Shaping mold for reserved hole in concrete wall

A technology for shaping molds and concrete walls, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of non-reusable, small rigidity, and easy deformation, and achieve prolonging service life. The overall rigidity is large and the effect of improving the deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

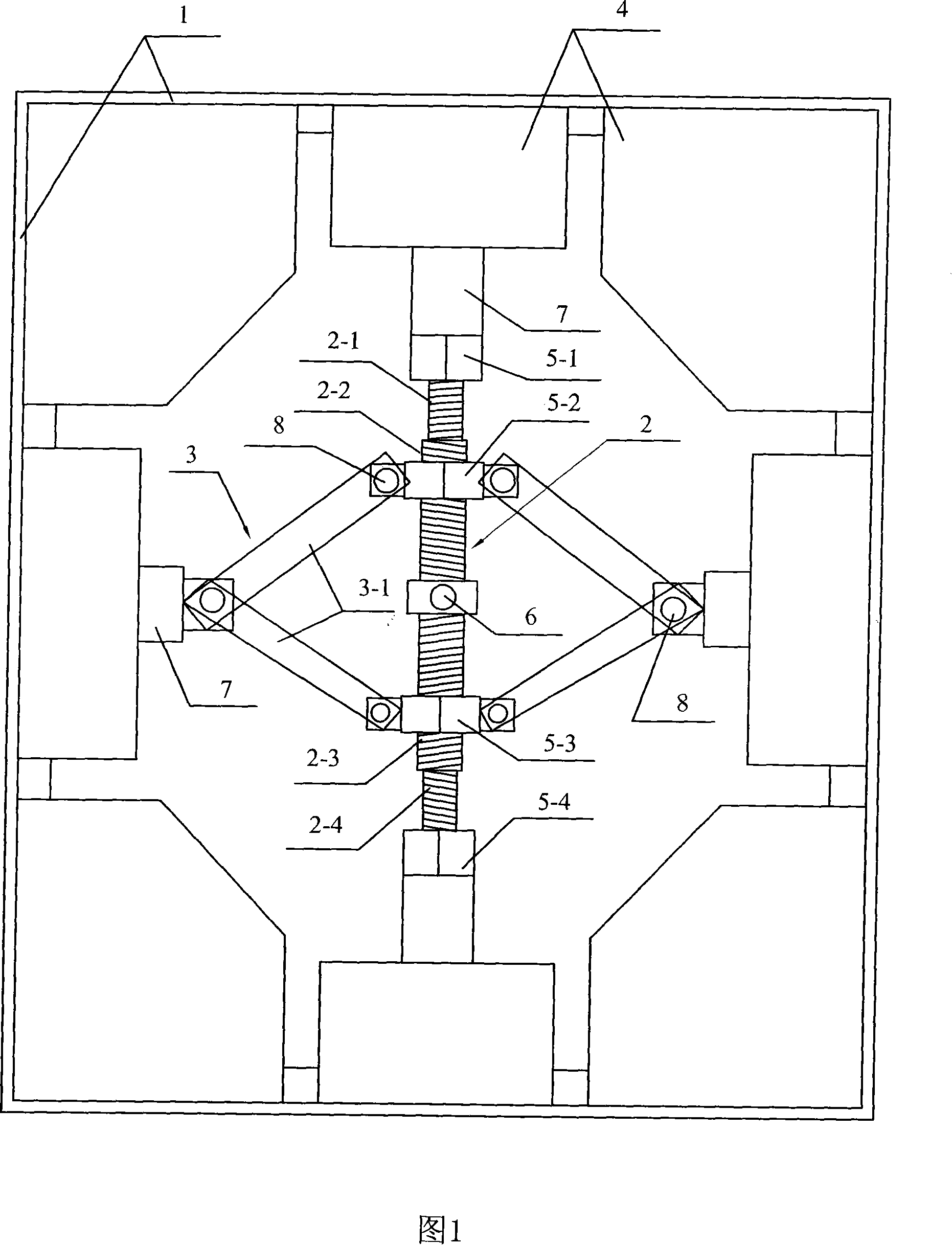

[0016] As shown in Figure 1, the schematic diagram of the shaping mold for the reserved hole in the concrete wall, the shaping mold frame has a rectangular structure and is composed of four templates 1. The templates are made of steel plates, which can improve the rigidity of the mold, and the quality of the formed concrete on the surface is high. Eight reinforcing ribs 4 are welded on the inner side of the template 1, and the reinforcing ribs are also made of steel plates to further enhance the rigidity of the mold and ensure that the mold will not be deformed due to extrusion when pouring concrete. The reinforcing ribs 4 are intermittently arranged on the inner side of the template, and the gaps left in the middle can improve the deformation ability of the mold when it is expanded or tightened. Fastening bases 7 are respectively wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com