 is shown in . The dispensing device 1 comprises a collapsible beverage container 2 having a base unit 3 placed within a pressurized unit of the dispensing device 1 for dispensing the contents of the container for consumption through a schematically indicated dispensing spout 4 . The pressurization unit comprises a base 5 , a cover 6 and a pressurized fluid inlet 7 communicating with a pressure chamber 8 constituted by the space between the base 5 , cover 6 , container 2 and base unit 3 . A pressurized fluid inlet 7 extends through the side wall of the base 5, ie the edge portion 13, in communication with a pressure source (not shown) such as a CO2 cylinder of a conventional draft beer dispensing device, a small air pump or simply tap water. Thus the pressurized fluid may be liquid or gaseous, either of which may be used.

[0075] For mounting, the lid 6 is separated from the base 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com