Polymerized plate vacuum adsorption device and polymerized plate manufacturing technology

A technology of vacuum adsorption and polymerized plates, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc. It can solve the problems of difficult construction, flammability, and high water absorption, and achieve transportation without damage and labor intensity. The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

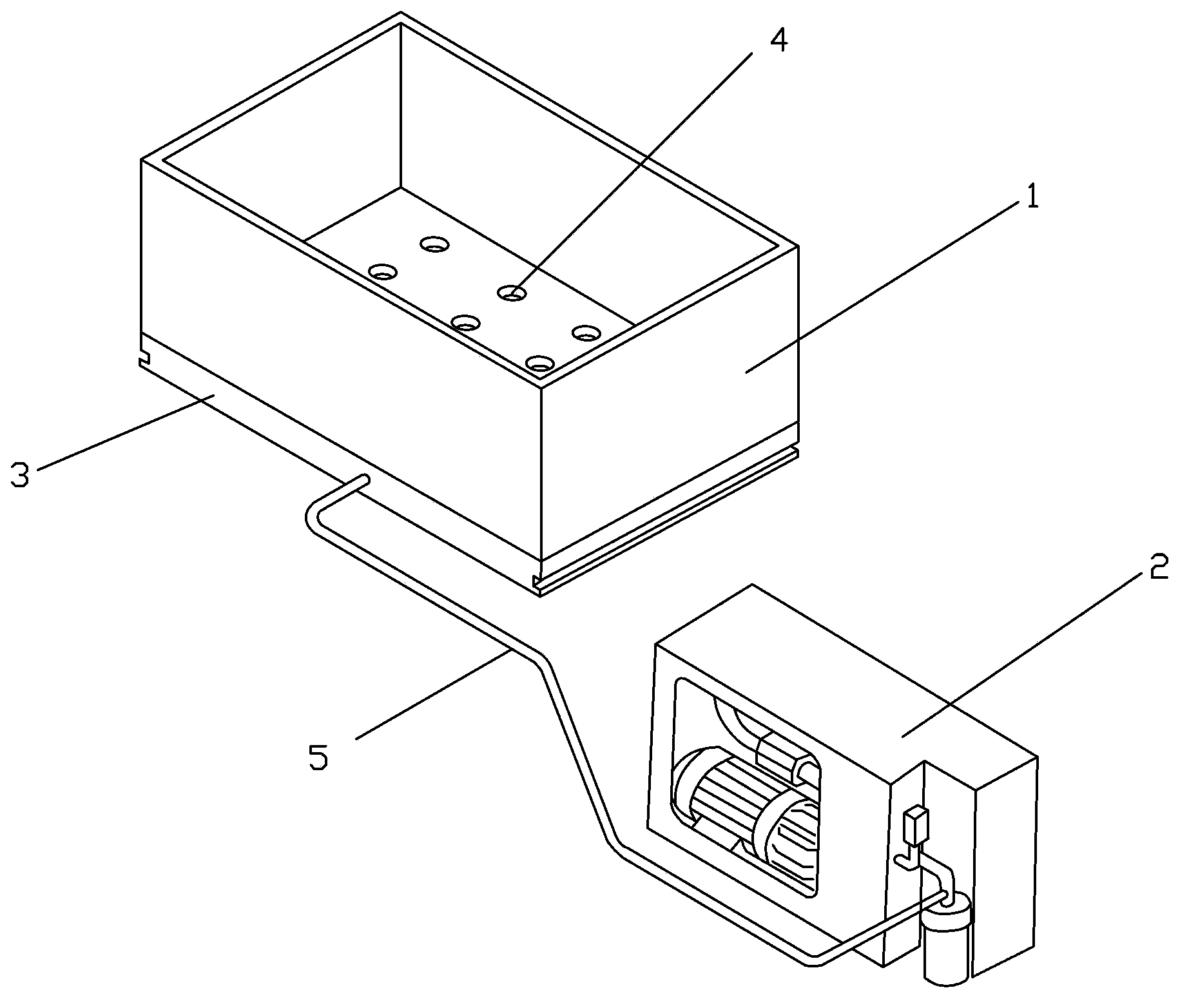

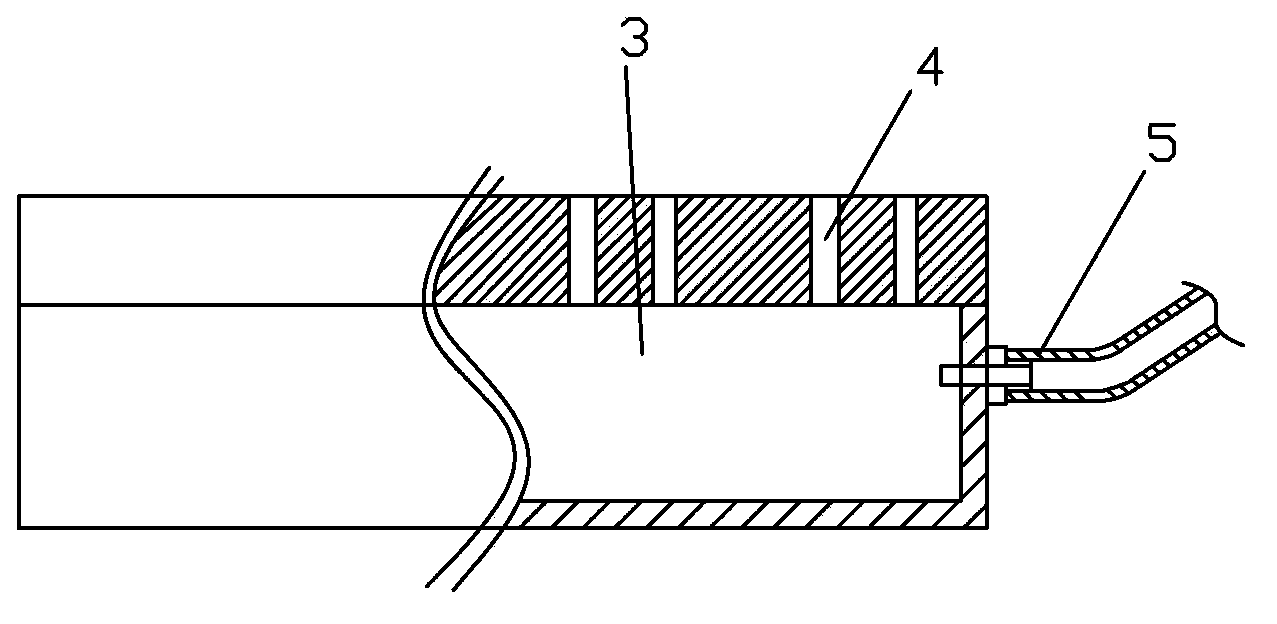

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1 to Figure 2 As shown, a polymer board vacuum adsorption device includes a box body 1 for holding plates and a vacuum pump 2. The bottom of the box body is provided with a vacuum groove 3, and the vacuum groove is used to place an extruded polystyrene foam board ( XPS) or expandable polystyrene board (EPS), the vacuum tank should not be too large, it can be designed to accommodate a plate size, the vacuum tank and the inner cavity of the box are connected through the flow hole 4, when When the vacuum pump generates negative pressure, the liquid in the inner cavity of the box can flow into the vacuum groove from the liquid flow hole. The vacuum tank communicates with the vacuum pump through a vacuum tube 5 . In order to prevent the liquid from flowing into the vacuum pump following the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com