Automatic opening equipment for ampoule bottles

An automatic opening and ampoule bottle technology, applied in bottle filling, electric operation device, manual cutting device, etc., can solve the problems of medical personnel injury, glass fragment pollution, hidden safety hazards, etc., to achieve stable bottle body and high bottle opening efficiency. , to avoid the effect of liquid contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

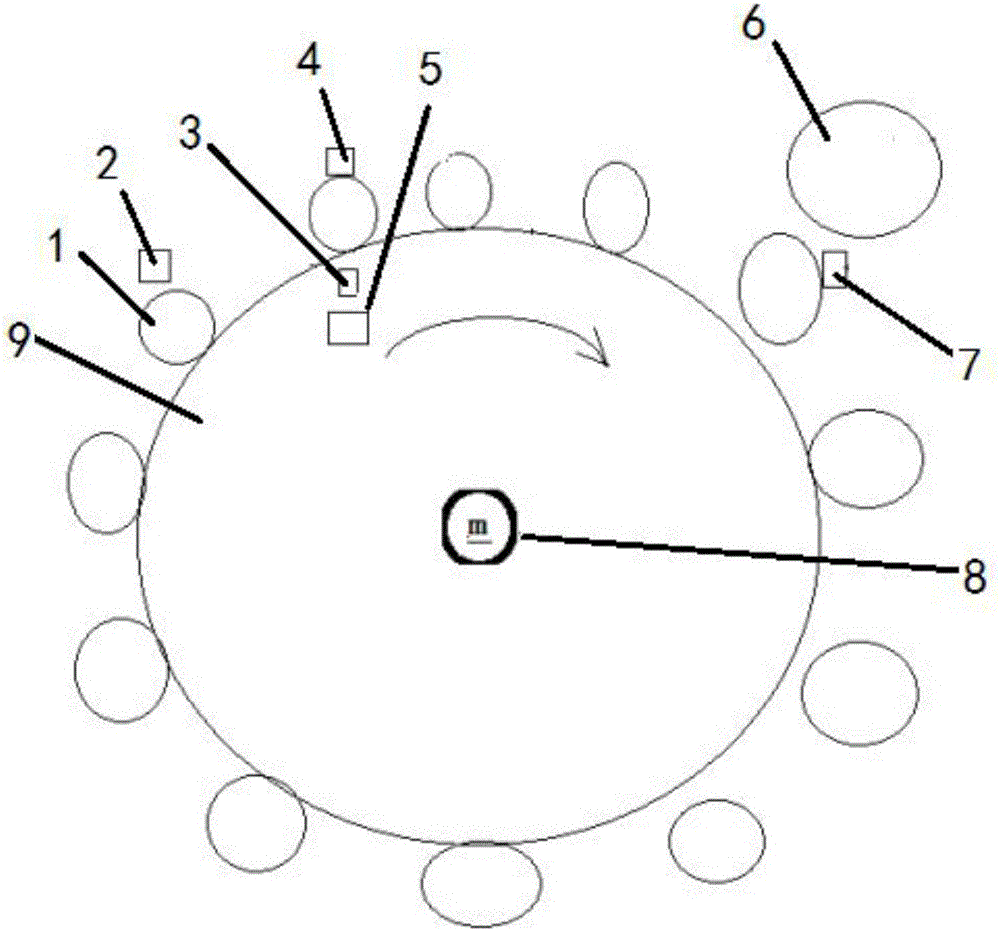

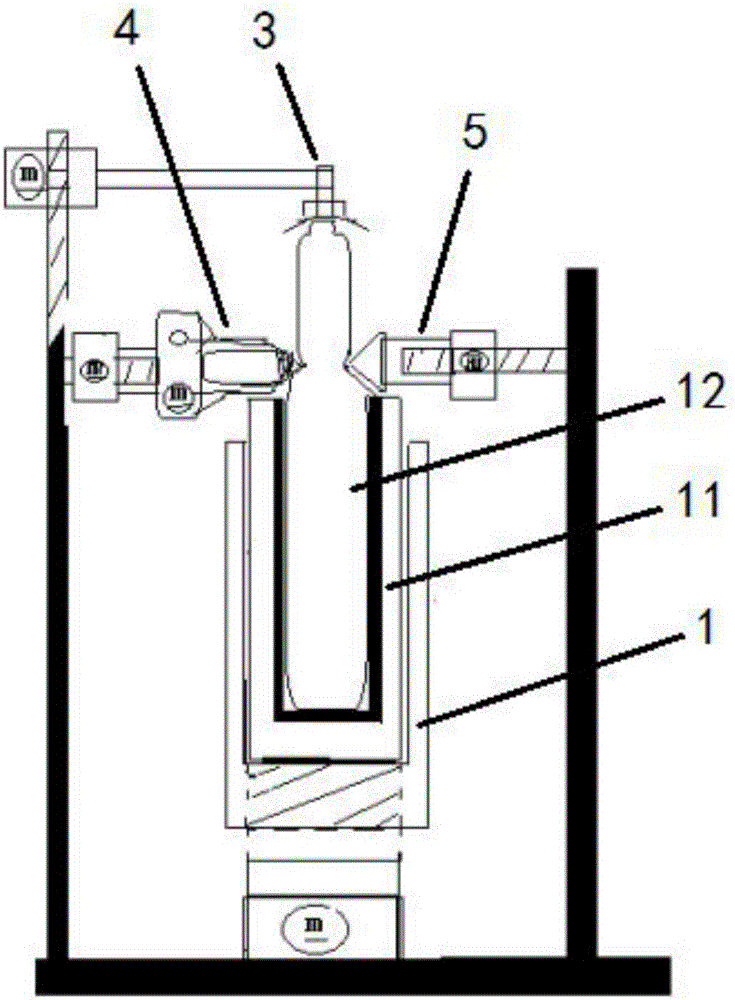

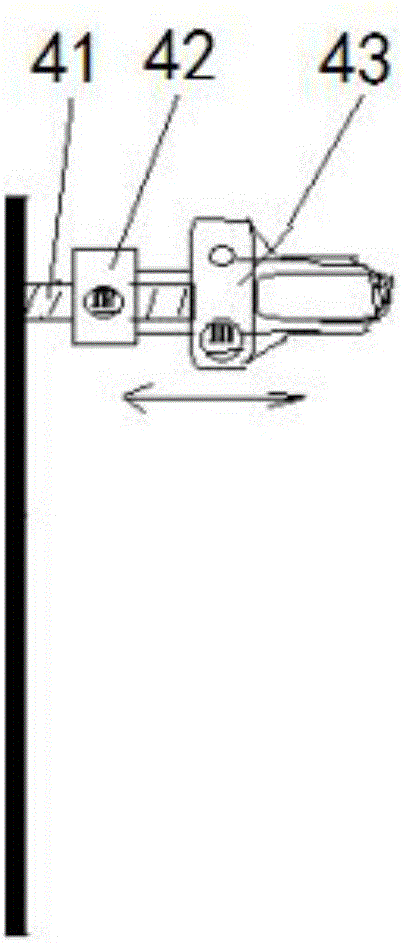

[0046] Such as figure 1 , figure 2As shown, an automatic opening device for ampoules includes several sleeve seats 1 with fixed motion trajectories. Several sleeve seats 1 move continuously and circularly along the motion trajectories, and press the sleeves on one or both sides of the motion trajectories. The movement direction of the seat is provided with a detection station, a cutting station and a bottle opening station in sequence. The detection station is provided with a photoelectric induction device 2, and the cutting station is provided with an ampoule cutting device 5, a top pressure fixing device 3 and a disinfection device 4. , the bottle opening station is provided with an ampoule breaking device 7 and a collector 6 for collecting broken ends of the ampoule, and an ampoule sleeve 11 for carrying the ampoule bottle 12 is installed in the sleeve seat 1;

[0047] The motion track of the sleeve base 1 is circular, including the feeding tray 9 driven by the motor 8, a...

Embodiment 2

[0067] Such as figure 2 , Figure 13 As shown, an automatic opening device for ampoules includes several sleeve seats 1 with fixed motion trajectories. Several sleeve seats 1 move continuously and circularly along the motion trajectories, and press the sleeves on one or both sides of the motion trajectories. The movement direction of the seat is provided with a detection station, a cutting station and a bottle opening station in sequence. The detection station is provided with a photoelectric induction device 2, and the cutting station is provided with an ampoule cutting device 5, a top pressure fixing device 3 and a disinfection device 4. , the bottle opening station is provided with an ampoule breaking device 7 and a collector 6 for collecting broken ends of the ampoule, and an ampoule sleeve 11 for carrying the ampoule bottle 12 is installed in the sleeve seat 1;

[0068] The motion trajectory of the sleeve seat 1 is rectangular, including a conveyor belt 201 driven by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com