Method for constructing circular hole of anchor bolt reserved by equipment foundation

A technology for anchor bolts and equipment foundations, which is applied in the construction field where circular holes for anchor bolts are reserved for equipment foundations. It can solve problems that affect the strength of anchor bolt holes, difficulty in using force, and limited space, and reduce labor intensity. , Improve the pull-out bearing capacity and reduce the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the technical solutions of the present invention will be further described below with reference to the embodiments and accompanying drawings.

[0024] The construction method for reserving circular holes for anchor bolts in the equipment foundation includes the following steps:

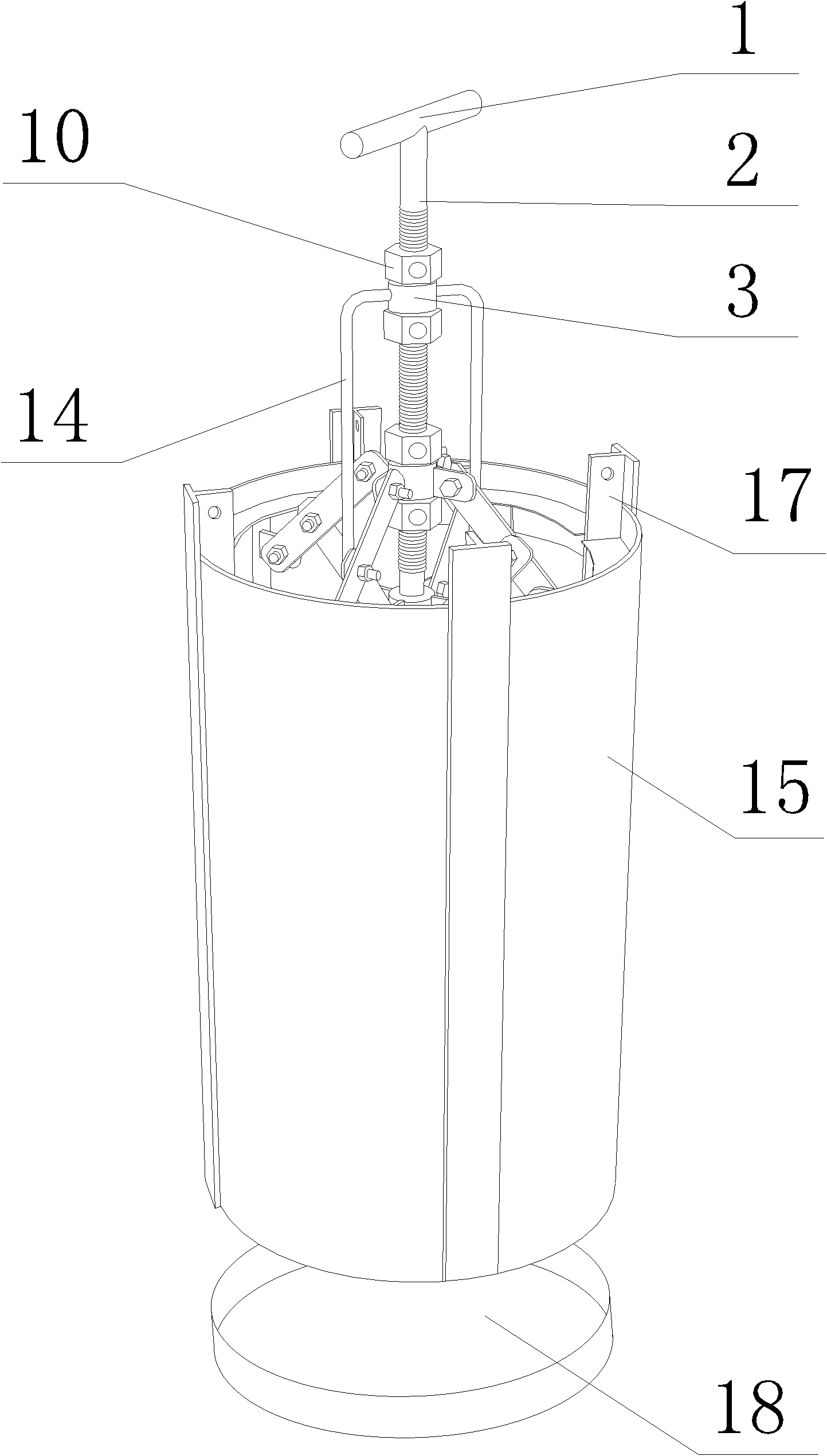

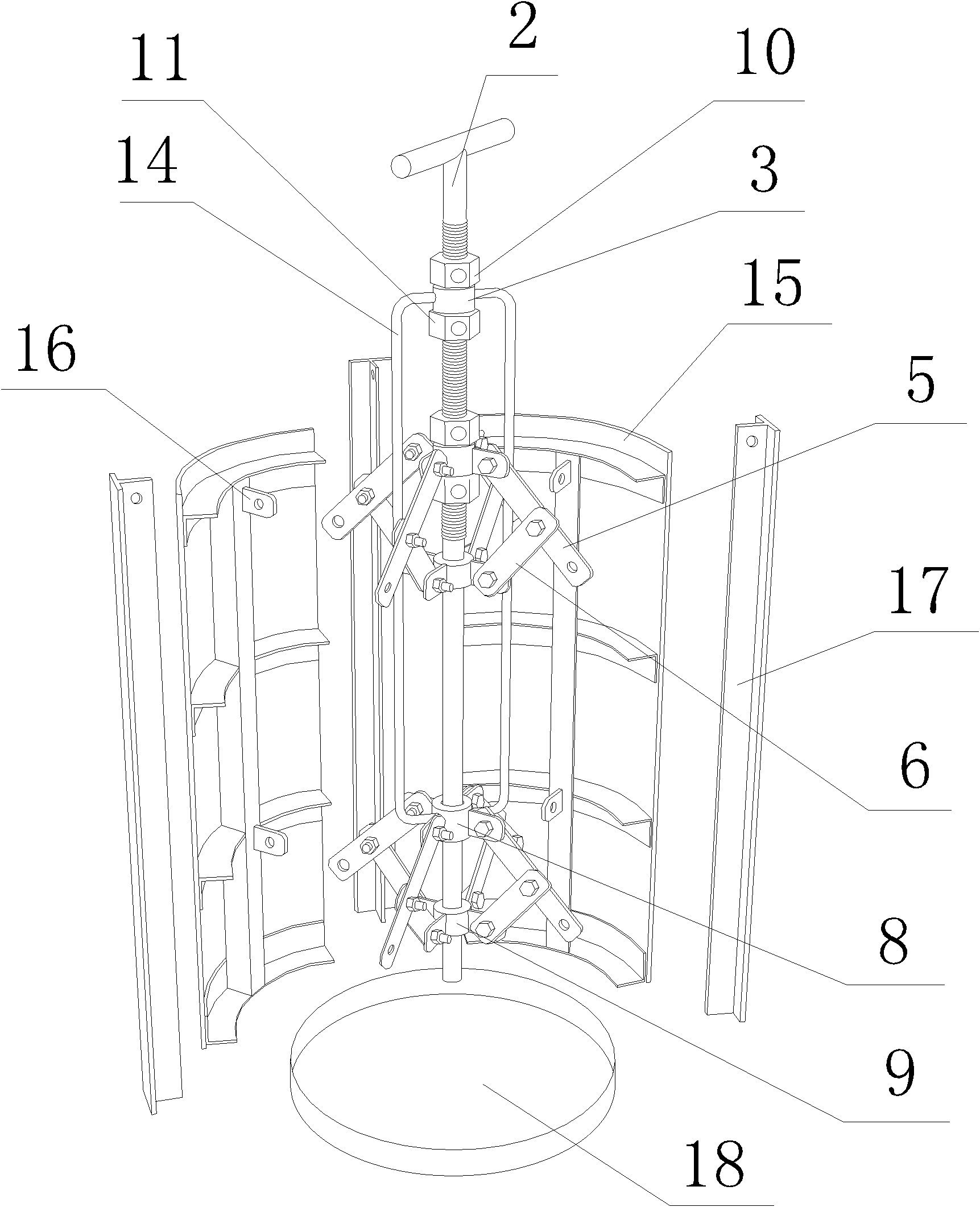

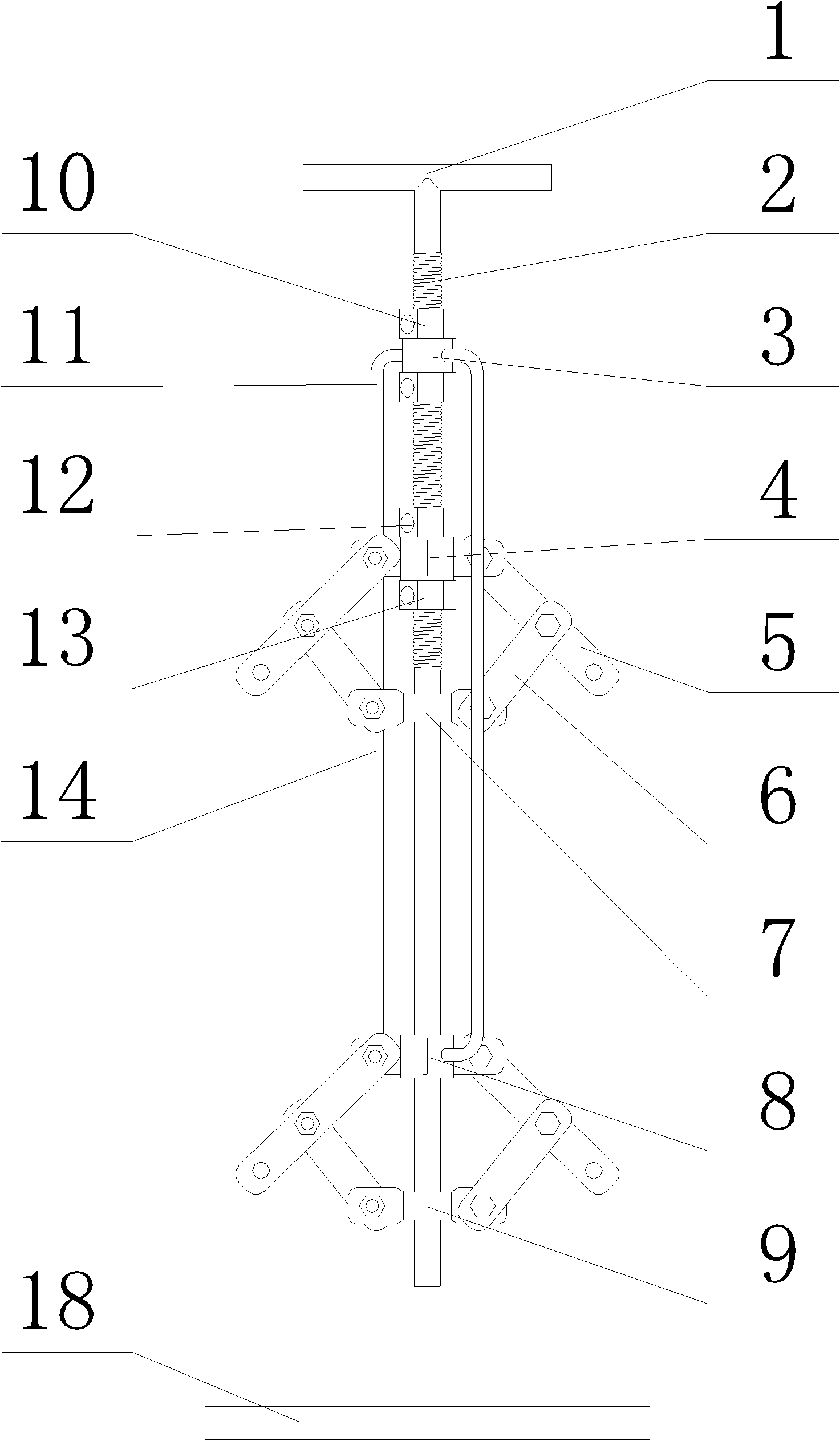

[0025] The first step, assembling the mold: the equipment foundation reserves the circular hole mold for the anchor bolt, and its structure is as follows Figure 1 to Figure 3 As shown, it includes a central axis 2, a first expansion and contraction device, a second expansion and contraction device, 4 templates 15, and 4 seam patches 17; the 4 templates 15 are arc-shaped (this embodiment The size of the 4 templates is the same), the 4 templates 15 are evenly distributed along the circumference, and a patch panel 17 is inserted between the template 15 and the template 15 (the size of the 4 patch panels in this embodiment is the same), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com