Movable bottom formwork trolley system suitable for large concrete prefabricated component and method for prefabricating base plate of large concrete component

A technology of prefabricated components and movable bottoms, which is applied in building construction, infrastructure engineering, and building materials processing, etc., can solve the problems of complex process, reduced component prefabrication efficiency, and low degree of mechanization, saving social resources and promoting technology. The effect of improving and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

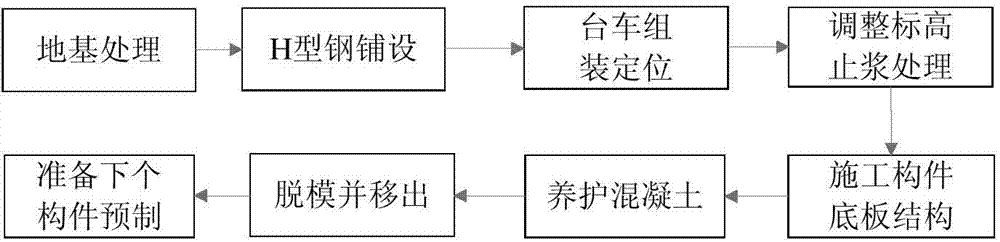

Method used

Image

Examples

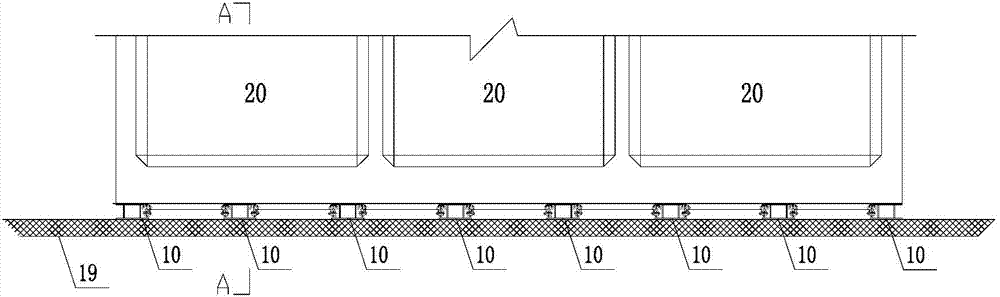

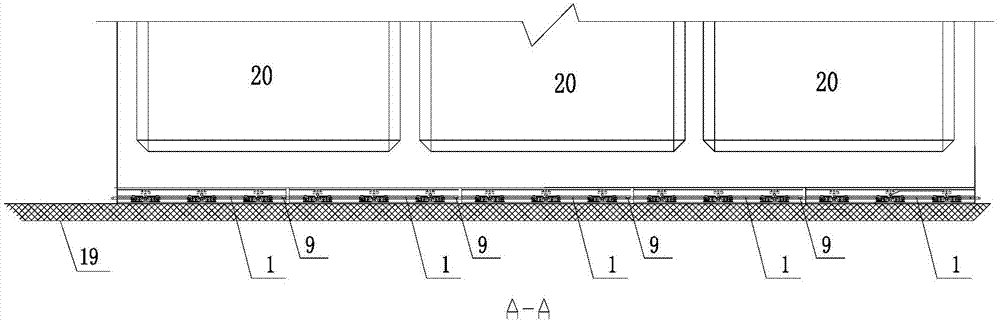

Embodiment Construction

[0049] It should be understood that directional terms such as up, down, left, right, up, down, left, and right in this specification are descriptions for the orientations shown in the drawings, and these orientations are not limiting. If not specifically stated, the terms inward, outward, inner, outer, inner, and outer refer to the range relative to the center of the component, for example, taking the motor axis as a reference, and inner and inner refer to positions that are closer to or point to the motor axis Or orientation, outboard and outboard refer to parts that are farther from the center of the motor. Furthermore, the terms horizontal, erect, overhang, etc. do not mean that the part is required to be absolutely level or overhang, but a slight inclination is allowed. For example, horizontal only means that its direction is more horizontal than vertical, and does not mean that the structure should be completely horizontal, but can be slightly inclined.

[0050] The mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com