Drawing device

A molder and formwork technology, applied in the field of drafters, can solve problems such as hidden safety hazards, formwork slippage, inconvenient operation, etc., and achieve the effects of improving mold removal efficiency, rapid mold removal, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

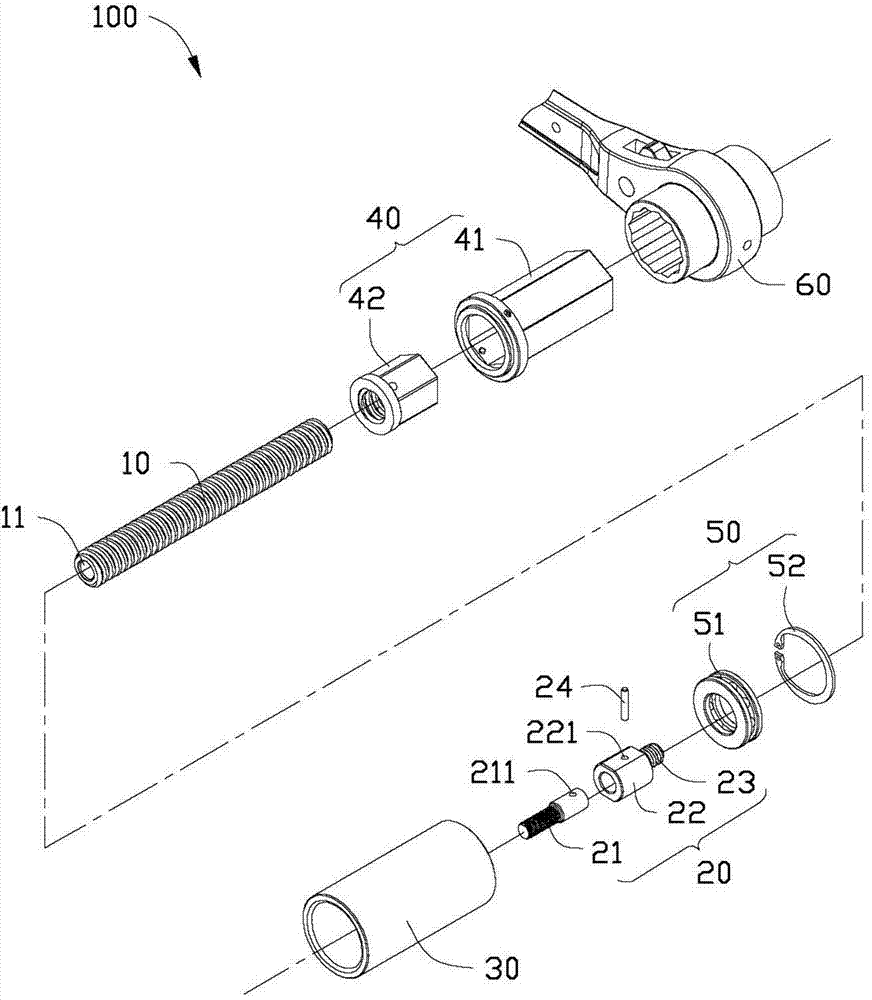

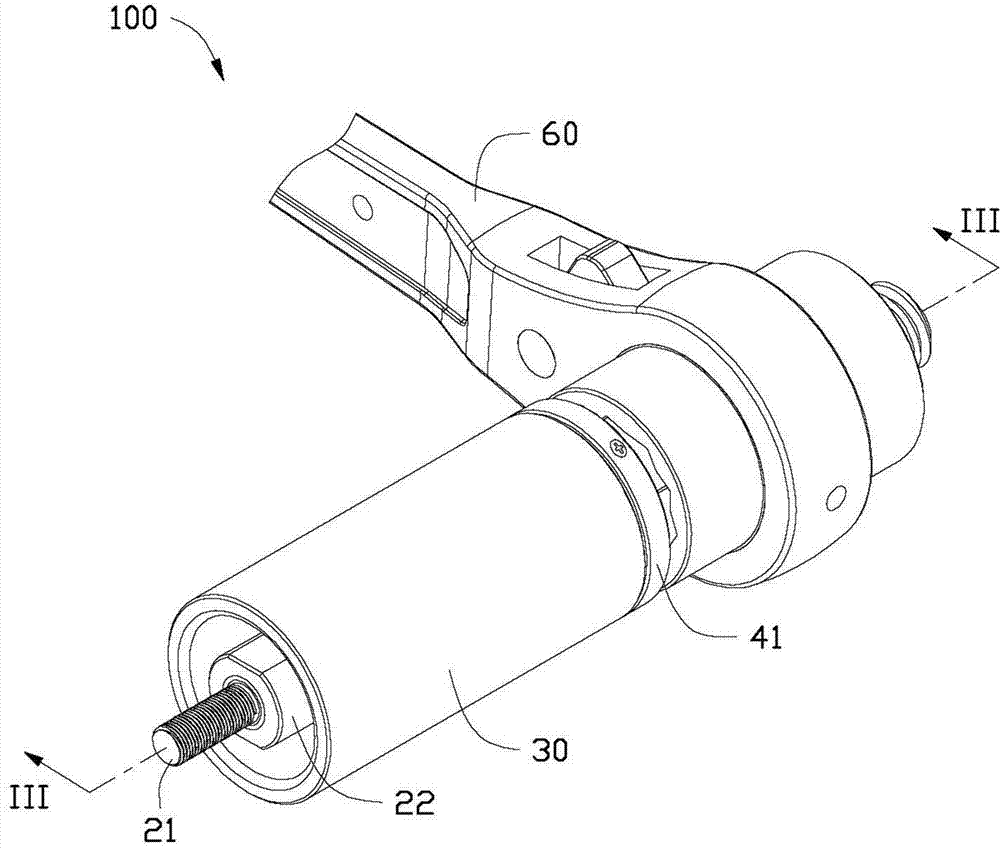

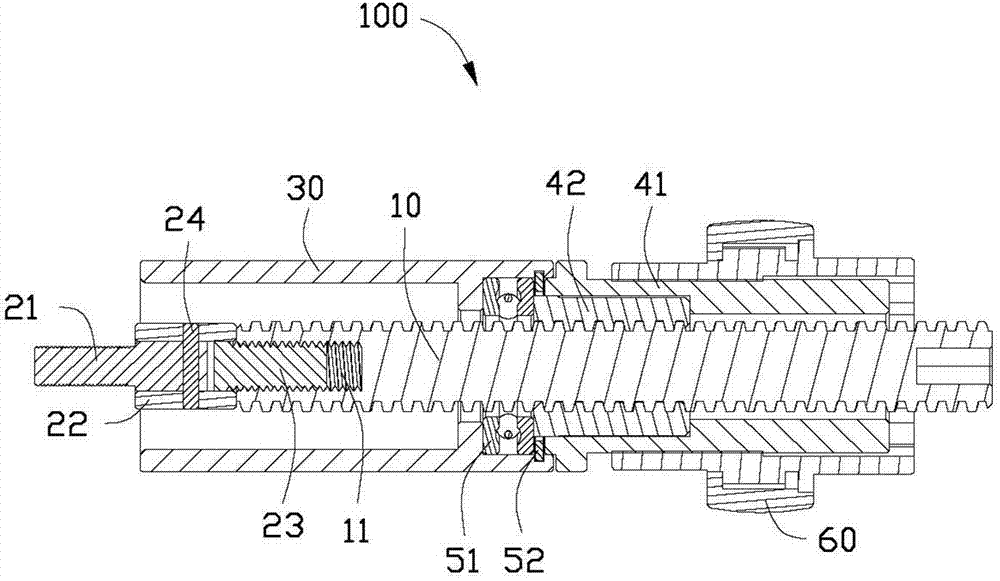

[0013] see figure 1 A preferred embodiment of the present invention provides a puller 100 , including a lead screw 10 , an adapter assembly 20 , a sleeve 30 , a nut assembly 40 and a transmission assembly 50 .

[0014] The lead screw 10 is approximately cylindrical, and its outer surface is provided with several threads, and the threads are 30-degree trapezoidal. One end of the lead screw 10 is provided with a screw hole 11 , and the screw hole 11 extends from one end of the lead screw 10 to the opposite end.

[0015] The adapter assembly 20 includes a screw 21 , a connecting portion 22 and a connecting rod 23 . The screw rod 21 is roughly cylindrical, and its outer surface is provided with several threads. The specific shape and structure of the screw rod 21 correspond to the shape and structure of the workpiece to be drawn, such as the shape and structure of the positioning screw and the positioning pin, and are used for fastening and connecting with the workpiece to be dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com