Prefabricated composite slab general combined assembling formwork and using method thereof

A technology of combining molds and laminated plates, which is applied in the directions of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of low versatility of prefabricated laminated plates, lack of rib stability, and difficulty in demoulding, so as to reduce production costs and achieve universal use. Strong and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

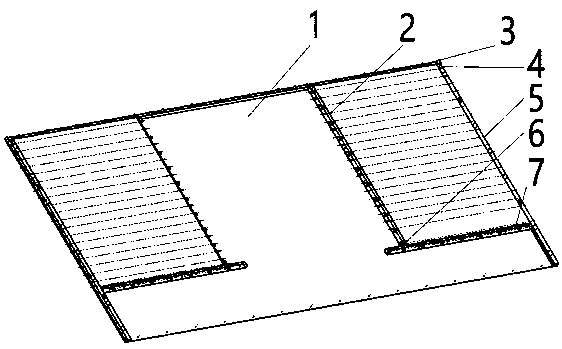

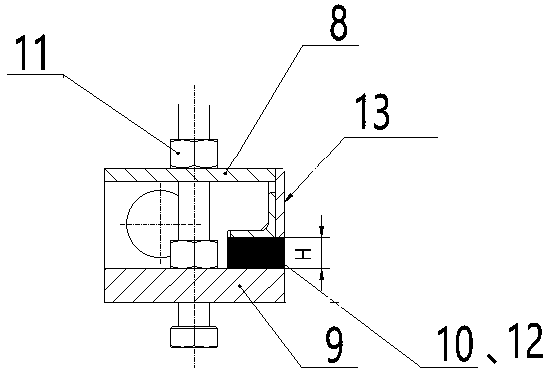

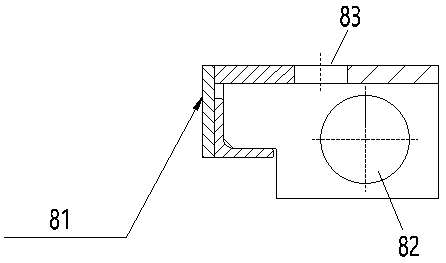

[0043] Such as Figure 1-Figure 8 As shown, an embodiment of the general composite mold for prefabricated laminated panels of the present invention includes a mold table 1, on which the first general side form 3 and the second general side form 5 are fixedly installed, and the middle part of the mold table 1 is passed through a magnetic The box fixture can be detachably installed with the net size side form 2 and the third universal side form 7, the first universal side form 3, the second universal side form 5, the third universal side form 7, and the net size side form 2 are sequentially connected to form a stack Plywood forming molds.

[0044] Die table 1 is existing structure, thereby does not do too much introduction. Two or more laminated plate forming molds can be installed on one mold table 1, so two or more laminated plate components can be produced simultaneously.

[0045]The net-foot side formwork 2 can be customized according to different laminated slab sizes and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com